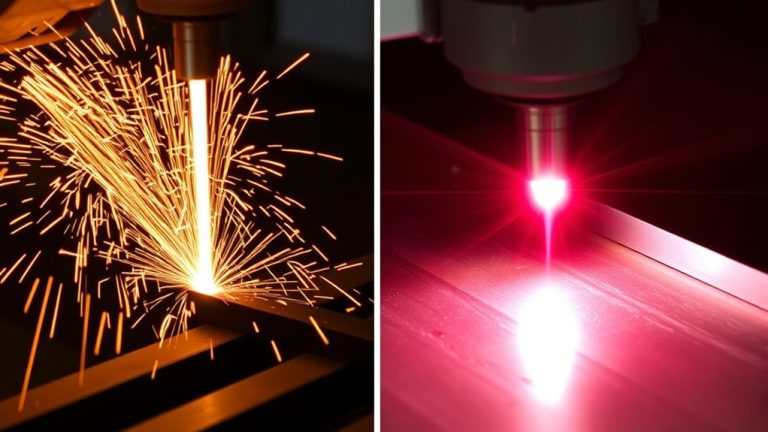

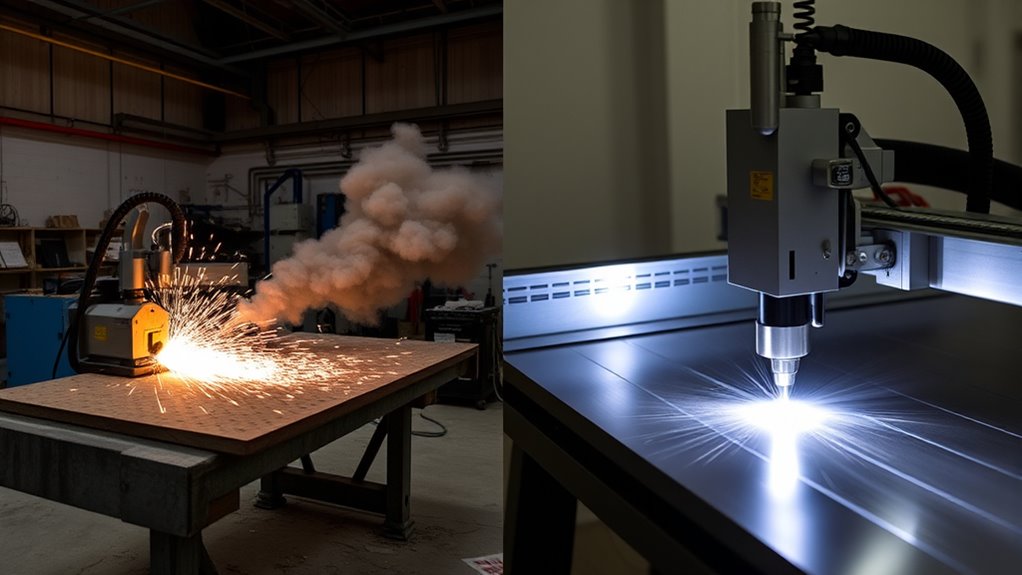

When deciding between plasma and laser cutting, it’s essential to understand their fundamental differences. Plasma cutting excels with thicker, conductive materials, offering a lower initial cost but sacrificing precision and producing more waste. Laser cutting, on the other hand, is renowned for its accuracy and clean edges, ideal for detailed designs but limited to thinner materials and requiring a higher investment. How do these factors influence your project requirements?

Understanding Laser Cutting

When it comes to precision cutting, understanding laser cutting is essential for leveraging its full potential.

Laser cutting techniques utilize a concentrated beam of light to quickly heat, melt, and vaporize materials, delivering precise edge cuts without burrs. This method is versatile, capable of cutting metals, plastics, wood, and ceramics, making it suitable for various laser cutting applications. High-powered computer guidance enables intricate designs with tolerances as low as ±0.003 mm, allowing you to achieve exceptional detail and precision.

Utilize laser cutting for precise, burr-free edges and intricate designs across various materials with exceptional detail.

Despite its efficiency, laser cutting has limitations. It’s generally effective for materials up to 19 mm thick, making it less suitable for very thick sections.

Additionally, the initial investment is substantial, with system costs ranging from $50,000 to $500,000. However, the precision and versatility offered by laser cutting techniques can outweigh these limitations for applications demanding high accuracy and intricate detailing across diverse materials.

