If you’re using a plasma cutter with an internal compressor, it draws in ambient air, pressurizes it, and feeds a steady, regulated gas flow to the torch so you get a stable arc without an external air supply. That makes setups faster and the unit more portable, but it also limits continuous run time, cooling needs, noise and peak CFM compared with shop compressors—so weigh convenience against sustained performance before picking one.

How an Internal Compressor Powers Plasma Cutting

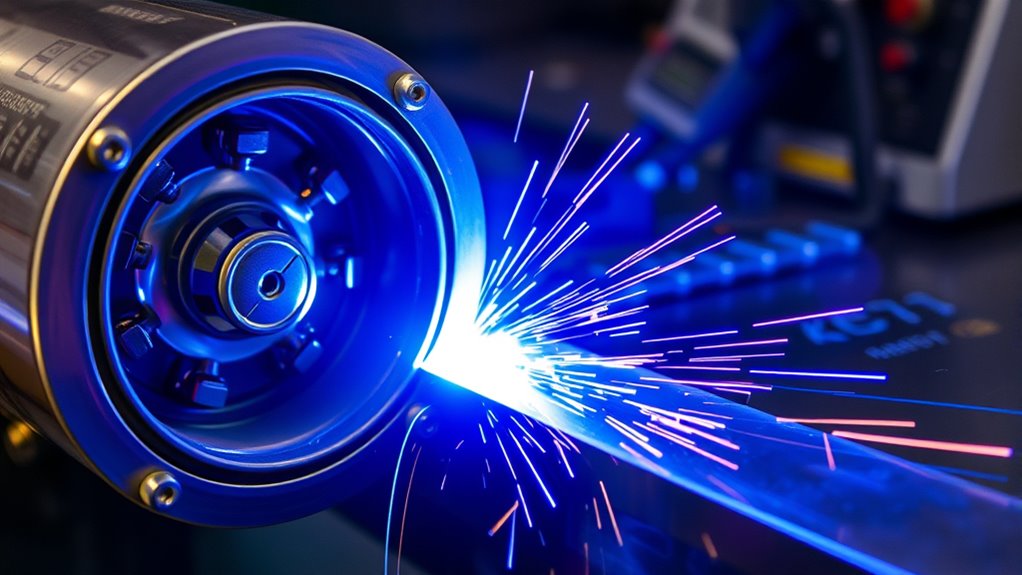

When you trigger the torch, the internal compressor draws in ambient air, pressurizes it, and delivers a steady stream of gas to the torch head so the plasma arc can form and stay stable.

You rely on internal compressor functionality to supply consistent airflow and pressure, which directly controls plasma arc stability and cut quality. The compressor compresses ambient air, filters and meters it, then feeds the nozzle at the required pressure and flow rate so ionization occurs reliably.

Internal compressor performance ensures steady, filtered, metered air delivery—stabilizing the plasma arc and preserving consistent cut quality.

With steady gas output, you avoid pressure dips that would vary arc shape, reduce metal deformation, and minimize dross. That consistency also supports higher cutting speeds—typically two to three times faster than oxyacetylene—so you maintain productivity on repetitive cuts.

You won’t need external gas plumbing, and the integrated control simplifies setup and reduces points of failure. Overall, precise internal compressor functionality is the core mechanical factor that sustains a clean, repeatable plasma arc and dependable cutting performance.

Convenience and Portability Advantages

With an internal compressor you’ll move a self-contained plasma cutter between sites without hauling an external air unit.

You’ll cut setup time because there’s no compressor hookup or extra hoses to position.

That mobility speeds shifts and keeps workflow tight on high-volume jobs.

Built-in Compressor Mobility

Although you might need to move between jobs frequently, an internal compressor in a plasma cutter eliminates the extra bulk of an external air unit, so you’ll carry a single, self-contained tool that’s faster to load, transport, and set up.

You gain clear mobility benefits: one chassis houses power, control electronics, cutting torch, and compressed air, reducing trip counts and simplifying logistics.

That compact integration preserves cutting efficiency for light-duty tasks by supplying consistent air without long hose runs or separate mounts.

You’ll find on-the-go deployments easier, with fewer accessories to track and fewer compatibility issues.

For professionals and DIY users who prioritize portability and straightforward operation, built-in compressors offer a practical, space-saving solution that streamlines field work.

