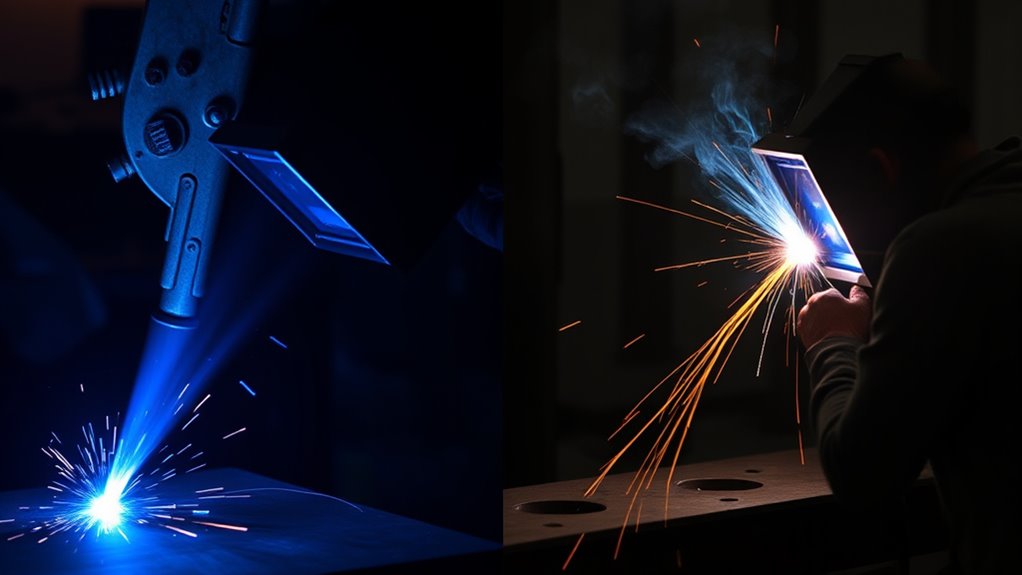

When comparing plasma welding and TIG welding, you’ll find that each method offers distinct benefits and challenges in precision, heat input, and applications. Plasma welding, with its concentrated arc, excels in high-volume industrial environments, handling hard-to-weld materials effectively. Conversely, TIG welding provides meticulous control over heat input, ideal for detailed and aesthetic projects. Understanding their core principles and mechanisms will guide you in selecting the right technique for your welding needs.

Understanding Plasma Welding and TIG Welding

When diving into the world of welding techniques, understanding the intricacies of plasma welding and TIG welding is essential.

Plasma welding offers significant advantages, particularly in high-volume production settings. By employing a constricted arc and superheating gas, it achieves deep penetration with minimal heat-affected zones. This makes plasma welding ideal for thicker materials and hard-to-weld components like titanium and nickel-based alloys.

Plasma welding excels in high-volume production, achieving deep penetration with minimal heat-affected zones, ideal for thick, tough materials.

The process operates at temperatures up to 30,000 degrees Fahrenheit, making it effective for automation and high-speed applications.

In contrast, TIG welding showcases versatility, excelling in precision work. Utilizing a non-consumable tungsten electrode, it allows for manual addition of filler material, giving you precise control over heat input.

This precision is vital when working with thinner sections of metals, ensuring high-quality, aesthetically pleasing welds. TIG welding is particularly favored in applications requiring minimal impurities, such as aerospace and artistic projects, highlighting its adeptness for detailed craftsmanship.

