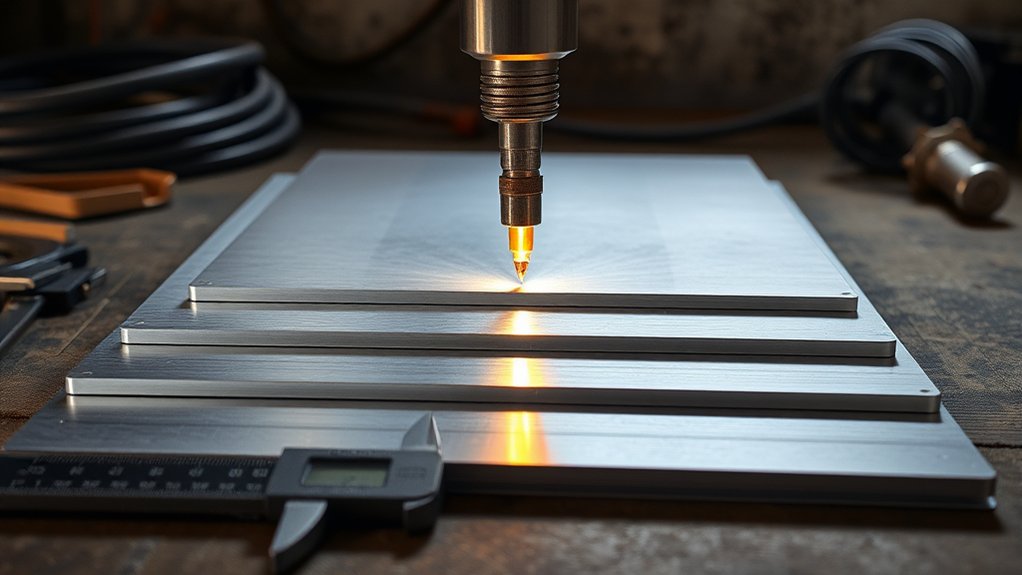

You need the right amps per aluminium thickness to control kerf, bevel, and dross while meeting tolerance. Set too low and you stall with heavy dross; too high and you widen the kerf and overheat edges. For 1/8 in, 30–40 A preserves edge integrity; 1/4 in works at 50–60 A; 3/8–1/2 in needs 70–80 A. Pair amperage with correct speed, torch height, and gas to lock in repeatable results—here’s how to dial it in.

Why Amperage Matters When Cutting Aluminium

Although several variables influence plasma cutting, amperage governs arc energy density and penetration in aluminum. You control arc power with the current setpoint, and that dictates melt rate, kerf geometry, and cutting precision.

Amperage dictates arc energy, melt rate, kerf geometry, and precision in aluminum plasma cutting.

The core amperage effects are measurable: too low and the arc stalls, increasing dross and bevel; too high and heat input expands the HAZ, risking distortion and a wider kerf. Adhering to published charts and process guidelines stabilizes current delivery, improves repeatability, and supports tight tolerances.

You’ll see productivity gains when you run the maximum allowable amperage for the application because higher current raises cutting speed while maintaining acceptable edge quality. However, you must balance energy density against thermal load to prevent warping.

Consistent amperage—verified at the torch and power supply—reduces variance in kerf width and minimizes rework. In practice, standard operating procedures that lock current settings and verify output guarantee uniform penetration, predictable HAZ, and clean edges with minimal dross.