Understanding Plasma Cutting

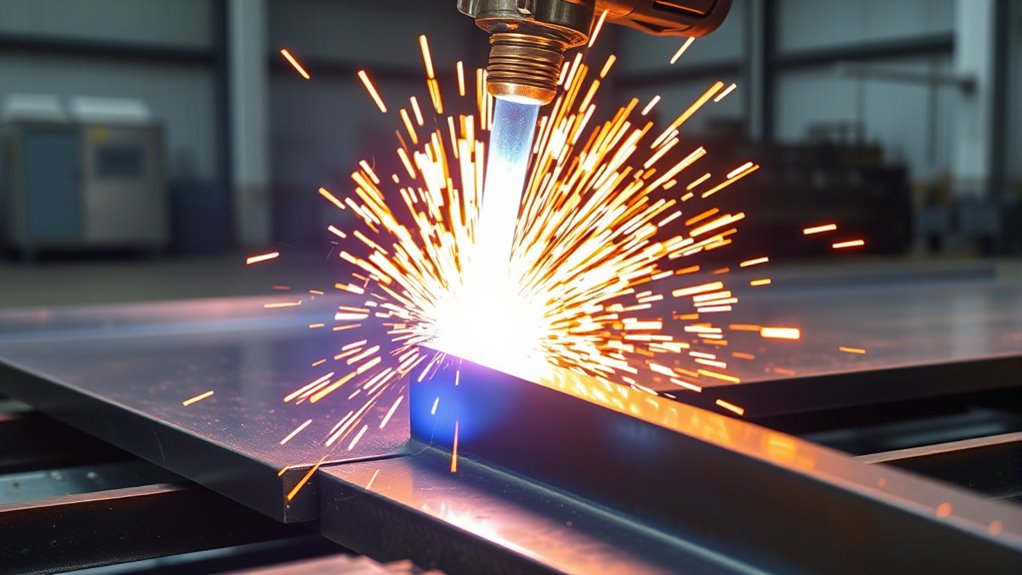

While laser cutting offers unparalleled precision for intricate designs, plasma cutting emerges as a robust alternative, especially for thicker materials. Plasma cutting utilizes plasma properties to achieve temperatures up to 20,000°C, efficiently slicing through conductive materials like steel, aluminum, and copper.

The cutting techniques involve a plasma torch that generates a high-velocity arc, allowing you to handle materials up to 38 mm thick—perfect for heavy-duty applications.

You can engage in plasma cutting using handheld torches for flexible manual tasks or automated CNC systems for enhanced precision and speed in industrial settings.

Although the kerf size is larger than that of laser cutting, plasma cutting delivers faster speeds for thicker materials. This method is more cost-effective with regard to initial investment and operational costs.

However, it produces more cutting slag, requiring additional cleanup. Consequently, plasma cutting is ideal when speed and material thickness outweigh precision needs.

Advantages of Laser Cutting

When considering laser cutting, you’ll find its precision and accuracy are unmatched, with tolerances as tight as ±0.003 mm, making it perfect for intricate designs and micro-components.

This method’s versatility extends across a diverse range of materials, from metals to ceramics, offering broad application potential.

Precision and Accuracy

Laser cutting stands out for its exceptional precision and accuracy, offering tolerances as tight as ±0.003 mm. This capability is essential for projects requiring stringent cutting tolerances and design intricacy.

Laser technology enables the production of highly detailed components with narrow kerfs, ensuring minimal material wastage and clean edges. Unlike plasma cutting, laser cutting excels at delivering complex contour cuts and intricate engravings, making it indispensable for applications demanding precision.

The process’s efficiency also reduces the likelihood of errors, further enhancing the quality of the final product. Its energy-efficient operation supports faster processing times, particularly with thinner materials, thereby boosting productivity.

This makes laser cutting a superior choice when precision is non-negotiable in your manufacturing processes.

Material Versatility

Given its unparalleled material versatility, laser cutting emerges as a top choice for diverse manufacturing needs. You’ll find it offers exceptional material adaptability, efficiently handling metals, wood, plastics, and ceramics. This flexibility makes laser cutting suitable for a broad spectrum of cutting applications.

Unlike plasma cutting, which restricts you to electrically conductive materials, laser technology expands your options to both conductive and non-conductive materials, greatly broadening its usability.

The precision inherent in laser cutting enables intricate designs and fine details, essential for fields like electronics, aerospace, and automotive manufacturing. You’ll appreciate the smoother, cleaner edges it produces, reducing post-processing requirements.

Furthermore, its energy-efficient nature often means consuming less power than plasma systems while delivering high-quality cuts across various material types.