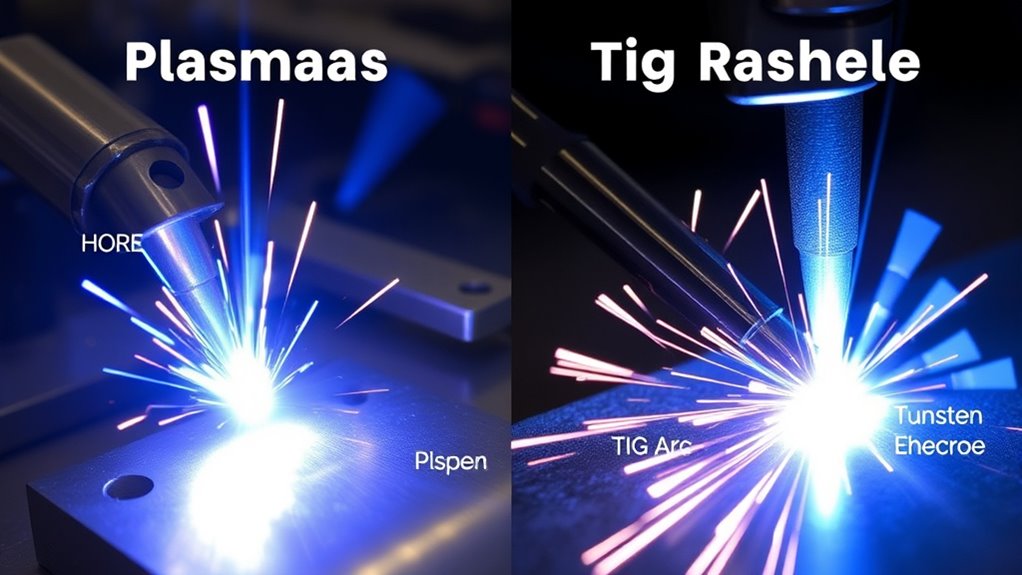

Core Principles and Mechanisms

In understanding the core principles of plasma and TIG welding, focus on how the plasma arc formation and TIG electrode function differ fundamentally.

Plasma welding utilizes a constricted arc, reaching temperatures up to 30,000 degrees Fahrenheit, enabling deep penetration and efficiency in welding thicker materials.

Conversely, TIG welding relies on precise heat input control with a non-consumable tungsten electrode, offering superior control for thinner sections and applications requiring aesthetic precision.

Plasma Arc Formation

Although plasma arc formation might seem complex, it fundamentally hinges on the ionization of gas, creating an intensely hot, conductive state. This process involves plasma ionization effects, where gas is heated to extreme temperatures, reaching up to 30,000 degrees Fahrenheit.

The arc’s stability factors are essential, as the arc forms between a tungsten electrode and the workpiece, with plasma gas ensuring a constricted, precise arc.

- Enables deep penetration welding with minimal heat-affected zones.

- Supports faster travel speeds, reducing arc wander.

- Operates in soft plasma or keyhole mode for varied welding needs.

- Enhances precision suitable for high-volume, automated production.

- Ionized gas creates a focused plasma stream capable of melting metals.

These features make plasma welding a versatile choice across applications.

TIG Electrode Function

Understanding the function of the tungsten electrode in TIG welding is fundamental, as it serves as the heart of the arc generation process. This non-consumable electrode, crafted from pure tungsten or tungsten alloys, withstands extreme temperatures up to 6,000 degrees Fahrenheit without melting.

Selecting the appropriate electrode type is critical, as it impacts arc stability and heat concentration necessary for precise welding. Common diameters, ranging from 1/16″ to 1/8″, cater to diverse applications, ensuring ideal performance.

Inert gas, typically argon, shields the electrode and molten weld pool from atmospheric contamination, preventing oxidation. Maintaining a clean, pointed tungsten tip is essential for achieving consistent arc stability and minimizing weld defects, ensuring high-quality results in the TIG welding process.

Heat Input Control

Controlling heat input is a crucial aspect of both plasma and TIG welding, particularly when precision and material integrity are paramount.

In plasma welding, heat management is achieved through a constricted arc, guaranteeing deeper penetration and a narrower heat-affected zone. This process allows for precise welding on thin materials, thanks to the arc’s extreme temperatures of up to 30,000 degrees Fahrenheit.

- Plasma welding’s focused arc minimizes thermal spread, reducing warping risk.

- TIG welding demands manual adjustments for comparable penetration and control.

- Plasma’s automated capabilities allow rapid thermal control adjustments.

