Imagine you’re working with a high-definition CNC plasma cutter, achieving a remarkable tolerance of ±0.25 mm on mild steel. Plasma cutting accuracy hinges on the process and material type, with entry-level machines offering ±0.77 mm tolerances. Metals like stainless steel and aluminum vary in precision, reaching ±0.38 mm and ±0.64 mm, respectively. Factors such as cutting speed, operator skill, and material thickness further influence precision. Curious about how these elements interact?

Plasma Cutting Processes and Their Tolerances

When examining plasma cutting processes and their tolerances, it’s essential to understand the variations in precision across different systems.

Plasma cutting accuracy hinges on the system used, with each type offering distinct tolerance standards. Entry-level CNC plasma cutters provide a baseline with tolerances of ±0.77 millimeters. As you advance to light-industrial models, expect improved edge tolerances of 0.38 to 0.64 millimeters. For mass production, heavy-industrial systems refine this further, achieving tolerances between 0.25 to 0.51 millimeters.

High-definition plasma cutting systems stand out, delivering exceptional precision with tolerances as tight as ±0.25 millimeters. This makes them ideal for applications demanding high precision.

It’s important to remember that factors like material type, cutting speed, and operator expertise can markedly impact plasma cutting accuracy. Understanding these differences liberates you to choose the right system, ensuring best performance tailored to your specific needs while meeting stringent tolerance standards.

Handheld Plasma Cutting: Achieving Precision

Although handheld plasma cutting offers remarkable versatility, achieving precision hinges greatly on the operator’s skill and experience. Skilled operators, through refined cutting techniques, can reach a tolerance of approximately 1.6 millimeters. This level of precision, while impressive for a manual process, varies considerably with the operator’s adeptness.

Experience empowers you to master the nuances of hand control, directly influencing the quality and accuracy of your cuts. As you refine your technique, you’ll find that the path to superior precision is a blend of artistry and technical prowess, setting apart professional fabricators from novices.

While handheld systems can’t quite match the precision of CNC machines, they offer a unique liberation: the freedom to express creativity through manual skill. Embrace the challenge of achieving high-quality results by honing your expertise in handheld plasma cutting, where each cut reflects your personal touch and mastery of the craft.

CNC Plasma Cutting Machines: Entry-Level to Heavy-Industrial Systems

CNC plasma cutting machines span a range of capabilities, from entry-level models suitable for hobbyists to heavy-industrial systems designed for mass production.

Entry-level machines offer tolerances of ±0.77 millimeters, ideal for small shops where precision is less critical. As you progress to light-industrial applications, CNC burn tables enhance durability and achieve tighter tolerances between 0.38 to 0.64 millimeters, accommodating low to moderate workloads effectively.

Entry-level machines provide ±0.77 mm tolerances, while light-industrial models tighten to 0.38-0.64 mm for better precision.

For those embracing industrial applications, heavy-industrial plasma cutters provide superior precision with tolerances ranging from 0.25 to 0.51 millimeters, depending on material thickness.

These systems excel in mass production, thanks to features like automated torch height control, which optimizes accuracy by adjusting to material variations in real-time.

The freedom to achieve precise cuts depends on understanding the machine’s capabilities and selecting the right system for your needs.

High-definition systems elevate your potential, delivering precision that transforms your workflow.

Factors Affecting Plasma Cutting Accuracy

To achieve ideal plasma cutting accuracy, you must consider several vital factors that influence performance. Cutting speed is paramount; while faster speeds can increase productivity, they often compromise cut quality, resulting in wider kerf and reduced precision.

Slower speeds enhance control, allowing for tighter tolerances, often reaching ±0.25 mm with high-definition systems.

Equally essential is operator expertise. Skilled operators can greatly impact accuracy by mastering settings and techniques. They know how to adjust parameters to accommodate different materials, ensuring better edge precision and reduced warping in softer metals.

Their ability to maintain the cutting system—especially the torch and nozzle—prevents performance deviations, ensuring consistent results.

The material type also plays a role, but with adept handling and proper speed management, you can tackle both softer and harder metals effectively.

