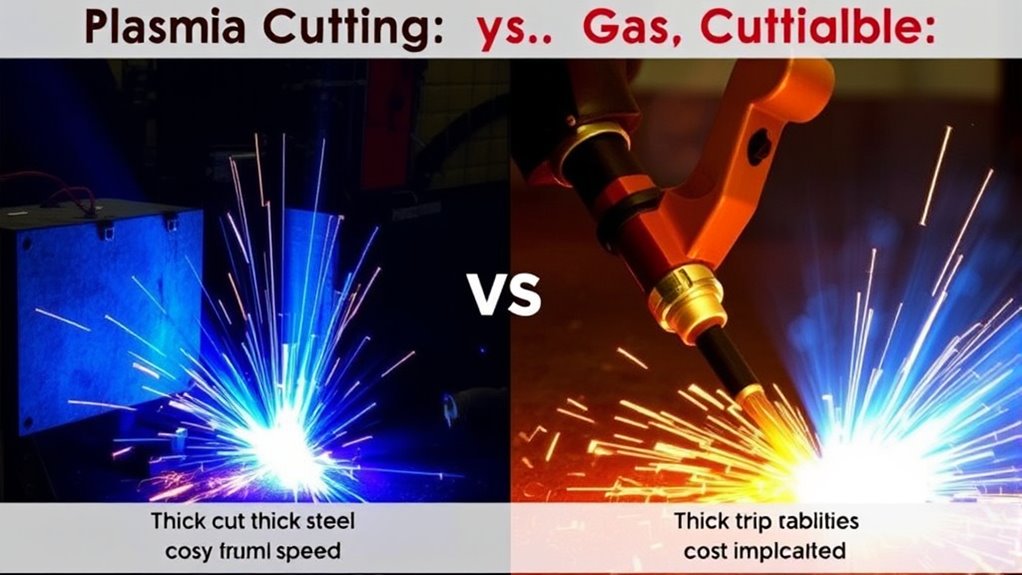

Imagine you’re a craftsman choosing between a scalpel and a saw. Plasma cutting, with its precision and speed, is akin to a scalpel, ideal for materials up to 2 inches thick, operating 5 to 6 times faster than oxy-fuel on thin carbon steel. But when tackling hefty ferrous metals, oxy-fuel’s saw-like ability cuts up to 24 inches. Each method’s cost-effectiveness hinges on specific project demands. Which tool aligns with your cutting needs?

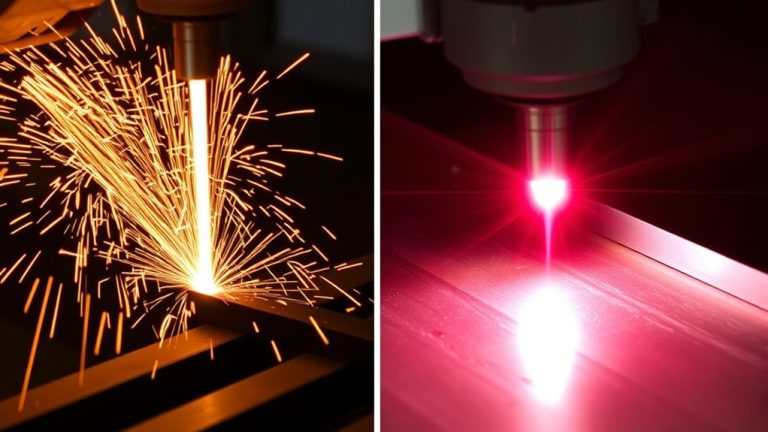

Understanding Plasma Cutting and Oxy-Fuel Cutting

When comparing plasma cutting and oxy-fuel cutting, it’s crucial to understand their fundamental differences and applications.

Plasma technology utilizes superheated, electrically ionized gas to reach cutting temperatures up to 2700°C, enabling it to slice through thin, electrically conductive metals with speed and precision, without the need for preheating. This method is particularly efficient for applications demanding high productivity and minimal thermal impact, as it operates 5 to 6 times faster than oxy-fuel cutting on thin carbon steel plates.

On the other hand, oxy-fuel cutting relies on gas combustion, where a flame generated by burning fuel gas, like acetylene, with oxygen, preheats the metal to its ignition temperature. This process is highly effective for cutting thick ferrous metals, reaching depths of up to 20 inches.

Despite higher initial costs, plasma cutting offers lower operational expenses due to reduced fuel usage and less slag, averaging 0.49 RMB per meter compared to oxy-fuel’s 0.91 RMB.

Comparing Cutting Thickness Capabilities

While exploring cutting thickness capabilities, it’s essential to distinguish between the strengths of plasma cutting and oxy-fuel cutting for various material thicknesses.

Understanding these capabilities is vital for selecting the right cutting applications based on material compatibility.

- Oxy-fuel cutting: This method excels in cutting ferrous steels up to 24 inches thick, making it indispensable for heavy-duty applications requiring substantial material thickness.

- Plasma cutting: Ideal for materials up to 2 inches thick, it’s particularly effective with non-ferrous metals like aluminum and stainless steel, ensuring precise cuts with minimal distortion.

- Carbon steel plates (1-to-2-inch range): Both cutting methods are viable, but plasma cutting offers faster speeds and cleaner edges, enhancing productivity and end-product quality.

