You’re choosing a 30 amp plasma cutter to balance portability with precise cuts, but output and setup define your results. Expect clean severance on mild steel from 20 ga (0.032 in) to 1/4 in, with best quality to 3/16 in. Keep air at 55–60 psi and match tip size, amperage, and travel speed to thickness. Aluminum often needs roughly double the amperage. If kerf, edge dross, or warping appears, your next adjustments matter.

Power and Voltage Basics for 30 Amp Plasma Cutting

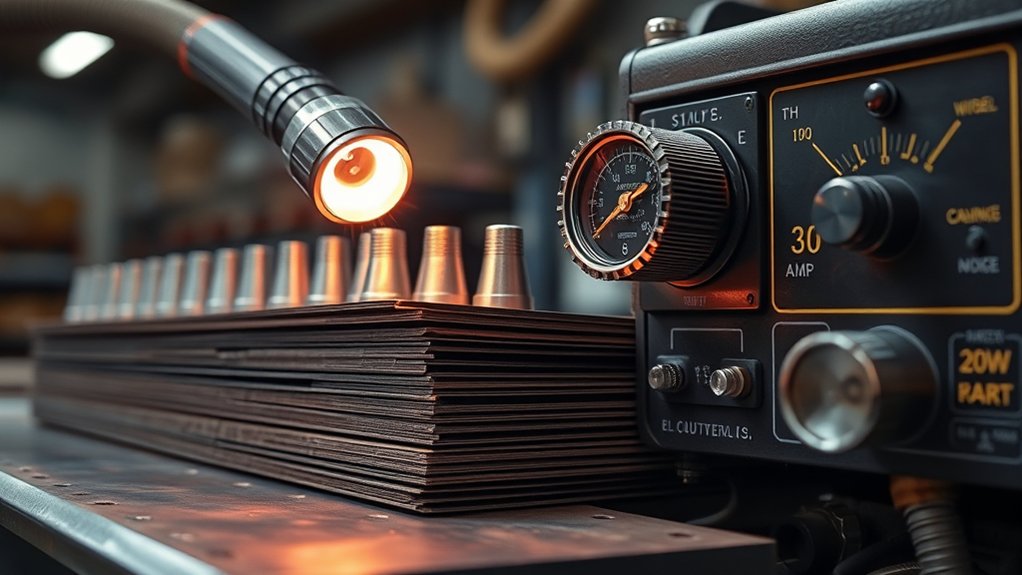

Although amperage defines cutting capacity, you’ll dial in a 30 A plasma cutter by matching current, air pressure, and tip size to the material. For stable arc energy at this rating, target 55–60 psi at the torch with a 0.8 mm (.030) tip. This range sustains a high-velocity jet, preserves arc constriction, and supports about 10 inches per minute on rated mild steel cuts.

Verify line pressure under flow; static readings can mislead. Perform air pressure adjustments at the regulator while observing torch test flow, not idle.

Set pressure while air is flowing; idle, static readings can mislead and undercut true torch pressure.

Use the manufacturer’s chart to confirm current, tip, and standoff, then validate cut quality by kerf width, dross class, and heat tint. As part of plasma cutter maintenance, inspect the regulator, filter, and consumables; leaks or saturated filters drop dynamic pressure and destabilize the arc.

Maintain clean, dry air per ISO 8573 recommendations. Document settings and results to standardize repeatability across materials and operators.

