You want a plasma cutter that balances power, reliability and price so you can finish metal projects faster and cleaner. This guide helps you compare practical features like cutting capacity, pilot-arc vs HF starts, dual-voltage capability, consumable costs and portability so you can choose the right machine for your shop or garage. Focus on what saves you time and money and what actually fits your power and air setup, and you’ll avoid buyer’s remorse.

Top Picks

| Category | Product | Score |

|---|---|---|

| 🏆 Best Overall | LOTOS LTP5000D | 92/100 |

| 💰 Best Value | bestarc BTC500DP | 90/100 |

| 🎯 Best Lightweight | TOOLIOM TL-50C | 78/100 |

| 🚀 Best Performance | YESWELDER CUT-60DS | 88/100 |

| 🔰 Best Budget Starter | S7 CUT50 | 80/100 |

How We Picked These Cutters

You need a cutter that fits your projects and workshop. We evaluated machines on cutting capacity (clean cut and severance ratings), start type (pilot arc vs HF vs blowback), dual-voltage support, duty cycle at usable amperage, consumable availability and cost, build quality and cord/torch ergonomics, plus price and real-world reviewer feedback. We also weighted portability and ease of setup higher for hobbyists and small shops, while placing more emphasis on steady duty cycle and performance for units aimed at pros.

If you’re looking for a portable plasma cutter that handles a lot of everyday garage and light-fabrication tasks, this LOTOS LTP5000D is easy to get along with. You can plug it into 120V for lighter jobs or switch to 240V when you need more cutting muscle, and the non-touch pilot arc makes starting on painted, rusty, or uneven metal much less fiddly.

It’s light enough to carry to a job or move around the shop, sets up quickly with the front-mounted regulator, and will chew through common materials like mild steel, stainless, aluminum and copper for hobby parts, farm repairs, car projects or cutting scrap.

Field Notes: Our research highlighted a couple of key setup details. While the included air gauge isn’t always clearly marked in PSI (requiring some estimation), the “clamp-style” standoff guide is a standout feature—it grips securely and makes cutting hard materials like AR500 steel plate much easier for beginners.

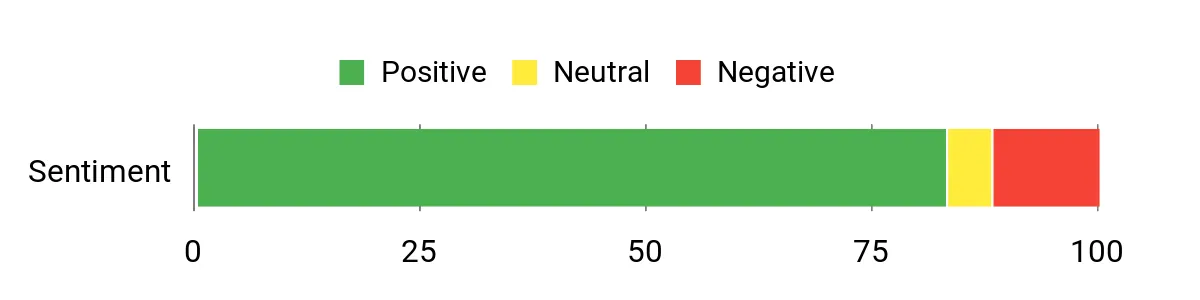

What People Say

Most users appreciate the pilot arc and overall cutting power — people say it starts reliably and makes cleaner cuts than hobby grinders. You’ll also hear that it’s portable and easy to set up, though common gripes are short power/ground leads and the need to buy longer cords or a better ground clamp. A few buyers report receiving defective units, but many praise LOTOS support and the helpfulness of online setup guides and videos.

Overall Sentiment: Positive

Ease Of Use

| Feature | Ease Level |

|---|---|

| Initial Setup | Easy |

| Torch Handling | Easy |

| Controls & Settings | Moderate |

| Consumable Changes | Moderate |

| Mobility/Transport | Easy |

Safety Features

The non-touch pilot arc reduces back-splash and the need to place the torch tip on the work, which lowers torch wear and operator annoyance. The unit includes a regulator and front-mounted pressure control so you can set compressed air safely; still, use proper PPE, an air dryer or moisture trap, and follow electrical safety when switching voltages.