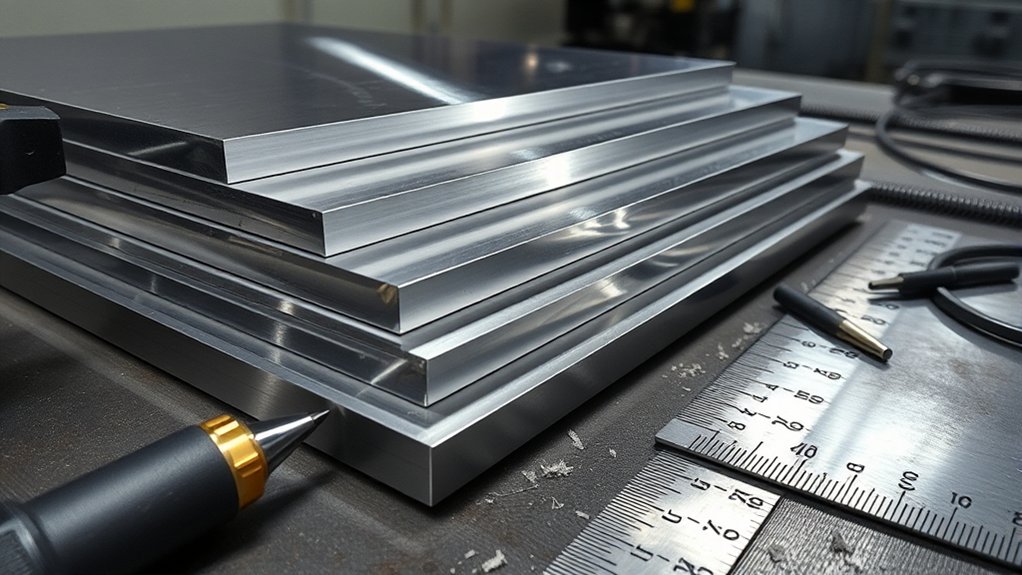

Matching Amps to Aluminium Thickness

With amperage established as the control knob for arc energy and penetration, you now match current to aluminum thickness to keep melt rate, kerf width, and HAZ within spec.

For thin sheet up to 1/8 in (3.2 mm), set 30–40 A; you’ll maintain edge integrity and avoid overburn on most aluminum alloys.

At 1/4 in (6.4 mm), use 50–60 A to balance cut speed, kerf straightness, and minimal top-edge rounding.

For 3/8–1/2 in (9.5–12.7 mm), step to 70–80 A; this maintains a stable arc column and reduces dross formation.

Verify your machine’s duty cycle at the chosen current and adjust travel speed so the arc exits cleanly with a slight rear-side drag line.

If you see widening kerf or heat tint, you’re running too hot; reduce amps or increase speed.

If dross builds or the arc snuffs, increase current.

Always cross-check the plasma cutter manual and aluminum-specific cutting techniques for precise settings.

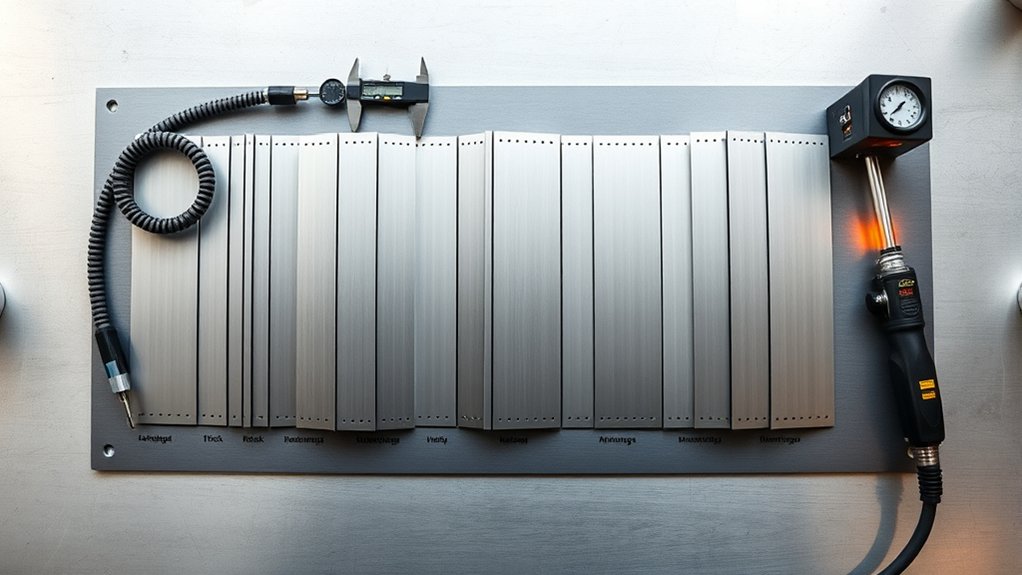

Recommended Cut Charts by Thickness Range

You’ll set thin-gauge starting points at 30–50 A with 40–60 IPM and pierce height at 1.5–2× cutting height for clean, low-dross edges.