Faster Jobsite Setup

Carrying a plasma cutter that already houses its air supply lets you get to work faster because you don’t have to connect an external compressor or lay out hoses. You reduce setup time dramatically: the integrated compressor removes separate power and air connections, so transport-to-operation takes minutes.

That streamlines workflows and boosts jobsite efficiency, especially when moving between short-duration tasks or confined locations. The self-contained design simplifies logistics — one unit to lift, secure, and plug in — and minimizes ancillary gear to inventory and maintain.

You won’t manage extra hoses, fittings, or compressor warm-up cycles, which cuts pre-cut checks and failure points. For technicians who value rapid turnaround and predictable setup time, built-in compressors provide clear, practical gains.

Impact on Cutting Speed and Productivity

Because an internal compressor delivers a steady, high-pressure air stream, you’ll cut 2–3 times faster than with traditional oxyacetylene setups, dramatically shortening job cycles.

That speed gain directly improves cutting efficiency and compresses project timelines: you complete more parts per shift and reduce machine idle time. The integrated compressor provides stable gas output, so you don’t chase inconsistent arc behavior that slows progress or forces rework.

Operationally, the built-in unit removes external air supply coordination, trimming setup and teardown minutes and lowering transport complexity on the jobsite.

For high-volume tasks, the result is predictable throughput — you can plan daily output targets with confidence. Maintenance remains straightforward: monitor compressor filters and pressure regulators to sustain consistent performance.

To summarize, the internal compressor converts reliable, continuous airflow into measurable productivity gains, letting you optimize labor allocation and meet tighter deadlines without relying on ancillary air equipment.

Effects on Cut Quality and Metal Deformation

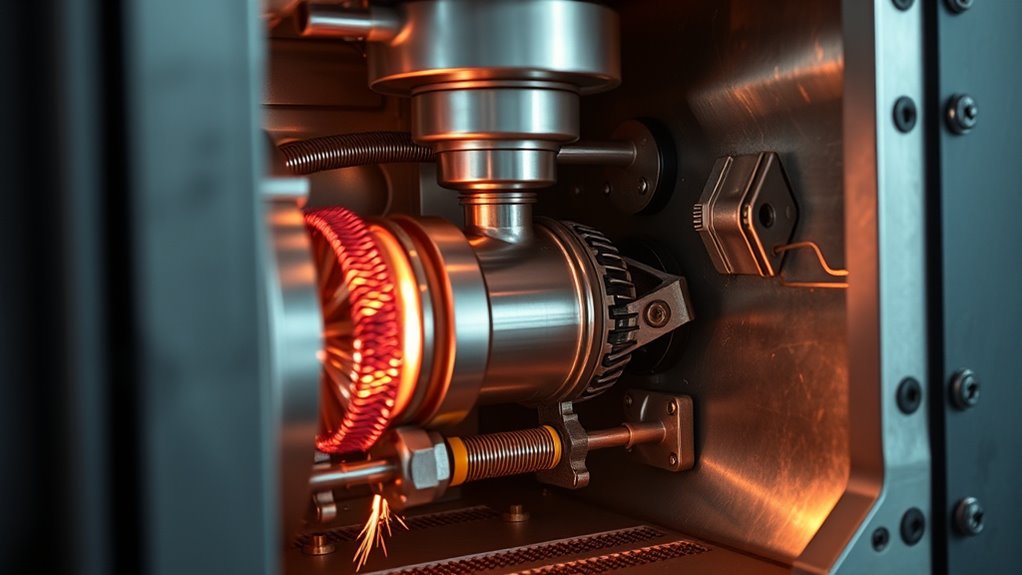

You’ll notice the internal compressor’s stable pressure narrows the heat-affected zone, concentrating thermal input and preserving nearby microstructure.

That reduced HAZ, together with faster, more consistent cutting and reliable pilot arc starts, lowers the risk of warping and distortion.

Eliminating external air sources also cuts contamination-related consumable wear that can worsen deformation and edge quality.

Heat-Affected Zone

When plasma cutting, the heat-affected zone (HAZ) marks where metal microstructure and properties change, and controlling it’s critical to cut quality and part integrity.

You’ll use heat management and quality control practices to limit HAZ size: a stable gas output from an internal compressor keeps cutting temperatures consistent, reducing overheat and microstructural alteration.