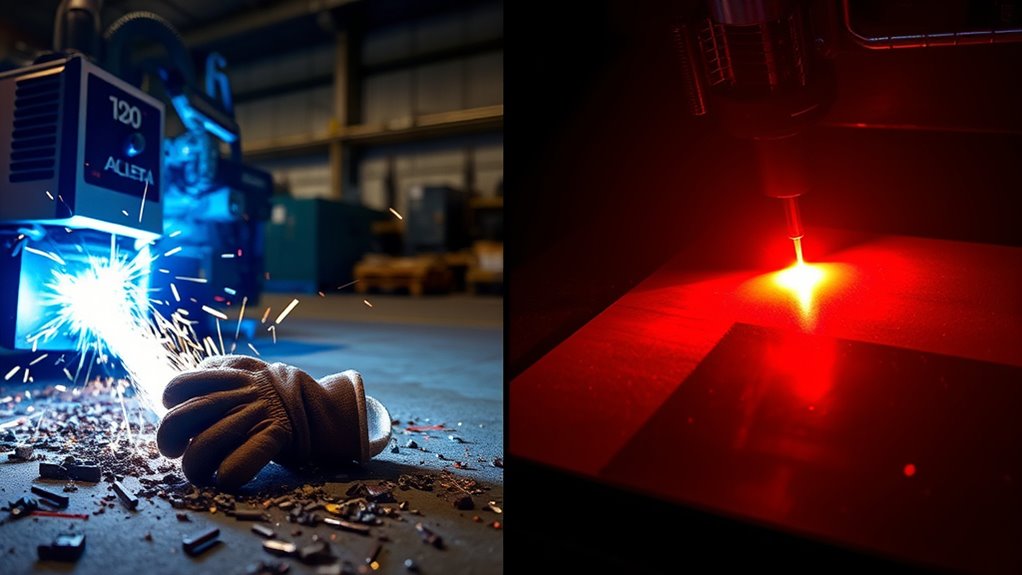

Disadvantages of Laser Cutting

Although laser cutting is a highly precise and versatile technology, it does come with several disadvantages that you should consider.

Operational challenges arise when working with highly reflective materials like copper and brass, as lasers struggle to cut these effectively, leading to inefficiencies. Furthermore, laser cutting typically accommodates material thicknesses only up to 19 mm, making it unsuitable for thicker applications.

Safety risks are another concern. Cutting certain materials, such as PVC, releases toxic fumes, which necessitate additional safety measures to protect operators and maintain a safe working environment.

Additionally, the high capital investment required for laser cutting systems, ranging from $50,000 to $500,000, is substantial compared to plasma cutting options. This significant financial outlay, coupled with demanding maintenance requirements, leads to increased operational costs over time.

These factors combined can impact your decision if cost-effectiveness and versatility across material types and thicknesses are critical to your operations.

Advantages of Plasma Cutting

When considering plasma cutting for your industrial needs, you’ll appreciate its ability to efficiently handle materials up to 38 mm thick, making it ideal for heavy-duty applications.

Its cost-effectiveness stems from lower initial investment and operational costs, allowing you to maximize budgetary constraints without sacrificing performance.

Furthermore, its versatility in cutting various electrically conductive materials, such as steel and aluminum, guarantees broad applicability across metalwork projects.

Efficient Thick Material Cutting

If you need to cut through thick materials efficiently, plasma cutting stands out as a superior choice. Its thick material efficiency is unrivaled, enabling you to slice through metals up to 38 mm thick. This capability is essential for heavy-duty applications in construction and manufacturing.

When considering cutting speed comparison, plasma cutting often surpasses laser cutting for thicker sections, thanks to its rapid generation of high-temperature plasma via an electric arc. This results in faster processing times and increased productivity.

Consider these advantages:

- Efficient Thickness Handling: Capable of cutting up to 38 mm thick metals.

- Speed Advantage: Outpaces laser cutting in thicker materials.

- Broad Metal Compatibility: Works with steel, stainless steel, aluminum, and copper.

- Reduced Thermal Distortion: Large heat-affected zone minimizes thermal distortion risks.

Cost-Effective for Metalwork

Plasma cutting offers significant cost-effective advantages for metalwork, making it an attractive option for many operations. When you conduct a cost comparison, you’ll notice plasma systems require a lower initial investment, typically between $5,000 and $20,000. In contrast, laser systems can range from $50,000 to $500,000. This substantial difference aligns plasma cutting with budget considerations, particularly for small to medium-sized operations.

Operational costs also favor plasma cutting, particularly for materials up to 38 mm thick. Its faster cutting speeds and reduced energy consumption translate into savings.

Additionally, plasma cutting’s simplicity means easier maintenance without needing specialized technicians, further reducing costs. With its minimal heat-affected zones, plasma cutting maintains material integrity, preventing warping and ensuring quality outcomes.

