You care about cut speed but you also need consumables to last; post-flow is the quiet interval that bridges that gap. You’ll learn how this short cooldown protects the nozzle and electrode, reduces oxidation, and stabilizes cut quality when tuned to material thickness and process. Get the right settings and air supply checks, and you’ll avoid common wear and quality problems—here’s what to adjust and why.

What Post-Flow Is and How It Protects the Torch

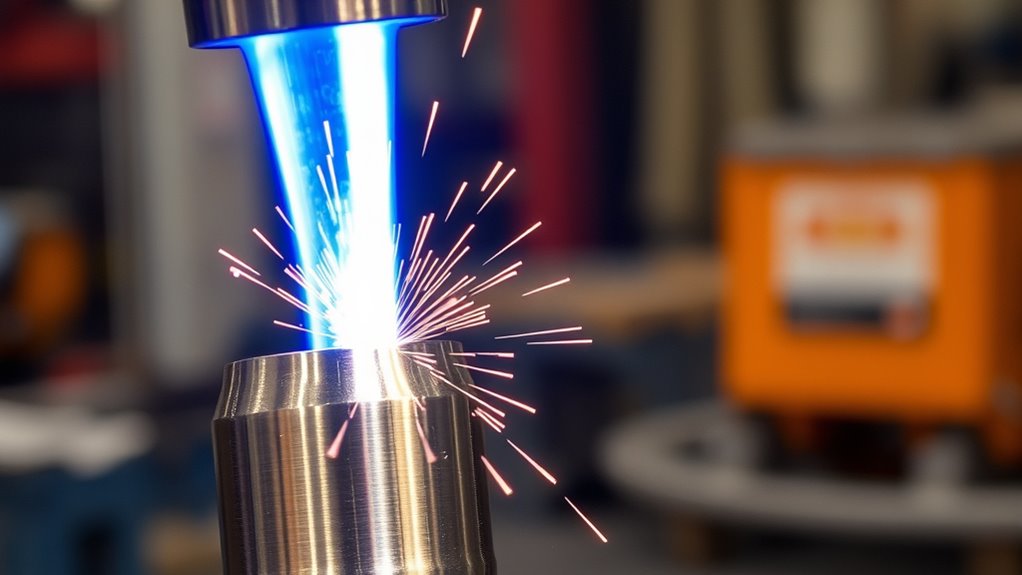

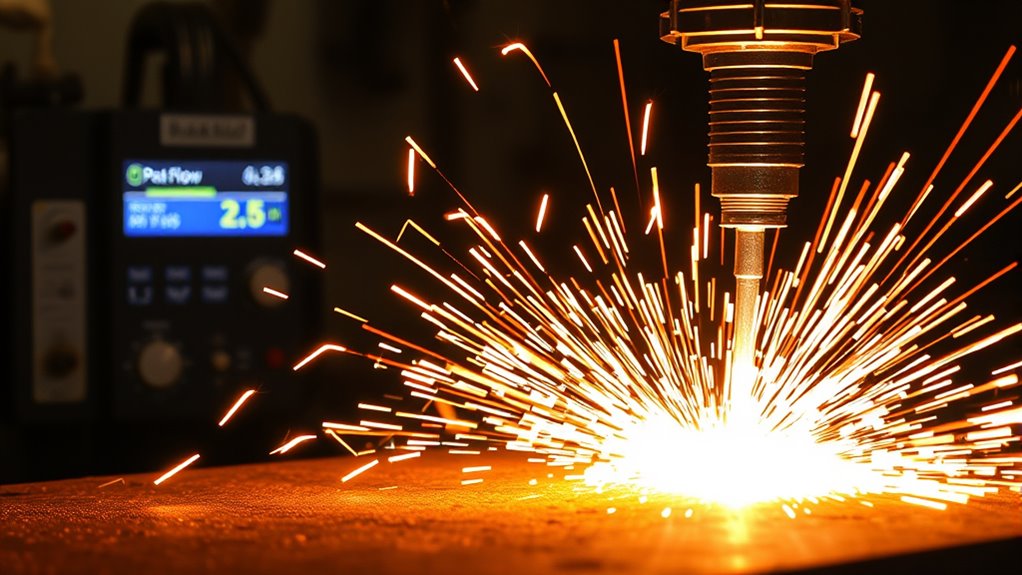

Think of post-flow as the plasma cutter’s cooldown cycle: after you shut off the arc the system keeps flowing gas for a set time (commonly 15–20 seconds) to carry heat away from the nozzle and electrode.

You rely on that interval for effective torch cooling once the arc extinguishing event occurs, preventing residual heat from degrading consumables. With proper post-flow you’ll reduce thermal stress on the nozzle and electrode, maintain consistent orifice geometry, and limit oxidation or material buildup that shortens service life.

Post-flow cools the torch after arc shutoff, protecting consumables from heat, oxidation, and wear for longer life.

If your unit offers adjustable post-flow, you can match duration to duty cycle and cut length: increase time after high-amperage, extended cuts; shorten for intermittent work to speed re-fire.