Higher cutting speeds enabled by reliable compressor flow shorten thermal exposure, producing a narrower HAZ and cleaner kerf.

You must monitor and adjust compressor airflow and pressure; inadequate flow raises local temperatures and widens the HAZ, degrading edge toughness and increasing grinding work.

In short, the internal compressor gives you tighter thermal control, improving dimensional accuracy and surface condition by minimizing heat penetration without addressing subsequent warping or distortion.

Warping and Distortion

If you want to minimize warping and distortion during plasma cutting, keep the gas supply stable—an internal compressor delivers consistent pressure and flow that reduces uneven heating and localized thermal expansion.

You’ll get measurable warping prevention and distortion reduction because stable gas flow prevents momentary overheat spots and metal deformation. The result is cleaner kerfs, tighter tolerances, and less rework.

- Stabilized pressure: consistent force at the torch maintains uniform arc energy, reducing asymmetric shrinkage that causes warping.

- Steady flow: continuous gas eliminates pulsing that creates localized overheating and distortion.

- Operational efficiency: built-in compressors remove external variability, lowering material waste and maintenance while improving overall cut quality through better thermal control.

Air Delivery: Pressure, CFM and Stability

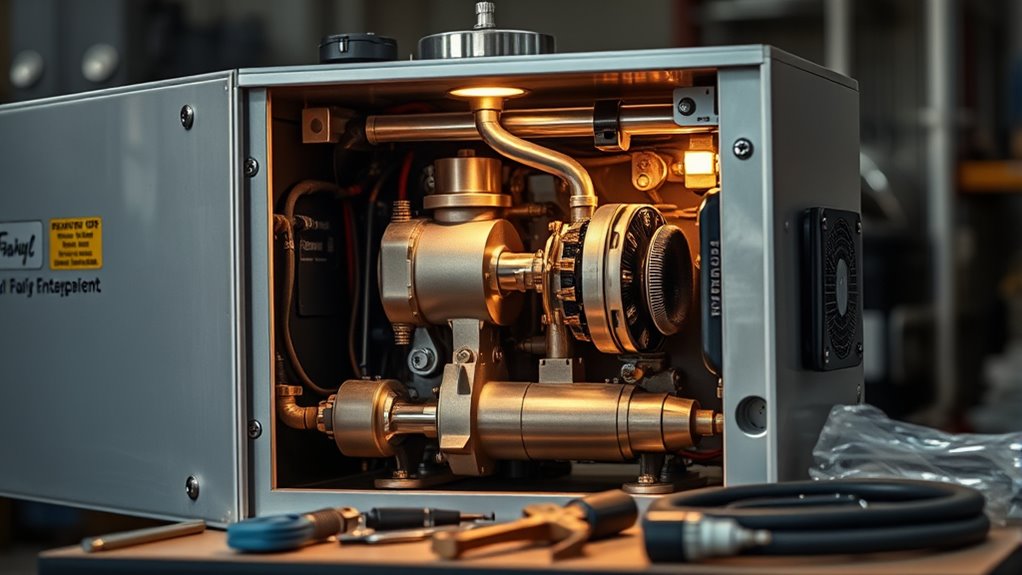

Proper air delivery is critical for plasma cutting: the internal compressor must supply 60–100 PSI and the CFM the torch requires, steadily and without pressure swings, to maintain arc stability and consistent cut quality.

You’ll rely on precise airflow regulation and pressure consistency to prevent arc wander, dross buildup, and edge melting. Match compressor CFM output to the manufacturer’s minimum for the torch and factor in duty cycle — undersized CFM drops arc energy and slows cutting, oversized capacity reduces load cycling but adds weight.

Integrated compressors simplify setup and keep delivery lines short, improving transient response and reducing pressure loss. Monitor supply pressure and CFM with gauges or inline sensors; avoid sustained pressure near the lower limit.

Stabilized output produces cleaner kerfs, higher speeds, and repeatable results that outperform oxyacetylene by 2–3× in throughput.

Design choices should prioritize steady CFM under load, rapid recovery after high-flow pulses, and tight pressure regulation to maintain consistent metallurgical outcomes.

Maintenance, Reliability and Common Issues

While internal compressors simplify setup, you’ll need a focused maintenance routine to keep them reliable: routinely check for air leaks, clean or replace filters, and monitor oil levels and condensate drains to prevent moisture-related damage.

