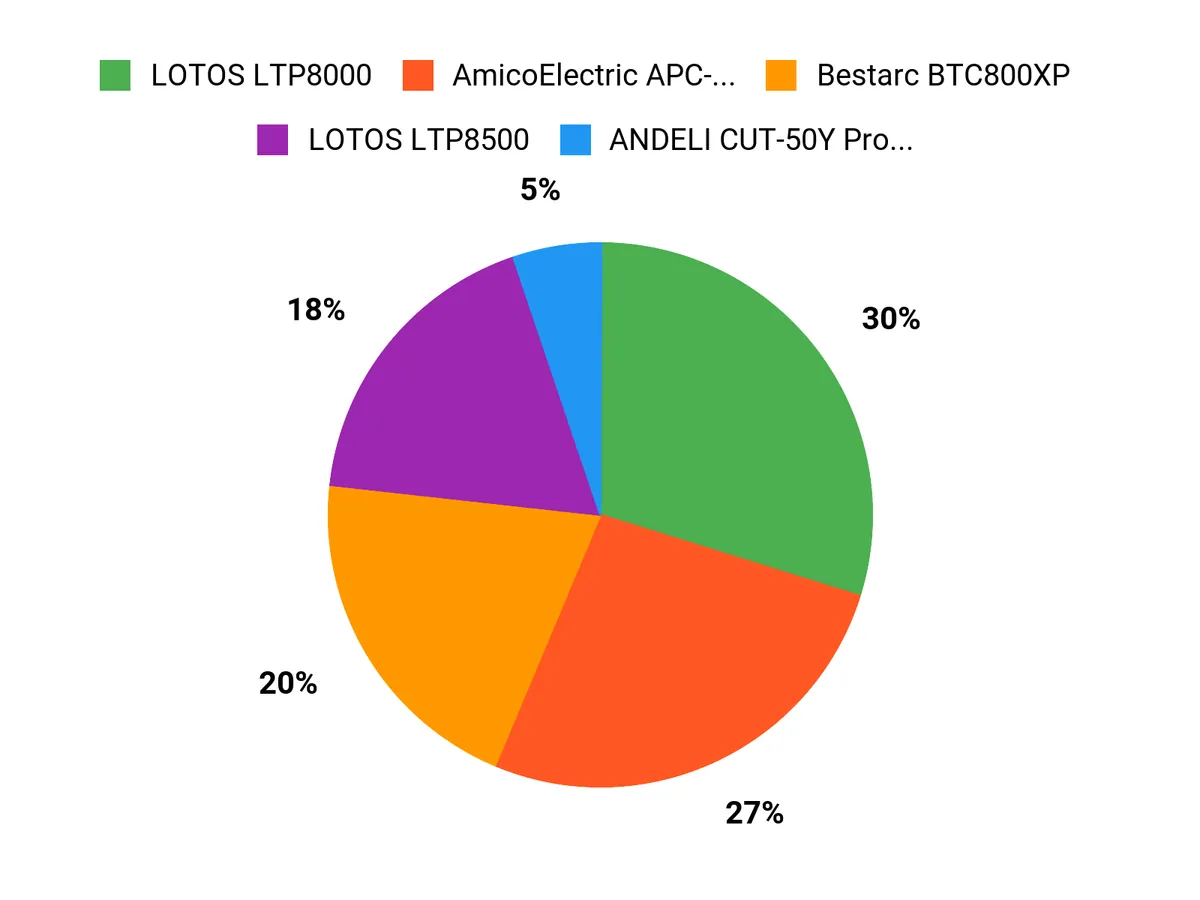

You want a plasma cutter that expands what you can do in your shop without forcing you to buy industrial equipment. In this guide you’ll find five machines that balance cutting power, reliability and affordability so you can tackle thicker metal, speed up projects and avoid constant grinding. Each pick is practical for real-world use — from portable units you can take into the field to heavy hitters that handle 3/4″–1″ work — and all are priced under $1,000 so you get serious capability without the industrial sticker shock.

