Does the theory hold that plasma arc welding on steel tubes delivers deeper, more consistent penetration with tighter fit-up tolerance than GTAW? You’ll see how the constricted arc stabilizes keyhole mode for full-fusion roots, uniform reinforcement, and repeatable bead geometry per ISO 15614 and AWS D17.1 practices. We’ll quantify heat input, HAZ width, and travel speed, compare gas mixes for stainless, and outline automation impacts—so you can judge whether PAW justifies the cycle time and QA gains.

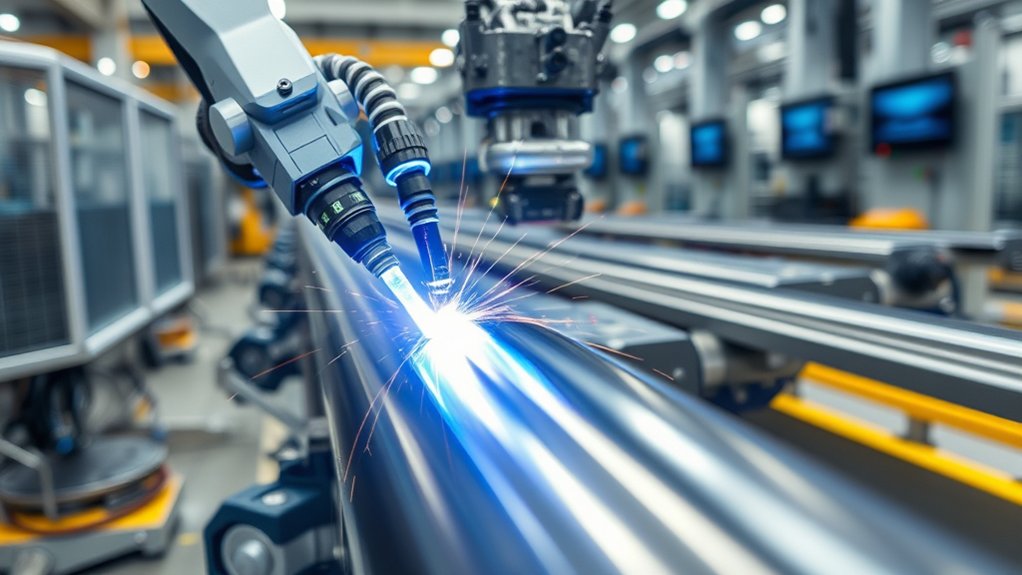

How Plasma Arc Welding Works on Steel Tubes

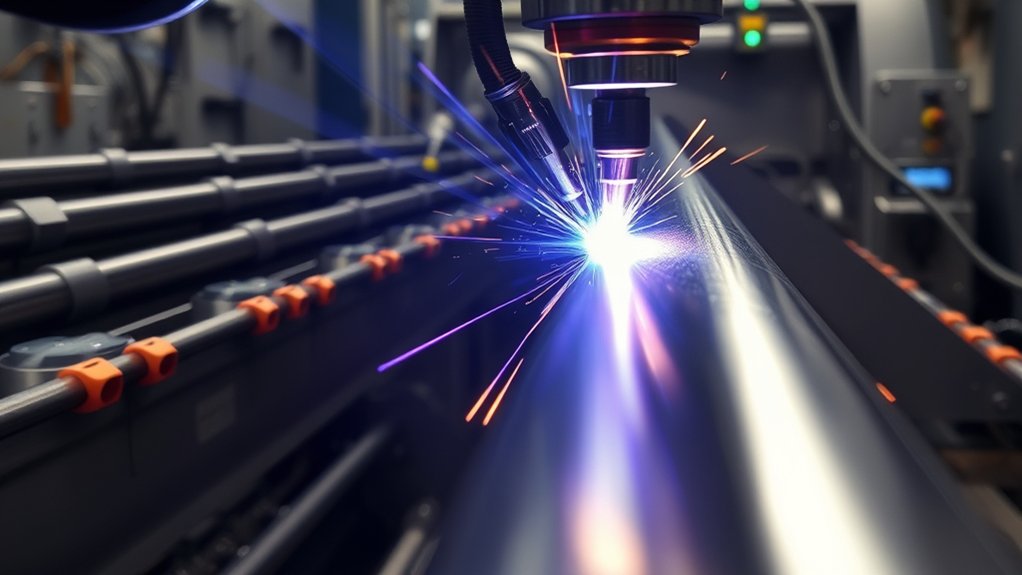

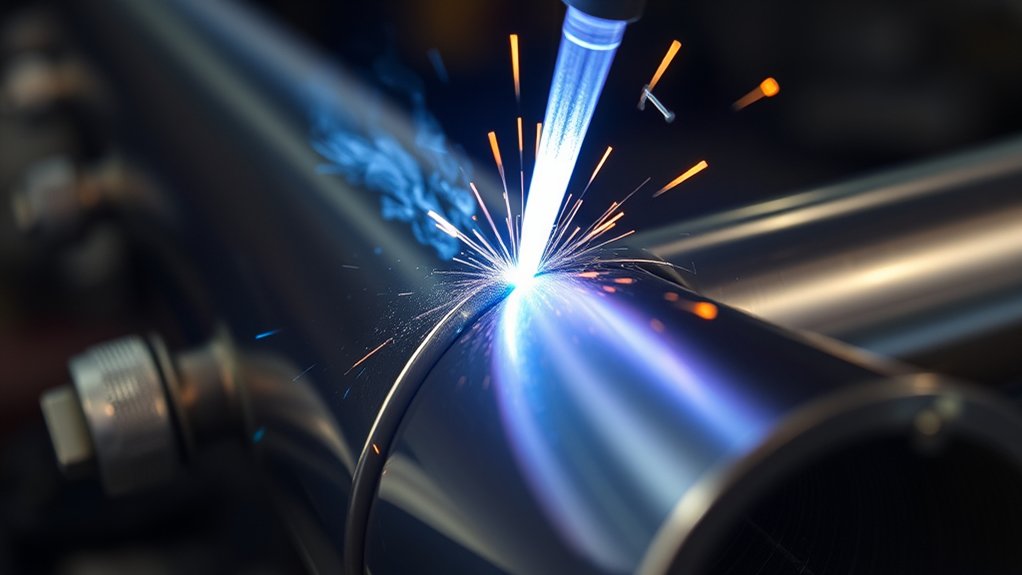

Two key mechanisms define how Plasma Arc Welding (PAW) joins steel tubes: a constricted arc and a high-velocity plasma jet. You initiate arc formation between a nonconsumable tungsten electrode and the tube, then constrict it through an orifice to raise current density and energy flux. The result is a focused plasma column that delivers deep, narrow penetration with minimal thermal spread, improving welding stability on butt joints and thin-walled sections.

With proper parameter control (current, plasma gas flow, travel speed), you achieve full-penetration welds on steel tubes up to 10 mm in a single pass. The constricted jet reduces spatter and limits the heat-affected zone, lowering distortion and preserving dimensional tolerance. This enables rapid, single-pass seams with consistent bead geometry and clean surfaces.

Advanced control systems maintain arc length and heat input within tight bands, ensuring repeatable fit-up and quality under production tolerances. You gain predictable fusion, low rework rates, and stable throughput aligned with standards-driven manufacturing.

Key Components of a PAW System for Tube Mills

