When I first tried to MIG weld 304 stainless steel, I ran into problems that most welders eventually face—discoloration, porosity, and beads that looked fine at first but didn’t hold up. Stainless can be tricky compared to mild steel, because everything from the filler wire choice to joint preparation, shielding gas mix, and arc control plays a role in whether the weld turns out strong and clean. A lot of folks also wonder if MIG is really the right process, or if they should switch to TIG for stainless jobs.

The good news is, with the right setup and careful attention to metal thickness and heat input, MIG can produce durable, corrosion-resistant welds without blowing the budget. In this guide, I’ll walk you through the practical tips and battle-tested steps that make MIG welding 304 stainless a whole lot easier.

What Makes 304 Stainless Steel Special

Let me tell you about 304 stainless—it’s like the workhorse of the stainless family. This austenitic alloy packs about 18% chromium and 8% nickel, giving it strong corrosion resistance without extra coatings. I’ve used it on everything from restaurant counters to marine hardware, and it holds up in wet environments where regular steel would rust overnight.

But here’s the catch: its low carbon content (≤0.08% for 304; ≤0.03% for 304L) makes it weldable yet sensitive to heat. Hold material in the sensitization range (~450–850 °C) too long and chromium carbides can precipitate at grain boundaries, reducing corrosion resistance. Using 304L and minimizing heat input helps mitigate this risk [15], [16].

When to reach for 304? It’s ideal for non-magnetic applications needing formability, like bending pipes or sheets. For hobbyists fabricating tool carts or pros building process equipment, it’s cost-effective compared to 316. Just remember—it’s not for extreme chloride exposure or sustained high temperatures; pick a more suitable grade there.

Why MIG Welding is a Great Choice for 304 Stainless

MIG welding shines for 304 stainless because it’s fast and forgiving once set up right. Unlike TIG, which demands pinpoint control and slower speeds, MIG lets you lay down beads quickly on thicker sections, perfect for production runs or DIY repairs. With correct wire and gas, it produces clean welds with minimal oxidation [1], [2].

The process feeds a continuous wire electrode while shielding gas protects the pool from contamination. It’s especially handy for out-of-position work, like overhead joints on frames, and for pulsed/spray transfer on thicker stock when you want smooth, consistent beads [9].

Essential Equipment for MIG Welding Stainless Steel

First things first: you need a capable MIG welder with enough output for your thickness (pulsed capability helps on thin sheet). Choose a comfortable gun and keep a dedicated stainless liner, contact tip, and consumables to avoid cross-contamination.

Drive rolls: Use V-groove rolls for solid stainless wire. Reserve V-knurled rolls for flux-cored/metal-cored wires and U-groove for very soft wires like aluminum. Using knurled rolls on solid stainless can shave wire and clog the liner [6], [7], [11].

Other must-haves: dedicated stainless brushes and grinding wheels to avoid carbon pickup, good clamps/fixtures, and a sturdy table. Safety gear is non-negotiable—more on that below.

How to Prepare Your 304 Stainless Steel for Welding

Prep work makes or breaks stainless welds. Degrease with acetone or a dedicated cleaner, then use stainless-only brushes. Don’t share abrasives with carbon steel—cross-contamination can rust later.

For joint prep, bevel thicker stock (>3 mm / 1/8 in.) for penetration. On thin sheet, tight-fit square butt joints work. Tack frequently to fight distortion.

Purge where needed: For tubing or sanitary work, back purging with argon prevents internal oxidation (“sugaring”) and preserves corrosion resistance. Critical work often targets very low oxygen levels before welding; specialized purge systems and monitors help verify purge quality [13], [14].

Selecting the Right Filler Wire and Shielding Gas

Filler wire: For 304/304L, use ER308L. Silicon-bearing variants like ER308LSi improve wetting and bead appearance. For 304 to mild/carbon steel, use ER309L/309LSi to handle the dissimilar joint chemistry [3], [4], [12].

Shielding gas (by transfer mode):

Short-circuit (thin sections, out-of-position): A helium-rich tri-mix—about 90% He / 7.5% Ar / 2.5% CO2—is widely used for clean puddle fluidity and good penetration while keeping CO2 low [1], [12].

Spray or pulsed-spray (thicker sections/production): Use Ar-rich blends with a small reactive component, typically 98% Ar / 2% O2 or ≤5% CO2. These stabilize the arc and improve wetting without excessive oxidation [2], [9], [10].

Not recommended: 100% argon for MIG on stainless steel; it yields poor arc characteristics and lack of fusion—reserve pure Ar for TIG on stainless or MIG on non-ferrous metals [2], [11].