- Electrical parameters and gas flow rates are critical in both methods.

- Plasma welding is superior for high-precision applications due to its concentrated heat management, offering less material distortion.

Understanding these mechanisms guarantees ideal welding outcomes.

Equipment Setup and Components

Setting up equipment for plasma and TIG welding involves distinct components and configurations tailored for their specific processes.

Distinct components and configurations are essential when setting up equipment for plasma and TIG welding.

In plasma welding, you’ll need a plasma torch with a tungsten electrode and a constriction nozzle, which guarantees precise equipment functionality. The power supply must deliver a constant current with high-frequency start capabilities to maintain a stable arc, essential for component compatibility.

You’ll also require a dual gas supply system: one for forming the plasma arc and another for shielding, providing ideal protection and precision.

For TIG welding, the setup includes a non-consumable tungsten electrode and a gas supply system using pure argon for shielding. The TIG torch doesn’t require a constriction nozzle, simplifying the setup.

While plasma welding often incorporates a water cooling system to manage high-amperage conditions, it’s less vital in TIG welding due to its lower heat input, reflecting the differing operational demands and equipment configurations between the two processes.

Process Parameters and Control

Having set up your equipment correctly, you now focus on mastering the process parameters and control fundamental for effective plasma and TIG welding.

Parameter refinement is essential to achieve high-quality welds. In plasma welding, you’ll adjust current control, gas flow rates, and travel speed. Fine-tuning these parameters lets you enhance weld quality and penetration depth.

TIG welding, on the other hand, emphasizes precise control of heat input through amperage and travel speed adjustments, resulting in cleaner welds.

To guarantee successful welding, consider the following control techniques:

- Current Control: Critical for both processes to manage penetration and prevent defects.

- Gas Flow Rates: Plasma uses a mix, while TIG typically requires pure argon.

- Travel Speed: Affects heat input and can be adjusted for ideal results.

- Arc Focus: Plasma’s constriction nozzle allows deeper penetration.

- Shielding Gas Management: Essential for weld integrity and performance.

These parameters need precise management for ideal results.

Material Compatibility and Thickness Considerations

When considering material compatibility and thickness, understanding the strengths of both plasma and TIG welding is essential.

TIG welding excels with materials like aluminum, stainless steel, and copper, particularly in thin sections up to 1/8 inch thick. This precision makes it ideal for high-precision welding applications where aesthetics and quality are paramount. Its precise heat control allows delicate and intricate work without risking material distortion.

Plasma welding, however, is your go-to for thicker materials exceeding 1/8 inch. Its ability to achieve deep penetration is advantageous for structural applications, especially with hard-to-weld materials like titanium and nickel-based alloys.

Plasma’s robust heat input makes it suitable for high-volume production tasks where efficiency is key.

Speed and Efficiency in Welding Processes

When comparing process speeds, you’ll notice plasma welding‘s ability to achieve up to a 50% increase in travel speeds over TIG welding due to its focused arc and deeper penetration capabilities.

This efficiency is particularly advantageous in high-volume production settings, where reduced cycle times are essential for maintaining competitive throughput.

Additionally, plasma welding’s concentrated energy not only accelerates the welding process but also optimizes material handling by minimizing heat-affected zones, vital for industries requiring precision in thicker materials.

Comparing Process Speeds

While both plasma welding and TIG welding have their advantages, plasma welding typically excels in process speed due to its focused plasma arc that enables faster travel speeds and deeper penetration.

This method supports process optimization and welding innovations, especially suitable for high-volume production applications.

The concentrated heat of plasma welding allows:

- Quick travel speeds that boost productivity.

- Deeper penetration reducing the need for multiple passes.

- Reduced heat-affected zones, preserving material integrity.

- Efficient cycle times, enhancing industrial throughput.

- High-volume adaptability, ideal for mass production tasks.

In contrast, TIG welding, known for its precision, requires slower speeds to manage heat input effectively, especially on delicate, intricate projects.