- Versatility with thin materials: Automated plasma systems outperform oxy-fuel systems, cutting 1-inch thick steel at speeds 2 to 4 times faster, thereby boosting efficiency for thinner materials.

Selecting the appropriate method hinges on material thickness and desired outcomes.

Evaluating Cutting Speed and Efficiency

After examining cutting thickness capabilities, it’s important to assess how cutting speed and efficiency play a role in choosing between plasma and gas cutting methods.

Plasma cutting impressively outpaces oxy-fuel cutting, especially with thinner material types. For mild steel plates under 2 inches, plasma cutting operates at speeds 5 to 6 times faster, enhancing productivity considerably. This method also offers superior cutting precision, producing smoother edges with minimal thermal distortion, reducing the need for additional finishing processes.

However, as material thickness increases, plasma’s speed advantage decreases, making oxy-fuel cutting a viable choice for thicker ferrous metals, handling up to 24 inches.

Despite this, plasma’s efficiency with thinner materials can’t be overlooked, as it minimizes downtime and accelerates project timelines.

When evaluating these methods, consider both the cutting precision required and the specific material types involved to maximize efficiency in your cutting processes.

Analyzing Cost Implications and Operational Expenses

Considering the cost implications and operational expenses, it’s crucial to weigh the long-term financial impact of plasma versus gas cutting systems.

In operational budgeting, the hidden costs of each method can influence decision-making. Plasma cutting, despite its higher initial investment, offers lower consumable expenses at 0.49 RMB per meter. In contrast, oxyacetylene costs 0.91 RMB per meter due to ongoing fuel needs.

- Initial Costs: CNC plasma machines are pricier upfront, whereas oxy-fuel systems are cheaper but incur higher fuel expenses.

- Operational Speed: Plasma’s faster cutting speed, especially on materials up to 1-inch thick, reduces operational costs through increased productivity.

- Waste Management: Plasma cutting’s efficiency results in less waste, minimizing cleanup costs.

- Material Specificity: The cost-effectiveness varies; plasma is ideal for thin materials, while oxy-fuel is suitable for thicker metals.

Effective expense tracking helps optimize your cutting operations based on these factors.

Determining the Best Choice for Your Needs

How do you determine the best cutting method for your specific needs? You’ll want to weigh material compatibility and application suitability. If you’re working with non-ferrous metals or need precision on stainless steel, plasma cutting’s speed—up to four times faster on 1-inch materials—will boost productivity. However, for heavy-duty operations, oxy-fuel cutting shines by cleanly slicing through thick carbon steel up to 24 inches.

Consider cost implications: plasma cutting’s average operational cost is lower at 0.49 RMB per meter, whereas oxy-fuel climbs to 0.91 RMB due to fuel expenses. Also, factor in cleanup time; plasma is less demanding, producing minimal slag. Here’s a breakdown:

| Criteria | Plasma Cutting | Oxy-Fuel Cutting |

|---|---|---|

| Material Compatibility | Non-ferrous, Stainless | Thick Carbon Steel |

| Speed | 2-4x faster on 1-inch | Slower on thinner metals |

| Cost | 0.49 RMB/m | 0.91 RMB/m |

| Cleanup | Minimal slag | Significant slag |

Evaluate these aspects to make an informed decision.

Frequently Asked Questions

What Safety Precautions Are Necessary for Plasma and Oxy-Fuel Cutting?

Wear protective gear like gloves and goggles to shield yourself. Always inspect equipment for leaks to prevent fire hazards. Ascertain proper ventilation, maintain a clean workspace, and keep a fire extinguisher nearby for immediate response to emergencies.

Can Plasma or Oxy-Fuel Cutting Be Automated for Industrial Applications?

Yes, you can automate both plasma and oxy-fuel cutting for industrial applications, enhancing efficiency. Automation benefits include consistent quality, reduced labor costs, and increased throughput. Analyze machinery compatibility and software integration to maximize your industrial efficiency.

How Do Environmental Factors Affect Plasma and Oxy-Fuel Cutting Performance?

You’d think temperature fluctuation effects and humidity impact would enhance cutting performance, right? Instead, they ironically hinder it, causing inconsistent arcs and oxidation issues. Maintaining stable conditions guarantees precision and efficiency, despite environmental challenges.

What Maintenance Is Required for Plasma and Oxy-Fuel Cutting Equipment?

You’ll need to regularly inspect and replace electrodes in plasma cutters, while ensuring nozzle cleaning with each use. For oxy-fuel systems, check hoses and connections frequently, maintaining tip cleanliness for ideal cut quality and equipment longevity.

Are There Differences in Edge Quality Between Plasma and Oxy-Fuel Cuts?

When comparing plasma and oxy-fuel cuts, you’ll find plasma cutting offers superior edge smoothness and cut precision, reminiscent of a knight’s blade. Plasma delivers cleaner, more precise edges, while oxy-fuel often results in rougher, less defined edges.

Conclusion

When choosing between plasma cutting and oxy-fuel cutting, consider the project’s unique demands. Plasma cutting shines with materials up to 2 inches thick, boasting unmatched speed and precision, consequently gently nudging operational costs downward. Meanwhile, oxy-fuel cutting steps up for thicker ferrous metals, though it may whisper higher fuel expenses. Ultimately, your decision should delicately balance material thickness, desired efficiency, and budgetary considerations to achieve an ideal cutting solution tailored to your specific needs.