Imagine the bright, focused stream of a plasma arc slicing through metal, and you might wonder if filler material plays a role in this precise welding process. In Plasma Arc Welding (PAW), filler material is indeed utilized, especially for thicker sections over 25mm or when joining dissimilar metals. It enhances joint strength and durability, ensuring ideal fusion. Yet, there are instances where filler isn’t necessary, such as in root-pass welds, raising intriguing considerations.

Understanding Plasma Arc Welding

Plasma Arc Welding (PAW) is a precise and highly controlled welding technique that leverages an electric arc to melt metals for joining. This method exploits plasma properties—where ionized gases conduct electricity—to initiate and sustain the arc.

In PAW, the electric arc is constricted through a fine-bore nozzle, producing a high-energy plasma jet, enabling superior control over the weld pool. Mastery of this welding technique is essential, as it allows for fine adjustments to the arc length and temperature, achieving temperatures up to 28,000°C.

You’ll find that such high temperatures facilitate minimal dilution of any filler materials used, maintaining their intrinsic properties. By understanding plasma properties and optimizing your welding techniques, you can achieve strong, reliable welds.

The precision in PAW enhances joint integrity and is particularly effective in applications requiring meticulous weld control, such as aerospace and marine industries.

The Role of Filler Material in Welding

In plasma arc welding, you’ll find that the necessity of filler material hinges on joint configuration, particularly in butt and fillet welds where it enhances structural integrity.

Selecting appropriate filler types, such as stainless steel or nickel-based alloys, is critical to maintaining base metal properties and controlling the weld pool.

Utilizing the right filler material mitigates undercutting and fusion issues, ensuring ideal weld quality and performance.

Filler Material Necessity

Although Plasma Arc Welding (PAW) often achieves sufficient penetration without additional material, especially in root-pass welds, the strategic use of filler material can’t be overlooked.

Filler material considerations are vital when dealing with thicker joints or dissimilar metals. By adding filler at the leading edge of the weld pool, you enhance control over weld quality and mechanical properties.

Filler material selection, such as tungsten or Hastelloy alloys, directly influences the weld’s strength and corrosion resistance.

Additionally, employing filler material can mitigate defects like undercutting or tungsten inclusions, ensuring a more stable weld.

It also helps reduce dilution with the base material, preserving the desirable properties of the filler and improving the overall performance of the welded component.

Filler Types and Applications

When selecting filler material for Plasma Arc Welding (PAW), understanding the specific requirements of your application is essential. Filler materials are critical for enhancing joint integrity, especially when welding thicker materials or requiring additional strength. You might choose from alloys like 309L, Hastelloy, or Tungsten Carbide, depending on the desired properties for the joint and compatibility with the base metals.

Here are some considerations for filler materials in PAW:

- Wire Form: Ideal for consistent feeding into the weld pool.

- Powder Form: Introduced through the torch for flexible application.

- Minimize Dilution: Preserves base metal properties.

- Strength Enhancement: Critical for thicker joints.

- Root-Pass Exclusion: Typically omitted for initial bonds.

Strategic selection of filler materials optimizes your welding techniques.

When to Use Filler Material in PAW

Given the intricacies of plasma arc welding (PAW), understanding when to incorporate filler material is vital for achieving ideal weld integrity and performance. The decision hinges on filler selection criteria and joint design considerations.

In PAW, incorporating filler material is crucial for weld integrity and performance through careful selection and design.

For thicker sections over 25mm, filler material becomes essential, especially in square butt, J, or V joints, where joint design may introduce gaps. It enhances strength and durability by reinforcing the joint.

Introducing filler metal at the leading edge of the weld pool is significant, particularly for non-root-pass welds. This approach guarantees optimal fusion and structural integrity.

You should select filler materials—available in wire or powder forms—based on compatibility with the base material to minimize dilution and maintain weld quality.

While root-pass welds often forego filler to focus on a robust primary bond, for thicker joints or those requiring additional reinforcement, filler material is indispensable in PAW applications.

Advantages of Using Filler Material

In plasma arc welding, incorporating filler material enhances joint strength by augmenting the weld’s structural integrity, particularly in high-stress applications.

You can achieve improved weld appearance through precise filler metal placement, minimizing defects like undercutting.

Additionally, filler materials offer greater material compatibility, allowing you to select alloys that optimize the weld’s performance and durability in challenging environments.

Enhanced Joint Strength

By incorporating filler material in plasma arc welding, you markedly enhance joint strength, which is vital for achieving ideal weld quality. The filler material benefits include increased welding joint durability by effectively bridging gaps and reinforcing welds, especially in root-pass operations.

- Compatibility: Choose stainless steel or nickel alloys to guarantee mechanical properties and corrosion resistance align with the base metals.

- Defect Minimization: Filler material reduces risks of undercutting and lack of fusion, guaranteeing robust welds.

- Weld Pool Control: Enhanced control over the weld pool leads to improved penetration and minimized heat-affected zones.

- Wear Resistance: Specific filler materials impart hardness and toughness, extending the component’s service life.

