If you’re evaluating heavy-duty plasma cutters, focus on power output, true duty cycle, and verified thickness capacity. Machines like the Hypertherm MAX200/HD200MAX deliver stable arcs at high amperage, cut up to 2 in steel, and run at a 100% duty cycle for continuous production. Match amperage to material and gas to balance speed and edge quality. Get these parameters wrong and you’ll bottleneck throughput—get them right and you’ll unleash capacity you didn’t know you had.

Understanding Power Output and Cutting Performance

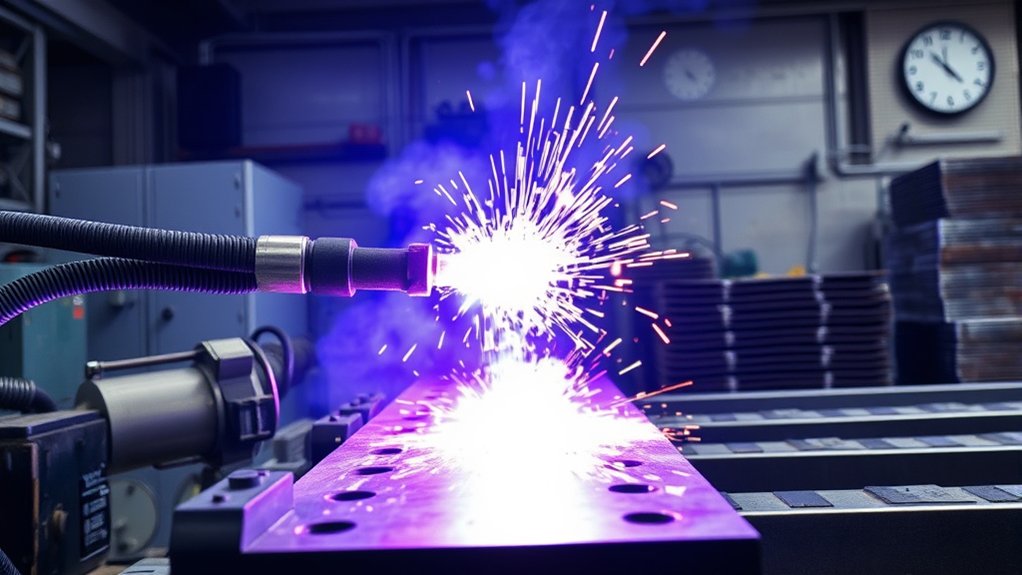

Why does amperage matter so much in a heavy-duty plasma cutter? Because it directly sets arc energy, penetration capacity, and travel speed—the core performance metrics that define cutting technology outcomes.

Higher current increases jet enthalpy and current density, stabilizing the arc through thicker cross-sections and enabling faster, cleaner kerfs with less dross.

You can see it in the data: a Hypertherm MAX200 at 200 amps severs 2-inch steel at 6 IPM. Step down to a Python 125 at 125 amps and you’ll still cut up to 1-3/4 inches, but at 10 IPM on thinner stock to maintain cut quality.

On lighter gauges, power translates to speed: a Powermax105 SYNC shows 220 IPM on 1/4-inch material at 94 amps, demonstrating how optimized output and gas dynamics drive throughput.

Match amperage to material, thickness, and desired edge quality.

With industrial-grade systems, high power and advanced torch design deliver consistent results across mild steel, stainless, and aluminum.

Duty Cycle Explained: What 100% Really Means in Production

Although often treated as a spec-sheet checkbox, a 100% duty cycle is a production guarantee: the cutter can run continuously at its rated output without thermal shutdown. You get predictable throughput, no forced cooldowns, and stable cut quality during extended shifts. The duty cycle implications are straightforward: continuous operation transforms scheduling, consumable planning, and labor efficiency.

Consider data-backed examples. Hypertherm Powermax105 SYNC sustains a 100% duty cycle at 94A, so you can hold high travel speeds without pausing. For heavier sections, a MAX200 at 200A cuts 2 in plate at about 6 IPM, illustrating how uninterrupted amperage translates into linear feet per hour and reliable takt times.

| Metric | Production Impact |

|---|---|

| 100% duty cycle | Eliminates thermal delays |

| 94A at 100% (Powermax105 SYNC) | Sustained high-performance |

| 200A, 2 in at ~6 IPM (MAX200) | Predictable throughput |

When you routinely run long nests or thick parts, selecting a platform with a true 100% rating guarantees uptime, consistent kerf, and fewer schedule risks.

Thickness Capacity by Material: Mild Steel, Stainless, and Aluminum

Start by matching amperage and torch technology to the thickness and alloy you cut most. For mild steel, the HD200MAX offers a 25 mm production pierce, 32 mm maximum cutting capacity, and 60 mm severance capacity.