Top Picks

| Category | Product | Score |

|---|---|---|

| 🚀 Best for Thick Metal | LOTOS LTP8500 | 92/100 |

| 🎯 Best for Fabrication Work | LOTOS LTP8000 | 90/100 |

| ⭐ Best for Long Runs | Amico APC-80HF | 88/100 |

| 🎨 Best for CNC & Hobby | bestarc BTC800XP | 84/100 |

| 🚗 Best for Portability | ANDELI CUT-50Y | 78/100 |

How We Picked These Plasma Cutters

You need a cutter that fits the work you do and the power you have. We focused on: cutting capacity (clean cut vs severance thickness), duty cycle and how the machine performs during longer jobs, pilot-arc or non-touch features for cutting rusted/painted surfaces, air requirements and whether a built-in compressor or external shop air is expected, input voltage and breaker needs, CNC compatibility if you use a table, warranty and manufacturer support, overall build quality and torch ergonomics, and of course value — machines that deliver real capability for under $1,000 so you don’t overpay for features you won’t use.

We weighted real-world performance and reliability highest, then added points for useful features (pilot arc, built-in regulator/filter, dual voltage) and portability.

If you want a workhorse that upgrades your shop without fuss, this LOTOS unit is a solid pick. You can tackle trailer frames, farm gear, structural steel and metal art with confidence thanks to the 85A output and pilot-arc start that handles painted or rusty surfaces.

Setup is straightforward if you have a 220–240V circuit and a reliable air supply, and the drag-cut capability makes tracing templates or freehand lines much less frustrating. For day-to-day repairs and bigger projects alike, it’s the kind of tool that saves time and feels dependable when you reach for it.

What People Say

You’ll notice a lot of buyers praising how quickly it cuts through thicker steel and how reliable the pilot arc is on less-than-perfect surfaces. People also like the torch comfort and the long cable, and many comment that the consumables hold up well for normal use.

A common caveat is that it needs the right power and shop air setup to perform at its best.

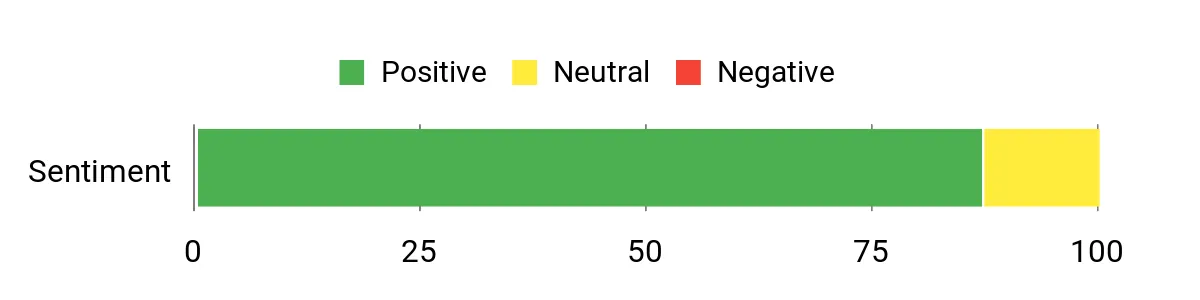

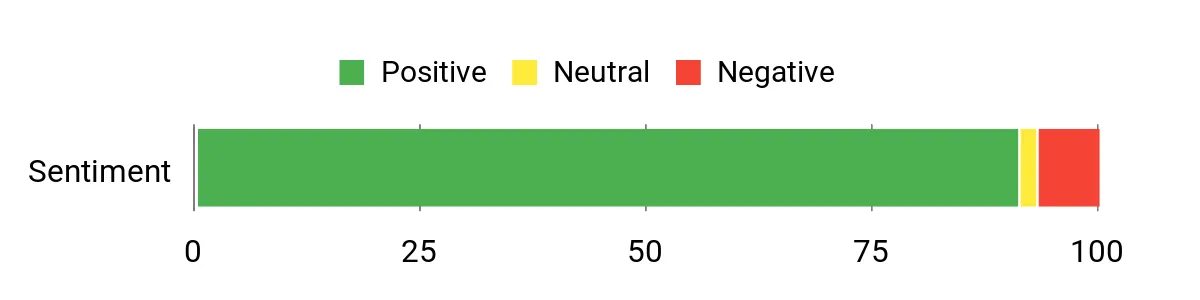

Overall Sentiment: Positive

Long-Term Savings

Because the unit cuts faster and needs fewer re-dos than manual methods, you save on labor time and wear-and-tear on other tools. Consumables are replaceable and seem to be reasonably durable, so over time you’ll likely recoup the upfront effort through increased productivity and fewer headaches.