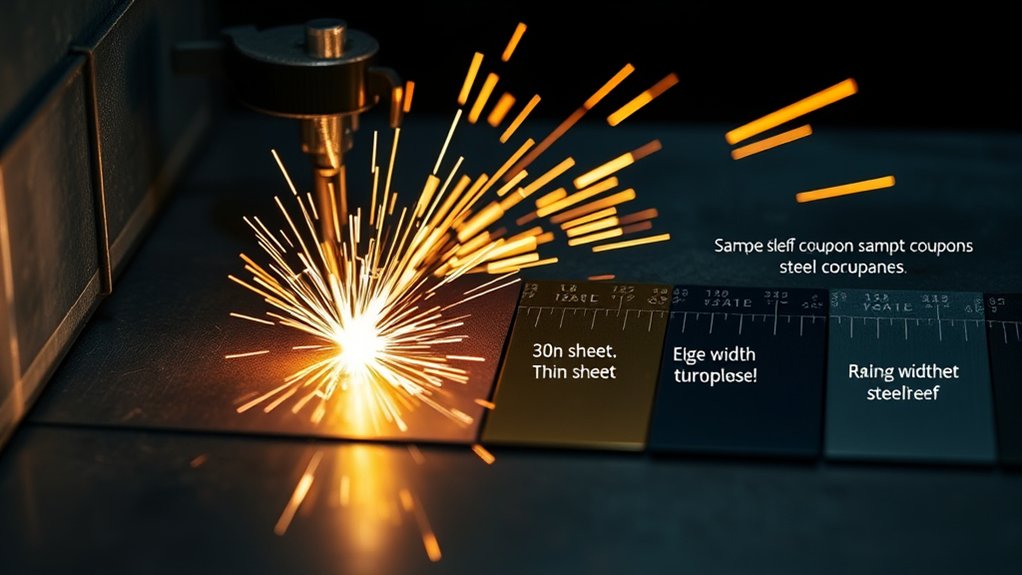

Recommended Material Thickness Range for 30 Amp Tips

With a 30 amp tip (0.8 mm orifice), you’ll target thin-gauge stock through about 1/4 in mild steel, with stainless typically capped near 1/8 in for efficient performance.

Set air at 55–60 psi and expect travel speeds around 20–25 ipm to maintain consistent kerf and minimal dross.

You should anticipate clean, square edges within this range, recognizing that thicker sections will force slower speeds, increased bevel, and more post-cut cleanup.

Typical Thickness Range

For a 30 amp plasma tip, the recommended material thickness spans 20 gauge (0.032 in / 0.81 mm) up to 1/4 in (6.35 mm) mild steel.

Within this typical range, you’ll maximize cut efficiency when your plasma settings match thickness and speed. Stay inside the band to keep kerf narrow, edges square, and dross low.

1) 20–12 ga: Use higher travel speeds; maintain 55–60 psi air pressure for a stable arc and clean edges.

2) 1/8–3/16 in: Moderate speeds; hold torch height precisely to preserve arc focus and contour fidelity.

3) 1/4 in: Expect about 21–30 IPM; verify airflow at 55–60 psi and maintain a steady pace to minimize top bevel.

Avoid thicker stock; exceeding 1/4 in typically degrades quality and increases post‑cut cleanup.

Material Compatibility Notes

Even within a 30 amp class, material choice and thickness govern cut quality and speed. Use a 30 amp tip on materials up to 1/4 in (6.4 mm); it’s well-suited to sheet metal and thin steel.

Operate within 21–30 A and 55–60 psi air to maintain stable arc characteristics. Account for material properties: aluminum conducts heat rapidly and typically needs roughly double the amperage versus steel to sustain an efficient plasma column.

Plan your cutting techniques around kerf: expect ~0.8 mm (0.030 in) kerf width for precise layout and fit-up on thin sections.

Adjust travel speed to thickness and alloy. For mild steel, target about 24–38 ipm for quality cuts at ≤1/4 in. Increase speed slightly on thinner stock; slow marginally as thickness approaches the 1/4 in limit.

Cut Quality Expectations

Although a 30 amp tip can sever up to about 1/2 in (12.7 mm), you should plan quality expectations around thinner stock. For best edge fidelity, treat 3/16 in (4.76 mm) as the quality limit; 1/4 in (6.35 mm) remains acceptable for rated cuts with moderate cleanup.

Beyond that, kerf widens, bevel increases, and dross rises, requiring stricter dross management and slower travel.

- Set parameters: run 21–30 A on mild steel with dry air at 55–60 psi; verify flow under load.

- Apply cutting techniques: maintain standoff, square torch angle, and constant speed; pierce off‑part and lead in.

- Inspect results: target bright, continuous arc, minimal top spatter, light bottom dross; if heavy, reduce speed slightly or increase air.

Amperage, Nozzle Size, and Air Pressure Settings

When dialing in a plasma cutter, match amperage, nozzle orifice, and air pressure to the material and cut quality targets. With a 30 A machine, use a 30 A tip with a 0.8 mm (0.030 in) orifice for work in the 21–30 A range. Set clean, dry air to 55–60 psi at the torch while flowing. This pairing stabilizes the arc, limits amperage effects like excessive kerf width or undercut, and supports consistent edge squareness.