Be aware fixed post-flow may impede quick re-ignition, so balance protection against workflow needs. In practice, monitor torch temperature and consumable wear to validate selected post-flow settings, adjusting only when empirical evidence indicates improved cooling or operational efficiency.

How Post-Flow Duration Affects Consumable Life and Cut Quality

You’ll see that extending post-flow to the typical 15–20 second range improves consumable cooling efficiency by carrying heat out of the nozzle and electrode, which directly prolongs life.

If you shorten post-flow and force frequent re-lighting, you’ll introduce thermal shock and faster wear that degrades cut consistency and increases dross.

Use adjustable post-flow (as on units like the Primeweld Cut 60) to match cooling time to duty cycle and cut length for peak consumable performance and edge quality.

Consumable Cooling Efficiency

Because consumables absorb significant residual heat after an arc extinguishes, setting post-flow to the proper duration—typically 15–20 seconds—lets you cool the torch body, nozzle, and electrode sufficiently to extend their life and preserve cut consistency.

Proper thermal management directly improves consumable lifespan and stabilizes cutting parameters.

- Match post-flow to duty cycle: higher amperage or long cuts need 18–20 s for effective heat dissipation.

- Use adjustable timers: adapt cooling to real-time loads to avoid undercooling or unnecessary gas use.

- Monitor wear patterns: irregular edges or glazing indicate insufficient post-flow and accelerated consumable degradation.

- Balance cost and performance: ideal post-flow reduces replacement frequency, lowering operating expenses while maintaining cut quality.

Set and verify post-flow empirically for predictable cooling and reproducible results.

Post-Flow Versus Re-Lighting

Although longer post-flow reliably cools the torch and extends consumable life, it can delay relighting and slow workflow if set as a fixed interval; you should consequently balance cooling requirements with production needs by using adjustable post-flow or relight-enabled models when fast restart is important. You’ll find typical post-flow durations of 15–20 seconds protect consumables, but fixed timers reduce re lighting efficiency. Use post flow flexibility to scale cooling to duty cycle: longer for extended cuts, shorter for intermittent work. Models allowing relight during post-flow (e.g., RW45) maintain throughput while limiting wear. Insufficient post-flow increases consumable replacement and degrades cut quality from overheating. Adjust settings based on cut length, material thickness, and duty cycle to optimize lifespan and productivity.

| Parameter | Effect |

|---|---|

| Long post-flow | Better cooling |

| Fixed timer | Slower relight |

| Adjustable | Optimized cooling |

| Relight-enabled | Higher efficiency |

| Short post-flow | Increased wear |

Recommended Post-Flow Settings by Material Thickness and Process

For most handheld and mechanized plasma systems, set post-flow times according to material thickness to guarantee torches and consumables cool properly: 15 seconds for materials up to 1/8″, 20 seconds for 1/8″–1/4″ thicknesses, and adjustable settings up to 60 seconds for thicker sections or prolonged duty cycles—tweak within these ranges based on your machine’s duty cycle and observed signs like re-firing difficulty or increased dross.

- For light-gauge work (≤1/8″), use 15 s post flow to stabilize consumable temperature and prevent premature wear.

- For moderate thickness (1/8″–1/4″), set 20 s to reduce residual heat, improving cut quality and consumable life.

- For heavy sections (>1/4″), program up to 60 s and monitor thermal accumulation; increase only as required by temperature and duty cycle.

- Use observed indicators (difficulty re-firing, excess dross) to fine-tune post flow settings per material thickness and process, balancing cooling with cycle time.

Adjusting Post-Flow for CNC and Rapid-Fire Cutting Sequences

When running CNC or rapid-fire sequences you’ll need dynamic post-flow timing that matches cycle rate and material to avoid overheating consumables.

Set re-fire readiness strategies so the torch can re-ignite immediately when pressure and cooling thresholds are met, and account for compressor cycling which can delay re-pressurization.

Test and log post-flow durations and compressor recovery times to optimize throughput without shortening component life.

Dynamic Post-Flow Timing

If you’re running a CNC table or rapid-fire cutting sequence, dynamically adjusting post-flow timing lets you match cooling time to the actual duty cycle and heat load, improving consumable life and preventing premature re-firing.

You’ll use dynamic adjustments to extend post-flow from standard 15–20s up to systems that allow 60s, tuning for cut length, torch duty cycle, and material thickness to maximize cooling efficiency.

Monitor temperature and duty cycle metrics, and increase post-flow for long or high-current cuts.

Be aware of high CFM demands—some systems need compressor upgrades to support extended post-flow without pressure drop.

Implement control logic that scales post-flow with cumulative heat input to preserve consumables and maintain cycle throughput.

- Match post-flow to duty cycle

- Scale time with cut length

- Monitor torch temperature

- Check compressor capacity

Re-Fire Readiness Strategies

You’ve already tuned post-flow to match duty cycle and cut length; now focus on preparing the torch for immediate re-fire during CNC and rapid-fire sequences by adjusting post-flow timing and related settings.

Set baseline post-flow to 15–20 seconds, then implement variable post-flow tied to duty cycle so the controller shortens timing during high-volume runs.