Precision starts with hardware: a PAW system for tube mills centers on a water‑cooled plasma torch with a constricting nozzle and nonconsumable tungsten electrode, a constant‑current power source with HF start, tightly controlled gas delivery (plasma and shielding, typically argon-based), and a closed‑loop control console for current, gas flow, and pulse parameters.

You specify components to meet duty cycle, tube OD/WT, and line speed, then validate settings by WPS/PQR per recognized standards.

- Torch and plasma nozzle design: Select orifices to match amperage and standoff; water jackets stabilize temperature and jet coherence. Specify wear-resistant copper alloys and concentricity tolerances.

- Tungsten electrode types: Choose 2% thoriated, ceriated, or lanthanated based on start reliability and contamination risk; grind axial tips to controlled included angles.

- Power source: Use CC output with HF start and microsecond-level current ramp/pulse control; verify ripple and dynamic response.

- Gas delivery and control: Meter plasma and shielding flows independently; use mass flow controllers, dew-point control, and interlocks to prevent misflow.

Why PAW Excels at Deep, Consistent Penetration

One reason PAW delivers deep, consistent penetration in steel tubes is its stable keyhole mode: a constricted, high-enthalpy plasma column drives a through-thickness keyhole that supports single-pass, full-penetration welds up to ~10 mm. You gain repeatable penetration depth because the constricted arc concentrates current density, stabilizes the weld pool, and maintains a well-formed keyhole. Compared with GTAW, PAW’s focused plasma increases energy density, enabling full fusion at lower current while improving weld consistency on thin-walled tubes.

