Consider a craftsman deciding between a torch and a laser for precision work; this choice mirrors the decision between plasma and oxy-acetylene cutting. When safety is your priority, plasma cutting offers reduced explosion risks and less smoke exposure. With regard to speed, plasma outpaces oxy-fuel, particularly on thicker materials. Initial costs and ongoing expenses also lean in favor of plasma. Explore how these differences can impact your operation’s efficiency and bottom line.

Key Differences in Safety

When considering the safety aspects of plasma and oxy-acetylene cutting, you’ll find that plasma cutting stands out as the safer option due to its avoidance of explosive gases and open flames.

By eliminating the use of combustible gases, plasma cutting reduces explosion hazards, an important factor in any hazard assessment. This method also minimizes the heat-affected zone (HAZ), decreasing the risk of warping and burns, essential for safety protocols, especially when cutting thinner materials.

Plasma cutting reduces explosion risks and minimizes heat-affected zones, enhancing safety when cutting materials.

Moreover, plasma cutting generates less smoke and fumes, which leads to improved air quality and a reduction in respiratory hazards. This cleaner operation results in less harmful waste, contributing to a safer workplace environment.

It’s important to implement proper ventilation and use respiratory protection, but with plasma cutting’s reduced fume output, these safety measures are more effective. Consequently, plasma cutting’s inherent safety advantages make it the preferred choice for maintaining a secure working environment.

Analyzing Cutting Speed

When you’re analyzing cutting speed, plasma cutters offer a clear advantage with their ability to cut 1/2-inch steel at speeds up to 80 inches per minute, far surpassing the 8-10 inches per minute typically achieved by oxy-fuel systems on 2-inch plates.

Plasma technology not only excels with thinner materials but also maintains efficiency on thicker materials through higher-amperage machines.

Keep in mind, oxy-fuel requires a preheat phase, adding time and complexity, which could impact both productivity and safety considerations in your operations.

Plasma Cutter Speed

Although both plasma cutters and oxy-acetylene torches have their places in metal cutting, plasma cutters excel when it comes to speed, particularly with thinner materials. With cutting speeds reaching up to 80 inches per minute on 1/2-inch steel, plasma cutting offers significant speed advantages. The efficiency grows with thinner materials, being 2 to 4 times faster than oxy-fuel at 1-inch thickness. High-amperage plasma systems maintain rapid speeds even on thicker metals, ensuring consistent efficiency. Additionally, plasma cutting minimizes the heat-affected zone, reducing distortion and eliminating the slow preheating step required by oxy-fuel.

| Material Thickness | Plasma Cutting Speed |

|---|---|

| 1/2-inch Steel | 80 inches/minute |

| 1-inch Steel | 2-4x Faster |

| 2-inch Steel | Consistent Speed |

| Thinner Materials | Maximum Efficiency |

| HAZ Impact | Minimized |

Oxy-Fuel Cutting Speed

While plasma cutters offer speed advantages, especially on thinner materials, oxy-fuel cutting provides a different set of strengths.

In oxy fuel applications, you’re dealing with thicker ferrous metals where the process truly excels. Although it operates at a slower rate, typically 8-10 inches per minute for 2-inch thick steel, it can handle materials up to 20 inches thick. This capability is unmatched in certain industrial settings, despite the slower speed.

However, be aware that the kerf width ranges from 1/8 to 3/16 inches, leading to more material waste and additional cleanup. Preheating the metal to its ignition temperature is necessary, adding to the total cutting time.

Yet, for specific applications, these trade-offs might be justified by the robust capabilities offered.

Speed Efficiency Comparison

Plasma cutting stands out for its speed efficiency, particularly on thinner materials, making it a superior choice for projects demanding rapid throughput.

You’ll find that plasma advantages include cutting speeds of 80 inches per minute on 1/2-inch steel, far surpassing the 8-10 inches per minute achieved by oxy-fuel on 2-inch plates.

As metal thickness decreases, plasma’s speed advantage widens, being 2 to 4 times faster than oxy-fuel at 1-inch thickness.

Oxy fuel limitations are evident as it requires preheating, adding time. Plasma eliminates this step, enhancing speed efficiency.

While both methods perform comparably on 1-to-2-inch ferrous metals, plasma consistently delivers cleaner cuts with minimal slag, reducing the need for secondary operations and boosting overall efficiency and safety.

Evaluating Initial Costs

When evaluating the initial costs of cutting systems, it’s important to contemplate the differences between plasma and oxy-acetylene options.

Conducting an initial investment comparison reveals that professional-grade oxy-fuel cutting torches typically range from $800 to $1,200, positioning them as a more accessible choice for entry-level users. In contrast, plasma cutters demand a higher initial outlay. Entry-level models start at $500 to $1,000, but mid-range plasma cutters can cost between $1,500 and $3,000, with high-end and CNC systems reaching $5,000 to over $30,000.

In a cost benefit analysis, you must weigh these upfront costs against the systems’ capabilities and your specific needs. While oxy-fuel systems offer lower initial costs, remember they involve ongoing gas expenses.

Plasma systems, although pricier, boast faster cutting speeds, which may justify their initial investment through time savings and increased productivity.