Your choice between these methods should weigh the critical need for speed against the precision demands of your application.

Efficiency in Material Handling

Efficiency in material handling is essential in streamlining welding processes, and choosing the right method can drastically impact productivity.

Plasma welding excels in process optimization with its faster travel speeds and higher penetration rates, making it ideal for high-volume production, especially with thick materials. Its focused arc reduces the heat-affected zone, minimizing distortion and enhancing efficiency in material handling by reducing rework. The ability to weld thicker materials without multiple passes further boosts efficiency, cutting down on time and costs in industrial applications.

Conversely, TIG welding, while offering precise heat input control for superior quality, operates at slower speeds, impacting productivity in extensive tasks.

However, it remains crucial for intricate and high-precision welding demands where process optimization prioritizes quality over speed.

Weld Quality and Aesthetic Differences

Although both plasma and TIG welding offer distinct advantages regarding weld quality and aesthetics, the choice between them depends largely on your specific application needs.

TIG welding excels in delivering high-quality, aesthetically pleasing welds with minimal spatter, perfect for applications emphasizing weld aesthetics like artistic metalwork or aerospace components. It’s renowned for producing fewer impurities, crucial for high-performance uses.

Ideal for artistic metalwork and aerospace, TIG welding ensures high-quality, aesthetically pleasing welds with minimal spatter and impurities.

In contrast, plasma welding provides deeper penetration with a narrower bead profile, advantageous for thicker materials, and yields cleaner welds in high-volume production settings.

Consider these factors:

- Weld Aesthetics: TIG’s clean finish and minimal spatter.

- Impurity Levels: TIG’s low impurity levels, important for critical applications.

- Heat Input Control: TIG allows precise adjustments, reducing distortion.

- Bead Profile: Plasma’s narrow profile suits thicker materials.

- Thermal Distortion: Plasma’s localized heat zone minimizes distortion.

Both methods necessitate careful parameter control to guarantee ideal weld quality and integrity.

Operator Skill Requirements and Training

In mastering plasma welding, you must focus on advanced calibration and precise parameter control, demanding a thorough training program to handle power supplies and gas flow accurately.

While TIG welding offers a more accessible entry point with its manual control and clear visual cues, continuous skill development is essential to refine technique and minimize defects in both methods.

Certification enhances your expertise, especially in plasma welding, where specialized equipment and high-stakes applications demand a higher proficiency level.

Skill Development Necessity

Mastering plasma welding demands a higher level of expertise compared to TIG welding, due to its intricate equipment and precise control requirements.

You’ll need to undertake a thorough skill assessment to guarantee proficiency in advanced techniques necessary for successful operations. Plasma welding’s complexity arises from the need to expertly manage gas flow rates and current settings, which directly impact weld quality.

Here’s what you must focus on:

- Skill assessment: Evaluate your capability to handle equipment and tasks.

- Advanced techniques: Gain expertise in manipulating arc characteristics.

- Parameter enhancement: Adjust settings for ideal performance.

- Material compatibility: Understand how different materials react during welding.

- Hands-on practice: Regular practice to refine skills and stay updated.

Your commitment to continuous skill development will enhance production standards.

Training Program Importance

When delving into the training programs for plasma and TIG welding, it’s essential to focus on equipping operators with a deep understanding of advanced calibration and parameter control.

Effective training methods should integrate thorough curriculum design, emphasizing the specific applications of each welding method. You’ll learn TIG welding for precision tasks and plasma welding for handling thicker materials with deep penetration.

Hands-on training in equipment setup, such as managing gas flows and power settings, is fundamental for high-quality welds. Incorporating regular assessments guarantees that you stay updated with the latest techniques and technologies.

Furthermore, understanding safety protocols and maintenance procedures is critical to guarantee a safe working environment and enhance the longevity of your welding equipment.

Practical Applications and Industry Use Cases

Although both plasma welding and TIG welding serve critical roles in various industries, their practical applications and industry use cases highlight distinct strengths.

