First time I tried welding outside with my gas MIG welder. The wind kept blowing away the shielding gas, my arc control went out the window, and the welds were full of porosity. That’s when I realized I needed to learn how to convert a gas MIG welder to gasless. A lot of welders hit this same wall—especially when working on car panels, farm equipment, or outdoor repairs where dragging a gas bottle isn’t practical.

Switching over to flux-core wire solves the problem, but it also raises questions about settings, metal thickness, joint prep, and how it stacks up against MIG or even TIG welding. The truth is, making this conversion can improve weld quality, boost safety, and save money on consumables—if you do it right. In this guide, I’ll break down exactly how to make the switch so you can keep laying strong, reliable beads no matter where the job takes you.

Image by mig-welding.co.uk

What Is Gasless Welding and Why Convert?

Gasless welding, technically flux-cored arc welding (FCAW), uses a special wire with a flux core that creates its own shielding gas when heated. Unlike traditional MIG welding, which relies on an external gas cylinder (like argon or CO2), gasless welding is self-contained, making it ideal for outdoor work or shops without gas setups. I’ve used gasless welding for everything from fixing farm equipment to building gates in windy fields—it’s a lifesaver when you can’t lug around a gas bottle.

Converting your gas MIG welder to gasless saves you the cost of gas cylinders and regulators, simplifies your setup, and lets you weld in tough conditions. But it’s not for every job—gasless welds can produce more spatter and may not be as clean for thin metals. Knowing when to use it (and when not to) is key.

Why it matters: Gasless welding is forgiving on rusty or dirty steel, which is common in repair jobs. It’s also portable, making it perfect for DIYers or pros working remote. But you’ll need to adjust your machine and technique to avoid issues like porosity or weak welds.

Can Your MIG Welder Be Converted?

Before you start, check if your welder supports flux-cored welding. Most modern MIG welders in the U.S. (like Lincoln, Miller, or Hobart) can handle both gas and gasless setups, but older or entry-level models might not. I learned this the hard way when I tried converting a cheap 110V welder that didn’t have the polarity switch needed for gasless wire—ended up with a mess of spatter and no penetration.

Flip through your welder’s manual or check the control panel for a polarity switch (usually labeled DCEP and DCEN). Gasless welding requires DCEN (Direct Current Electrode Negative), while gas MIG uses DCEP (Direct Current Electrode Positive). If your machine lacks this switch, you may need to manually swap the polarity inside the welder—more on that later. Also, ensure your welder can handle the amperage for flux-cored wire, typically 80-200 amps for 0.030” to 0.045” wire.

Pro Tip: If your welder is gas-only, don’t force a conversion—it’s not worth frying your machine. Upgrade to a dual-purpose model if needed.

Tools and Materials You’ll Need

Converting to gasless welding doesn’t require a ton of gear, but you need the right stuff. Here’s what I keep on hand in my shop:

Flux-cored wire: 0.030” or 0.035” for general use; 0.045” for thicker steel. I like Lincoln’s Innershield NR-211-MP for its versatility.

Drive rollers: Knurled rollers for flux-cored wire (smooth rollers for gas MIG won’t grip properly).

Contact tips: Match the tip size to your wire (e.g., 0.035” tip for 0.035” wire). Keep extras—they wear out faster with flux-cored.

Nozzle (optional): A gasless nozzle or no nozzle at all works; gas nozzles can clog with spatter.

Basic tools: Screwdriver, wrench, or hex key to open your welder and swap parts.

Safety gear: Welding helmet (auto-darkening, shade 10-12), gloves, jacket, and a well-ventilated workspace.

Cleaning supplies: Wire brush, anti-spatter spray, and a chipping hammer for slag removal.

I once tried running flux-cored wire with smooth rollers—big mistake. The wire slipped, causing erratic feeding and a bird’s nest of wire in my gun. Always double-check your rollers match the wire type.

Step-by-Step Guide to Converting Your MIG Welder

Here’s how I convert my welder to gasless in my shop. Follow these steps, and you’ll be welding in no time:

Power down and unplug: Safety first—unplug your welder to avoid shocks. I’ve zapped myself once or twice; trust me, it’s not fun.

Remove the gas setup: Turn off the gas cylinder, disconnect the regulator, and remove the gas hose from the welder. Cap the cylinder for storage.