Prioritize safety and evaluate which system best aligns with your operational requirements.

Understanding Ongoing Expenses

When analyzing ongoing expenses, consider the costs associated with gas refills and consumables, as they greatly impact oxy-fuel cutting systems.

Plasma cutters, in contrast, rely mainly on electricity, requiring less frequent consumable replacements, consequently offering a cost-efficient alternative for high-demand operations.

Gas and Consumable Costs

Understanding the gas and consumable costs of cutting systems is essential for managing ongoing expenses effectively. For oxy-fuel systems, gas pricing can fluctuate, impacting your cost management strategy.

You’ll need to account for frequent oxygen and fuel gas refills, which vary with local market rates. Additionally, consumable lifespan plays a role in your expenses, as oxy-fuel torch tips cost between $5 and $15 each, requiring regular replacements.

In contrast, while plasma cutters have a higher initial investment, they rely less on gas, reducing ongoing costs.

Instead, you must consider the price of consumables like electrodes and nozzles, which range from $20 to $100 per set. Despite higher consumable costs, plasma’s faster cutting speeds can offer long-term savings in high-volume scenarios.

Electricity and Maintenance

Although plasma cutters demand a higher electricity input, their efficiency can justify the expense in many applications. Small models consume 15-40 amps, while larger units require 220/240V power and draw 50-100 amps. This electricity consumption is significant but offset by reduced maintenance frequency.

Plasma systems have fewer moving parts, translating to less frequent maintenance and lower downtime. Consumables like electrodes and nozzles, priced from $20 to $100 per set, also contribute to ongoing costs but don’t require constant replacement.

In contrast, oxy-fuel systems incur expenses for refilling gas cylinders and replacing torch tips, ranging from $5 to $15 each. This makes plasma systems, despite higher initial costs, a viable option for operations prioritizing cost-efficiency and reliability.

Efficiency and Productivity

Switching focus from electricity and maintenance, let’s explore how efficiency and productivity impact ongoing expenses in plasma and oxy-acetylene systems.

Plasma cutters, with advanced cutting techniques, offer significant operational advantages by minimizing ongoing costs. They rely solely on electricity and compressed air, unlike oxy-acetylene systems, which demand continuous gas cylinder refills.

While plasma cutting consumables can range from $20 to $100 per set, oxy-fuel tips are cheaper but accumulate due to frequent replacements.

Plasma systems excel with thinner materials, enhancing efficiency and reducing waste, thereby eliminating the need for costly secondary operations. Despite higher initial costs, their faster cutting speeds boost productivity, offsetting initial investments.

Oxy-fuel systems, while less expensive upfront, face escalating expenses, particularly in high-volume applications, reducing long-term cost-effectiveness.

Comparing Metal Cutting Capabilities

When comparing the metal cutting capabilities of plasma and oxy-acetylene systems, it’s crucial to evaluate the types of materials each method can handle.

For cutting applications involving diverse materials, plasma cutting stands out due to its material compatibility with a wide range, including aluminum and stainless steel. Oxy-acetylene is limited to ferrous metals, making it less versatile.

Plasma cutters excel in handling thicknesses up to 1 inch, providing rapid operation without preheating, which enhances efficiency, especially on thinner materials.

In contrast, oxy-fuel systems can tackle thicker ferrous metals up to 20 inches, but require preheating, slowing down the process.

Speed is another factor; plasma cutters slice through 1/2-inch steel at approximately 80 inches per minute, considerably faster than oxy-fuel’s 8-10 inches for 2-inch plates.

Plasma’s narrower kerf results in cleaner cuts, while oxy-fuel cutting often produces rougher edges, impacting your finished product’s quality.

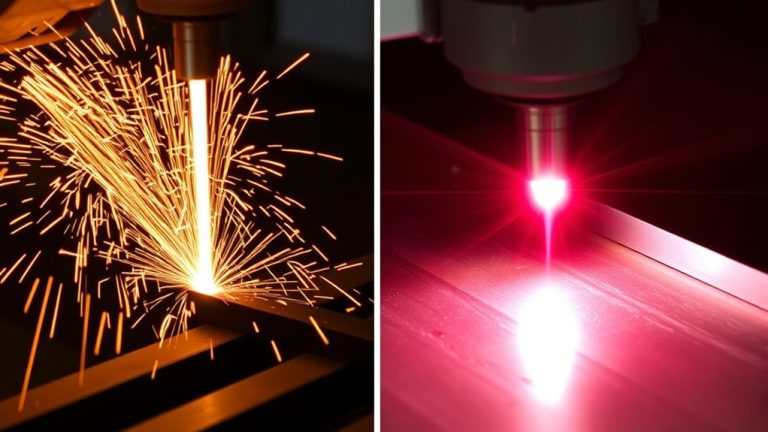

Precision and Cut Quality

While precision and cut quality are essential in metalworking, plasma cutters offer distinct advantages over oxy-acetylene systems. With plasma, you achieve superior cutting accuracy due to narrower kerfs, ranging from 1/16 to 1/8 inches. This precision is vital for intricate designs and complex shapes.

