If you’re wondering how to weld aluminum with gasless MIG, you’re in the right place. I’ve spent years in the shop, tackling everything from backyard projects to industrial repairs, and I’m here to walk you through this process like we’re working side by side. Aluminum is a fantastic material—lightweight, corrosion-resistant, and widely used in everything from boat hulls to custom bike frames.

But welding it with a gasless MIG setup? That’s a bit of a curveball. It’s not the most common approach, but it’s doable with the right know-how, equipment, and patience. Let’s dive into why this matters, how to pull it off, and the tricks I’ve learned to make your welds strong and clean.

Photo by reddit

Why does this topic matter? Aluminum welding is tricky due to its high thermal conductivity and pesky oxide layer, which can lead to weak welds if not handled properly. Using a gasless MIG welder adds another layer of complexity, but it’s a game-changer for DIYers and pros working in windy or remote job sites where hauling gas cylinders isn’t practical.

Getting it right means stronger welds, safer work, and cost savings—no need for expensive shielding gas. Whether you’re a hobbyist building a trailer or a pro fixing aluminum parts, mastering this technique can save you time and money while boosting your skill set.

What Is Gasless MIG Welding, and Why Use It for Aluminum?

Gasless MIG welding, also known as flux-cored arc welding (FCAW), uses a special wire with a flux core that creates its own shielding gas when it burns. This eliminates the need for an external gas cylinder, like the argon or helium mix typically used for aluminum MIG welding. The flux core melts, forms a protective gas shield around the weld pool, and leaves a slag layer you’ll clean off later. It’s a rugged, portable option, perfect for outdoor work where wind might blow away traditional shielding gas.

So, why use gasless MIG for aluminum? For starters, it’s portable and cost-effective. No gas bottles mean fewer trips to the supplier and less gear to lug around. It’s also versatile for fieldwork, where power or space is limited. However, aluminum’s unique properties—high heat conductivity, low melting point, and that stubborn oxide layer—make gasless MIG less common.

The flux-cored wire designed for aluminum is niche, and the process demands precision to avoid issues like porosity or weak welds. But with the right setup, it’s a viable option for DIYers and pros alike.

I once helped a buddy repair an aluminum boat hull in a windy lakeside spot. We didn’t have access to a gas cylinder, so we used a gasless MIG setup with aluminum flux-cored wire. It wasn’t perfect, but it got the job done, and we learned a ton about controlling heat and cleaning up slag. If you’re in a pinch or love the challenge, this method’s worth exploring.

Challenges of Welding Aluminum with Gasless MIG

Aluminum isn’t your average metal. Its high thermal conductivity means it sucks up heat fast, making it easy to burn through thin pieces. Its oxide layer, which melts at a much higher temperature than the base metal, can cause contamination if not cleaned properly. Add in the flux-cored wire’s tendency to produce spatter and slag, and you’ve got a recipe for frustration if you’re not prepared.

Common mistakes I’ve seen (and made) include not cleaning the aluminum thoroughly, using incorrect welder settings, or rushing the weld. These lead to porous, brittle welds that won’t hold up. The fix? Take your time with prep, dial in your machine, and practice on scrap pieces. Trust me, I’ve burned through plenty of aluminum before I got the hang of it. Patience is your friend here.

Equipment You’ll Need for Gasless MIG Welding Aluminum

Before you strike an arc, let’s talk gear. You’ll need a MIG welder capable of running flux-cored wire. Most modern MIG welders can handle this, but check your machine’s specs. For aluminum, a spool gun or push-pull gun is a must—aluminum wire is soft and prone to tangling in standard wire feeders. A spool gun holds the wire spool right at the torch, reducing feed issues. I’ve used a Lincoln Electric spool gun for years, and it’s a lifesaver for smooth wire delivery.

You’ll also need aluminum-specific flux-cored wire, like ER4043 or ER5356. These wires are designed for gasless MIG, with flux that creates a shielding gas when heated. ER4043 is great for general-purpose welding, while ER5356 is better for stronger, corrosion-resistant welds. A 0.035-inch wire diameter is a good starting point for most aluminum thicknesses.

Other essentials include:

- Stainless steel wire brush: For cleaning the aluminum’s oxide layer.

- Chemical cleaner (acetone or alcohol): To remove grease and dirt.

- Smooth drive rollers: Designed for soft aluminum wire to prevent damage.

- Safety gear: Welding helmet (shade 10-12), heat-resistant gloves, flame-resistant jacket, and good ventilation to handle flux fumes.

One tip from my shop days: dedicate a brush for aluminum only. Using one that’s touched steel can introduce contaminants, ruining your weld. I learned this the hard way when a “clean” brush left me with a porous mess.

Step-by-Step Guide to Welding Aluminum with Gasless MIG

Let’s break this down into a clear, repeatable process. Follow these steps, and you’ll be laying down solid welds in no time.