You can tune plasma gas flow to balance keyhole robustness and surface finish, preventing turbulence that would disrupt fusion. The result is uniform root reinforcement, minimal undercut, and consistent bead geometry aligned with ISO 15614 and AWS C1.1 quality criteria for tube joints.

| Measure | Feeling |

|---|---|

| 8–10 mm single-pass penetration | Confidence |

| ±0.2 mm penetration tolerance | Control |

| <1% rework rate on test coupons | Relief |

Dialed-in parameters give you deep fusion without compromising dimensional accuracy.

Managing Heat Input and Minimizing Heat-Affected Zones

Although PAW is a high-energy process, its constricted arc lets you meter heat input precisely to protect thin-walled steel tubes and shrink the HAZ.

You leverage a concentrated plasma column to localize thermal energy, enabling rigorous heat management and distortion prevention while preserving base-metal properties adjacent to the fusion line.

- Set current intelligently: Use lower amperage with a constricted nozzle to achieve keyhole penetration and reduce lateral heat spread. This lowers net heat input (kJ/mm) and tightens the HAZ.

- Control travel speed: Maintain a consistent, higher travel speed to limit dwell time. One-pass welds reduce cumulative thermal cycles versus multi-pass methods, further minimizing distortion.

- Optimize gas flow: Stabilize the arc with correct plasma and shielding gas flow rates and composition. Stable ionization raises energy density, improves penetration efficiency, and protects adjacent areas.

- Verify with metrics: Track interpass temperature, bead width-to-penetration ratio, and hardness gradients across the HAZ. Use procedure qualification records and WPS limits to guarantee repeatable outcomes within standards.

Fit-Up Tolerance and Gap Bridging Capabilities

You’ll maintain consistent edge alignment by exploiting PAW’s controllable arc length, focused energy density, and stable low-amperage operation, which limit angular mismatch and hi–lo per ISO 13919-1 acceptance criteria.

Quantify your gap-bridging limits by process mode: keyhole plasma supports single-pass full penetration up to ~10 mm wall with permissible root gaps significantly larger than GTAW, while melt-in mode requires tighter gaps and reduced root face.

Validate these limits with procedure qualification records (per ISO 15614-1 or ASME IX), recording amperage, travel speed, and plasma orifice to establish repeatable tolerances.

Consistent Edge Alignment

Even with minor misalignments, plasma arc welding (PAW) maintains consistent edge alignment by combining a stable, constricted arc with precise energy delivery.

You benefit from superior arc stability, uniform heat input, and reliable edge fusion on steel tubes, even when fit-up varies slightly. The focused plasma column limits the heat-affected zone, protecting nearby geometry while keeping edges aligned under thermal load.

- Expect consistent penetration across up to 0.5 mm joint variation; the constricted jet regulates energy density and weld pool behavior.

- Achieve uniform edge fusion because the stabilized arc locks the keyhole and tracks the joint line with minimal wander.

- Reduce joint-prep time; PAW accommodates slight bevel inconsistencies without sacrificing weld integrity.

- Maintain dimensional control; the narrow arc reduces distortion, preserving tube roundness and minimizing post-weld sizing operations.

Gap-Bridging Limits

While joint fit-up isn’t always perfect, PAW reliably bridges gaps up to 0.5 mm by leveraging a constricted, stable arc that regulates energy density and weld pool flow.

You get consistent penetration despite local variations in joint alignment, because the plasma column maintains arc stiffness and directional heat input, improving gap bridging reliability.

Use keyhole plasma mode when you need full penetration on tubes up to 10 mm wall; the keyhole stabilizes root fusion even with moderate mismatch or edge offset.

Because PAW achieves target penetration at lower current, you reduce net heat input, limiting distortion and preserving dimensional control across the seam.

These process characteristics suit automated cells: tighter statistical control of penetration, fewer rejects due to fit-up drift, and higher throughput without extensive pre-fit rework.

Comparing PAW to TIG for Tube Welding

Although both processes deliver high-quality fusion on steel tubes, Plasma Arc Welding (PAW) provides a more focused, stable, and constricted arc than Gas Tungsten Arc Welding (TIG), yielding deeper penetration, narrower heat-affected zones, and cleaner bead profiles at lower amperage.

You’ll see clear PAW advantages when you need consistent penetration and dimensional control, while TIG limitations appear as heat input rises and arcs widen on thin sections.

1) Penetration and passes: PAW’s keyhole mode delivers single-pass, full-penetration welds on thicker tubes; TIG typically needs multi-pass, increasing cycle time and distortion risk.