Comparing Plasma Cutting Tolerances Across Different Metals

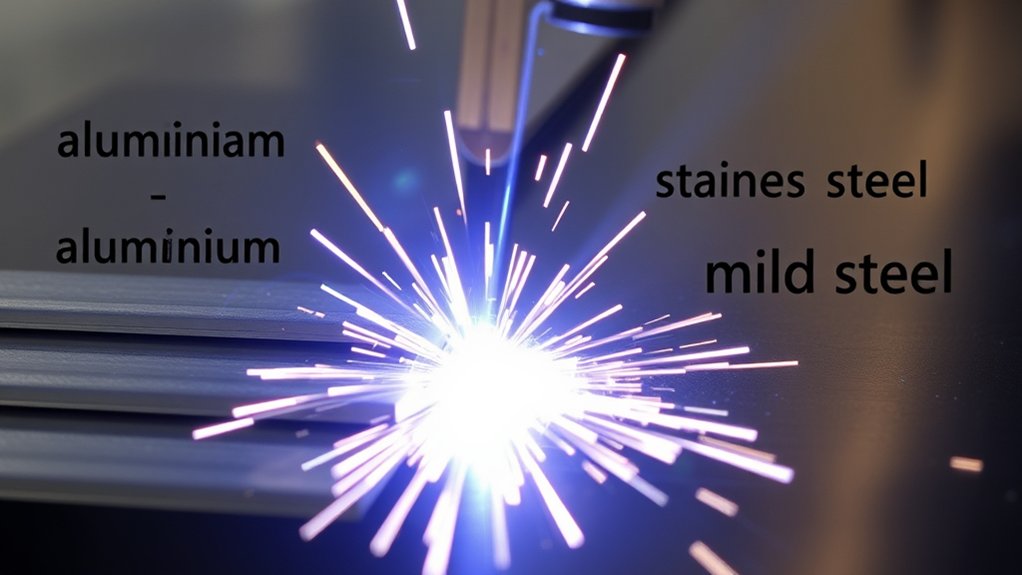

Understanding the factors that affect plasma cutting accuracy sets the stage for exploring how tolerances vary across different metals. With plasma cutting, the metal type greatly influences precision.

Aluminum, a softer metal, generally allows for tolerances of ±0.64 mm, while harder materials like stainless steel can achieve tighter tolerances around ±0.38 mm. Such variations highlight the need for precision in choosing metal types for specific applications. High-definition plasma systems can enhance accuracy, reaching tolerances as precise as ±0.25 mm in mild steel.

The thickness of metals also plays an essential role; thicker pieces often offer better edge quality and tighter tolerances, while thinner metals may challenge maintaining precision.

To master the nuances of plasma cutting, consider:

- Material Behavior: Warping and bowing in softer metals can disrupt precision.

- Technology’s Role: Advanced systems improve accuracy.

- Optimal Settings: Adjust cutting speed and amperage for each metal type.

These factors empower your cutting processes, revealing potential and precision.

Frequently Asked Questions

How Does Plasma Cutting Compare to Waterjet Cutting in Terms of Accuracy?

You’ll find that waterjet cutting typically offers higher precision than plasma cutting. In a plasma comparison, the cutting precision of waterjet allows for tighter tolerances, making it ideal for intricate designs requiring liberation from traditional constraints.

What Are the Common Applications Requiring High Tolerance in Plasma Cutting?

Imagine sleek automotive bodies and intricate aerospace components; plasma cutting shines in these high-tolerance applications. You achieve precision by mastering techniques and understanding material properties, liberating designs from constraints and pushing the boundaries of manufacturing possibilities.

Can Plasma Cutting Be Used for Artistic Metalwork With Intricate Designs?

Yes, you can use plasma cutting for artistic metalwork with intricate designs. Artistic plasma techniques offer precision and flexibility, enabling you to create detailed patterns. Embrace this technology for liberating your creative expression in metal artistry.

How Do Environmental Conditions Affect Plasma Cutting Accuracy?

You’re dealing with plasma cutting accuracy when ambient temperature and humidity levels fluctuate. A 10% increase in humidity can alter arc stability, affecting precision. Control these variables to maintain freedom from errors and achieve your desired results.

What Safety Precautions Should Be Taken When Operating a Plasma Cutter?

Guarantee plasma cutter safety by wearing protective gear, maintaining a clutter-free workspace, and verifying proper grounding. Prioritize operator training to understand equipment limitations and emergency procedures, empowering you to work confidently and minimize risks effectively.

Conclusion

You’ve seen how plasma cutting’s accuracy hinges on the process and metal type, with high-definition systems achieving impressive tolerances of ±0.25 mm, especially with mild steel. Curiously, while stainless steel can reach ±0.38 mm, aluminum typically allows ±0.64 mm. Remember, cutting speed, operator skill, and material thickness also greatly impact precision. So, whether you’re using an entry-level CNC or high-end equipment, understanding these variables helps you achieve the best results in your metalworking projects.