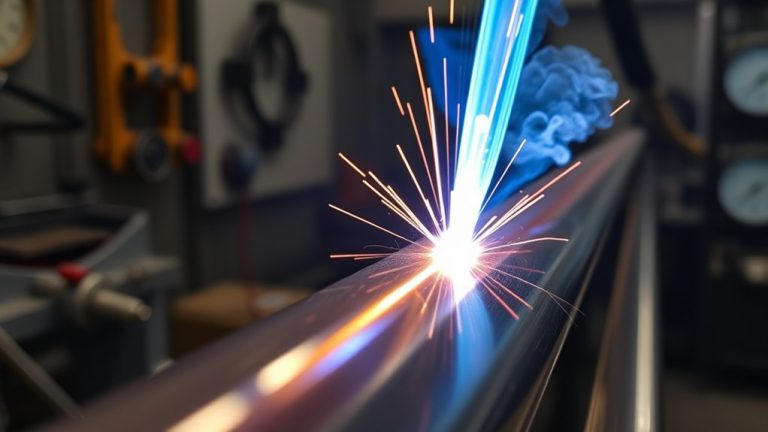

Like a modern forge, plasma cutting quietly shapes the products you use every day. You’ll see it in automotive and EV lines for precise lightweight components, on construction sites slicing beams and plate, and in aerospace shops handling complex geometries in high‑grade alloys. Shipyards rely on it for hull sections, while artists and sign makers craft intricate patterns. It also shines in MRO and field work for fast, clean cuts. But what really determines which process fits your workflow?

Automotive Manufacturing and EV Production

Whether you’re cutting chassis rails, exhaust assemblies, or body-in-white panels, plasma cutters deliver fast, repeatable cuts in lightweight, high‑strength steels and aluminum alloys while holding tight tolerances.

You standardize pierce heights, gas flow, and torch speed to maximize plasma efficiency, then verify kerf width and edge quality with in-line sensors. Automated gantry or robotic systems integrate nesting software to minimize scrap and drive takt time, supporting automotive innovation without sacrificing tolerance stacks.

For EV platforms, you profile battery trays, motor mounts, and crash structures with intricate geometries, using fine-feature consumables to hold sub‑millimeter accuracy.

Closed-loop motion control shortens cycle times, while real-time arc-voltage sampling maintains consistent standoff on warped panels. You switch programs rapidly to accommodate trim variants and late-stage design changes, enabling just-in-time builds.

Statistical process control tracks cut roughness, heat‑affected zone, and dross levels, ensuring repeatability across shifts and model years, and lifting throughput while improving downstream fit-up and weld quality.

Construction, Steel Fabrication, and Heavy Equipment

Blueprints turn into steel faster when you bring plasma cutting onto the jobsite. You cut beams, plates, and gussets to spec with kerf widths under a millimeter, maintaining tight tolerances that drive construction efficiency.

Portable units let you modify connection details on-site—coping a flange, trimming a web, or adding access holes—so crews avoid rework cycles and transport delays, keeping schedules and budgets aligned.

Portable plasma units enable on-site flange copes, web trims, and access holes, cutting rework and keeping schedules on track.

In steel fabrication, CNC plasma tables translate nest files into rapid, repeatable cuts, minimizing scrap through optimized nesting and consistent edge quality.

You preserve structural integrity by controlling heat input, using proper amperage, gas selection, and cut speed to reduce HAZ and maintain weld-ready edges.

Heavy equipment manufacturers rely on plasma cutting for chassis rails, boom sections, and wear plates across carbon steel, HSLA, and stainless.

You meet engineering requirements by holding perpendicularity, pierce timing, and bevel angles, accelerating throughput while ensuring fit-up accuracy.

The result: faster turnaround, less waste, higher quality.

Aerospace and Defense Applications

Precision defines aerospace and defense plasma cutting, where you profile complex geometries in high-grade alloys—aluminum, titanium, nickel-based—while holding tight tolerances and minimizing HAZ.