Return on Investment

You get ROI mostly from time saved on jobs and the ability to take on thicker, more profitable work that a smaller cutter couldn’t handle. For hobbyists and small shops, faster cycle times and less manual grinding translate to real cost recovery.

Situational Benefits

| Situation | How It Helps |

|---|---|

| Repairing farm or trailer equipment | High amperage and solid severance capability make short work of structural steel and worn brackets so you can finish repairs faster. |

| Cutting painted or rusty metal | Pilot-arc start avoids needing clean bare metal, so you can pierce and cut without time-consuming prep. |

| Freehand or template tracing | Drag-cut readiness and comfortable torch handling let you follow patterns smoothly for metal art or custom parts. |

| Shop projects with continuous runs | Customers report good duty performance under heavy use, though reliable shop air and cooling help maintain consistency. |

Ease of Use

| Feature | Ease Level |

|---|---|

| Setup and hookups | Moderate |

| Torch handling | Easy |

| Controls and adjustments | Easy |

| Consumable replacement | Moderate |

Versatility

This cutter handles a broad mix of tasks — from thin sheet work to heavier plate — and works on stainless, mild steel, aluminum and copper, making it useful for both shop projects and field repairs.

Durability

Build quality feels robust and many owners report long service life with normal maintenance. Consumables move through sooner with heavy piercing, but replacements are readily available.

Problem Solving

The pilot-arc start and non-HF blowback design help you cut through painted or expanded metal without false starts or interference, and drag-cut capability solves the hassle of tracing templates by hand.

Speed & Response

Cuts are generally fast — users report noticeably quicker throughput on common tasks and good continuous-use performance when paired with adequate air and power. Expect fast pierces and smooth kerfs when set up correctly.

Key Benefits

- Strong cutting power for thicker plate work

- Pilot-arc start works on painted, rusty, or expanded metal

- Drag-cut ready for tracing and freehand work

- Thoughtful controls and torch ergonomics

- Durable consumables and a long torch lead

Rating: 4.6 (total: 44+)

If you want a no-nonsense plasma cutter that actually pulls its weight in a busy shop, this LOTOS unit is worth a look. You can slice through structural steel, trailer parts, and metal art with confidence thanks to the pilot-arc start and high amperage range.

Setup is straightforward if you have a 220–250 V circuit and a decent air supply — the pre-installed air filter/regulator speeds things up — and the machine’s duty specs mean it can handle longer runs when you mind the cooling. For everyday fixes and bigger projects alike, it’s the kind of tool you reach for when manual cutting would slow you down.

What People Say

Most buyers say it cuts cleanly and consistently, and they like that the pilot arc handles less-than-perfect metal without a lot of prep. Customers often mention the solid cutting power up to around 1″ for clean work and that consumables last reasonably well if you keep the air dry.

A few users note you do need the right breaker and air setup to get the best results, but service and replacement parts are easy to find.

Overall Sentiment: Positive

Long-Term Savings

Because it speeds up cuts and reduces grinding and rework, you save time and lower labor costs. Consumables are replaceable and commonly stocked, and the steady performance means fewer wasted parts and less downtime over the long run.

Return on Investment

You recoup cost through faster job completion and the ability to take work you couldn’t with hand tools alone. For hobbyists and small shops, the reduced prep time and quicker throughput translate into real value.

Situational Benefits

| Situation | How It Helps |

|---|---|

| Repairing farm or trailer equipment | High amperage and good severance capability let you cut brackets and structural pieces quickly so repairs don’t eat your weekend. |

| Cutting painted, rusty, or expanded metal | Pilot-arc start means you don’t have to sand every piece to bare metal before cutting, which saves prep time. |

| Metal art and template tracing | Stable arc and comfortable torch handling make following patterns and freehand cuts more predictable. |

| Long shop runs | Decent duty cycle when matched with proper cooling and compressor setup keeps throughput up during extended jobs. |

Ease of Use

| Feature | Ease Level |

|---|---|

| Setup and hookups | Moderate |

| Torch handling | Easy |

| Controls and adjustments | Easy |

| Consumable replacement | Moderate |

Versatility

This cutter works across a wide range of jobs — from thin sheet metal to heavier plate — and handles stainless, mild steel, aluminum and copper, so it’s useful for home projects, shop work and field repairs.