Plasma welding excels in high-volume industrial applications, particularly when deep penetration and minimal heat-affected zones are essential. This makes it ideal for aerospace and medical device manufacturing, where material selection often includes hard-to-weld materials like titanium and nickel alloys.

Plasma welding is ideal for aerospace and medical manufacturing with its deep penetration and minimal heat-affected zones.

Conversely, TIG welding shines in projects requiring high precision and aesthetic quality. Its capability to produce clean, high-quality welds makes it the preferred method for intricate designs and thin materials in automotive and artistic metalwork.

Consider these industry-specific applications:

- Aerospace: Plasma welding for titanium and nickel alloy structures.

- Medical Devices: Plasma welding for precise, low-distortion joins.

- Automotive: TIG welding for thin panels and detailed components.

- Artistic Metalwork: TIG welding for complex, visually appealing designs.

- High-End Furniture: TIG welding for stainless steel fabrication.

Both methods are indispensable, each with unique advantages.

Future Trends and Technological Developments

As the welding industry moves forward, integrating intelligent systems and automation is revolutionizing both plasma and TIG welding applications. These advancements enhance precision and efficiency, driving significant improvements in manufacturing. With the development of multi-component fluxes, you can achieve superior weld penetration, especially vital for lightweight materials. Automation advancements lead to innovations in gas management systems, optimizing shielding gas usage, reducing operational costs, and improving weld quality.

Research into advanced materials and coatings supports handling high-strength, difficult-to-weld materials. Digitalization trends allow real-time monitoring and control, guaranteeing consistent quality and reducing defects.

| Feature | Benefit |

|---|---|

| Intelligent Systems | Enhanced precision and efficiency |

| Automation Advancements | Reduced costs, improved weld quality |

| Multi-component Fluxes | Better penetration and efficiency for lightweight materials |

| Advanced Materials & Coatings | Improved handling of difficult-to-weld materials |

These technological developments guarantee that plasma and TIG welding remain at the forefront of cutting-edge manufacturing.

Frequently Asked Questions

Are There Any Environmental Considerations Between Plasma and TIG Welding?

You’re considering environmental factors. Plasma welding generally has higher emission levels and energy consumption. TIG welding, conversely, tends to be more energy-efficient with lower emissions, making it a more environmentally friendly choice in many applications.

How Do Maintenance Requirements Differ Between Plasma and TIG Welding Equipment?

You’ll find plasma welding demands more frequent electrode maintenance due to higher wear, impacting equipment longevity. TIG welding, with lower thermal stress, requires less frequent maintenance, enhancing longevity. Regular checks guarantee ideal performance for both welding types.

What Safety Precautions Are Unique to Plasma Welding Compared to TIG?

You’re maneuvering through plasma welding’s unique safety landscape, aren’t you? Plasma hazards demand specialized safety gear, including flame-resistant clothing and face shields. Maintain constant vigilance against UV radiation and ozone, ensuring your workspace is well-ventilated and risk-free.

Can Plasma Welding Be Used for Artistic Applications Like TIG Welding?

Yes, you can use plasma welding for artistic metalwork, offering precise control for creative applications. It enables intricate designs and detailed processes, providing consistent heat input, though mastering it might require more practice compared to TIG welding.

How Does the Cost Comparison Between Plasma and TIG Welding Affect Project Budgeting?

Think of cost comparison as the project’s heartbeat; it determines your timeline’s pulse. Plasma welding’s higher initial cost factors can stretch budgets, whereas TIG welding offers more predictable expenses, consequently potentially streamlining project timelines and resource allocation.

Conclusion

In comparing plasma and TIG welding, precision and process predominate. Plasma welding provides powerful penetration for hard-to-weld materials, minimizing the heat-affected zone, while TIG welding offers unmatched meticulousness for intricate designs with superior heat input management. Both boast unique benefits, but your choice hinges on the task’s technical requirements. As industries innovate, staying informed about future trends and technology shifts guarantees you effectively employ these exceptional techniques, maximizing material mastery and maintaining manufacturing excellence.