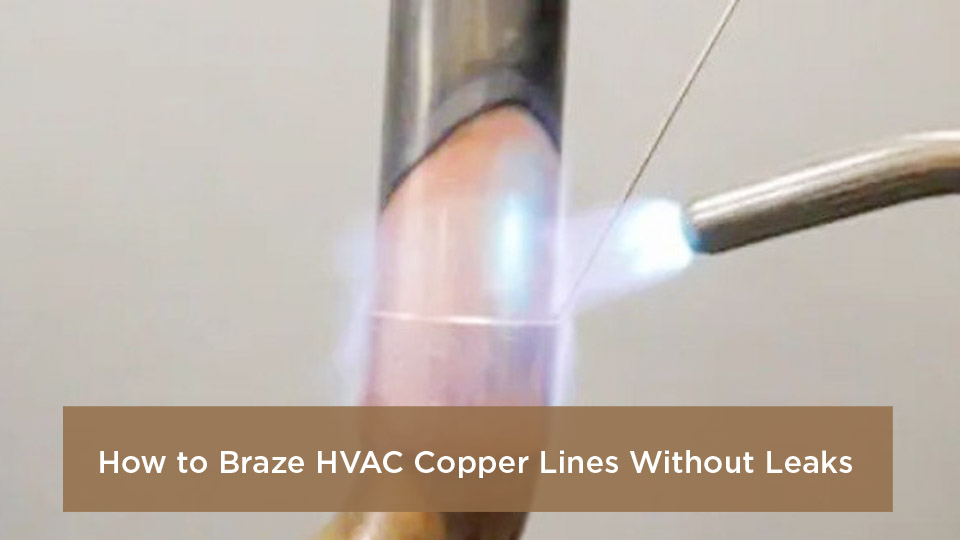

Brazing HVAC copper lines can feel high-pressure—one tiny leak costs time, refrigerant, and money. This guide focuses on heat balance, joint prep, nitrogen purging, and filler techniques that consistently produce clean, leak-free joints in real-world installs.

Clean and prep the joint, dry-fit with a slight capillary gap, and flow low-rate nitrogen through the tubing. Heat the fitting first, then the tube, and feed a 15% silver phos-copper rod as the alloy wets and draws in. Allow to air-cool, wipe residue, then pressure- and vacuum-test.

Key takeaways

- Prep is 80%: clean to bright metal, deburr, dry-fit for capillary action.

- Flow nitrogen at a whisper (~3–5 SCFH after purge) to prevent internal scale.

- Heat the fitting first; let capillary action draw the alloy through.

- Verify with soap bubbles, then a deep vacuum hold (≈500 microns).

What Is Brazing for HVAC Copper Lines?

Brazing uses capillary action to bond copper tubing and fittings with a silver-alloy filler at elevated temperatures (about 1,100–1,500°F). The base metal doesn’t melt; only the filler flows, creating a strong, vibration-resistant joint suited to refrigerant service.

In HVAC work, refrigerant lines see pressure swings and vibration. Brazing produces stronger, more durable joints than soft soldering—helping prevent leaks that can vent refrigerant or starve systems of charge.

Brazing vs Soldering: Which One for Your Project?

Soldering melts filler below 840°F and is fine for low-stress tasks (e.g., drains, sensors) where you want less heat. Brazing, performed above 840°F, creates higher-strength, vibration-resistant joints for refrigerant lines and service valves. When in doubt on refrigerant circuits, choose brazing.

| Aspect | Soldering | Brazing |

|---|---|---|

| Temp range | Below 840°F | About 1,100–1,500°F |

| Relative strength | Lower (for low-pressure tasks) | Higher (for refrigerant lines) |

| Best for | Drains, sensors, thin walls | Refrigerant lines, service valves |

| Pros | Faster; gentler heat | Stronger; vibration-resistant |

| Cons | Weaker under load | Higher heat; requires nitrogen purge |

| Filler | Tin-based alloys | 15% silver phos-copper (BCuP-5) |

Bottom line: On anything carrying refrigerant, braze it. It’s the pro move that helps keep leaks at bay and maintains system integrity.

Essential Tools and Materials You’ll Need

A reliable torch, correct filler, and a nitrogen setup make the job safer and smoother—whether you’re in a shop bay or a tight attic.