Durability

The build feels solid and many owners report long service life with routine maintenance; consumables wear with heavy use but are easy to source and replace.

Problem Solving

Pilot arc and the inverter design help you cut through rough or painted surfaces without a lot of finagling, and stable output reduces dross and warping on common tasks — just keep the air dry and the power stable.

Speed & Response

Cuts are quick and pierces happen fast when the machine is set up correctly; users notice noticeably faster throughput versus oxy-fuel or handheld grinding for common jobs.

Key Benefits

- Pilot-arc start that cuts painted or rusty surfaces with minimal prep

- High current range for clean cuts through medium to thicker plate

- Quick setup with pre-installed air filter/regulator

- Robust inverter design for steady arc and precise kerfs

- Widely available consumables and responsive customer support

Rating: 4.6 (total: 200+)

This AmicoElectric unit feels like the kind of cutter you reach for when a job needs to be fast and fuss-free. You get a true pilot-arc start so you can slice through painted or rusty panels without endless prep, an 80% duty cycle for longer runs, and an internal air filter/regulator that saves you one less setup step.

It’s best if you have a 220–250 V circuit and a decent compressor, but once it’s dialed in you’ll appreciate how it shortens both small shop jobs and heavier repair work. If you want a reliable, workhorse-style cutter that’s comfortable for everyday use and rugged enough for tougher projects, this one’s worth considering.

What People Say

Customers commonly praise the cutter’s ability to slice through rough or painted metal without a lot of prep and like that the built-in air filter/regulator simplifies setup. Many users note the steady cutting power and solid duty cycle for longer runs, while a few mention you do need the right 230 V supply and a dry compressor to see the best performance.

Overall Sentiment: Positive

Long-Term Savings

Because it reduces prep and rework, you spend less time grinding and straightening, which saves labor. Durable components and standard consumables mean you can keep it running without frequent, expensive replacements.

Return on Investment

You start to pay it back through faster job completion and the ability to tackle work you couldn’t with hand tools alone. For backyard fabricators and small shops, the time saved on cutting and cleanup turns into real value.

Situational Benefits

| Situation | How It Helps |

|---|---|

| Trailer and farm repairs | High amperage and good severance let you cut brackets and structural parts quickly so repairs don’t drag out. |

| Cutting painted, rusty, or dirty metal | Pilot-arc start reduces prep, so you can cut directly without sanding every piece to bare metal. |

| Shop production runs | 80% duty cycle and automatic voltage compensation keep throughput steady when you’ve got longer batches. |

| On-site field work | Internal air filter and compact form make it easier to set up quickly at jobsites with limited gear. |

Ease of Use

| Feature | Ease Level |

|---|---|

| Setup and hookups | Moderate |

| Torch handling | Easy |

| Controls and adjustments | Easy |

| Consumable replacement | Moderate |

Versatility

Works across stainless, mild steel, aluminum and copper for tasks from thin sheet work to moderate plate, so it’s useful for hobbyists, fabricators and repair techs alike.

Durability

Solid metal construction, fan cooling and multiple protection circuits give it a dependable feel; regular maintenance and dry air will keep it running well over time.

Problem Solving

Pilot arc, inverter stability and automatic voltage compensation help you cut imperfect or fluctuating materials with less fiddling and less dross, as long as the air and power are right.

Speed & Response

Pierces and cuts come fast once the machine and air are set up; movement speed specs and the high current range give noticeably quicker throughput than oxy-fuel for typical shop jobs.

Key Benefits

- Pilot-arc start that handles painted or rusty surfaces with minimal prep

- 80 Amp range with 80% duty cycle for sustained cutting

- Built-in air filter and pressure gauge for quicker setup

- Automatic voltage compensation for unstable power

- Multiple safety protections (over-temp, over-current, overload)

Rating: 4.5 (total: 150+)

You’ll like this if you want a versatile cutter that works for quick shop jobs and occasional heavier projects. It boots with a blow-back pilot arc so you can cut painted or rusty metal without fuss, and the built-in air sensor and LED display make it easy to see what’s happening while you work.