Stainless steel tracks similarly for pierce at 25 mm, with maximum cutting up to 54 mm. For aluminum cutting, you’ll hold a 25 mm production pierce and reach 54 mm maximum thickness.

If you regularly process plate beyond 1 inch, the PowerPlasma 102i handles 1 1/4 in routinely, maintains clean cuts to 1 1/2 in, and reaches 1 5/8 in severance. When you need extreme thickness, the Hypertherm MAX200 delivers up to 2 in cutting at 6 IPM, suitable for low-speed, high-power passes.

Use production pierce limits to size your job mix; reserve max cut and severance capacity for occasional work.

Align consumables and torch choice to material type—mild steel, stainless steel, or aluminum—to maintain consistent edge integrity.

Speed, Quality, and Gas Choices for Heavy-Duty Cuts

You’ll balance speed and edge quality by matching amperage to thickness: a MAX200 can sever 2 in at 6 IPM (200A) while a Python 125 runs 1-3/4 in at 10 IPM (125A).

For stainless and aluminum, you’ll select an argon‑hydrogen mix to tighten the arc, reduce dross, and extend consumable life.

Use systems with optimized gas parameters and 100% duty cycle to sustain high throughput without compromising cut accuracy.

Balancing Speed and Quality

When cutting thick stock, balance speed and quality by pairing machine capability, gas selection, and consumable strategy to the material. Use speed optimization to protect cut quality: for 2-inch steel, heavy-duty systems like the Hypertherm MAX200 deliver about 6 IPM, but slowing slightly often improves edge fidelity and reduces dross.

Maintain a 100% duty cycle (e.g., HD200MAX) to keep parameters stable during long runs and avoid thermal drift that degrades accuracy. Choose long-life consumables and dial gas flows to spec to extend nozzle life and maintain kerf consistency.

- Set baseline speed from charts, then reduce 5–15% on thick sections to improve edge squareness

- Use argon-hydrogen on stainless and aluminum for tighter arcs and smoother faces

- Monitor arc voltage; adjust to maintain torch-to-work distance

- Track consumable wear; replace at defined pits/ohmic thresholds

Optimal Plasma Gas Selection

With speed and edge fidelity set, the next lever is plasma gas selection, which dictates arc energy density, penetration, and consumable life. Match gas chemistry to the alloy. For stainless and aluminum, use argon-hydrogen at 65/35 (Ar/H2) to maximize arc constriction, reduce dross, and deliver cleaner kerfs.

On mild steel, oxygen boosts cutting speed and penetration versus air, but you may trade some surface quality and nitriding risk.

Prioritize gas purity to stabilize the arc, minimize double-arcing, and extend nozzle and electrode life in high-duty cycles.

Calibrate flow rate to thickness: increase flow on thicker sections to maintain jet momentum, evacuate molten material, and prevent reattachment.

Validate by coupon tests: tune current, stand-off, and swirl with gas parameters to lock in speed and consistency.

Selecting the Right Machine for Your Application

Though project requirements vary, anchor your selection on quantified performance: match amperage to thickness and speed, duty cycle to production cadence, and material capacity to your mix.

Use data to drive machine selection and confirm application suitability before purchase. For thick-section work, a 200A class unit (e.g., Hypertherm MAX200) sustains 2-inch cuts near 6 IPM.

Use data to guide plasma selection; 200A units can cut 2-inch plate at roughly 6 IPM.

If your shop runs nonstop, prioritize a 100% duty cycle platform (e.g., Python 125) to avoid thermal pauses. Validate material capacity against your part mix: an HD200MAX handles mild steel to 32 mm and stainless to 54 mm, covering most heavy fab needs.

Favor systems with optimized gas parameters and long-life consumables to stabilize kerf geometry and reduce cost per meter. Guarantee compatibility with air or oxygen for finish and productivity targets.

- Align amperage to minimum IPM on your thickest plate.

- Specify duty cycle to match shift length and takt time.

- Verify material capacity by alloy and thickness.

- Prioritize gas flexibility and consumable life for throughput.

Safety, Consumables, and Maintenance Best Practices

You’ll set the baseline for performance and safety with correct PPE and machine setup: heat-resistant gloves, safety glasses, reinforced boots, dry air via a water trap or dryer, and amperage/duty cycle matched to material thickness.

You’ll select and replace consumables—electrodes and nozzles—based on cut quality indicators like kerf width, arc stability, and edge dross, swapping parts before wear triggers taper or double-arcing.

You’ll implement a preventive schedule that includes air-filter cleaning, moisture control checks, and inspection of cables and connectors to reduce failures and extend tool life.