For portability, MAPP-style torches work on light tubing; step up to oxy-acetylene for heavier sections. For copper-to-copper, choose a phosphorus-bearing silver filler (e.g., 15% Ag BCuP-5) that self-fluxes on copper. Flux is needed for brass/steel transitions—clean residues after.

| Tool/Material | Why it matters | Pick/Tip |

|---|---|---|

| Torch (MAPP or Oxy-Acetylene) | Delivers even heat for capillary flow | Use a swirl tip; practice heat control |

| Brazing rods (15% Ag) | Wets gaps; seals tight | Common size: 1/16″ cut to manageable lengths |

| Nitrogen regulator & hose | Prevents internal oxidation/scale | Purge, then braze at ~3–5 SCFH |

| Emery cloth & pipe brush | Bright metal for sound bonds | ~180-grit; clean to a shine |

| Flux & brush | Needed for brass/steel joints | Use HVAC-appropriate flux; remove residue |

| Pipe cutter & reamer | Square cuts; removes burrs | Deburr ID to avoid leaks |

| Safety gear | Protects from burns/fumes | Leather gloves; shade 5 goggles |

Budget builds can come together under $200 if you already have PPE. Keep a fire blanket and extinguisher within reach.

Preparing Your Copper Lines Like a Pro

Prep is most of the battle. Cut square with a tube cutter, ream burrs, and clean to bright metal—inside and out. Dry-fit with a light, uniform gap for capillary action (around a few thousandths of an inch). Map suction vs. liquid lines and recover refrigerant on existing systems (EPA 608 compliance in the U.S.).

Safety Gear and Best Practices Before You Start

Wear FR clothing, leather gloves, and proper eye protection (e.g., shade 5 for oxy-acetylene). Ensure ventilation—flux fumes and torch gases can build quickly in tight spaces. Protect nearby components with damp rags, and work with a buddy on large runs.

Note: Handling refrigerant requires EPA Section 608 certification in the U.S.; plan recovery/evacuation accordingly.

Step-by-Step: How to Braze HVAC Lines Without Leaks

Set up your station: Secure the joint. Connect nitrogen downstream; purge to displace air, then reduce to a low “whisper” flow (~3–5 SCFH).

Dry-fit and mark: Twist-fit and mark insertion depth so you can confirm full seating during heat.

Flux if required: Skip for copper-to-copper with phos-bearing rods; use flux for brass/steel transitions (apply thinly).

Light and preheat: Use a neutral flame. Heat the fitting first; sweep around the base. Watch visual cues (flux activity, metal color) rather than chasing the rod.

Feed the rod: Touch the alloy to the hottest edge and let capillary action draw it through. For tees, start opposite the branch and work around.

Maintain purge: Keep nitrogen flowing during the braze to prevent internal scale. Aim for a smooth, continuous fillet—shiny, not dull.

Controlled cool: Kill the flame and let it air-cool. Wipe residues warm; leave nitrogen on until the joint returns to ambient.

Torch Tips and Flame Control

Match flame size to tube OD; keep the inner cone off the alloy. Angle the flame ~45°, orbit smoothly, and avoid overheating. A reducing (slightly fuel-rich) flame can limit oxidation; practice on scrap to lock in timing and motion.

Common Mistakes I Learned the Hard Way (and How to Fix Them)

- Dirty prep: Filler won’t wet; always clean to bright metal.

- Overheating: Moves grain structure, thins walls; keep the torch moving and heat the fitting first.

- No nitrogen: Internal “black scale” can foul components; flow low-rate nitrogen while brazing.

- Too much flux: Can pit or leave residues—apply sparingly and remove after.

- No vibration relief: Add loops/isolators to avoid fatigue.

- Forced cooling: Don’t quench; allow air cooling to reduce thermal shock.

Testing Your Joints: Ensuring No Leaks Get By

Soap-bubble test: Pressurize with nitrogen (e.g., ~150 psi) and check all joints.

Deep vacuum: Pull to about 500 microns and hold; rising pressure suggests moisture/leak. For systems, a triple-evac method is common practice.

Longer holds/electronics: Higher-pressure nitrogen holds, electronic sniffers, or ultrasonic checks add confidence on critical jobs.

References

FAQs

- Can Beginners Braze HVAC Copper Lines Safely?

- Absolutely—with practice on scrap, good ventilation, and proper PPE. Keep nitrogen flowing at a low rate to prevent internal oxidation. Don’t handle refrigerant without the appropriate EPA certification in the U.S.

- What’s the Best Brazing Rod for Copper Refrigerant Lines?

- A 15% silver phos-copper rod (often labeled BCuP-5) is a versatile, self-fluxing choice for copper-to-copper joints.

- Do I Need Flux Every Time I Braze HVAC Lines?

- No—phos-bearing rods self-flux on copper. Use flux for brass/steel connections and remove residues afterward.

- How Can I Tell If My Brazed Joint Is Leak-Free?

- Look for a smooth, shiny fillet. Pressure test with nitrogen and soap solution, then perform a deep vacuum hold (≈500 microns). Electronic or ultrasonic detectors can confirm.

- Why Braze Instead of Solder for AC Lines?

- Brazed joints handle higher pressures and vibration better than soft-soldered joints, making them the standard for refrigerant circuits.

Related articles

U.S. compliance note: Technicians who handle refrigerants must be certified under EPA Section 608.