You leverage high-definition plasma, fine kerf widths, and robust torch height control to maintain ±0.25–0.5 mm accuracy across varied thicknesses, supporting aerospace innovations and mission-critical defense technologies.

In aircraft fabrication, you cut lightweight, high-strength skins, ribs, and brackets, optimizing heat input to preserve mechanical properties and fatigue life.

Automated gantry systems and CNC nesting maximize yield, reduce scrap, and standardize quality across lots. For armored vehicles and weaponry components, you use automated cells with barcode-driven programs and interlocks to guarantee repeatability and compliance with safety standards.

Process control is rigorous: you log consumable life, gas mixes, current, and cut speeds for full traceability and regulatory adherence (AS9100 workflows).

Statistical process control reduces rework, while integrated probing, bevel heads, and post-cut inspection streamline flow—shortening lead times and boosting first-pass yield for national defense and commercial fleets.

Artistic, Signage, and Custom Metalwork

You use plasma cutters to execute intricate design capabilities, producing tight kerf widths and repeatable tolerances across steel, aluminum, and copper.

With CNC-driven personalization, you import vector files, set amperage and cut speeds, and achieve high-fidelity cuts that reduce scrap and cycle time.

For mixed-metal sculpture work, you sequence pierce timing, gas settings, and toolpaths to handle varying thicknesses and alloys without compromising edge quality.

Intricate Design Capabilities

From filigreed signage to custom sculptures, plasma cutters deliver intricate design capability by accurately tracing toolpaths through steel, aluminum, stainless, and more.

You translate design innovation into precise kerfs, achieving tight radii, lattice patterns, and relief cuts that elevate creative expression without sacrificing dimensional accuracy. By importing vectors from digital design software, you streamline nesting, lead-ins, and pierce sequencing, minimizing heat-affected zones and dross.

Rapid prototyping lets you iterate profiles quickly, validate fit, and finalize surface-ready parts for finishing.

- Generate high-fidelity patterns with controlled amperage, gas flow, and cut speed for consistent edge quality

- Translate vector art to machine code, optimizing kerf compensation and micro-tabs

- Manipulate challenging alloys, expanding decorative and sculptural options

- Compress concept-to-part timelines through repeatable, data-driven cut routines

Cnc-Driven Personalization

Building on intricate toolpath control, CNC-driven personalization extends those capabilities into on-demand artworks, signage, and custom metalwork with repeatable accuracy. You translate vector models into machine-ready code, align kerf and pierce parameters, and cut steel or aluminum with tight tolerances. By coupling CAD/CAM with digital fabrication techniques, you iterate fast, minimize scrap, and follow custom design trends without sacrificing throughput or finish quality.

| Material | Application | Precision Cue |

|---|---|---|

| Steel | Outdoor signage | Fine kerf, low dross |

| Aluminum | Indoor décor | Heat-managed paths |

| Corten | Address plates | Controlled patina zones |

| Stainless | Brand logos | Micro-tab retention |

| Brass | Monograms | Low-amp detail cuts |

You validate geometry, nest parts, simulate paths, and output G-code, reducing human error on both one-offs and batch runs. Rapid revisions let you tailor letterforms, negative space, and attachment points to client specs.

Mixed-Metal Sculpture Work

While combining dissimilar alloys introduces thermal and metallurgical challenges, plasma cutting streamlines mixed‑metal sculpture, signage, and custom metalwork with precise, repeatable workflows.

You leverage plasma techniques to contour steel, aluminum, and copper into intricate geometries, holding tight kerf tolerances and minimizing heat‑affected zones.

With CAD/CAM integration, you translate artistic inspiration into toolpaths, iterate rapidly, and prototype complex assemblies with predictable cut quality.

Nesting algorithms reduce scrap; high duty cycles and fast pierce times compress schedules so you spend more time designing and less time grinding.

- Material stackups: parameterize current, gas, and speed for each alloy

- Precision signage: reproduce brand fonts and logos with consistent kerf

- Rapid prototyping: import vectors, simulate paths, validate fit-up

- Lean fabrication: optimize nesting, track waste, standardize consumables

Shipbuilding and Marine Engineering

Because ship hulls and structural frames demand tight tolerances in thick steel, plasma cutters are integral to marine fabrication workflows, delivering high‑speed, precision cuts on plates often exceeding 50 mm.