For mid-thickness (1/4–3/8 in), target 50–70 A, scale travel speed down proportionally, and keep pierce delay consistent with manufacturer tables.

For heavy plate (>3/8 in), use 70–100 A, slower IPM for full penetration, and verify pierce height and delay per cut chart to meet cut-quality standards.

Thin-Gauge Starting Points

For thin-gauge aluminum (around 24GA), start at 20–30 A, target 80–120 IPM, and hold a precise standoff to stabilize bevel and kerf.

Apply cutting techniques that account for aluminum properties: high thermal conductivity and low melting point. Set cutting height per your torch spec, then set pierce height at 1.5–2× that value to protect the nozzle and minimize top-edge spatter.

Use nitrogen shield gas to tighten the arc, reduce dross, and improve edge smoothness.

Control standoff with AVC or a calibrated shim to keep arc voltage consistent; even small deviations skew bevel angles.

Verify cut quality by measuring kerf width, dross type (cold vs. hot), and HAZ. If edges round or show micro-keyholing, increase speed; if dross increases, reduce speed or slightly lower amperage.

Mid-Thickness Performance

Two settings anchor mid‑thickness aluminum (1/8–1/4 in.) performance: 40–60 A and 30–50 IPM, tuned to alloy, temper, and edge spec. You’ll validate with test coupons, targeting square kerf, minimal dross, and heat-affected width within spec.

Set cutting height per your torch chart, then hold pierce height at 1.5–2× that value to protect the nozzle and keep entry clean. Use nitrogen shield gas when surface finish and dross reduction are priorities; air is acceptable but increases cleanup.

Control standoff precisely—small increases steepen bevel and widen kerf. Monitor arc voltage if available to stabilize torch-to-work distance.

Apply consistent cutting techniques: lead-ins/lead-outs, proper kerf compensation, and pierce dwell limits. Prioritize equipment maintenance—inspect consumables, check gas flow, verify coolant/air quality, and recalibrate height control.

Heavy Plate Parameters

When stepping into heavy plate (1/4–1/2 in.) aluminum, set 80–120 A and target 10–15 IPM to achieve full penetration with controlled bevel and minimal dross.

Use nitrogen plasma for higher edge quality, reduced oxidation, and lower dross compared to air. Apply a pierce height of 1.5–2× cutting height to shield consumables during initial arc establishment.

Lock in a consistent standoff using a height control system to stabilize arc voltage and keep bevel angle uniform through thickness.

For cutting techniques, square edges favor the lower end of amperage with slower travel; productivity favors the upper end with careful dross monitoring.

Verify consumable condition, maintain adequate gas flow, and confirm plate grounding.

Record amperage, speed, and height per thickness to standardize repeatability.

Speed, Amperage, and Heat-Affected Zone

You should match amps to thickness—about 20 A at 1/8 in and up to 100 A at 1/2 in—then set an ideal travel speed (e.g., ~100 IPM on automated rigs) to prevent overheat.

Run too slow with excess amperage and you’ll enlarge the HAZ, risk melt‑through, and degrade edge quality.

Maintain correct standoff and tune gas flow to minimize HAZ width while meeting your machine’s process limits.

Optimal Travel Speed

Dialing in travel speed is a control problem: match inches per minute to amperage and thickness to keep the kerf narrow and the heat-affected zone (HAZ) minimal.