Test on scrap to fine-tune your combo—the right pairing makes welding feel effortless.

Here’s a quick comparison table for gases:

| Gas Mix | Pros | Cons | Best For |

|---|---|---|---|

| Tri-mix (≈90% He / 7.5% Ar / 2.5% CO2) | Very fluid puddle, stable arc at low heat, clean beads when tuned | More expensive; availability varies | Short-circuit on thin to medium 304; out-of-position [1], [12] |

| 98% Ar / 2% O2 | Excellent arc stability and wetting in spray/pulsed; low spatter | Requires sufficient heat input; not for short-circuit | Spray & pulsed MIG on thicker 304 [2], [10] |

| 98% Ar / ≤2–5% CO2 | Good penetration and arc stability; cost-effective | More heat tint/cleanup than O2 blends if CO2 is higher | Spray/pulsed (keep CO2 low); some short-circuit cases [1], [9] |

| 100% Argon | — | Unstable arc and poor fusion on stainless in MIG | Not recommended for GMAW stainless [2], [11] |

Dialing in Your MIG Welder Settings

Set polarity to DCEP (electrode positive) for most stainless GMAW [2]. Typical indoor gas flow is roughly 20–30 CFH, adjusted for nozzle size, travel speed, and drafts [8]. Favor a push (forehand) travel angle (≈10–15°) for cleaner surface appearance and gas coverage; this is also common with pulsed MIG [9].

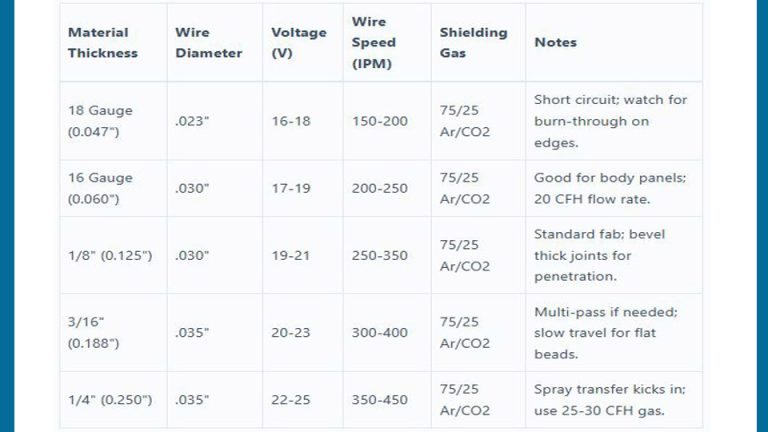

As a starting point for ~1/8-in. (3 mm) 304 with .035-in. ER308L: try about 18–20 V and 200–250 IPM in short-circuit with tri-mix, then adjust to achieve a flat profile without undercut. Always confirm against your machine’s chart and the wire datasheet; for example, ESAB lists broad operating windows for 308LSi that bracket these values [4].

Tips: Keep stickout consistent (~1/2–3/4 in. depending on mode), increase inductance moderately for a softer arc if your machine allows, and move faster than you would on mild steel to minimize heat tint and distortion.

Step-by-Step: MIG Welding 304 Stainless Steel

Alright, let’s get hands-on. Assume your material’s prepped and machine’s set.

Step 1: Secure the workpiece. Clamp it down to prevent movement—304 expands notably with heat.

Step 2: Tack weld the joint. Use short bursts, spaced evenly; let tacks cool to control warping.

Step 3: Start the arc. Hold a 10–15° push angle, ~1/2-in. stickout. Trigger and move steadily.

Step 4: Lay the bead. Use a slight weave for wider joints, keeping speed consistent. Watch the puddle— it should be oval, not a cold, round mound.

Step 5: End the weld. Backstep slightly to fill the crater, maintaining shielding until solid.

Step 6: Inspect. Look for uniform ripples and fusion. If you see undercut, porosity, or tall beads, tweak voltage/wire speed and travel.

Common Pitfalls and How to Dodge Them

Cross-contamination: Using carbon-steel tools on stainless can seed rust later—dedicate brushes, wheels, and even liners.

Overheating / heat tint: Straw to blue colors or soot indicate excess heat. Increase travel speed, reduce heat input, and confirm gas choice (keep CO2 low on stainless). Consider post-weld cleaning/passivation to restore the passive film [4].

Fit-up & distortion: Poor fit-up leads to gaps or cold lap. Use more tacks, sequence welds (skip/backstep), and fixture parts. Purge tubes as needed to prevent internal oxidation [13], [14].

Troubleshooting Your Welds

Porosity? Check for drafts, nozzle cleanliness, correct gas flow, and base-metal cleanliness. Increase flow cautiously indoors [8].