Durability

Build quality generally feels solid for a consumer-oriented plasma cutter; many owners report reliable performance and sturdy cords, though a handful mention early failures or weak factory ground leads. Replacing short cables with heavier, longer ones is a common upgrade to improve real-world durability.

Problem Solving

This machine solves the usual garage headaches: it replaces slow grinders for cutting scrap, saves time on farm or fence repairs, and lets you start cuts on rusted or painted surfaces without scoring the metal. You will still need a decent compressor and proper extension cords to get the best, consistent results.

Key Benefits

- Non-touch pilot arc for cutting painted or rusty metal with less tip wear

- Dual voltage (120/240 V) so you can use household or workshop power

- Compact and relatively lightweight for easy transport around the shop

- Capable clean cuts up to the advertised thicknesses for a 50 A unit

- Front-mounted regulator and simple setup make it quick to start cutting

Rating: 4.4 (total: 3923+)

If you want a portable 50 A plasma cutter that’s friendly to DIYers and small shops, this bestarc BTC500DP is worth a look. You can run it on 110 V for lighter jobs or switch to 220 V when you need more cutting muscle, and the pilot arc means you don’t have to touch the torch to the metal — handy for painted or rusty pieces.

The large LED displays air pressure, current and voltage on the front so you can tune settings quickly, and the built-in air filter/sensor helps keep consumables lasting longer.

Field Notes: This unit punches above its weight class, with tests confirming it works surprisingly well on CNC tables. Pro Tip: The digital air gauge is dynamic; for accurate settings, you must pull the trigger to let air flow before adjusting the pressure knob, otherwise your reading may be off.

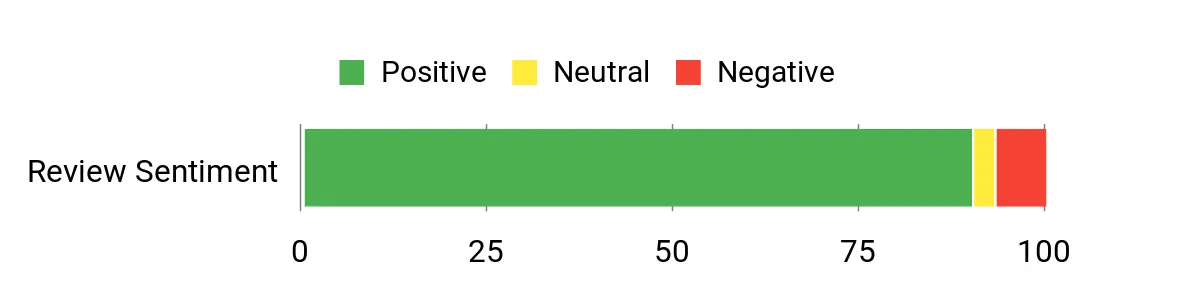

What People Say

Most buyers praise the pilot arc and real cutting performance — people often note clean cuts on common materials and that the machine is surprisingly capable for hobby use. The LED display and air sensor get repeated positive mentions because they make setup and troubleshooting easier.

On the downside, some customers report occasional quality control issues or short factory leads, so you may end up swapping cables or checking fittings when you first unbox it.

Overall Sentiment: Positive

Ease Of Use

| Feature | Ease Level |

|---|---|

| Initial Setup | Easy |

| Torch Handling | Easy |

| Controls & Settings | Moderate |

| Consumable Changes | Moderate |

| Mobility/Transport | Easy |

Safety Features

The pilot arc non‑contact start reduces tip wear and lowers the need to drag the torch across the work. The unit shows air pressure on the front panel and includes a built-in filter and regulator port, so you can set safe compressor pressure before cutting. It also supports adjustable post‑flow to cool the torch after a cut. Still follow standard PPE and compressed‑air safety practices and use an air dryer or moisture trap for consistent results.