You’ll balance travel speed and cut quality by holding a constant arc, tight kerf, and minimal bevel. For manual work, target 10–15 IPM; automated systems can exceed 100 IPM for productivity while maintaining consistency.

- Set baseline speed: 10–15 IPM for hand cutting; increase toward 100+ IPM on CNC when arc stability and consumables allow.

- Tie speed to amperage: e.g., ~30 A on 1/8 in aluminum supports moderate IPM; thicker sections at up to 100 A sustain higher IPM without widening HAZ.

- Monitor kerf: slow = dross/HAZ growth; fast = bevel, arc lag.

- Control standoff/voltage to stabilize bevel and maintain consistent cut quality.

Amps-To-Thickness Pairing

Two variables drive aluminum plasma results: amperage matched to thickness and the speed that amperage can sustain without inflating the HAZ.

You’ll set amperage by thickness first, then validate travel speed to maintain cut quality. As a baseline, target about 20 A for 1/8 in and 40 A for 1/4 in aluminum.

Because the amperage–thickness relationship is non-linear, thicker sections require disproportionately higher amperage adjustment to maintain energy density.

At the correct setting, aluminum favors higher speeds—typically 50–100 IPM depending on thickness and current.

If amperage is too low for the section, expect lagging kerf, bevel, and heavy dross. If it’s too high without matching speed, the HAZ widens and edge rounding increases.

Pair current and IPM empirically, then lock parameters.

Minimizing HAZ Width

With current matched to thickness, the next control lever for keeping the heat‑affected zone tight is speed.

You’ll drive HAZ reduction by holding aluminum cutting speeds in spec: 10–15 IPM for manual work; >100 IPM on CNC.

Pair that with maximum appropriate amperage to accelerate travel, cut dwell time, and limit heat soak.

Maintain consistent standoff to stabilize the arc column and avoid extra heat input.

Set pierce height at 1.5–2× cutting height to prevent overmelting.

- Target speed: 10–15 IPM (manual); >100 IPM (automated) for minimal HAZ.

- Use highest amperage suitable for thickness to raise speed and curb distortion.

- Keep standoff constant to control arc geometry and heat deposition.

- Apply correct pierce height (1.5–2×) as part of disciplined cutting techniques.

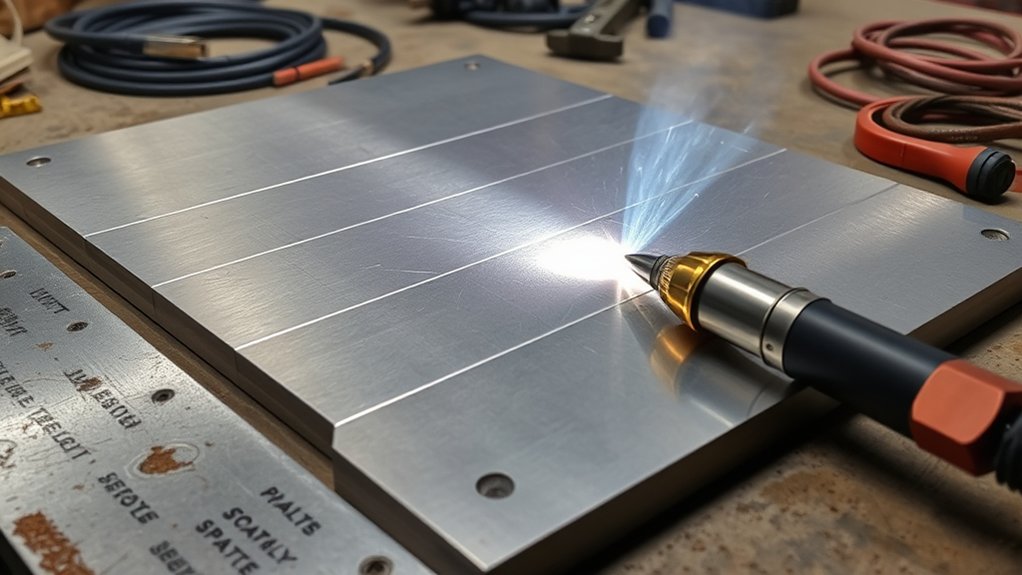

Voltage and Torch Height for Consistent Bevel

A stable arc voltage and precise torch-to-work standoff are the primary controls for a predictable bevel profile in aluminium. You’ll set torch voltage to regulate arc length; as voltage rises, bevel angle increases and edges become more angular.