For mild steel up to 1/4 in, start at the charted amperage and pressure from your manufacturer. Low pressure risks arc blowout and incomplete penetration; excessive pressure increases dross and can slow the process. Verify dynamic pressure with the trigger depressed.

Perform nozzle maintenance: inspect orifice roundness, replace worn tips, and keep electrodes within spec to prevent double-arcing and erratic kerf.

Validate settings on scrap, then adjust in small increments to correct angularity, dross, or arc lag before production cuts.

Cutting Speed Expectations by Metal Type and Thickness

Set realistic cut speeds by matching metal type and thickness to your 30 A system’s capability and verifying with test cuts.

Cutting speed depends on material types, thickness, and proper air delivery. At 55–60 psi with a 30 A tip, expect consistent arc focus and predictable feed rates.

1) Mild steel: Target a rated cut of 3/8 inch at roughly 10 IPM.

Thinner gauges scale faster; for 1/4 inch, increase travel speed proportionally while maintaining full penetration. If you see trailing sparks or dross, raise speed slightly or confirm pressure.

2) Stainless steel: Plan for 1/4 inch at about 6–8 IPM.

Stainless conducts heat poorly, so avoid excessive dwell. Keep torch angle square and maintain steady motion to control heat input and prevent slow, dross-prone passes.

3) Aluminum: Cut up to 3/8 inch at >15 IPM due to its lower melting point.

Use brisk starts and maintain higher travel speed to minimize heat soak. Verify edge continuity and adjust speed before production.

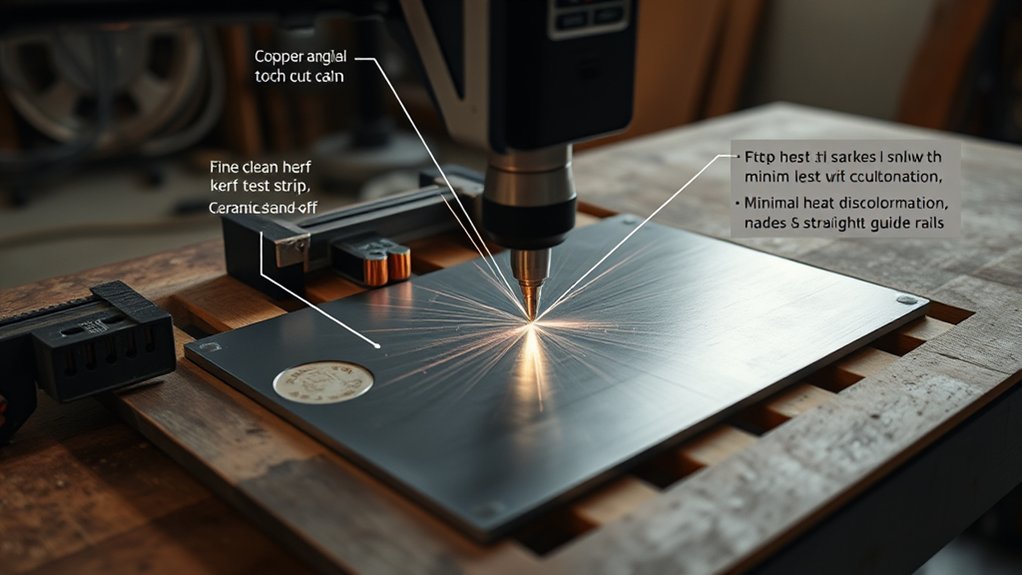

Kerf Width and Edge Quality With 30 Amp Consumables

With a 30 A tip using a 0.8 mm (0.030 in) orifice at 55–60 psi, you can expect a narrow, consistent kerf suitable for precision work on thin to moderate gauges, especially around 1/4 in mild steel. You’ll hold kerf integrity by pairing amperage with proper pressure and maintaining steady travel speed. Too slow and heat input widens the kerf and raises dross; too fast and you’ll undercut edges. On mild steel and aluminum, you’ll typically see clean, square edges with minimal secondary processing. Target 1/4 in mild steel for the best balance of speed and edge refinement.

| Parameter | Guidance |

|---|---|

| Amperage | 21–30 A (tip rated) |

| Air pressure | 55–60 psi (stable, dry) |

| Kerf width | Narrow; material-dependent |

| Travel speed | Moderate; avoid lingering |

| Best thickness | 1/4 in mild steel |

Verify consumable condition, maintain torch-to-work distance, and keep motion uniform to preserve kerf integrity and minimize dross while maximizing edge refinement.