2) Heat input and distortion: PAW achieves target fusion at lower current, tightening HAZ per AWS D10.11 guidance, which helps maintain ovality on thin-walled tubes.

3) Bead quality: The constricted arc cuts spatter and improves surface finish, reducing post-weld finishing.

4) Fit-up tolerance: PAW’s higher arc stiffness bridges modest gaps and misalignment better than TIG, improving first-pass yield in production tube joints.

Shielding and Plasma Gas Choices for Stainless Steel

You’ll specify argon as the primary plasma gas for stainless steel, then evaluate argon–hydrogen shielding blends (≈90–98% Ar with 2–10% H2) to increase wettability and travel speed while maintaining corrosion performance per AWS D10.11 and ISO 14175.

Distinguish functions: the plasma gas stabilizes the constricted arc and keyhole, while the shielding gas prevents atmospheric contamination and controls surface oxidation and bead morphology.

Set and verify flow rates to balance penetration and keyhole stability—avoid helium-induced instability, and prevent turbulence and entrainment by staying within manufacturer-recommended L/min for your nozzle size and standoff.

Argon-Hydrogen Blends

Even at low concentrations, hydrogen in argon-based shielding and plasma gases materially changes arc physics and weld metallurgy on stainless steel. You’ll see argon hydrogen advantages in the common 90–98% Ar with 2–10% H2 range: higher thermal conductivity, hotter constricted arcs, cleaner surfaces, and smoother beads.

Use welding parameter optimization to exploit deeper penetration while holding a tight puddle for tube seams.

- Target penetration: Increase current or travel speed as H2 rises; expect narrower fusion with greater depth, ideal for precision tube joints.

- Surface quality: Hydrogen lowers oxide film formation and acts as a lubricity agent, reducing spatter and improving wetting.

- Productivity: Faster travel speeds become viable in automated cells due to improved thermal efficiency.

- Control: Set gas flow carefully; excessive H2 or flow can destabilize keyhole mode and degrade quality.

Plasma Vs Shielding Roles

While both gases share the torch, they serve distinct functions you must tune independently: the plasma gas (typically pure argon) sustains a stable, constricted high-energy arc, and the shielding gas (often Ar with 2–5% H2) protects the pool and tailors heat input and bead shape.

You rely on argon in the plasma stream for repeatable plasma characteristics, tight columnar constriction, and controllable keyhole behavior. Helium in the plasma stream raises temperature but degrades keyhole stability on stainless due to lower mass and higher thermal conductivity.

For shielding effectiveness, an Ar-H2 blend improves wettability, increases travel speed, and deepens fusion, producing smoother toe shifts and cleaner surfaces. The shielding mix also manages heat tint and oxidation, enhancing bead integrity and dimensional control.

Flow Rates and Stability

With roles defined, the next control lever is gas flow, because arc stability and bead quality on stainless hinge on precise delivery of the plasma and shielding streams.

You’ll set argon as the plasma gas and use Ar + 2–5% H2 for shielding to boost wettability and travel speed. Control both circuits to avoid gas turbulence at high flow and under-protection at low flow; flow consistency drives penetration uniformity and defect minimization.

1) Target stable laminar flow: size nozzles to keep exit velocity below the turbulence threshold; verify with flowmeters traceable to ISO 5171.

2) Tune plasma flow for constriction and keyhole stability; overflow entrains air, underflow destabilizes the arc.

3) Set shielding to prevent oxidation and minimize HAZ width.

4) Audit flows during production; log setpoints, ambient conditions, and weld outcomes.

Productivity Gains: Single-Pass Speed and Automation

Speed is the headline: plasma arc welding (PAW) delivers single-pass, full-penetration welds on steel tubes up to ~10 mm, eliminating multi-pass cycles and cutting arc time.

You convert layers of beads into one controlled keyhole pass, improving production efficiency and creating clear automation advantages. With a constricted arc and stable keyhole, travel speeds typically exceed GTAW, enabling high-throughput cells without sacrificing penetration.

In automated lines, PAW’s consistent arc column and narrow bead geometry reduce sequencing and torch dwell, supporting continuous operation and lower labor minutes per joint.

You’ll see fewer interpass stops, less heat input per unit length, and shorter cycle times, which aligns with lean takt targets. The deeper penetration and minimal post-weld cleanup further compress overall weld station time.

Integrate standard interfaces (robot/PLC, AVC, seam tracking) to maintain process windows and repeatability. The result is higher OEE: more parts per shift, reduced consumable use, and stable, standards-compliant throughput.