- Structural Integrity: Filler materials provide structural reinforcement, essential for sensitive components.

Improved Weld Appearance

When you incorporate filler material in plasma arc welding, it greatly enhances weld appearance through a smoother, more uniform surface finish. This improved weld aesthetics is essential in sectors like automotive and electronics, where visual appeal and precision are paramount.

Filler material bridges gaps and imperfections, optimizing alignment and minimizing defects such as undercutting and lack of fusion. These defects can compromise weld integrity, but a consistent surface finish alleviates these risks.

Moreover, controlled heat input from filler material reduces distortion and warping, vital for maintaining component geometry. This uniformity guarantees the welded assembly meets stringent industry standards.

Ultimately, selecting appropriate filler materials not only improves weld aesthetics but also contributes to a robust, visually appealing final product.

Greater Material Compatibility

Enhancing weld appearance with filler material is just one facet of its utility in plasma arc welding; another is the remarkable material compatibility it offers. Filler selection is essential for optimizing material bonding, especially when welding dissimilar metals or alloys.

The strategic addition of filler material enhances mechanical properties, ensuring robust and ductile joints. Its use minimizes defects such as porosity or incomplete fusion, vital for complex joint geometries.

- Dissimilar Metal Welding: Facilitates joining metals that are otherwise incompatible.

- Tailored Properties: Filler materials like 309L match base metal properties, enhancing corrosion resistance.

- Defect Reduction: Decreases porosity risks, ensuring weld integrity.

- Thermal Management: Controls heat input, reducing distortion.

- Enhanced Dynamics: Improves weld pool dynamics, optimizing deposition rates.

Filler selection provides a strategic advantage in plasma arc welding, ensuring consistent, high-quality welds.

Challenges and Considerations

Although plasma arc welding (PAW) offers significant advantages in achieving high-quality welds without filler material, the introduction of filler material presents its own set of challenges and considerations.

Filler material considerations are paramount in preventing welding defects; improper selection or contamination can result in issues such as pin-hole leaks. The choice of filler material, whether stainless steel or specific alloys, must align with the base metal to maintain metallurgical properties and prevent dilution. You need to guarantee strict cleanliness protocols during preparation to avert contamination.

Additionally, adding filler material at the weld pool’s leading edge can enhance joint strength and control over the weld profile. However, this introduces potential changes in corrosion resistance.

Consequently, you must carefully evaluate welding parameters and filler selection to address these challenges. Missteps in these areas not only compromise the weld quality but also affect the structural integrity of the final product.

Omission of Filler Material in PAW

In the domain of plasma arc welding (PAW), omitting filler material isn’t just an option; it’s often a strategic choice for enhancing weld quality.

Omitting filler material in plasma arc welding is a strategic choice for superior weld quality.

When engaging in autogenous welding, the absence of filler material during root-pass welds guarantees that the weld pool alone can forge robust joint integrity. By not introducing additional material, you minimize the risk of contaminants and pin-hole leaks, which are common pitfalls with excessive heat application.

This technique allows for a focused heat input, especially beneficial for thin sheets, reducing distortion and maintaining metallurgical integrity.

Consider these advantages of omitting filler in PAW:

- Reduces contamination: Less risk of foreign material inclusion.

- Improves joint strength: Often surpasses joints with filler.

- Minimizes distortion: Beneficial for thin materials.

- Maintains corrosion resistance: Proper management guarantees durability.

- Enhances structural integrity: High-strength joints without additional materials.

Embrace this approach for precise, high-quality welds where applicable.

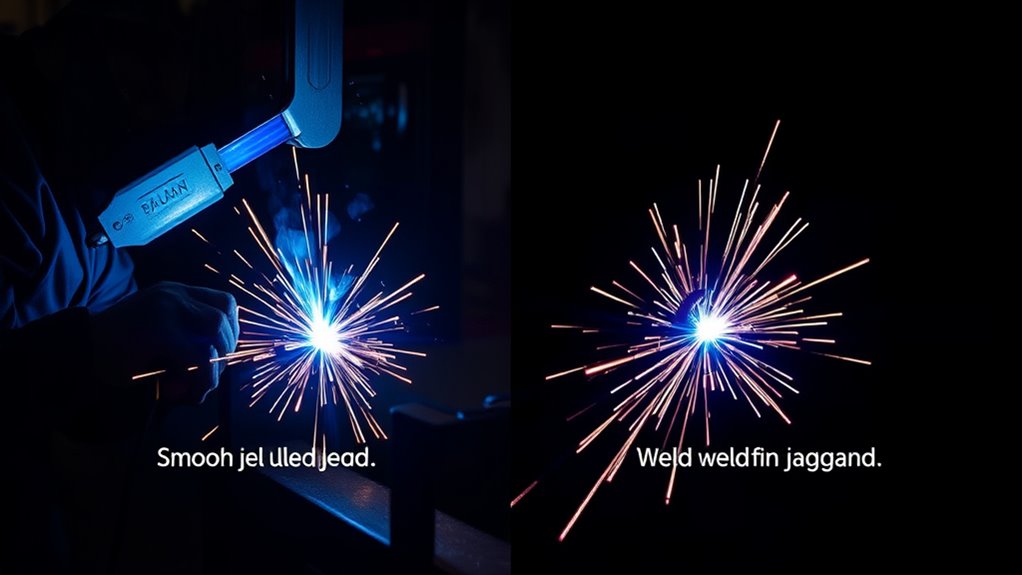

Comparing Weld Quality: With and Without Filler

When comparing weld quality in plasma arc welding (PAW), whether with or without filler material, it’s essential to take into account the specific requirements of your project.