Switch polarity to DCEN: Open the welder’s side panel and locate the polarity terminals (usually near the wire feed). Swap the leads—connect the gun to the negative (-) terminal and the ground clamp to the positive (+) terminal. If your welder has a polarity switch, just flip it to DCEN.

Install knurled drive rollers: Replace smooth rollers with knurled ones sized for your wire (check your manual). Tighten them snugly but don’t overtighten—too much pressure can crush the wire.

Load flux-cored wire: Thread the wire through the drive system and into the gun. Ensure it feeds smoothly without kinks. I use 0.035” wire for most jobs—good balance of penetration and control.

Swap contact tips: Install a contact tip that matches your wire size. Flux-cored wire burns hotter, so check tips frequently for wear.

Remove or adjust the nozzle: If your gun has a gas nozzle, you can remove it or use a gasless nozzle to reduce spatter buildup.

Set your machine: Start with your welder’s recommended settings for flux-cored wire (check the door chart). For 0.035” wire on 1/4” steel, I set my Lincoln 180 to 120-150 amps and 18-20 volts, then fine-tune from there.

Test weld: Clamp a scrap piece of steel, strike an arc, and run a bead. Adjust voltage and wire speed until you get a smooth arc and minimal spatter.

Common Mistake: Don’t skip the test weld. I once jumped straight into a project without testing and ended up with porous welds because my voltage was too high. Always dial in your settings first.

Machine Settings for Gasless Welding

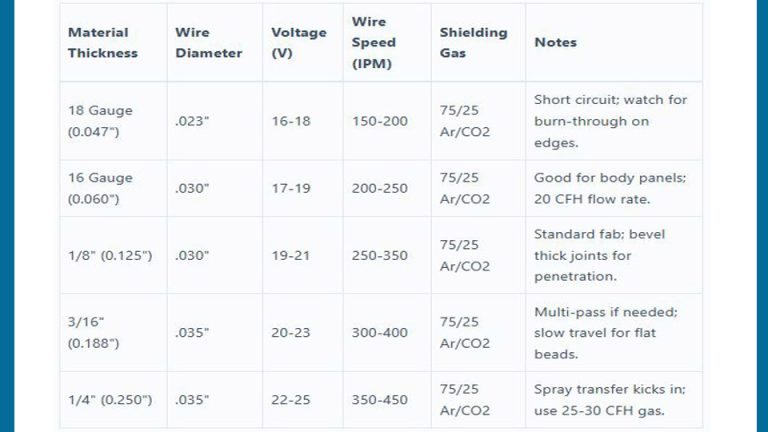

Getting your settings right is critical for clean welds. Flux-cored welding runs hotter than gas MIG, so you’ll need to tweak your machine. Here’s a starting point for common setups:

- 0.030” wire, thin steel (1/8”): 80-110 amps, 16-18 volts, wire speed 200-250 in/min.

- 0.035” wire, medium steel (1/4”): 120-150 amps, 18-20 volts, wire speed 180-220 in/min.

- 0.045” wire, thick steel (3/8”+): 150-200 amps, 20-22 volts, wire speed 150-200 in/min.

These are ballpark figures—your welder’s chart or manual will have specifics. I always start low and creep up, listening for a steady “bacon sizzle” sound. If it’s popping or spitting, lower the voltage or increase wire speed. Too much heat can burn through thin metal, while too little leaves weak welds.

Anecdote: On a trailer repair job, I cranked the amps too high for 0.035” wire and blew holes in the steel. Had to grind it out and start over. Take your time dialing in settings—it saves rework.

Pros and Cons of Gasless Welding

Here’s a quick table I put together based on my experience with gasless welding:

| Aspect | Pros | Cons |

|---|---|---|

| Cost | No gas cylinders or regulators needed | Flux-cored wire is pricier than solid wire |

| Portability | Easy to move, no gas bottle to carry | Heavier wire spools can be bulky |

| Weld Quality | Good for dirty/rusty steel, deep penetration | More spatter, slag cleanup required |

| Ease of Use | Forgiving for beginners, works in wind | Requires practice to minimize spatter |

| Applications | Ideal for outdoor repairs, heavy steel | Less clean for thin metals or cosmetic welds |

If you’re welding indoors on thin stock, consider sticking with gas MIG for cleaner results. Gasless shines on outdoor or heavy-duty jobs.