Quality and Distortion Control on Thin-Walled Tubes

Because thin-walled tubes are sensitive to heat input and restraint, plasma arc welding (PAW) safeguards quality by concentrating energy into a stable, constricted arc that minimizes the heat-affected zone and limits angular and longitudinal distortion.

PAW’s stable, constricted arc minimizes HAZ, cutting angular and longitudinal distortion in thin-walled tubes.

You’ll see measurable distortion reduction because PAW localizes thermal input, controls bead geometry, and stabilizes the keyhole. The result is high weld quality with minimal rework on tubes up to 10 mm.

- Use keyhole mode to achieve full-penetration single-pass seams with a narrow bead; you’ll reduce transverse shrinkage and ovality while maintaining joint integrity per ISO 3834 quality requirements.

- Optimize energy density (current, travel speed, orifice size) to limit peak interpass temperatures; track HAZ width and straightness tolerances against EN ISO 13920.

- Maintain low spatter through precise gas flow control; it improves surface finish and cuts post-weld finishing, supporting dimensional conformance.

- Validate arc stability with calibrated power sources and flowmeters; monitor voltage/current waveforms and bead profile to meet acceptance criteria in ISO 5817 (Level B/C), ensuring consistent weld quality and distortion reduction.

Maintenance, Training, and Safety Considerations

Although PAW delivers tight control on thin-walled steel tubes, you’ll only sustain that performance through disciplined maintenance, competency-based training, and strict safety compliance.

Implement maintenance practices with defined intervals: inspect torch bodies each shift, clean nozzles and gas passages, and replace constrictor orifices on hours-run or arc-start counts to stabilize arc column geometry. Verify cooling flow, interlocks, and gas purity to extend equipment lifespan and reduce drift.

Prioritize operator training that blends theory and hands-on qualification: set current, plasma/secondary gas flow, and stand-off to maintain arc stability; read keyhole behavior; and execute troubleshooting for double-arcing, porosity, and misalignment. Use checklists and process windows validated by procedure qualification records.

Apply safety protocols aligned to OSHA/EN/ISO: full PPE (eye/face filters for UV, heat-resistant gloves, FR clothing, hearing protection), local exhaust for fumes/ozone, and lockout/tagout for high-voltage supplies.

Monitor noise and gas exposure, verify grounding, and document compliance to minimize electrical and mechanical hazards.

Frequently Asked Questions

What Tube Joint Designs Work Best Specifically for PAW?

Use square-butt and narrow-gap butt joints with precise land (0.5–1.0 mm) and tight root openings (0.1–0.2 mm) for PAW. You’ll maximize joint efficiency in tubular connections, guarantee stable keyhole penetration, and control distortion per AWS standards.

How Does PAW Handle Galvanized or Coated Steel Tubes?

Measure twice, cut once: you pre-strip zinc via coating removal to avoid porosity and zinc fumes. You weld with controlled heat input, fume extraction, and post-weld sealing to restore corrosion resistance per AWS D1.1/D1.3 and ISO 9606.

What Surface Preparation Is Required Before PAW on Tubes?

You must remove coatings to bright metal, perform surface cleaning with solvent per ISO 8504, do rust removal to SSPC-SP11, deburr/degrease, guarantee Ra ≤1.6 µm, maintain 10–20 mm clean zone, dry to <50 mg/m² chloride, verify with white-cloth wipes.

Can PAW Integrate With In-Line NDT for Tube Mills?

Yes—you can marry PAW with in-line NDT; think sentinels guarding a glowing river. You’ll navigate integration challenges, synchronize encoders, calibrate thresholds, validate signals, and document quality assurance per ISO 10893, EN 1291, and SPC-driven defect detection metrics.

How Does PAW Affect Internal Bead Shape for Flow Applications?

It produces a smoother, lower-crown internal bead, improving internal flow by reducing disturbance and ΔP. You control bead formation via current density, keyhole stability, torch oscillation, and backing gas. Validate with profilometry and ISO 15614/ASTM A999 acceptance limits.

Conclusion

You choose PAW because it cuts like a laser and anchors like a rivet. With constricted arcs, 2–4 mm keyholes, and controlled heat input, you hit full fusion, uniform roots, and ISO 3834-level repeatability. You bridge gaps, tame HAZ growth, and keep thin walls straight. Specify Ar–H2 or N2 shielding, dial amperage to WPS, and let automation sing. When every tube must pass NDE and SPC, PAW turns production into clockwork—and waste into rounding error.