Step 1: Prepare the Aluminum Surface

Aluminum’s oxide layer is your biggest enemy. It melts at 3700°F, while the base metal melts at around 1200°F, so you’ve got to remove it. Start by wiping the surface with acetone or isopropyl alcohol to get rid of grease and oils. Then, use a stainless steel wire brush to scrub away the oxide layer. Brush in one direction to avoid smearing contaminants. For thicker pieces (over 1/8 inch), consider preheating to 300°F to reduce thermal shock—just don’t overdo it, or you’ll warp the metal.

I once skipped this step on a rush job and ended up with a weld that looked like Swiss cheese. Never again. Cleanliness is non-negotiable with aluminum.

Step 2: Set Up Your Welder

Your MIG welder needs to be set to Direct Current Electrode Negative (DCEN) for gasless aluminum welding. This polarity works best with flux-cored wire, providing good arc stability. Start with these baseline settings for 1/8-inch aluminum:

- Wire feed speed: 450-600 inches per minute (IPM). Aluminum needs faster feed than steel due to its thermal conductivity.

- Voltage: 21-23 volts. Adjust based on material thickness—thicker pieces need more juice.

- Spool gun settings: Ensure the tension on the drive rollers is light to avoid crushing the soft aluminum wire.

Test these settings on scrap aluminum. Listen to the arc—it should sound like sizzling bacon with steady pops. A popping arc means your wire speed is too low or voltage too high; a hissing arc means the opposite. Fine-tune until it’s smooth.

Step 3: Choose the Right Filler Wire

Picking the right wire is critical. ER4043 is versatile and flows well, making it ideal for beginners. ER5356 is stronger and better for marine or corrosion-prone environments but can be trickier to control. Match the wire to your base metal—check the alloy grade (like 6061 or 5052) to ensure compatibility. I stick with ER4043 for most projects unless I need extra strength.

A quick story: I once used ER5356 on a thin aluminum sheet, thinking it’d be tougher. The weld was solid but harder to control, and I ended up with more spatter than I’d like. Lesson learned—match the wire to the job.

Step 4: Welding Technique

Hold the torch at a 10-15 degree angle and use the push technique—move the torch forward, pushing the weld pool away from you. This reduces contamination and improves penetration. Keep the stickout (distance from the contact tip to the workpiece) at about 1/2 inch. Move steadily to avoid overheating, which can warp aluminum or cause burn-through.

Watch the weld pool closely. Aluminum’s shiny pool can be hard to read, but aim for a smooth, flowing puddle. If it’s too hot, you’ll see ripples or burn-through; too cold, and the weld won’t penetrate. Adjust your travel speed or voltage as needed.

Step 5: Post-Weld Cleanup

Gasless MIG leaves flux residue and slag, which you’ll need to clean off. Use a wire brush or chipping hammer to remove it, then wipe the weld with a clean rag. Inspect for defects like porosity or cracks. If you spot issues, grind them out and re-weld. For critical welds, consider post-weld heat treatment to relieve stresses, especially on thicker pieces.

Machine Settings and Joint Prep Tips

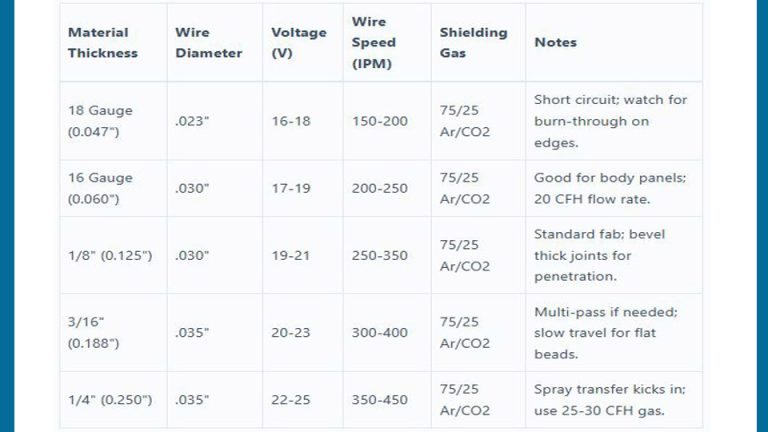

Getting your welder dialed in is half the battle. Here’s a quick reference table for settings based on aluminum thickness:

| Thickness (inches) | Wire Diameter (inches) | Wire Feed Speed (IPM) | Voltage (Volts) | Notes |

|---|---|---|---|---|

| 1/16 | 0.030 | 400-500 | 20-22 | Thin sheets, use low heat to avoid burn-through |

| 1/8 | 0.035 | 450-600 | 21-23 | General-purpose setting for most DIY projects |

| 1/4 | 0.045 | 500-700 | 23-25 | Preheat thicker pieces to 300°F for better results |

For joint prep, bevel edges on materials thicker than 1/4 inch to ensure good penetration. Use a 90-degree flange on thin sheets to prevent warping. Always tack weld to hold pieces in place before running a full bead. I’ve found that skipping tacks leads to misalignment, especially on long seams.