Setup for Thin Sheet Metal to Minimize Warping

For thin sheet, you’ll secure the work with rigid fixturing and edge clamps to eliminate flex and slip that trigger distortion.

Set high travel speeds (e.g., ≥38 IPM) and pair a 30 A tip with FineCut consumables to maintain a narrow kerf and a stiffer arc.

Control heat input by matching amperage to thickness per manufacturer specs and minimizing dwell, ensuring consistent, low-distortion cuts.

Secure Fixturing Methods

Although thin sheet metal cuts fast, you’ll only hold tolerance if the sheet is rigidly constrained to limit heat-induced distortion.

Apply fixturing techniques and stability methods that keep the work flat, immobile, and evenly supported. Use clamps or modular fixtures to prevent sliding and flexing, especially on polished stainless and aluminum where rigidity preserves edge quality and dimensional accuracy. Distribute restraint uniformly to avoid localized bow.

1) Use low‑profile edge clamps at 150–300 mm spacing; add crossbars or vacuum pods to hold interior zones flat without obstructing the torch path.

2) Place copper or aluminum backing bars beneath kerf lines to absorb heat and support the cut; maintain continuous contact to reduce dross.

3) Employ weighted plates or magnetic hold‑downs to balance load across the panel; verify squareness and flatness with feeler gauges before piercing.

High Travel Speeds

Even on thin sheet, you control distortion by running the torch fast enough to outrun heat spread. For 30 A class machines, implement speed optimization by targeting ≥10 inches per minute (IPM) as a minimum baseline for clean edges without deformation.

Validate with a straight-line test: look for a narrow, vertical kerf and minimal dross; increase speed until arc lag appears, then back off 5–10%.

Apply cutting techniques that use FineCut consumables to tighten kerf width and focus the arc, improving edge fidelity at higher speeds.

Secure the sheet to prevent flex and sliding; movement forces you to slow down, increasing heat propagation.

Reduce pierce time by edge-starting rather than stacking layers, preserving cut quality while maintaining commanded travel speed.

Heat Input Control

High travel speed limits heat spread, but you still need to set the machine to control total heat input on thin sheet. Use cutting techniques that prioritize heat management: keep traverse above 10 IPM to minimize propagation, match amperage to thickness, and stabilize the work. For ~1/8 in material, a 30 amp tip provides adequate energy density without overdriving the kerf.

1) Set parameters: adjust current to the thinnest section, verify gas flow, and select FineCut consumables to yield a narrow kerf and stiff arc that lowers distortion risk.

2) Control starts: program pierce delay just long enough for full penetration; avoid over-piercing when starting off-edge.

3) Fixturing: clamp sheets at multiple points to suppress flex, maintain standoff, and guarantee consistent arc energy distribution.

Techniques for Clean Cuts on 1/8 to 1/4 Inch Materials

When you cut 1/8 to 1/4 inch stock with a 30‑amp plasma system, lock in foundational settings first: set amperage to 21–30 A for 1/8 inch, hold air pressure at 55–60 psi, and use FineCut consumables to tighten kerf and stiffen the arc on thin material.

Apply disciplined cutting techniques: square the torch, set standoff at 1/16–1/8 inch, and verify plasma settings with scrap test passes before production. Track speed by edge lag; for 1/4 inch, target 24–30 IPM to minimize dross and bevel.

| Visual cue | Action standard |

|---|---|

| — | — |

| Bright, narrow arc column | Maintain standoff; don’t outrun the arc |

| 5–10° trailing sparks | Travel 24–30 IPM on 1/4 inch |

| Minimal top spatter | Air 55–60 psi, clean dry supply |

Index your lead‑in off‑part to avoid divot marks, then pierce perpendicular and shift to a 10–15° drag angle.

Keep the kerf centered; adjust speed if slag tails forward (too slow) or sparks exit upward (too fast). Finish with a brief, straight lead‑out to prevent crater formation.