Durability

Overall build feels solid for a consumer machine and many owners report reliable day‑to‑day use. A noticeable minority experienced early issues like air leaks or weak connectors; replacing short factory leads or checking fittings on arrival is a common DIY fix that improves long‑term reliability.

Problem Solving

This cutter replaces slow grinders for cutting scrap, makes fence and farm repairs faster, and lets you pierce painted or rusty metal without scoring. It’s not a continuous industrial workhorse, but for weekend fabrication, small shop projects and occasional heavy cuts on 220 V it handles the usual headaches — just remember a decent air compressor and good cables are part of the setup.

Key Benefits

- Pilot arc (non‑touch) makes starting on painted or rusty metal easier

- Dual voltage (110/220 V) for home outlets or shop power

- Front LED display and built-in air sensor for quick setup and monitoring

- Adjustable PA timing and post‑flow to extend consumable life

- Compact and reasonably lightweight for moving around the shop

Rating: 4.5 (total: 2524+)

If you’re after a compact 50 A plasma cutter that handles weekend projects and small‑shop work, this TOOLIOM unit is a sensible option. You can run it on 110 V for lighter jobs or switch to 220 V when you need more cutting power, and the pilot arc lets you start without dragging the tip across painted or rusty metal. The front LCD and built‑in regulator make it simple to see and tweak air pressure, and the plug‑in filter connector speeds up setup with an air compressor.

Field Notes: While the “race car” aesthetic and 13-pound weight are great, the factory quality control can be hit-or-miss. We recommend giving the box a shake to check for loose internal hardware (like heat sink screws) before plugging it in, and upgrading the included air hose immediately to avoid leaks.

What People Say

Buyers frequently compliment the cutting performance and the convenience of the pilot arc — many say it makes clean starts on messy metal much easier. The LCD/regulator combo and the dual‑voltage flexibility get regular praise because they simplify setup, but customers commonly note the factory hose and regulator are weak and that a few units arrive with air leaks or other QC issues. Many users fix or swap small parts and then report solid, reliable use for hobby and light‑duty shop work.

Overall Sentiment: Positive

Ease Of Use

| Feature | Ease Level |

|---|---|

| Initial Setup | Easy |

| Torch Handling | Easy |

| Switching Voltage | Moderate |

| Controls & Settings | Moderate |

| Consumable Changes | Moderate |

Safety Features

The pilot arc non‑contact start reduces tip wear and lowers the need to drag the torch across work. The front panel shows air pressure and the unit has a built‑in regulator and a post‑flow timer to cool the torch after a cut.

Important safety note from users: when you change between 110 V and 220 V, let the machine sit unplugged for a few minutes so internal capacitors discharge before plugging in on the other voltage. Always use proper PPE and a clean, dry air supply.

Durability

For most owners the build holds up well for hobby and occasional shop use, and consumables last a reasonable time if you dial in air and amperage. That said, a noticeable minority report early failures, air leaks or weak factory fittings — replacing the supplied hose or regulator and checking connections when you unbox it is a common precaution that improves reliability.

Problem Solving

This cutter replaces slow grinders for cutting and trimming, handles painted or rusty pieces without dragging the torch, and speeds up repairs around the yard or garage. It’s not designed as a continuous industrial workhorse, but for weekend fabrication, car/trailer fixes and occasional heavier cuts on 220 V it solves the common headaches you’d otherwise wrestle with.

Key Benefits

- Pilot arc (non‑touch) for easier starts on painted or rusty surfaces

- Dual voltage (110/220 V) gives flexibility for home outlets or shop power

- Front LCD shows air pressure for quicker setup and troubleshooting

- Post‑flow and selectable 2T/4T modes help cool the torch and extend consumables

- Plug‑in air filter connector makes hooking up a compressor straightforward

Rating: 4.0 (total: 980+)

If you want a portable cutter that can handle weekend weld prep, shop jobs and heavier cuts when you switch to 220 V, this YesWelder unit is a solid option. You get a non‑touch pilot arc so you don’t have to touch the tip to the metal, and the bright digital display helps you keep an eye on air pressure, current and error codes while you work.

