If you’ve ever tried to figure out how to MIG weld thin metal without burning through, you know it’s a tricky balance. I’ve been there and torch in hand, cursing a hole I accidentally burned through a sheet of 20-gauge steel. MIG welding thin metal—think anything under 1/8 inch—is a skill that takes patience, but it’s a game-changer for projects like auto body repair, custom exhausts, or lightweight frames.

Whether you’re a DIYer fixing a car panel, a hobbyist building a sculpture, or a pro tackling a precision job, this guide will walk you through the techniques, settings, and tricks I’ve learned to keep your welds clean and hole-free.

Photo by instructables

Thin metal is unforgiving—too much heat, and you’re left with a gaping hole; too little, and you get weak welds that fail. Proper technique ensures strong, durable joints, saves material costs, and keeps your project looking professional. It’s also about safety, as burn-through can weaken structures or create fire hazards. Let’s dive into how to MIG weld thin metal without burning through, with real-world tips from my shop experience.

Why MIG Welding Thin Metal Matters

MIG welding thin metal is critical for industries like automotive, HVAC, and fabrication, where lightweight materials like sheet steel or aluminum are common. A good weld on thin metal ensures structural integrity, prevents leaks in systems like exhausts, and meets standards like AWS D1.1 for structural work. For DIYers, it’s about saving money by repairing things like car fenders or lawnmower decks instead of replacing them. For pros, it’s about delivering quality welds that pass inspection.

I learned the hard way when I burned through a car hood early in my career. The client wasn’t happy, and I had to patch it up with filler—embarrassing and costly. Mastering thin metal welding saves time, material, and your reputation, whether you’re in a garage or a professional shop.

Challenges of MIG Welding Thin Metal

Thin metal (typically 24-gauge to 1/8 inch) conducts heat quickly, making it prone to burn-through, warping, or distortion. MIG welding’s continuous wire feed delivers consistent heat, which is great for thicker materials but tricky for thin ones. Too much heat melts the metal, while too little causes poor fusion. Other challenges include:

- Spatter: Excess wire or high voltage can create messy spatter, ruining the finish.

- Warping: Heat buildup distorts thin metal, affecting fit-up.

- Material Sensitivity: Aluminum or galvanized steel requires specific settings and prep to avoid issues like porosity or toxic fumes.

I once welded a thin aluminum panel with steel settings—total disaster. The weld was full of holes, and I had to start over. Understanding your material and welder settings is key to avoiding these pitfalls.

Tools and Materials for MIG Welding Thin Metal

To weld thin metal without burning through, you need the right gear. Here’s what I keep in my shop:

- MIG Welder: A machine with adjustable voltage and wire feed speed, like a Lincoln Power MIG or Miller Millermatic. Inverter-based welders offer better control for thin metal.

- Wire: Use 0.023” or 0.030” wire for thin steel (ER70S-6) or aluminum (ER4043 or ER5356). Smaller wire reduces heat input.

- Shielding Gas: 75/25 argon/CO2 for steel; pure argon for aluminum. Flow rate: 15-20 CFH.

- Nozzle and Tips: Use a small contact tip (matching wire size) and a clean nozzle to minimize spatter.

- PPE: Welding helmet (shade 10-12), flame-resistant gloves, leather jacket, and a respirator for galvanized steel.

- Prep Tools: Wire brush, grinder, degreaser, and sandpaper (120-220 grit) for cleaning metal.

- Clamps or Jigs: To hold thin metal securely and prevent warping.

Mistake to Avoid: Don’t use a thick wire (like 0.035”) on thin metal—it delivers too much heat. I learned this when I burned through a 22-gauge steel panel with the wrong wire.

Techniques to Prevent Burn-Through

MIG welding thin metal without burning through comes down to controlling heat and technique. Here are the methods I use to get clean, strong welds.

Lower Heat Settings

Low voltage and wire feed speed reduce heat input, preventing burn-through. For 20-24 gauge steel, I set my welder to 14-16 volts and 100-150 IPM (inches per minute) with 0.023” wire. For aluminum, I use pure argon and slightly higher settings (16-18 volts, 150-200 IPM).

Why It Works: Lower heat keeps the weld pool small, reducing the risk of melting through thin metal.

Practical Tip: Start with the lowest settings recommended for your welder and test on scrap metal. Adjust up if the weld doesn’t penetrate enough.

Mistake to Avoid: Don’t crank the voltage too high thinking it’ll weld faster—I did this once and blew holes in a steel sheet.

Short-Circuit Transfer Mode

MIG welding has different transfer modes, and short-circuit transfer is best for thin metal. The wire touches the metal, shorts out, and deposits small droplets of filler, keeping heat low.

Why It Works: Short-circuit mode creates a fast, low-heat arc that’s ideal for thin materials like sheet metal or exhaust tubing.

Practical Tip: Set your welder to short-circuit mode (check the manual) and listen for a consistent “sizzle” sound—a crackling bacon-like noise means you’re in the zone.

Mistake to Avoid: Don’t use spray transfer mode—it’s too hot for thin metal. I tried it on a car fender and ended up with burn-through city.