Using filler material is advantageous for achieving superior joint integrity, especially in thicker materials or joints with irregularities. It enhances tensile strength and resistance to weld fatigue, making it ideal for high-stress applications. Filler material fortifies the weld pool, reducing defects and enhancing the overall mechanical properties of the weld.

Conversely, autogenous welding, which omits filler, yields high-quality welds with minimal base metal dilution. However, it may compromise joint integrity in applications demanding robust structural support. The absence of filler can lead to increased susceptibility to weld fatigue over time, especially under cyclic loading conditions.

While using filler material may introduce contamination risks, maintaining a controlled welding environment mitigates these issues, ensuring excellent weld quality and joint durability.

Common Applications Requiring Filler Material

For specific applications in plasma arc welding (PAW), incorporating filler material is vital to achieving ideal weld strength and integrity.

You’ll find that various industrial applications demand precise filler material types to guarantee robust and reliable welds. In scenarios involving thicker joints, typically above 5mm, filler materials are essential for proper penetration and weld strength.

When working with dissimilar metals or base materials with differing melting points, introducing filler is indispensable for a strong bond.

In the automotive sector, filler materials reinforce high-stress components, enhancing durability. Medical device manufacturing relies on filler to produce high-strength, corrosion-resistant welds for surgical instruments.

Consider the following common applications:

- Thicker joints exceeding 5mm

- Welding dissimilar metals

- Automotive frames and suspension parts

- Medical devices needing void-free welds

- Preventing cracking and porosity with 309L stainless steel wire

Each application underscores the necessity of selecting the appropriate filler material types for peak performance.

Best Practices for Effective Welding

Understanding the necessity of filler materials for specific applications sets the stage for mastering best practices in plasma arc welding (PAW). When applying advanced welding techniques, it’s vital to recognize how material selection impacts joint integrity.

Filler material, strategically incorporated at the weld pool’s leading edge, bolsters joint strength, especially in thicker sections. In PAW, you’ll find that root-pass welds often bypass filler metal, capitalizing on the keyhole mode for full penetration and heightened efficiency.

To guarantee ideal results, adept control of welding parameters, such as current and gas flow rates, is paramount. This precision minimizes risks like tungsten inclusions and stabilizes the weld pool.

Selecting appropriate filler materials, such as stainless steel or specialized alloys, guarantees compatibility and desired mechanical properties, enhancing weld quality. Additionally, filler materials combat contamination effects and facilitate superior fusion between dissimilar metals, guaranteeing weld integrity and reliability.

Frequently Asked Questions

What Types of Filler Materials Are Compatible With PAW?

You should use compatible filler material types like stainless steel, aluminum, and titanium alloys in Plasma Arc Welding. Consider filler material properties such as melting point, thermal conductivity, and oxidation resistance to guarantee ideal joint integrity and performance.

How Does Filler Material Affect Paw’s Energy Consumption?

How does filler efficiency optimize energy savings in plasma arc welding? By selecting efficient filler, you minimize heat input, reduce arc time, and enhance weld quality. This approach maximizes energy efficiency, ensuring cost-effective and sustainable welding operations.

Can Filler Material Influence the Color of the Weld?

Yes, filler material can influence weld color. Different filler types affect weld aesthetics by altering the chemical composition, impacting oxidation and heat reactions. Choose materials carefully to achieve desired hues in specific industry applications and specifications.

Are There Specific Safety Concerns Using Filler Material in PAW?

You should note that 20% of welding accidents involve improper filler handling. Adhering to safety regulations is essential to mitigate risks like toxic fume inhalation and material contamination in PAW. Always prioritize PPE and proper ventilation.

Does Filler Material Impact Paw’s Environmental Footprint?

Yes, filler material can influence plasma arc welding’s environmental impact. You’re dealing with increased resource consumption and potential emissions. Analyze filler properties and optimize usage to minimize waste, ensuring a more sustainable welding process in your operations.

Conclusion

In the world of Plasma Arc Welding, the choice to use filler material is pivotal. It guarantees robust joint strength, especially in thicker sections or when welding dissimilar metals. Remember, “an ounce of prevention is worth a pound of cure”—using filler prevents undercutting and preserves metallurgical integrity. However, evaluate each project’s demands; sometimes, a root-pass weld with no filler suffices. Always align your approach with the specific application to achieve ideal weld quality.