Versatile Material Applications

Having highlighted the cost-effectiveness of plasma cutting for metalwork, it’s important to evaluate its versatility in material applications.

Plasma cutting excels across a broad spectrum of materials, setting it apart from laser applications. Here’s how:

- Material Variety: Plasma applications are effective for cutting steel, stainless steel, aluminum, and copper, addressing diverse industrial needs.

- Thickness Capability: With the ability to cut materials up to 38 mm (1.5 inches) thick, plasma is ideal for heavy-duty manufacturing.

- Speed Efficiency: High cutting speeds on thicker plates streamline production for time-sensitive projects, enhancing operational efficiency.

- Reflectivity Tolerance: Unlike laser applications, plasma is less affected by material reflectivity, allowing efficient cutting of reflective metals without compromise.

These factors guarantee versatility and adaptability in industry applications.

Disadvantages of Plasma Cutting

While plasma cutting offers several advantages, it also comes with notable disadvantages that can impact its suitability for certain applications.

One key issue is its cutting efficiency, which is hampered by material limitations. Plasma cutting is restricted to electrically conductive materials, such as metals, leaving non-conductive materials like wood and plastics out of reach. This limitation narrows its application scope considerably.

Plasma cutting’s efficiency is limited to conductive metals, excluding non-conductive materials like wood and plastics.

Furthermore, plasma cutting produces a larger kerf size, leading to decreased accuracy compared to laser cutting, which boasts tolerances as tight as ±0.1 mm. This can be a critical factor if precision is paramount in your project.

The process also generates a considerable amount of cutting slag, necessitating additional cleanup and post-processing.

Additionally, the larger heat-affected zone (HAZ) can cause thermal damage to surrounding areas, altering the material properties.

Finally, plasma cutting lacks engraving capabilities, restricting its use for intricate designs or detailed markings.

Choosing the Right Cutting Method for Your Needs

Understanding the limitations of plasma cutting is important, but equally essential is selecting the right cutting method for your specific needs.

Evaluate cutting techniques based on your project requirements to maximize efficiency and quality. Consider these critical factors:

- Material Thickness: Plasma cutting excels with thicker materials (up to 38 mm), while laser cutting offers precision with tolerances as tight as ±0.003 mm.

- Design Complexity: Opt for laser cutting if intricate designs and clean edges are paramount, as it delivers smooth, burr-free finishes compared to plasma’s rougher edges.

- Cost Efficiency: Plasma cutting is more cost-effective for thick cuts due to lower initial investment and operational costs, whereas laser cutting involves higher capital and maintenance expenses.

- Material Type: Laser cutting accommodates a wider range of materials, including non-conductive surfaces, while plasma cutting is limited to electrically conductive materials.

Carefully matching your cutting techniques to these factors guarantees ideal results for your project.

Frequently Asked Questions

How Do Maintenance Costs Compare for Plasma and Laser Cutting Machines?

You’ll find laser cutting machines generally require less frequent maintenance, translating to higher maintenance efficiency. However, a detailed cost analysis reveals laser equipment parts are pricier, potentially increasing overall costs compared to typically cheaper plasma machine maintenance.

Can Plasma or Laser Cutting Be Used for Non-Metal Materials?

Yes, you can use laser cutting for non-metal materials like wood, plastic, and acrylic due to laser applications’ precision. Plasma applications are primarily for metals, as it lacks the finesse required for non-metal materials.

What Safety Precautions Are Necessary for Plasma and Laser Cutting?

Better safe than sorry: when handling plasma and laser cutting, you must wear appropriate safety gear and complete thorough operator training. Make certain your workspace is well-ventilated and follow all safety protocols to minimize risks effectively.

How Does the Energy Consumption Differ Between Plasma and Laser Cutting?

You’ll find that laser cutting generally boasts higher energy efficiency compared to plasma cutting. Laser cutting requires less power due to its precision, while plasma cutting demands greater power requirements, leading to increased energy consumption.

Are There Environmental Impacts Unique to Plasma or Laser Cutting?

Ironically, you’re thinking plasma cutting’s emissions might improve air quality. In reality, it produces harmful gases. Laser cutting’s precision minimizes waste, but its energy demand complicates waste management. Both impact the environment differently, demanding careful analysis.

Conclusion

Imagine guiding a precision laser through delicate lace, its path illuminated by a focused beam, crafting intricate patterns with immaculate edges. Contrast this with the raw power of plasma, slicing through thick steel like a hot knife through butter, sparks dancing in the air. Each method, with its own strengths and limitations, is like a tool in your arsenal. Weigh your project’s demands carefully, balancing precision against power, to choose the cutting method that fits your needs best.