Stitch Welding

Instead of a continuous bead, use stitch welding—short bursts of welding (1-2 seconds) followed by pauses to let the metal cool. This minimizes heat buildup and warping.

Why It Works: Stitch welding spreads heat over time, preventing distortion on thin panels like auto body sheets.

Practical Tip: Weld in 1-inch segments, pausing for 2-3 seconds between stitches. I use this for car panels, moving in a zigzag pattern to distribute heat evenly.

Mistake to Avoid: Don’t stitch too close together—it defeats the purpose. I warped a thin steel sheet by stitching too continuously early on.

Tack Welding

Start with small tack welds to hold the metal in place, then fill in with short beads. Tacks reduce movement and help manage heat.

Why It Works: Tacks act as anchors, keeping thin metal aligned while you weld, preventing gaps or warping.

Practical Tip: Place tacks every 2-3 inches along the joint. For 20-gauge steel, use quick, low-heat tacks (1-second bursts).

Mistake to Avoid: Don’t make tacks too big—they add unnecessary heat. I overdid tacks on an aluminum panel once, causing distortion.

Backing Bars or Heat Sinks

For very thin metal (24-gauge or thinner), use a copper or aluminum backing bar behind the weld area to absorb excess heat.

Why It Works: The backing bar dissipates heat, preventing burn-through and keeping the weld pool controlled.

Practical Tip: Clamp a copper pipe or bar tightly against the backside of the joint. I used a copper plate to weld a 24-gauge exhaust without burning through.

Mistake to Avoid: Don’t skip clamping—the bar must stay in contact to work. I had a loose backing bar once, and it was useless.

Step-by-Step Guide to MIG Welding Thin Metal

Here’s how I MIG weld thin metal (20-24 gauge steel) without burning through, based on countless shop projects.

Step 1: Prep the Metal

Clean the metal with a degreaser or acetone to remove oil, grease, or dirt. Use a stainless steel wire brush or 120-grit sandpaper to remove rust or mill scale. For aluminum, avoid steel brushes to prevent contamination. Ensure a tight fit-up with no gaps—thin metal is unforgiving.

Pro Tip: Bevel edges slightly for butt joints to improve penetration without adding excess heat.

Mistake to Avoid: Don’t weld over paint or rust—it causes porosity. I ruined a weld on a steel panel by skipping this step once.

Step 2: Set Up Your Welder

For 20-24 gauge steel, use 0.023” ER70S-6 wire, 14-16 volts, and 100-150 IPM wire feed speed. Set gas flow to 15-20 CFH with a 75/25 argon/CO2 mix. For aluminum, use 0.030” ER4043 wire, pure argon, and 16-18 volts. Test settings on scrap metal to ensure a steady, sizzling arc.

Practical Tip: If your welder has a “thin metal” or short-circuit setting, use it. Check the manual for recommended settings based on material thickness.

Step 3: Secure the Workpiece

Clamp the metal to a welding table or use jigs to prevent movement. For large sheets, use multiple clamps to avoid warping. I welded a car fender without enough clamps once, and it buckled from heat stress.

Pro Tip: Place a copper backing bar under very thin metal (24-gauge) to absorb heat and prevent burn-through.

Step 4: Tack Weld the Joint

Make small tack welds (1-second bursts) every 2-3 inches along the joint to hold it in place. Keep the gun at a 10-15° angle and use low heat to avoid burning through. Check alignment after tacking.

Mistake to Avoid: Don’t make tacks too hot or large—they can distort the metal or create weak spots.

Step 5: Weld with Stitch Technique

Weld in short, 1-inch segments, pausing 2-3 seconds between stitches to let the metal cool. Hold the MIG gun at a 10-15° angle, pushing the weld pool for better control. Use a slight zigzag motion for wider coverage on butt joints. The weld should be flat and smooth, with minimal spatter.

Practical Tip: Keep a consistent travel speed to avoid piling up filler or burning through. Practice on scrap to get the rhythm.

Step 6: Inspect and Clean

Check the weld for uniformity, no holes, or excessive spatter. Grind down any spatter with a 120-grit flap disc and smooth the weld with 220-grit sandpaper if painting. For pressure applications (e.g., exhausts), test with a soap bubble solution for leaks.

Pro Tip: If the weld looks porous or uneven, you may have too much heat or dirty metal. Clean and re-weld with lower settings.

Comparing MIG Welding Techniques for Thin Metal

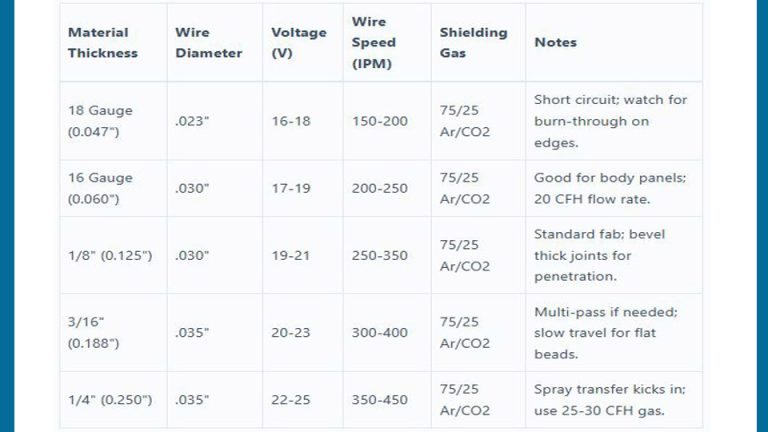

Here’s a table of techniques to prevent burn-through, based on my experience.