It runs on 110 or 220 V, so you can use it handheld in the garage or hook it to a CNC table when the project calls for precision. For hobbyists and small shops, it’s a practical, no-nonsense choice that covers a lot of ground.

What People Say

You’ll see a lot of people pointing out the cutter’s cutting power and value for the money, especially for hobby and light-shop use. Customers often mention the pilot-arc reliability, the handy LED readout and built-in air regulator, and that it can be integrated with CNC setups — while a minority note quirks around torch outputs or small air leaks.

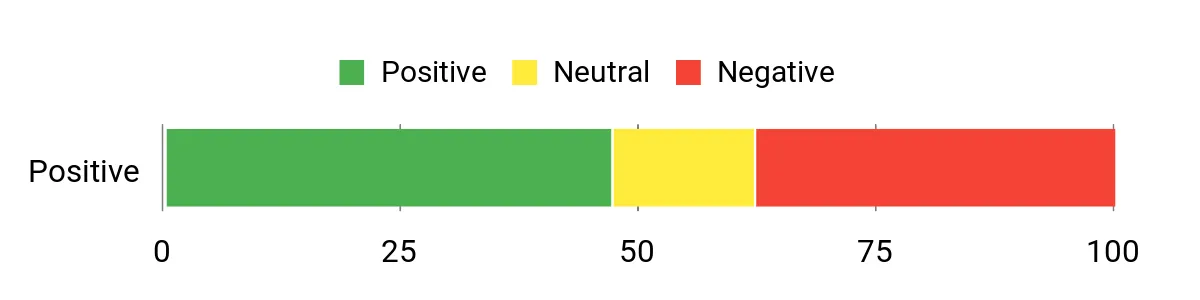

Overall Sentiment: Positive

Long-Term Savings

Because consumables are common and relatively affordable, you won’t be dumping money into parts every few months. The ability to cut cleaner with less prep also reduces time spent grinding and reworking, which adds up over many jobs.

Return on Investment

You recover time and effort quickly: faster cuts, less surface prep, and the option to take on CNC work or thicker material that you couldn’t handle with hand tools. For a backyard fabricator or small shop, that means more completed jobs without upgrading to much pricier pro gear.

Situational Benefits

| Situation | How It Helps |

|---|---|

| Auto body and metal repair | Pilot-arc start lets you cut painted or dirty panels without full sanding prep, so repairs move faster. |

| CNC table work | Non-HF blow-back design and external control ports make it easier to integrate with CNC height controllers and signal setups. |

| Home workshop projects | Dual voltage compatibility means you can use it on a standard 110 V outlet for light work or 220 V for heavier cuts. |

| On-site repairs and field work | Compact, portable build and built-in air handling simplify setup where you don’t want to haul extra gear. |

Ease of Use

| Feature | Ease Level |

|---|---|

| Setup and hookups | Moderate |

| Torch handling | Easy |

| Controls and display | Easy |

| CNC integration | Moderate |

| Consumable replacement | Moderate |

Versatility

Handles mild steel, stainless, aluminum and copper for everything from thin sheet work to moderate plate; dual-voltage and CNC-friendly features make it useful for both casual projects and more precise fabrication.

Durability

Sturdy iron chassis and standard cooling protections give a dependable feel, though torch components and fit-and-finish aren’t as rugged as top-end brands; regular maintenance and dry air will prolong service life.

Problem Solving

Pilot-arc and blow-back tech reduce the need for surface prep and the non-HF design helps avoid interference with CNC electronics; the LED screen and error codes make troubleshooting quicker when something’s off.

Speed & Response

Once air pressure and power are set, ignition and cuts happen quickly; the high current range gives noticeably faster throughput than oxy-fuel for typical shop tasks.