Stable arc voltage and precise standoff govern aluminium bevels; higher voltage lengthens arc, steepening angle and sharpening edges.

To keep cut quality within spec, hold standoff to the machine’s nominal value (typically 1.5–2.0 mm for mechanized cutting) and verify it continuously.

Monitor bevel variation from heat distortion, warpage, and surface irregularities. These induce arc length changes that shift the bevel. Use a height control with real‑time voltage feedback; tools like the Beacon app can auto‑trim voltage to maintain the commanded standoff.

Log voltage setpoint, actual voltage, and standoff deviation; maintain ±1 V and ±0.2 mm where feasible.

Calibrate on each thickness: record voltage that yields target bevel, then lock limits to prevent drift.

Inspect kerf face angle and edge taper after test cuts and adjust voltage or standoff in small increments.

Pierce Height and Delay to Protect Consumables

For ideal pierce height, set 1.5–2.0× your cutting height to form a stable molten pit and prevent back-splash into the torch.

Then dial pierce delay to 0.19–0.24 s so the arc stabilizes before dropping to cut height, reducing consumable wear.

Adhering to these settings improves cut quality, extends torch life, and maintains process efficiency.

Optimal Pierce Height

Set pierce height at 1.5–2.0× the cut height to shield torch consumables from the molten pit and upward spatter during aluminum piercing.

You’ll reduce blowback, prevent nozzle erosion, and stabilize the arc before moving to the programmed cut height.

Calibrate by thickness: as material increases, scale pierce height proportionally to maintain clearance and protect wear parts while preserving cut quality and efficiency.

- Define baseline: cut height per manufacturer spec (e.g., 1.0–1.5 mm); set pierce height to 1.5–2.0× that value.

- Verify with test coupons; inspect nozzle orifice and shield for micro-pitting after 5–10 pierces.

- Monitor kerf geometry; excessive top bevel suggests pierce height too low, excessive crown indicates too high.

- Log thickness, pierce height, and wear intervals to standardize settings across jobs.

Dialing Pierce Delay

With pierce height established at 1.5–2.0× cut height, pair it with a pierce delay in the 0.19–0.24 s window to let the arc fully penetrate and stabilize before motion.

Use a disciplined pierce technique: command a stationary arc at pierce height, hold for the programmed delay, then shift to cut height and feed. This delay adjustment limits molten aluminum blowback, protects the nozzle and shield, and preserves tip geometry.

Calibrate by inspecting entry holes: undercut or bevel indicates a short delay; excessive spatter or a wide crater indicates an overly long delay.

Aim for a round, minimal-diameter pierce mark with no upward gusher. Validate settings across thicknesses and amperage changes, maintaining constant standoff.

Document delay versus thickness to standardize results and extend consumable life.

Kerf Width Compensation for Accurate Parts

Although the plasma arc removes a narrow swath of metal, you must explicitly compensate for that kerf to hold nominal dimensions on aluminum parts.

Apply kerf management in your CAM by offsetting the toolpath by half the measured kerf on each side to preserve cutting precision. Use the plasma kerf chart for aluminum to select a starting kerf value by alloy and thickness, then verify on test coupons with calibrated calipers and update your post settings.

- Measure: Cut a straight coupon, deburr, then mic the gap and part—record kerf to ±0.001 in (±0.025 mm).

- Offset: Program toolpath compensation (G41/G42 or CAM cutter comp) with the verified kerf; distinguish inside vs. outside profiles.