You apply them early in marine vessel design and naval architecture to profile bulkheads, stringers, and keel sections from large plate with consistent kerf width and minimal heat‑affected zone.

You load CAD/CAM nests, assign lead‑ins/lead‑outs, and set amperage and gas parameters to match plate thickness.

Automated gantry systems then execute bevel cuts for weld prep (e.g., V, Y, and K joints) while holding ±0.5–1.0 mm tolerance across multi‑meter runs.

With tight nesting and rapid traverse, you cut complex contours and penetrations, reducing scrap ratios and rework.

High duty cycles sustain throughput on long parts lists for commercial and military builds.

Versatility lets you switch from mild steel to stainless or aluminum modules, enabling custom components without bottlenecking panel line production.

Maintenance, Repair, and Field Operations

Even in remote yards and on congested jobsites, plasma cutters let you execute fast, precise cuts on corroded or over‑thickness steel without hauling parts back to a shop.

You reduce downtime by cutting, trimming, and slotting components in situ, avoiding rigging and transport delays. Portable units with high duty cycles and stable output handle variable power conditions, so you complete critical repairs on first pass with minimal rework.

Use smart plasma systems with IoT telemetry to drive predictive and preventive maintenance.

Real‑time arc stability, consumable wear, and temperature data flag anomalies, so you service equipment before failures and extend equipment longevity.

Precision kerfs limit heat‑affected zones, preserving surrounding materials and minimizing secondary machining.

Safer workflows follow: faster separations reduce handling of heavy sections and exposure to hazards.

- Deploy portable, inverter-based cutters for immediate field repairs

- Log arc-on time and consumable metrics for predictive maintenance

- Execute precision cuts to minimize HAZ and rework

- Standardize PPE, grounding, and fume control for jobsite safety

Frequently Asked Questions

What Materials Cannot Be Cut With a Plasma Cutter?

You can’t cut wood, plastic, glass, stone, or ceramics; they’re Non metal materials. Plasma cutter limitations also include copper-clad laminates, composites, and reflective metals like aluminum without proper gases. Avoid painted, coated, or flammable materials due to toxic fumes.

How Does Plasma Cutting Compare to Laser Cutting?

You trade plasma advantages for laser precision: you cut faster, thicker, cheaper with plasma; you cut cleaner, narrower, finer with lasers. You assess material, thickness, tolerance, edge quality, and cost, then select torch type, gas, power, and speed.

What Safety Gear Is Required for Plasma Cutting?

You need plasma safety protective equipment: ANSI Z87+ shaded face shield, welding helmet, flame-resistant jacket, leather gloves, hearing protection, steel-toe boots, and respirator per fume levels. Ground workpiece, manage leads, verify ventilation, and maintain Class D fire readiness.

How Much Power and Air Supply Do Plasma Cutters Need?

You’ll need 120–240V, 20–50A circuits; 30–80A output drives cut capacity. Compressed air supply: 90–120 psi, 4–7 scfm, dry and filtered. Yes, electricity’s not optional. Verify duty cycle, line voltage stability, and compressor recovery.

What Training or Certifications Are Recommended for Operators?

You should complete operator training covering OSHA 10/30, NFPA 51B hot work, and manufacturer-specific courses. Pursue certification programs like AWS SENSE, ANSI Z49.1 compliance, and CPR/First Aid. Validate competency via WPS adherence, cut-quality metrics, and documented proficiency assessments.

Conclusion

You’ve seen where plasma cutters excel: automotive and EV lines, structural steel, aerospace alloys, marine hulls, custom art, and on-site MRO. When you quantify cycle time, kerf width, heat-affected zone, and cut repeatability, you can map process capability to each use case. Choose the right power source, gas, torch, and CNC parameters, and you’ll hit spec with speed. After all, isn’t precision the quiet engine driving throughput, quality, and cost—cut after cut, shift after shift?