Key Benefits

- Blow-back non-HF pilot arc for cutting painted or rusty metal

- Dual voltage 110/220 V for workshop or home use

- Built-in air sensor, LED display and error codes for easier setup

- CNC-friendly ports and PA/PT, 2T/4T controls

- Good severance with recommended max cut around 1.57″ (40 mm)

Rating: 4.1 (total: 101+)

If you need a portable, all-in-one cutter that you can toss in a truck or park in a small garage, this is worth a look. It runs on 110 V or 220 V, has a built-in air compressor so you don’t have to lug a separate unit, and the low-frequency pilot arc helps you cut painted or slightly rusty metal with less prep. It’s handy for everyday workshop tasks like brackets, repairs and sheet work, and it doubles as a field machine when you’re working off a generator. Keep in mind it shines for portability and convenience more than industrial nonstop duty, but for hobbyists and mobile pros it’s a practical choice.

What People Say

Most customers like the convenience — portability, the built-in compressor and the ready-to-use kit come up a lot. People report clean, straight cuts on thin to moderate steel and appreciate the dual-voltage flexibility for jobs away from the shop.

At the same time, reviewers note some units fail early or that the onboard compressor struggles on thicker stock, so experiences vary.

Overall Sentiment: Mixed

Long-Term Savings

Because the unit uses a pilot-arc style that reduces surface prep and includes a full set of consumables, you save time and the small recurring cost of parts is easier to swallow. The built-in compressor also means you don’t have to buy or maintain a separate air system for light-to-moderate use, though possible reliability repairs can offset savings if you get an unlucky unit.

Return on Investment

You’ll see ROI in saved setup time, less surface prep and the ability to take on mobile jobs you otherwise couldn’t. For a hobbyist or a service tech who values portability, the machine pays back by letting you finish more work without upgrading to a heavier shop-only cutter.

Situational Benefits

| Situation | How It Helps |

|---|---|

| On-the-road repairs | Built-in compressor and 110 V support let you cut off a generator or vehicle power without dragging extra gear. |

| Home garage projects | Dual-voltage setup and included consumables make it simple to handle sheet metal, brackets and small fabrication tasks. |

| Light shop work | Adjustable amperage covers a range of thin-to-moderate plates, keeping small jobs quick and tidy. |

| Rusted or painted material | Non-contact pilot arc starts on imperfect surfaces so you can cut without extensive sanding or cleaning first. |

Ease of Use

| Feature | Ease Level |

|---|---|

| Setup and hookups | Moderate |

| Torch handling | Easy |

| Controls and display | Easy |

| Built-in compressor use | Easy |

| Consumable replacement | Moderate |

Versatility

Useful across mild steel, stainless and aluminum for thin to moderate plate work; dual-voltage and adjustable amps give flexibility for garage projects, field repairs and light shop tasks, though heavy industrial cutting isn’t its primary role.

Durability

The chassis and protections feel solid, and the 2‑year warranty is reassuring, but reviews show mixed reliability with some units failing early. Regular maintenance and using dry, clean air will help extend its life.

Problem Solving

Pilot-arc technology minimizes surface prep and reduces slag, while the internal compressor solves the hassle of finding external shop air—handy when you need a quick setup away from a full workshop. If you need heavy, continuous cutting, pairing with shop air or a stronger unit is a better solution.

Speed & Response

Ignition and cuts are quick for thin and medium sections; thicker material requires slower passes and sometimes external shop air for best results, so throughput varies with job size.

Key Benefits

- Built-in air compressor removes need for external air source

- Dual voltage 110 V / 220 V for workshop or field use

- Low-frequency non-contact pilot arc for cutting painted or rusty surfaces

- Adjustable output (15–50 A) that handles moderate plate thickness

- Comes with torch, consumables and accessories for ready-to-use setup

Rating: 3.2 (total: 10+)

FAQ

How Do I Choose The Right Plasma Cutter For My Workshop?

You should match the cutter to the work you do by thinking about three things at once: the material thickness you cut most often, the machine’s duty cycle (how long it can run at a given amperage without overheating), and the power supply you have in your shop. If you plan to cut frequent 1/2″–1″ jobs, pick a higher‑amp unit and make sure your breaker and outlet can deliver the required 220V or 240V circuit. If you frequently cut rusty or painted metal, choose a model with a pilot arc/non‑touch start because it lets you cut without perfect surface prep. If you want portability or field work, a dual‑voltage unit or a machine with a built‑in compressor may be attractive, but remember built‑in compressors are convenient for light, short jobs while shop air + a dryer is more reliable for heavy use.