You’ll also inspect fittings and store the unit dry to avoid rust and corrosion that shorten component life. Addressing compressor maintenance proactively prevents degraded cut quality and shortened consumable life.

- Check filters and drains: clogged filters or filled condensate traps reduce airflow and cause reliability issues; replace media and purge water on schedule.

- Verify pressure regulation: test regulators and gauges; inconsistent pressure or failure to reach setpoints often indicates regulator faults or internal leaks.

- Monitor thermal and duty limits: small self-contained compressors can overheat under heavy use, lowering efficiency and causing shutdowns—respect duty cycles and cooldown periods.

You’ll log service actions and failure symptoms to spot trends and replace parts before they cause unplanned downtime.

Noise, Power and Operational Trade-Offs

Maintaining the compressor keeps it reliable, but you’ll also need to weigh noise, power and operational trade-offs when choosing or using a plasma cutter with an internal compressor. Internal units run around 60 dB — acceptable in industrial shops but potentially disruptive in homes or small workshops. You’ll want active noise reduction measures (isolation mounts, enclosures) if workspace comfort matters. Internal compressors usually run on 120V, limiting power efficiency and sustained cutting compared with 220V systems; that restricts heavy-duty use.

| Factor | Impact |

|---|---|

| Noise (~60 dB) | May require mitigation for small shops |

| 120V power | Limits continuous high-power cutting |

| Small tank / duty cycle | More cooling breaks, reduced throughput |

Operationally, smaller tanks and duty-cycle limits force frequent pauses, reducing uninterrupted run time and potentially harming cut quality under high-volume demand. If you need consistent airflow and extended duty, factor these constraints into workflow planning and tool selection.

When to Choose an External Compressor Instead

If you need sustained, high-quality cuts for industrial or high-volume work, choose an external compressor because it delivers steadier, higher airflow and larger tank capacity that keep arc stability and duty cycle consistent.

You’ll get the external compressor benefits most clearly when you run long shifts, cut thick materials, or require repeatable edge quality. External units supply cleaner, drier air that lengthens consumable life and reduces downtime.

- Use one for industrial applications where continuous operation and consistent arc stability matter; larger tanks smooth demand spikes and extend run time.

- Pick an external compressor if you share air across tools or need versatility; a single external unit can support multiple stations better than an internal compressor.

- Opt for external when portability isn’t critical and you prioritize power and efficiency; they outperform self-contained units for heavy-duty cutting and reduce moisture-related failures.

Choose external compressors when reliability, uptime, and consumable cost control outweigh the convenience of portability.

Frequently Asked Questions

Can an Internal Compressor Be Replaced or Upgraded Later?

Yes — you can replace or perform a compressor upgrade later; you’ll need compatible fittings, electrical capacity, and pressure/flow matching. Plan downtime, validate seals and controls, and test cut performance after compressor replacement or compressor upgrade.

Does the Internal Compressor Affect Consumable Lifespan?

Yes — like a metronome guiding an orchestra, it sets airflow tone; lower compressor efficiency increases consumable wear, while stable, efficient internal compressors reduce arc instability and extend tip and electrode life through consistent gas flow and pressure.

Are There Safety Certifications for Built-In Compressors?

Yes — you’ll find safety standards and certification processes for built-in compressors; manufacturers follow electrical, pressure, and EMC regulations (CE, UL, ASME where applicable), and units undergo testing, documentation, and inspection during certification processes.

Can Internal Compressors Operate in Cold Environments?

Yes — internal compressors can operate in cold environments, but you’ll see reduced cold performance and lower compressor efficiency below rated temps. Preheating, insulation, and lubricants suited for low temperatures will help maintain reliable operation.

How Does Altitude Affect Internal Compressor Performance?

Like a mountain guide, your compressor struggles uphill: you’ll need altitude adjustment because thinner air reduces pressure and flow, causing performance impact. You’ll compensate with higher intake, adjusted settings, or reduced cutting capacity to maintain output.

Conclusion

So you get a pocket-sized beast: the internal compressor feeds steady pressurized air to keep the arc alive, so you cut anywhere without hauling a tank. It’s practical—fast setup, decent cut quality, and portable—yet noisy and heat-limited, like a hamster on a treadmill: hardworking but needing frequent breaks. If you’re job-hopping and value convenience over marathon duty cycles, pick internal; for long, continuous runs, don’t.