Field Notes: This machine is an “auto-body dream” for cutting sheet metal. However, be aware that while powerful, it can feel hesitant on 110V when cutting thicker 1/4″ plate. For best results, use a 220V circuit. It is also one of the few consumer units confirmed to cut through braided steel cable cleanly.

What People Say

Customers consistently praise the cutting power and clean starts — many note the pilot arc and digital readout as real conveniences. People also like the dual‑voltage flexibility and that it cuts through thicker material on 220 V.

On the flip side, a number of users report quality‑control niggles like loose connectors, occasional air leaks or consumables arriving partially worn, so most recommend checking fittings and consumables right away.

Overall Sentiment: Positive

Ease Of Use

| Feature | Ease Level |

|---|---|

| Initial Setup | Easy |

| Torch Handling | Easy |

| Switching Voltage | Moderate |

| Controls & Settings | Moderate |

| Consumable Changes | Moderate |

Safety Features

The blow‑back non‑HF start and non‑touch pilot arc reduce electrical interference and limit the need to scrape the tip against metal, which also helps consumable life. The unit includes IP21 splash protection, overload and overheat safeguards, a visible air pressure readout and an adjustable post‑flow timer to cool the torch after cutting.

As always, use proper PPE and a stable, dry air source; users also recommend checking connectors before first use to avoid internal air leaks.

Durability

For hobbyists and light shop use the build generally holds up well and consumables last if you tune air and amperage. There are recurring reports of a minority of units arriving with loose parts, unplugged internal connectors or worn consumables, so many owners replace the factory hose/regulator or double‑check internal plugs to improve long‑term reliability.

Problem Solving

This cutter replaces slow hand tools for trimming and prep, slices through rusty or painted sections without dragging the torch, and speeds up bracket, plate and bumper work around the garage. It’s not aimed at nonstop industrial production, but for weekend fabrication, automotive repairs and occasional heavy cuts on 220 V it solves the common headaches of slow, messy metal cutting.

Key Benefits

- Non‑touch pilot arc for easier starts on painted or rusty surfaces

- Dual voltage (110/220 V) so you can use household outlets or shop power

- Clear digital display showing air pressure, current and error codes

- 2T/4T modes and adjustable post‑flow to protect the torch and consumables

- Blow‑back start (non‑high frequency) reduces interference with nearby electronics

Rating: 4.3 (total: 645+)

If you want a compact plasma cutter that can jump between household outlets and shop power, this S7 CUT50 is worth a look. You get dual voltage (110/220 V) plus an IGBT inverter and pilot arc that make starting on painted or slightly rusty metal easier, and the built‑in air regulator/pressure sensor keeps things straightforward when you hook up a compressor.

Field Notes: This unit is ideal for “field” work—it pairs excellently with a small generator and pancake compressor. Safety Note: The power supply wire is relatively thin; we recommend monitoring it for heat during long cutting sessions and ensuring the self-installed air regulator is bolted tight to prevent leaks.

What People Say

People commonly praise the cutting power and the convenience of dual‑voltage operation — a lot of users say it handles typical garage and shop tasks well, especially on 220 V. Reviewers also like the pilot‑arc and the included regulator, which make setup and cutting cleaner. The most frequent gripes are quality‑control issues like loose fittings, short or thin ground leads, occasional air leaks and a minority of units failing early, so many recommend checking connectors and consumables right away.

Overall Sentiment: Positive

Ease Of Use

| Feature | Ease Level |

|---|---|

| Initial Setup | Easy |

| Torch Handling | Easy |

| Switching Voltage | Moderate |

| Controls & Settings | Moderate |

| Consumable Changes | Moderate |

Safety Features

The CUT50 uses a pilot arc which reduces the need to drag the tip across metal and helps protect consumables. It also includes an air pressure sensor and regulator for consistent cutting and basic thermal/overload safeguards to prevent damage during heavy use.