Safety and Duty Cycle Considerations at 30 Amps

With settings dialed for clean cuts on 1/8–1/4 inch stock, you also need to manage operator safety and the machine’s 30 A duty cycle. At 30 amps, most units rate a 35% duty cycle—run for 3.5 minutes, then cool for 6.5 to prevent thermal shutdown and component stress.

Keep air at 55–60 psi to stabilize arc quality and minimize dross while avoiding excessive backpressure.

Maintain 55–60 psi air to stabilize the arc, reduce dross, and avoid harmful backpressure.

1) Safety gear and environment: Wear an ANSI Z87.1 face shield with shade per manufacturer, fire‑resistant gloves and clothing, and hearing protection. Confirm grounded work clamps, dry work area, and local exhaust or outdoor ventilation to control fumes and particulates.

2) Duty cycle control: Log arc‑on time, adhere to the 10‑minute duty window, and allow full cooldown if the thermal light trips. Avoid coiling leads on hot metal.

3) Consumables and air quality: Inspect tips/electrodes each session; replace when orifice is out‑of‑round. Use dry, oil‑free air via a filter/dryer to protect torch and maintain consistent cut performance.

Troubleshooting Cut Quality at 21–30 Amp Operation

Although 21–30 amp settings can sever up to 1/4 inch mild steel, prioritize thinner stock for best edge quality and use a 30 A tip (≈0.8 mm/.030) to tighten kerf.

For quality control, verify supply air at 55–60 psi under flow; pressure below spec causes dross, uncut webs, and arc instability. Inspect nozzle and electrode for pitting, ovality, and discoloration; replace as needed—consumable maintenance directly governs kerf width and angularity.

Apply consistent standoff (≈1.5–2.0 mm) and maintain a square torch to minimize bevel. Adjust cutting techniques by matching speed to thickness: slow slightly on thicker work within this range to avoid lag lines while preventing overheating and warping.

If slag accumulates on the top edge, increase speed; if it hangs on the bottom, reduce speed or raise pressure into spec.

Clean torch body, shield, and swirl ring routinely, and guarantee low-resistance grounding.

Stable work return lowers arc blow and improves repeatability.

Frequently Asked Questions

Can a 30 Amp Plasma Cutter Run on a Small Portable Generator?

Yes, if the generator capacity matches the plasma cutter requirements. Verify continuous wattage (≈4–6 kW), 120/240 V compatibility, stable frequency (60 Hz), low THD (<5%), and sufficient surge headroom. Use heavy-gauge cords and observe duty-cycle limits.

Which Air Compressor CFM Is Ideal for Consistent 55–60 Psi Delivery?

Choose a compressor delivering 4–5 CFM at 90 psi to maintain consistent 55–60 psi. You’ll meet CFM requirements with reserve, guarantee pressure stability under duty cycles, and align with common pneumatic specifications and regulator/receiver best practices.

How Do Altitude and Humidity Affect Cut Performance and Air Drying?

Altitude reduces available oxygen and compressor output, degrading arc stability and cut quality factors; you’ll compensate with higher flow. Humidity increases water load, worsening environmental effects; you’ll need efficient drying (refrigerated/desiccant), drains, and dew-point monitoring to maintain consistent cut performance.

What Extension Cord Gauge Is Safe for 30 Amp Plasma Cutters?

Go with 10 AWG copper for 30 A plasma cutters. As the saying goes, “an ounce of prevention…” Choose heavy‑duty extension cord types (SJTW/SOOW), 125/250 V rated, with oil/abrasion‑resistant wire insulation; keep runs under 50 ft to limit voltage drop.

Are CNC Tables Compatible With 30 Amp Torches and Arc-Start Types?

Yes. You can run most CNC tables with 30‑amp torches if the controller supports on/off and arc‑OK signals. Verify CNC compatibility by matching Torch types: blowback (pilot arc) vs HF start, ensuring EMI mitigation and grounding.

Conclusion

You’ve got the data to dial in your 30A plasma cutter. Stay within 20 ga to 1/4 in steel (best up to 3/16), hold 55–60 psi, and match travel speeds (24–38 ipm) to thickness. For aluminum, plan roughly double the amperage. Verify kerf and edge quality, adjust nozzle size, and control heat to prevent warping. Monitor duty cycle, PPE, and grounding. When in doubt, measure, don’t guess—because “measure twice, cut once” still saves consumables and time.