Common Mistakes and How to Fix Them

I’ve made plenty of mistakes converting and using gasless welders—here’s how to avoid them:

Wrong polarity: Using DCEP instead of DCEN causes erratic arcs and poor penetration. Double-check your polarity before welding.

Smooth rollers: Smooth rollers slip on flux-cored wire, causing feed issues. Always use knurled rollers.

Dirty metal: Flux-cored handles dirty steel better than gas MIG, but you still need to brush off heavy rust or paint for solid welds.

Overheating: High voltage burns through thin metal or creates excessive spatter. Start with lower settings and test on scrap.

Skipping slag removal: Flux-cored welds leave slag that must be chipped or brushed off. I use a chipping hammer and wire brush between passes.

One time, I forgot to switch to DCEN and spent an hour fighting a sputtering arc. Felt like a rookie mistake—always double-check your setup.

Safety Considerations for Gasless Welding

Safety is non-negotiable, especially with flux-cored welding’s hotter arc and extra spatter. Here’s what I keep in mind:

Wear proper PPE: A welding helmet (shade 10-12), flame-resistant gloves, and a jacket protect against burns and UV light. I prefer auto-darkening helmets for quick setup.

Ventilate your workspace: Flux-cored welding produces more fumes than gas MIG. Use a fume extractor or weld outdoors if possible.

Watch for slag: Hot slag can fly off during cleaning—wear safety glasses even after welding.

Ground properly: Ensure your ground clamp is secure to avoid stray arcs. I’ve seen sparks start fires on oily shop floors—keep it clean.

Follow U.S. codes: For structural welds, check AWS D1.1 standards to ensure your settings and technique meet requirements.

I once got a face full of slag because I skipped my safety glasses during cleanup. Never again—gear up every time.

Real-World Applications: Gasless Welding in Action

Gasless welding is a go-to for many jobs I’ve tackled:

DIY projects: Building trailers, gates, or BBQ grills. The portability and deep penetration make it perfect for backyard work.

Field repairs: Fixing heavy equipment like tractors or plows in windy conditions. No gas means no worries about shielding blowout.

Shop fabrication: Welding thick steel for structural frames or racks. Flux-cored handles mill scale and rust better than gas MIG.

Student training: Gasless is forgiving for beginners learning to control the arc. I’ve taught students on flux-cored before moving to gas MIG.

I once repaired a friend’s boat trailer in a windy marina using gasless welding. The flux-cored wire cut through the rusty steel like butter, and we were done in an hour.

Conclusion: Weld with Confidence, Gas or No Gas

Converting your gas MIG welder to gasless is a straightforward process that opens up new possibilities for your welding projects. By switching to flux-cored wire, adjusting polarity, and dialing in your settings, you’re ready to tackle outdoor repairs, thick steel, or rusty materials without the hassle of gas cylinders.

Whether you’re a DIYer fixing a fence, a pro on a construction site, or a student practicing in shop class, this guide gives you the tools to convert your welder and weld like a seasoned pro.

You’ve got the know-how to avoid common pitfalls, set up your machine, and keep safety first. So grab your flux-cored wire, fire up your welder, and get to work—your next project is waiting! Keep a spare set of contact tips handy—flux-cored wire chews through them faster than solid wire.

FAQ

Can any MIG welder be converted to gasless?

Most modern MIG welders can be converted by switching to DCEN polarity and using flux-cored wire with knurled rollers. Check your welder’s manual for polarity settings and amperage capacity. If it’s gas-only, you may need a new machine.

What’s the difference between gas and gasless MIG welding?

Gas MIG uses solid wire and an external shielding gas (like CO2 or argon) for clean welds on thin or clean metal. Gasless (flux-cored) uses self-shielding wire, ideal for outdoor or dirty steel but produces more spatter and slag.

Why are my gasless welds full of spatter?

Excessive spatter comes from incorrect settings (too high voltage or wire speed), wrong polarity (use DCEN), or smooth rollers. Dial in your settings on scrap metal, ensure DCEN polarity, and use knurled rollers for proper wire feed.

Is gasless welding stronger than gas MIG?

Flux-cored welding often provides deeper penetration, making it stronger for thick or dirty steel. However, gas MIG produces cleaner welds for thin metals or cosmetic work. Choose based on your project’s needs.

How do I clean slag from gasless welds?

Use a chipping hammer to break off slag, then brush with a stainless steel wire brush. Apply anti-spatter spray before welding to reduce sticking. Always wear safety glasses during cleanup.+