As always, wear proper PPE, keep the air supply dry and steady, and inspect hose fittings and ground connections before first use.

Durability

Many owners report solid performance for hobby and light shop work, and consumables last well when air pressure and amperage are tuned correctly. At the same time, a minority of customers receive units with loose internal or external connectors, short/thin ground leads or early failures, so buyers often replace or upgrade the ground cable and double‑check fittings to improve long‑term reliability.

Problem Solving

This cutter replaces slow, dusty methods like grinders for trimming, panel prep and rusted or painted metal — the pilot arc and adjustable air pressure help cut cleaner with less slag. On 220 V it can handle heavier cuts (manufacturer guidance suggests up to around 20 mm at higher amps), so it’s useful for weld removal, plate cutting and most garage fabrication tasks, although it’s not meant for nonstop industrial production.

Key Benefits

- Dual voltage (110/220 V) for home outlets or shop power

- IGBT inverter and pilot arc for easier starts on painted or rusty metal

- Integrated air pressure sensor and regulator for consistent cutting

- Portable and relatively lightweight for shop or job‑site use

- Includes torch, ground clamp and basic consumables so you can start quickly

Rating: 4.2 (total: 1733+)

If you need a portable plasma cutter that moves from a garage outlet to shop power without drama, this bestarc BTC500DP is built for that. You get true dual voltage (110/220 V), a pilot arc for non‑contact starts on painted or rusty metal, and a big LED display that shows air pressure, current and error codes so you can see what’s happening at a glance. It includes an internal air filter, quick‑connect fitting and adjustable post‑flow and pilot‑arc timing, which makes it handy for everything from trimming brackets and automotive work to metal art and light fabrication. On 220 V it handles heavier plate cuts, while 110 V is convenient for simple weekend projects — a solid option if you want a compact, feature‑rich unit for hobby and small‑shop use.

What People Say

Customers frequently praise the cutting power and the convenience of dual‑voltage operation — many say it makes quick work of typical garage and shop tasks. People also like the pilot arc and the LED air‑pressure readout because those features simplify setup and improve cut consistency. The main complaints are occasional quality control or air‑leak issues and uneven customer service, so many users advise checking fittings and consumables right out of the box.

Overall Sentiment: Positive

Ease Of Use

| Feature | Ease Level |

|---|---|

| Initial Setup | Easy |

| Torch Handling | Easy |

| Switching Voltage | Moderate |

| Controls & Settings | Moderate |

| Consumable Changes | Moderate |

Safety Features

The BTC500DP uses a pilot arc to prevent dragging the tip across the work, which helps protect consumables and reduce sparks. You also get an air pressure sensor and visible readout to help keep cutting pressure consistent, plus basic thermal/overload protection.

It still needs standard PPE and a dry, steady air supply — check hoses and fittings before you start.

Durability

Many owners report reliable performance for hobby and light‑shop work and reasonable consumable life when air pressure and amperage are properly tuned. A minority see early issues like loose fittings, internal air leaks or short ground leads, so users commonly verify connections and sometimes replace or upgrade cables to improve long‑term reliability.

Problem Solving

This unit replaces slow, dusty tools like grinders for trimming, panel prep and cutting painted or rusty metal thanks to the pilot arc. It’s perfectly suited for automotive repair, metal art, weld removal and general fabrication; on 220 V it can handle thicker plate.

It’s not designed for nonstop industrial production, but it’s a strong choice for most garage and small‑shop jobs.

Key Benefits

- Dual voltage (110/220 V) for household outlets or workshop power

- Pilot arc for clean non‑contact starts on painted or rusty metal

- Large LED display with air pressure readout and error codes

- Built‑in air filter and quick‑connect fitting for faster setup

- Adjustable post‑flow and pilot‑arc timing to extend consumables life

Rating: 4.5 (total: 2463+)

FAQ

How Do I Choose The Best Budget Plasma Cutter For My Needs?