- Validate: Hold ±0.005 in (±0.13 mm) or tighter by inspecting critical features and adjusting comp values per thickness.

- Optimize: Nest parts with actual kerf to minimize webs and scrap, increasing sheet utilization.

Maintain a controlled, repeatable process: consistent amperage, feed, height, and nozzle condition guarantee kerf width remains stable between runs.

Gas Selection and Flow for Clean Aluminium Cuts

Even on a dialed‑in amperage/thickness pairing, gas chemistry and flow control govern aluminum cut quality. Choose nitrogen as the plasma gas: it limits oxidation and delivers smoother edges than air. Pair it with a shield stream—air works, but nitrogen shield gas in high‑definition torches lowers dross and improves angularity. Use a dual‑gas setup (plasma + shield) to stabilize the arc column and maintain cooling at higher cut speeds.

Control matters. Set and hold consistent flow rates; verify in slpm or scfh at standard conditions. Too low and you’ll see double‑arcing, top spatter, and uncut whiskers; too high and the arc destabilizes, widening kerf. Calibrate per manufacturer spec, leak‑test lines, and keep filters/dryers serviced to avoid moisture‑induced porosity.

| Gas types | Typical plasma flow (slpm/scfh) | Typical shield flow (slpm/scfh) |

|---|---|---|

| Nitrogen/Nitrogen | 120–170 / 250–360 | 70–110 / 150–230 |

| Nitrogen/Air | 120–170 / 250–360 | 80–120 / 170–255 |

| Air/Air (economy) | 130–180 / 275–380 | 80–120 / 170–255 |

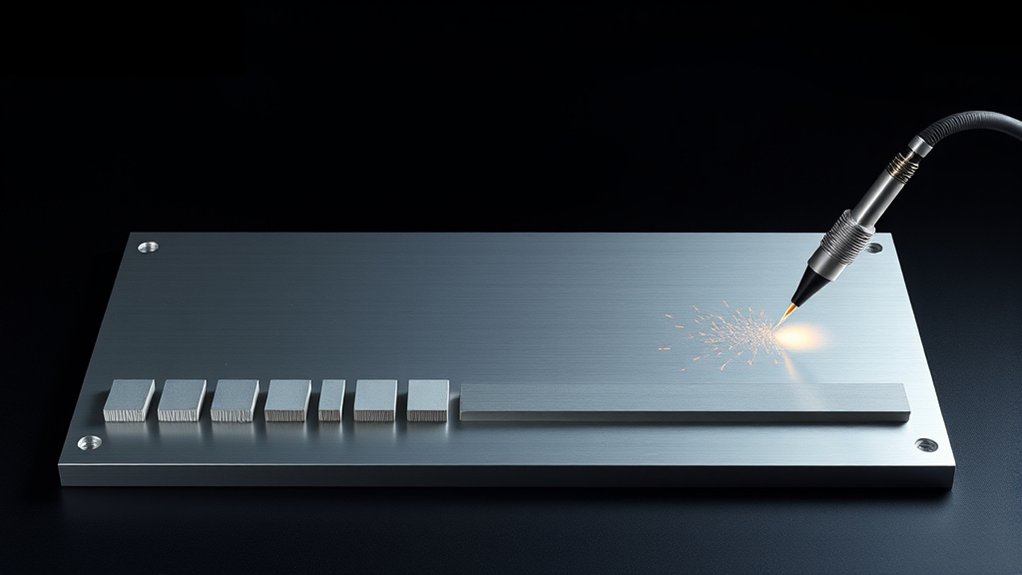

Sample Settings: Thin Sheet to Thick Plate

Gas control locked in, you can set amperage, speed, and heights to match aluminum thickness. Start with data-driven presets, then verify against your amp–thickness chart and machine manual. Match amps to material: thin sheet needs low current for a narrow kerf; thick plate needs higher current for penetration without over-melting.

Apply cutting techniques that stabilize arc length and honor safety precautions for glare, fumes, and hot slag.