| Technique | Best For | Pros | Cons | When to Use |

|---|---|---|---|---|

| Low Heat Settings | All thin metals | Reduces burn-through, easy to adjust | May need multiple passes | General thin metal welding |

| Short-Circuit Mode | Steel, aluminum | Low heat, fast arc | Requires welder adjustment | Sheet metal, auto body |

| Stitch Welding | Thin steel, aluminum | Minimizes warping, controls heat | Slower process | Large panels, exhausts |

| Tack Welding | All thin metals | Secures alignment, low heat | Time-consuming for long joints | Any thin metal joint |

| Backing Bar | Very thin metal (24-gauge or less) | Prevents burn-through, supports weld | Extra setup needed | Ultra-thin sheets or tubes |

When to Choose Each: Use low heat and short-circuit mode for most thin metal jobs. Add stitch welding for large panels, tack welding for alignment, and backing bars for ultra-thin materials like 24-gauge steel or aluminum.

Practical Tips for Success

Here are some tips I’ve learned from welding thin metal:

Test on Scrap: Always weld a scrap piece of the same material and thickness to dial in settings. It saved me from ruining a car hood once.

Use Smaller Wire: Stick to 0.023” or 0.030” wire for thin metal—it reduces heat input and spatter.

Clean Thoroughly: Degrease and brush the metal to remove all contaminants. Dirty metal caused me porous welds on an exhaust project.

Control Travel Speed: Move steadily to avoid lingering too long, which causes burn-through. Practice on scrap to find the right pace.

Check Gas Flow: Ensure 15-20 CFH for steel or aluminum. Too much gas creates turbulence; too little causes porosity.

Safety Considerations

MIG welding thin metal is safe with proper precautions, but risks are real:

Eye Protection: Wear a welding helmet (shade 10-12) to protect against arc flash. I got a mild burn once from glancing at the arc without my helmet.

Fumes: Use a fume extractor or weld in a well-ventilated area, especially for galvanized steel (zinc fumes cause metal fume fever).

Fire Safety: Keep a fire extinguisher nearby. Sparks can ignite rags or nearby materials—I had a close call with some shop towels.

Gloves and Clothing: Wear flame-resistant gloves and a leather jacket to avoid burns from spatter or hot metal.

Electrical Safety: Ensure your welder is grounded and avoid welding on wet surfaces to prevent shocks.

Real-World Applications in the USA

MIG welding thin metal is used across various projects:

- Automotive: Repairing car panels, fenders, or exhausts. I welded a 22-gauge steel hood for a classic car restoration.

- HVAC: Fabricating or repairing ductwork or thin copper lines. I used MIG to patch a steel HVAC duct.

- DIY: Fixing lawnmower decks, trailers, or building custom furniture. I welded a 20-gauge steel table frame for my shop.

- Industrial: Welding thin steel or aluminum for machinery guards or enclosures, often meeting AWS standards.

- Marine: Joining aluminum hulls or fittings for boats, requiring clean, corrosion-resistant welds.

For students, mastering thin metal welding opens doors to careers in auto repair, fabrication, or aerospace, where precision is key.

Conclusion

Knowing how to MIG weld thin metal without burning through gives you the skills to tackle delicate projects with confidence. By using low heat, short-circuit mode, stitch welding, tacks, and backing bars, you can create strong, clean welds on materials like sheet steel or aluminum.

You now understand how to prep your metal, set up your welder, and avoid common mistakes like excessive heat or poor cleaning. Whether you’re a DIYer repairing a car fender, a hobbyist building a custom exhaust, or a pro meeting industry standards, you’re ready to weld thin metal like a pro.

FAQ

What wire size is best for MIG welding thin metal?

Use 0.023” or 0.030” wire (ER70S-6 for steel, ER4043 for aluminum). Smaller wire reduces heat input, preventing burn-through on thin metal like 20-24 gauge.

How do I set my MIG welder for thin metal?

For 20-24 gauge steel, set 14-16 volts, 100-150 IPM wire feed speed, and 75/25 argon/CO2 at 15-20 CFH. For aluminum, use 16-18 volts and pure argon. Test on scrap first.

Can I MIG weld thin aluminum without burning through?

Yes, use 0.030” ER4043 wire, pure argon gas, and short-circuit mode with 16-18 volts. Stitch weld and use a copper backing bar to control heat.

Why do I keep burning through thin metal?

Burn-through happens from too much heat (high voltage or slow travel speed), thick wire, or improper technique. Lower the voltage, use 0.023” wire, and stitch weld to reduce heat.

Is MIG better than TIG for thin metal?

MIG is faster and easier for beginners on thin steel, but TIG offers more precision for aluminum or stainless. Use MIG for quick repairs, TIG for critical or aesthetic welds.