Pros and Cons of Gasless MIG for Aluminum

Let’s weigh the benefits and drawbacks so you know what you’re getting into.

Pros

- Portability: No gas cylinders make it ideal for fieldwork or remote sites.

- Cost-effective: Saves money on shielding gas and reduces setup complexity.

- Versatility: Works in windy conditions where gas shielding might fail.

- Good penetration: Flux-cored wire offers deep penetration, great for thicker aluminum.

Cons

- Messy welds: Flux residue and spatter require extra cleanup.

- Limited wire options: Aluminum flux-cored wire is harder to find and pricier than solid wire.

- Lower weld quality: Compared to TIG or gas-shielded MIG, welds may be less clean.

- Learning curve: Controlling heat and managing spatter takes practice.

I’ve used gasless MIG for quick repairs on aluminum trailers, and while it’s not as pretty as TIG, it’s reliable when you’re in a bind. If aesthetics matter, you might want to practice extensively or consider TIG for cleaner results.

Safety Considerations for Gasless MIG Welding Aluminum

Safety is non-negotiable in the shop. Aluminum welding with flux-cored wire produces fumes from the flux, which can be toxic. Work in a well-ventilated area or use a fume extractor. Wear a welding helmet with a shade 10-12 lens to protect your eyes from the bright arc. Heat-resistant gloves and a flame-resistant jacket are musts—sparks and spatter are common with flux-cored welding.

One close call I had was welding in a cramped garage without proper ventilation. The fumes gave me a headache that lasted hours. Now, I always crack a window or use a fan to keep the air clear. Don’t skip this step—it’s not worth the risk.

Common Mistakes and How to Fix Them

Even experienced welders mess up sometimes. Here are the top pitfalls and how to avoid them:

- Dirty aluminum: Always clean thoroughly. If you get porosity, grind out the weld and start over with a cleaner surface.

- Incorrect settings: A popping or hissing arc means your wire speed or voltage is off. Adjust based on the sound and weld bead appearance.

- Overheating: Move faster or lower the voltage to prevent burn-through, especially on thin aluminum.

- Poor wire feeding: Check your spool gun tension and use smooth drive rollers to avoid jams.

Practice on scrap pieces to dial in your technique. I keep a pile of aluminum offcuts in my shop just for this—saves me from ruining good material.

Real-World Applications for Gasless MIG Aluminum Welding

This technique shines in specific scenarios. DIYers can use it for small repairs, like fixing aluminum lawn furniture or custom brackets. Pros might find it handy for field repairs on trailers, boats, or farm equipment where gas cylinders aren’t practical. Students learning welding can experiment with gasless MIG to understand aluminum’s quirks without investing in a full TIG setup.

I once helped a student weld an aluminum toolbox for a truck bed using a gasless MIG setup. It wasn’t perfect, but it held up through years of rough use. That’s the beauty of this method—it’s practical and gets the job done when conditions aren’t ideal.

Conclusion

Welding aluminum with gasless MIG is a niche but valuable skill. It’s not the cleanest or easiest method, but it’s a lifesaver for portable, cost-effective welding in tough conditions. By mastering surface prep, welder settings, and technique, you can produce strong, reliable welds that stand up to real-world demands. Whether you’re a DIYer tinkering in your garage, a student learning the trade, or a pro tackling field repairs, you’re now equipped to handle this challenge with confidence.

FAQ

Can you weld aluminum with a gasless MIG welder?

Yes, but it requires aluminum-specific flux-cored wire, like ER4043 or ER5356, and a spool gun for smooth feeding. Clean the aluminum thoroughly and adjust your welder to DCEN for best results.

What’s the best wire for gasless MIG aluminum welding?

ER4043 is great for general-purpose welding with good flow, while ER5356 offers higher strength and corrosion resistance. Match the wire to your base metal and project needs.

How do I avoid porosity in aluminum welds?

Clean the aluminum with a stainless steel brush and acetone to remove oxides and contaminants. Maintain a consistent travel speed and proper torch angle to ensure good shielding from the flux.

Is gasless MIG welding aluminum as strong as TIG?

Gasless MIG welds are strong but typically less clean than TIG welds. They’re suitable for repairs or structural work but may not match TIG’s precision for aesthetic or critical applications.

What safety gear do I need for gasless MIG welding aluminum?

Use a welding helmet (shade 10-12), heat-resistant gloves, a flame-resistant jacket, and ensure good ventilation to handle flux fumes. A fume extractor is ideal for indoor work.