1) 24 ga sheet (≈0.6 mm): 20–30 A, 60–100 IPM manual if stable, >100 IPM on cobot; cut height 0.060–0.080 in; pierce height 1.5–2× cut height.

2) 1/8 in (3 mm): 30–40 A, 30–60 IPM manual; consistent standoff; pierce 1.5–2×.

3) 1/4 in (6 mm): 40–50 A, 15–25 IPM manual; automated up to 60–80 IPM; pierce 1.5–2×.

4) 1/2 in (12 mm): 50–60 A, 10–15 IPM manual; assist gas stable; pierce 1.5–2×.

Validate with test coupons, observe kerf symmetry, and adjust amps or speed to prevent distortion or excessive melting.

Troubleshooting Cut Quality and Dross

When cut faces show dross, bevel, or striations, diagnose in order: amperage-to-thickness, gas flow, speed, and heights.

First, match current to the aluminum thickness per your amp–thickness chart. Underset current increases adhering dross; slight overset current often improves edge angularity and dross reduction.

Next, verify plasma gas flow against the torch’s specification. Low flow reduces arc energy density, raising dross and widening kerf.

Tune travel speed: slow passes overheat the edge and pile molten aluminum; excessive speed leaves uncut islands and severe striations. Target a stable, vertical drag line pattern with a modest lead angle.

Confirm pierce height at 1.5–2× cutting height to protect consumables and maintain consistent arc length; then set cutting height to the manufacturer’s standoff.

For aluminum, prioritize high-definition plasma with nitrogen plasma gas to increase arc constriction, improve cut efficiency, and minimize dross.

Document settings, measure edge bevel and roughness, and iterate one variable at a time.

Frequently Asked Questions

How Does Ambient Temperature Affect Aluminum Plasma Cutting Performance?

Ambient temperature shifts arc stability and gas density, so you’ll see measurable impacts on aluminum plasma cutting performance and cutting quality. You’ll adjust amperage, gas flow, and travel speed to maintain ISO 9013 tolerances, kerf width, and dross levels across temperatures.

What PPE Is Best for High-Reflectivity Aluminum Cutting?

You’ll wear flame-resistant PPE: leather cutting gloves, ANSI Z49.1-compliant jacket, NFPA 2112 hood, reflective goggles with IR/UV-rated shade per ANSI Z87.1, full-face shield, hearing protection (NRR≥25), respirator P100 for fumes, and metatarsal, EH-rated boots.

Can Power Supply Duty Cycle Limit Long Continuous Aluminum Cuts?

Yes. You’re limited by the power supply’s duty cycle; exceeding its rated percentage causes thermal shutdown or derating. For long aluminum cuts, size the machine for 100% duty cycle at required amperage per IEC/EN test standards.

How to Manage Aluminum Oxide Layer Without Chemical Pre-Cleaners?

You manage the oxide layer mechanically: use stainless wire brushing, Scotch-Brite, or light sanding, then wipe with deionized water. Example: before a 5083 weld per AWS D1.2, you performed Aluminum surface preparation using Oxide removal techniques, reducing porosity measurably.

Are There Safety Concerns With Aluminum Dust and Ventilation Requirements?

Yes. You face combustible aluminum dust hazards and respiratory risks. Use ventilation systems meeting NFPA 484/652 and ACGIH guidelines: capture velocities 0.5–1.5 m/s, explosion-rated ducting/collectors, HEPA filtration, bonding/grounding, housekeeping schedules, dust monitoring, and maintain oxygen below limiting oxidant concentration.

Conclusion

You’re the navigator, and amperage is your compass. When you match amps to thickness—30–40 A for ≤1/8 in, 50–60 A for 1/4 in, 70–80 A for 3/8–1/2 in—you trace a true line: minimal dross, controlled kerf, stable bevel. Keep travel speed, torch height, voltage, and gas flow inside spec, and the cut sings to standard. Miss the marks, and the metal blooms heat and error. Stay on chart—your parts stay on tolerance.