Essential PPE and Setup

Even before striking an arc, establish a safety-first setup that pairs the right PPE with a controlled work environment.

Define clear PPE requirements: wear heavy-duty gloves, safety glasses, reinforced boots, and heat‑resistant clothing to mitigate cuts, burns, and electrical risk.

Build a disciplined workspace setup with grounded tables, dry floors, and unobstructed egress.

Maintain clean, dry air to the torch—use an in-line air filter to strip oil, water, and particulates that degrade cut quality and accelerate wear.

Respect duty cycle limits; a 100% rating enables continuous operation without thermal trips.

- Verify ventilation and active fume extraction at the torch plume.

- Inspect torch leads, ground clamp, and connections before each shift.

- Check and replace electrodes and nozzles at measured erosion limits.

- Log runtime, duty cycle, and filter changes for traceable maintenance.

Consumable Selection Tips

With PPE, ventilation, and duty cycle under control, focus on the parts that shape the arc: consumables. Match electrode types and nozzle sizes to material and amperage.

For thin gauge sheet, choose FineCut to minimize kerf width and heat input; for thicker plate, step up orifices and current to maintain arc density. Set torch standoff per the consumable data sheet to stabilize the arc column and reduce double-arcing.

Inspect tips and electrodes frequently; replace when pit depth or orifice wear exceeds spec to prevent arc wander, dross, and higher operating cost.

Use an In-Line Air Filter Kit to strip moisture and oil, extending consumable life and preserving edge quality. Verify gas flow rates and purge lines to keep swirl stabilization consistent.

Preventive Maintenance Schedule

One disciplined preventive maintenance schedule keeps a heavy‑duty plasma cutter safe, consistent, and cost‑effective.

Use a data-driven maintenance checklist to standardize tasks and intervals. Inspect consumables daily—electrodes, nozzles, and swirl rings—to hold arc stability and edge quality; replace at wear limits to protect the torch and power supply.

Clean the air filter and water trap routinely; moisture and particulates degrade cut quality and accelerate erosion. Verify electrical connections, leads, and gas hoses for tightness, insulation integrity, and leaks; correct issues immediately to eliminate safety hazards.

Follow the manufacturer’s lubrication and wear guidelines to maintain duty-cycle reliability.

- Daily pre-operation inspection with functional checks

- Consumable evaluation and replacement at defined thresholds

- Air filtration and water trap cleaning schedule

- Periodic torque, hose, and cable integrity verification

Frequently Asked Questions

How Does the HD200MAX Handle CNC Table Integration and Torch Height Control?

It integrates via standard CNC compatibility signals—Start, Arc OK, and divided arc voltage. You connect your controller, enable Torch automation, and the HD200MAX outputs stable arc voltage for closed-loop THC, ensuring consistent standoff, pierce sequencing, and cut quality.

What Are the Electrical Power Requirements and Plug Configurations for Installation?

You need 480V three‑phase, 60Hz, 50A service; follow manufacturer power specifications. Use a 4‑wire L16‑50P or hardwire per local code. Ascertain dedicated breaker, proper grounding, neutral isolation, and verify installation requirements: voltage tolerance ±10%, 6‑AWG copper conductors.

Is There Remote Monitoring, Diagnostics, or Iot Connectivity for Maintenance Tracking?

Yes. You get remote diagnostics and IoT connectivity for maintenance tracking via Ethernet/Wi‑Fi. Monitor arc hours, consumable life, error codes, and firmware status. Enable alerts, export logs via API/MQTT, and integrate with CMMS dashboards for predictive service scheduling.

How Loud Is the Machine During Operation and Are Noise-Reduction Options Available?

You’ll hear 85–105 dB at the torch, depending on amperage, air pressure, and material. You can reduce noise levels with acoustic enclosures, sound insulation panels, water tables, downdraft extraction, quieter compressors, and PPE-rated earmuffs (NRR 25–33).

What Warranty Coverage and Service Response Times Are Included With Purchase?

You get a 3-year warranty duration on parts and labor, with consumables excluded. Service availability includes 24/7 phone support, 48-hour on-site response in metro areas, and advance-exchange components shipped next business day for critical failures.

Conclusion

You’ve seen how power, duty cycle, and thickness capacity drive real productivity. A 200-amp heavy-duty system can pierce and cut up to 2 inches and sustain a 100% duty cycle—meaning you can run continuously without thermal pauses. Consider this: moving from a 60% to 100% duty cycle can reclaim roughly 2.4 hours in a 6-hour cutting shift. Choose the right gases, match consumables to material, and you’ll maximize speed, edge quality, and consumable life.