When you shop for a budget plasma cutter, focus on real-world features rather than marketing claims. Prioritize Dual Voltage if you want portability between a typical garage 120/110V outlet and a dedicated 240/220V circuit, and look for a clear duty cycle rating so you know how long you can run at higher amps.

Pilot arc or true non-touch arc is a big plus because it saves consumables and lets you cut rusted or painted metal without dragging the tip. Check what consumables are compatible with the torch and how easy they are to source, and read about build quality and customer support because QC varies across budget brands.

Finally, consider practical things like torch lead and ground clamp length, weight for portability, and whether the unit uses high-frequency starts (which can interfere with electronics) versus low-frequency pilot arc systems.

What Power And Air Setup Do I Need For Reliable Cutting?

You want a stable power source and clean, dry air to get predictable cuts. If you plan to cut heavily or run long at full output, use a dedicated 220/240V circuit — trying to push high amps from a shared 110/120V outlet often causes voltage drop or tripped breakers.

For air, aim for consistent pressure in the general 60–85 psi range and adequate CFM for your chosen amperage; small pancake compressors can handle light hobby work but larger cuts usually need a larger tank or higher‑CFM unit. Add a good regulator, moisture trap, and an inline dryer or oil/water separator so your torch sees clean, dry air; wet or dirty air shortens consumable life and causes erratic arcs.

How Do I Get Cleaner Cuts And Make Consumables Last Longer?

Technique and maintenance matter as much as the machine. Keep a consistent correct standoff between the nozzle and the work, control your travel speed to avoid slag buildup, and clean or wire‑brush the ground connection so it stays cool and conductive. Use the pilot arc feature to start without touching the metal, avoid slamming the torch down (the ceramic shield and nozzle are fragile), and replace worn electrodes and nozzles promptly — inexpensive consumables are normal and will dramatically affect cut quality.

Finally, mark or note the best air pressure and amperage settings for common thicknesses so you can repeat clean cuts and reduce trial‑and‑error waste.