Plasma cutters provide superior cutting accuracy with narrower kerfs, essential for intricate and complex metalworking designs.

In contrast, oxy-acetylene torches produce wider kerfs, limiting your ability to make detailed cuts.

The heat-affected zone (HAZ) is another vital factor. Plasma cutting minimizes HAZ, reducing the risk of warping, especially on thin material thicknesses.

Oxy-fuel cutting, however, has a larger HAZ that can lead to material distortion.

Additionally, plasma cutting yields cleaner cuts with minimal slag and dross, reducing the need for secondary operations. This efficiency enhances productivity, especially since plasma cutting is 2 to 4 times faster than oxy-fuel at 1-inch thickness.

Your final product benefits from these advantages, offering high fidelity and quality with less post-processing.

Setup and Operation Time

Although both plasma and oxy-acetylene systems are effective in metal cutting, plasma cutters offer a significant advantage in setup and operation time. You can connect a plasma cutter’s power and air in less than a minute, showcasing its setup efficiency.

In contrast, an oxy-acetylene system demands 3-5 minutes for gas adjustments and flame tuning. Plasma systems are also typically lighter, weighing under 50 pounds, which boosts their operation simplicity and ease of handling.

Learning to operate a plasma cutter is straightforward; most new users can achieve operational proficiency within hours. This is due to its simple setup, requiring only a power source and compressed air.

Oxy-fuel cutting, on the other hand, involves managing gas tanks and precise flame adjustments, increasing complexity. Additionally, plasma cutters eliminate the need for preheating metal, reducing time. This efficient approach means you spend less time preparing and more time cutting.

Portability and Power Requirements

Plasma cutters stand out regarding portability and power requirements, offering a distinct advantage for those frequently on the move. Weighing around 20 pounds, these tools are designed for easy transportation to various job sites. Their compact size enhances mobility advantages, making them an excellent choice for professionals who need to move quickly between locations.

However, plasma cutters do require an electrical power source and compressed air to operate. This means you’ll need access to electricity, which could limit usage in remote areas without power.

In contrast, oxy-acetylene systems rely solely on gas tanks, making them power-independent and suitable for isolated environments.

While oxy-fuel setups are highly portable due to their gas cylinder reliance, they’re generally bulkier and require more setup time. Plasma cutters, on the other hand, connect to power and air in under a minute, streamlining operations while prioritizing safety and efficiency.

Choosing the Right Tool for Your Needs

When should you choose a plasma cutter over an oxy-acetylene system? Your tool selection should align with your specific application needs. If you’re working with thin to medium metals and require high-speed precision, a plasma cutter is ideal. It can cut at speeds up to 80 inches per minute without the need for preheating, and it delivers cleaner cuts with a narrower kerf, minimizing the heat-affected zone—important for preventing warping.

However, if your projects involve cutting ferrous metals up to 20 inches thick, an oxy-acetylene system is more suitable despite its slower speed and preheating requirement.

Cost considerations also play a role; although oxy-fuel systems have lower initial costs, ongoing expenses for gas refills can add up. Conversely, plasma cutters need only electricity and compressed air.

Evaluate whether the precision, speed, or material thickness aligns with your needs to make the best tool selection.

Frequently Asked Questions

Can Plasma Cutting Be Used Underwater?

Yes, you can use plasma cutting underwater. It’s efficient for underwater applications, offering precise cuts and maintaining plasma efficiency. Guarantee safety by using proper equipment, grounding techniques, and following protocols to mitigate risks associated with underwater operations.

Is Oxy-Acetylene Suitable for Cutting Non-Metal Materials?

Oxy-acetylene’s limitations in cutting non-metal materials make it as useful as a chocolate teapot. Consider alternative cutting methods for non-metals, prioritizing safety and efficiency, since oxy-acetylene’s high temperatures aren’t suitable for such tasks.

How Does Weather Affect Plasma Cutting Performance?

Temperature fluctuations and humidity levels can impact plasma cutting by affecting arc stability and cut quality. Guarantee ideal conditions by monitoring weather changes and adjusting equipment settings to maintain consistent performance and safety in varying environments.

What Are Common Maintenance Issues for Oxy-Acetylene Equipment?

Imagine a well-oiled machine, but with oxy-acetylene, leaks can spring like hidden snakes. Regularly inspect hoses for leaks and check for equipment wear. Prioritize safety by maintaining seals and connections to prevent accidents and guarantee peak performance.

Are There Environmental Impacts of Each Cutting Method?

Both plasma and oxy-acetylene cutting methods impact the environment. You’ll need to take into account environmental regulations as plasma cutting generates fewer emissions. However, oxy-acetylene can release harmful gases, requiring stricter adherence to cutting emissions guidelines for safety.

Conclusion

Coincidentally, when you weigh safety, speed, and cost, plasma cutting aligns perfectly with modern industrial needs. It not only reduces explosion hazards but also accelerates your workflow, operating up to four times faster on thick materials. While initially more economical, plasma cutting’s reliance on electricity over gas refills lowers ongoing expenses, enhancing its appeal. So, by choosing plasma, you’re not just cutting metal—you’re cutting risks and costs, all while boosting efficiency and precision in your operations.