Warping? Use backstepping or skip-weld patterns and allow cooling between passes. Pulsed MIG can help on thin 304 by lowering average heat input [9].

Cracking? Verify filler selection (ER308L for 304; ER309L for dissimilar), limit restraint, and avoid excessive heat. Ensure some ferrite in the weld metal (via filler choice) to reduce hot-crack susceptibility [3], [4].

Dark welds / poor wetting? Gas may be wrong or CO2 too high; switch to tri-mix for short-circuit or Ar/O2 for spray, and tune voltage/WFS [1], [2].

Safety First: Protecting Yourself in the Shop

Welding stainless can generate hexavalent chromium (Cr(VI)), a respiratory carcinogen. Use local exhaust ventilation, keep exposure below regulatory limits, and wear appropriate respiratory protection when needed—especially indoors or in confined spaces [5].

Wear an auto-darkening helmet rated for MIG, safety glasses underneath, leather gloves/jacket, and non-flammable clothing. Keep extinguishers handy and ensure proper work/return lead connections.

Advanced Techniques for Better Results

Pulsed MIG: Great for thin 304—lower average heat reduces distortion and spatter. Use Ar-rich blends with ≤5% CO2 and a push technique [9].

Back purging & heat sinks: Purge visible joints for clean insides and use copper chill bars as heat sinks on long runs [13].

Multi-pass strategy: Root with short-circuit or pulsed, then fill with pulsed/spray as thickness demands. Clean between passes and control interpass temperature to avoid sensitization (~450–850 °C) [15], [16].

Conclusion

Clean prep, the right wire (ER308L for 304; ER309L for dissimilar), a gas matched to the transfer mode (tri-mix for short-circuit; Ar/O2 or low-CO2 for spray/pulsed), tuned settings, and vigilant heat control will deliver strong, corrosion-resistant results. Always run a test coupon before the real thing, then lock your parameters.

Can I Use Regular MIG Wire for 304 Stainless Steel?

Use stainless wire for stainless jobs. ER308L/308LSi matches 304/304L. For stainless-to-carbon steel, use ER309L/309LSi to manage dilution and corrosion. Mild-steel wire (ER70S-x) compromises corrosion resistance and may crack under service [3], [12].

What Shielding Gas is Best for MIG Welding 304 Stainless?

Match gas to the transfer mode: Tri-mix (≈90He/7.5Ar/2.5CO2) excels in short-circuit. For spray/pulsed, go 98% Ar / 2% O2 or ≤2–5% CO2. Avoid 100% Ar for MIG on stainless [1], [2], [9], [10], [11].

How Do I Prevent Warping When MIG Welding Thin 304 Stainless?

Use faster travel, lower average heat (pulsed MIG helps), extensive tacking/fixturing, and heat sinks (copper). Alternate sides on long joints and keep interpass temperatures controlled [9].

What’s the Ideal Voltage and Wire Speed for 1/8-Inch 304?

As a starting window for .035-in ER308L in short-circuit: ~18–20 V and ~200–250 IPM, then tune based on bead profile and fusion. Always confirm against your machine chart and wire datasheet—308LSi data shows broad ranges depending on diameter and mode [4].

Is MIG or TIG Better for 304 Stainless Steel?

MIG wins for speed and productivity, especially on thicker sections and when using pulsed/spray transfer. TIG wins for thin or precision work and cosmetic detail. Choose based on thickness, finish requirements, and access [1], [2].

References

- Miller Electric — Improve Results When MIG Welding Stainless Steel (2025).

- Lincoln Electric — MIG Welding Stainless Steel (resource).

- Lincoln — Blue Max® 308L (ER308L for 304/304L).

- ESAB — OK Autrod 308LSi (datasheet & ranges) (PDF).

- OSHA — Hexavalent Chromium (Cr(VI)) Overview.

- Lincoln — Drive Roll Types & Use.

- Hobart Brothers — Choosing the Right Drive Roll.

- WeldGuru — MIG Welding Gas Flow (typical CFH).

- Miller — Introduction to Pulsed GMAW.

- Linde — Argon/Oxygen Mixtures (spray transfer).

- WeldGuru — MIG With 100% Argon (limitations; stainless not recommended).

- Lincoln — Blue Max® 309LSi (tri-mix & Ar/O2 options; dissimilar joints).

- Weldingtipsandtricks — Back Purging Stainless.

- Pipe Purge Masters — Purging & O2 Levels (PDF).

- ScienceDirect — Sensitization range for 304/304L.

- MDPI — Intergranular Corrosion Susceptibility (450–850 °C).