What Type of Gas Is Used for Plasma Cutting?

Curious about which gas—compressed air, oxygen, nitrogen, or argon‑hydrogen—delivers the best plasma cuts for your materials and budget?

Curious about which gas—compressed air, oxygen, nitrogen, or argon‑hydrogen—delivers the best plasma cuts for your materials and budget?

Aiming for precision in cutting 1/8 inch aluminum with a plasma cutter? Discover the perfect settings to achieve flawless results every time.

Unlock the secrets of plasma cutter gases—oxygen, nitrogen, air, and more—so you choose perfectly for clean cuts, lower costs, and longer consumable life.

Want to discover how a specialized plasma cutter can transform aluminum cutting precision? Explore the key factors for flawless results now.

Uncover the intriguing mechanics of contact-start plasma cutters and explore their benefits and drawbacks—what makes them tick compared to pilot arc systems?

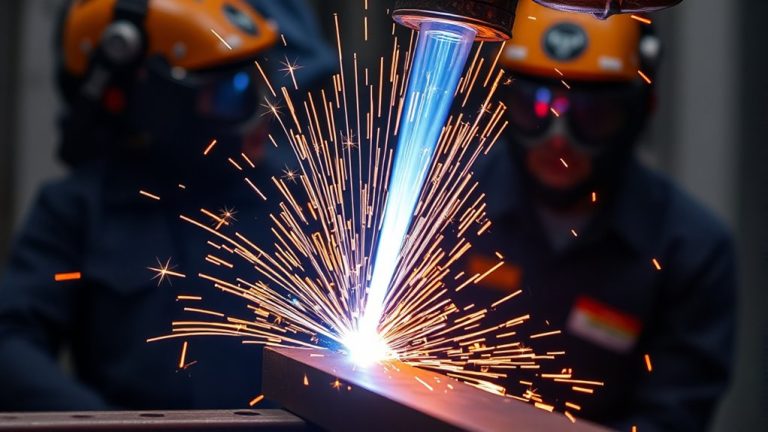

Optimized for precision, the pilot arc plasma cutter efficiently slices through metal without pre-drilling, offering numerous industrial applications—discover its full potential now.

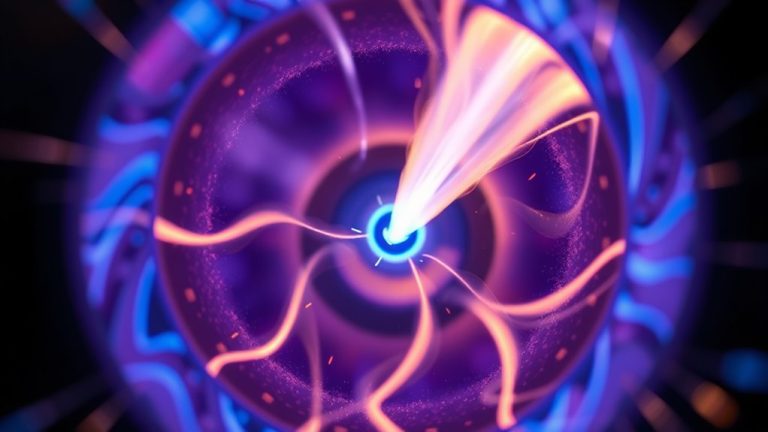

On a journey inside a plasma torch, discover the electrifying dance of arcs and airflow that powers cutting-edge metalwork. Curious for more?

Intrigued by plasma arc cutting's simplicity? Discover how mastering cutting speed, arc current, and gas pressure can revolutionize your metalwork precision and efficiency.

Navigating the world of plasma arc cutting machines reveals both impressive precision and challenging limitations—discover what you need to know before investing.

Updated on 2026-01-19 Welding safely while seeing clearly is one of the fastest ways to improve weld quality and protect your eyes for the long haul. Choosing an auto-darkening welding helmet can get confusing fast—shade range, sensor count, switching speed,…