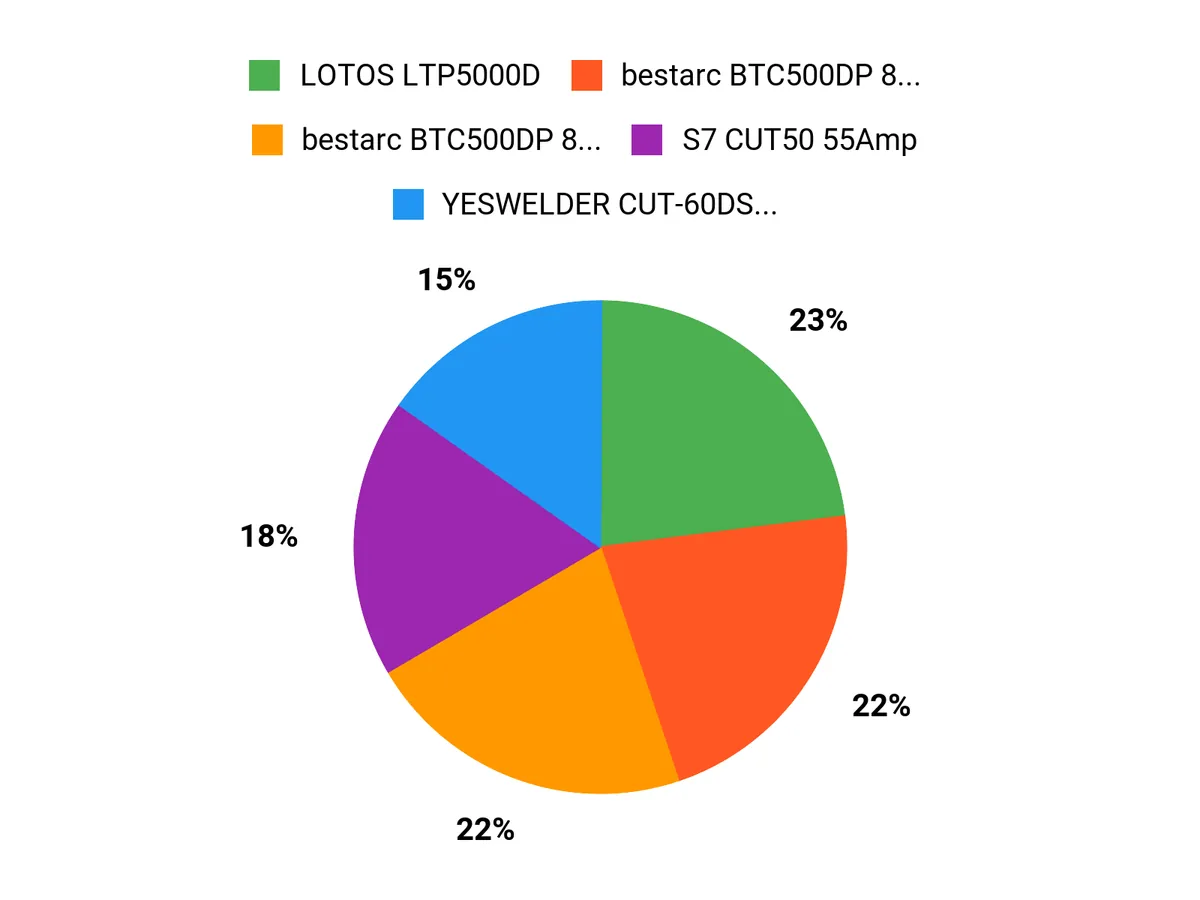

What Buyers Prefer

When choosing between the LOTOS LTP5000D, bestarc BTC500DP 8GEN, and TOOLIOM 50A HF, you typically prioritize cutting performance (how thick and how cleanly it cuts) and duty cycle so the machine can handle the work you plan. You also weigh start type (pilot arc/HF) and reliability, portability and ease of setup, consumable costs, and warranty/support to get the best balance of performance and long‑term value for your budget.

Wrapping Up

You now have a shortlist of dependable, budget-friendly plasma cutters and what makes each one stand out. LOTOS LTP5000D earns the top spot for overall balance of power, pilot arc and real-world reliability.

If you want maximum bang for your buck, bestarc BTC500DP is the best value choice. For portability choose the TOOLIOM TL-50C, while the YESWELDER CUT-60DS is the pick if raw cutting performance matters most. If you are buying your first unit on a tight budget, the S7 CUT50 gives the essentials without a large upfront cost.

Use the criteria in this guide to match a model to your power availability, compressor capacity and the thicknesses you cut most often, and you’ll avoid mismatched gear and extra expense.

| Product | Image | Rating | Cutting Power | Cutting Thickness | Weight |

|---|---|---|---|---|---|

| LOTOS LTP5000D Plasma Cutter |

|

4.4/5 (N reviews) | 50A, Dual Voltage 110V/220V | 1/2″ Clean Cut, 3/4″ Severance Cut | 19.4 lbs |

| bestarc Plasma Cutter |

|

4.5/5 (2,524 reviews) | 50A, Dual Voltage 110V/220V | 1/2″ Clean Cut, 3/4″ Max Cut | 16.76 lbs |

| TOOLIOM 50A Plasma Cutter |

|

4.0/5 (980 reviews) | 50A, Dual Voltage 110V/220V | 1/2″ Clean Cut | 19.71 lbs |

| YESWELDER CUT-60DS Plasma Cutter |

|

4.3/5 (645 reviews) | 60A, Dual Voltage 110V/220V | 1″ Clean Cut | 21.4 lbs |

| S7 CUT50 55Amp Plasma Cutter |

|

4.2/5 (N reviews) | 55A, Dual Voltage 110V/220V | 1/4″ Steel | 18.8 lbs |

This Roundup is reader-supported. When you click through links we may earn a referral commission on qualifying purchases.