Finally, check consumable availability, torch lead length, and whether the unit supports torch height control if you’ll ever use a CNC table.

Do I Need A Special Air Supply Or Electrical Setup?

Yes — clean, dry, stable air and the right electrical feed are the two most common hidden requirements. Most cutters ask for oil‑free, low‑moisture air at a specific pressure and flow; some machines list recommended flow like around 6–7 scfm at about 80–90 psi while higher‑amp continuous cutting can draw more.

If you use shop air, add a good filter/separator and a dryer because even small amounts of moisture destroy nozzles and electrodes quickly. If you rely on a built‑in compressor, understand it’s best for light or mobile jobs and may struggle with continuous heavy cutting. On electricity, confirm the unit’s voltage and breaker sizing before you plug it in; running a high‑amp cutter on undersized wiring will trip breakers and shorten component life. Use proper hose sizes and a receiver tank for steady flow, and follow the manufacturer’s air pressure recommendation for best cut quality.

What Maintenance And Safety Steps Should I Follow To Get Consistent Cuts?

Keep consumables on hand and inspect the nozzle and electrode before each session because worn parts cause poor cuts and wasted time. Use the correct standoff distance and cutting speed — too close or too slow creates dross, too far or too fast causes incomplete cuts.

Protect the machine from moisture and metal dust, purge and drain any separators, and replace filters periodically. For safety, always wear an auto‑darkening helmet, gloves, long sleeves, and a respirator when cutting coated metals or indoors, and ensure good ventilation. Ground the workpiece with a solid clamp and keep cable connections clean and secure.

Let the unit cool if you’re pushing the duty cycle, and avoid continuous full‑amp duty without proper cooling. If you plan to connect to a CNC or THC, check for HF interference and whether the cutter provides the correct voltage output for your height controller. Following these steps keeps cuts consistent and extends the life of your cutter.

What Buyers Prefer

You care most about cutting power and duty cycle — so if youre cutting thicker metal youll gravitate toward the higher‑output LOTOS LTP8500, while the more compact LOTOS LTP8000 or AmicoElectric APC‑80HF win when portability and lower upfront cost matter. You’ll also weigh arc‑start reliability, consumable cost and availability, ease of setup and controls, plus warranty and support to decide which best fits your workshop routine.

Wrapping Up

You now have five practical options that each solve different shop problems. If you regularly cut very thick plate and need raw power, the LOTOS LTP8500 is the standout. If you want a proven workhorse for fabrication and farm projects, the LOTOS LTP8000 balances power and usability. For long production runs or higher duty cycles, the Amico APC-80HF gives you industrial-style features at a mid-range price.

If your focus is CNC cutting or a compact hobby setup, the bestarc BTC800XP offers CNC-friendly outputs and dual-voltage flexibility. And when portability and field convenience matter most, the ANDELI CUT-50Y’s built-in compressor and 110/220 capability let you work away from the shop.

Use these picks to match the cutter to the jobs you actually do, so you spend less time fighting metal and more time getting work done.

| Product | Image | Rating | Cutting Power (Amps) | Max Cutting Thickness (inches) | Weight (Pounds) |

|---|---|---|---|---|---|

| LOTOS LTP8500 85AMP Plasma Cutter |

|

4.6/5 (N reviews) | 85 Amps | 1.0 inches | 40.9 lbs |

| LOTOS LTP8000 80 A Plasma Cutter |

|

4.6/5 (N reviews) | 80 Amps | 1.0 inches | 38 lbs |

| APC-80HF Plasma Cutter |

|

N/A | 80 Amps | 1.2 inches | 32 lbs |

| bestarc Plasma Cutter 80Amp |

|

4.1/5 (101 reviews) | 80 Amps | 0.625 inches | 37.9 lbs |

| ANDELI 50Amp Plasma Cutter |

|

3.2/5 (N reviews) | 50 Amps | 0.875 inches | 40.45 lbs |

This Roundup is reader-supported. When you click through links we may earn a referral commission on qualifying purchases.