For high-frequency systems, reduce post-flow within safe thermal limits to minimize interruptions and support rapid re-firing.

Use fine cut tips to lower air demand, helping maintain stable pressures for re firing techniques.

Monitor downstream supply so compressors meet required CFM; insufficient flow undermines post-flow effectiveness and delays re-fire readiness.

Log cycle times and iterate settings to maximize operational efficiency without compromising consumable life.

Compressor Cycling Impact

Because compressor cycling directly affects torch cooling and re-fire readiness, you should tune post-flow so it balances thermal protection with compressor capacity during CNC and rapid-fire sequences.

Adjusting post-flow duration mitigates compressor cycling by ensuring consumables cool adequately without forcing extra fills that reduce compressor efficiency. Fixed post-flow can block timely re-fires and slow CNC operations; variable post-flow adapts to duty cycle, aiding cycling reduction and extending consumable life.

High CFM cutters may still need compressor upgrades to maintain stable air delivery under rapid bursts. Implement controls that change post-flow by sequence length and measured duty cycle so you keep re-fire readiness, minimize compressor wear, and optimize cutting throughput.

- Match post-flow to duty cycle

- Monitor compressor load

- Use variable post-flow controls

- Plan for CFM upgrades

Compressor and Air Supply Considerations for Effective Post-Flow

When you’re sizing and maintaining compressors for post-flow, focus on meeting the required PSI and cold-flow CFM rather than simply buying a larger unit, because correct pressure and sustained flow directly control cooling effectiveness and consumable life.

For example, the Hypertherm Powermax 85 needs about 90 PSI and 500 scfh cold flow to achieve its specified post-flow cooling, while tip selection (fine-cut tips) and clean, debris-free lines reduce air consumption and help smaller compressors meet demand.

Check that your air pressure and flow rate remain within manufacturer tolerances under active post-flow cycles.

Monitor compressor duty cycle, receiver capacity and pressure drop through filters and tubing so cooling pulses aren’t starved.

Maintain inline filters, separators and drains on a scheduled basis and purge lines of moisture and particulates.

Use fine-cut consumables where appropriate to lower CFM demand.

If you document steady-state PSI and scfh during cutting and post-flow, you’ll optimize consumable life and maintain consistent post-flow cooling without oversizing equipment.

Troubleshooting Common Post-Flow Problems

If post-flow seems inadequate, start by confirming the actual duration, pressure and flow at the torch rather than relying on nominal settings: measure time (aim for 15–20 s unless the manufacturer specifies otherwise), verify PSI under load, and log cold-flow CFM during the post-flow interval.

You’ll quickly identify whether post flow issues stem from incorrect timing, low air pressure, or restricted flow.

- Check timing and adjust to an adjustable post-flow if fixed duration prevents rapid re-fires.

- Measure air pressure under load; < recommended PSI causes hard starts and poor cooling—repair leaks, drains, or regulator faults.

- Inspect air delivery: clean filters, replace hoses, and verify fittings to restore rated CFM and prevent consumable overheating.

- Diagnose HF interference: isolate grounding, use recommended HF suppression, and verify control circuitry to guarantee post-flow effectiveness.

Follow a logged checklist: duration, PSI, CFM, and maintenance actions.

That systematic approach pinpoints root causes and extends consumable life.

Frequently Asked Questions

Can Post-Flow Settings Differ Between Plasma Torch Brands?

Yes — you’ll find plasma torch comparison shows post-flow durations can vary; manufacturers provide brand specific settings because cooling designs, consumables, and pilot arcs differ, so you’ll adjust post-flow per torch for ideal cut quality.

Does Post-Flow Affect Cutting Speed or Cycle Time?

Yes — post-flow can impact cutting speed and cycle time; it improves cutting efficiency by aiding thermal management, so you’ll balance longer post-flow for edge quality versus shorter cycles when throughput matters, keeping parameters tightly controlled.

Can Water-Mist or Oxygen Plasmas Use Standard Post-Flow Timings?

You can’t always use standard post-flow timings; water mist effectiveness needs longer cooling and flushing, while oxygen plasma considerations demand shorter or tailored flows to control oxidation and dross—so you’ll test and adjust per process and material.

How Does Ambient Temperature Influence Required Post-Flow Duration?

Think of ambient conditions as a thermostat: you’ll extend post-flow when temperature effects slow nozzle cooling and plasma quenching. In colder ambient conditions you’ll need longer post-flow; in hotter conditions you can shorten it safely.

Is Post-Flow Programmable Per-Part in Cam/Post-Processor?

Yes — you can program post-flow per part in CAM/post-processor: you’ll configure programmable parameters for post flow customization, assign values per operation or part, and the controller will emit the specified post-flow duration automatically.

Conclusion

You’ve seen how post-flow cools the torch and saves consumables—think of it like letting a race car idle after a lap so brakes and engine don’t warp. In one shop, extending post-flow from 15 to 20 seconds cut nozzle replacements by 30%, proving small adjustments pay off. Apply the recommended times by material, tweak for CNC or rapid-fire sequences, and monitor air supply so your torch stays reliable, precise, and cost‑efficient.