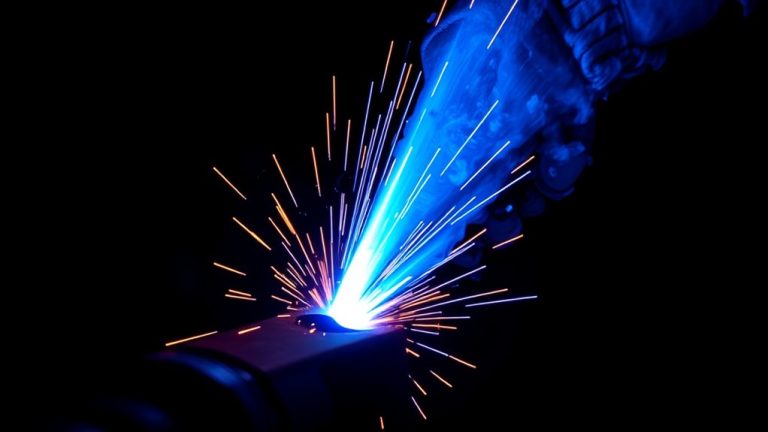

When using a contact-start plasma cutter, you’ll notice it operates by initiating a high-voltage spark as the torch tip makes contact with the workpiece. This spark creates an arc that transforms into a plasma jet, capable of slicing through metal with precision. You may find this method works well once heavy rust or paint has been cleaned back to bare or lightly coated steel, but contact-start systems generally perform best on clean or lightly prepared surfaces, while pilot arc designs handle heavily coated material more easily. However, be aware of the safety hazards and maintenance needs associated with its high-voltage operation. Curious about how it performs compared to pilot arc plasma cutters?

Understanding Contact-Start Plasma Cutters

When you’re trying to grasp the mechanics of contact-start plasma cutters, it’s crucial to understand how they initiate the cutting process. The contact-start mechanism begins by generating a high voltage spark when the torch tip makes contact with the workpiece. This immediate generation of a plasma arc allows for swift cutting action.

However, this system demands direct contact, making it less suitable than pilot arc designs for cutting through materials with heavy rust or thick paint. Typically, contact-start systems are more budget-friendly and are prevalent in economical plasma cutting equipment.

Older high-frequency (HF) contact-start designs aren’t ideal for CNC applications because of the electromagnetic interference they can cause. The high voltage involved in HF starting—often reaching tens of thousands of volts—poses electrocution hazards and could potentially damage nearby electronics if the system isn’t correctly grounded and shielded.

Additionally, the frequent contact with workpieces leads to wear on torch components, requiring regular maintenance and replacement of consumables to guarantee efficient cutting performance and prolong equipment lifespan.

Operating Principles of Contact-Start Plasma Cutters

When operating a contact-start plasma cutter, you initiate the arc by touching the torch tip to the workpiece, creating a high-voltage spark that establishes the plasma arc.

The electrode-nozzle interaction plays a vital role in maintaining the arc’s stability while the plasma gas dynamics convert the gas into a high-temperature plasma jet for effective material cutting.

Understanding these mechanisms is essential for optimizing performance and mitigating potential safety risks associated with this cutting technology.

Arc Initiation Mechanism

Although contact-start plasma cutters may seem straightforward, their arc initiation mechanism is a remarkable interplay of electrical principles.

At its core, the process begins with the electrode making direct contact with the workpiece. This contact generates a high voltage spark, which in HF contact-start systems can involve starting voltages in the tens of thousands of volts, even though the main cutting arc typically runs at a few hundred volts DC. The spark serves as the initial trigger, allowing the arc initiation mechanism to create a conductive path for the arc to form.

Once the arc is established, plasma gas is driven through a nozzle, getting ionized into a high-temperature plasma jet. In non-HF blowback-style contact-start designs, this method operates without the need for large external capacitors or complex high-frequency electronics, simplifying maintenance.

However, when high-frequency starting is used, it can cause electromagnetic interference, potentially affecting nearby electronics, and contact-start systems still tend to struggle more than pilot arc units with contaminants like heavy rust or paint on the surface.

Electrode-Nozzle Interaction

Understanding the interaction between the electrode and nozzle is essential for grasping the operating principles of contact-start plasma cutters.

Initially, the electrode and tip contact each other directly, establishing a connection with the workpiece. When you activate the trigger, the high voltage spark ionizes the surrounding gas, converting it into plasma.

As the nozzle lifts away from the work, an arc is established. This arc initiation method relies on a clean, conductive surface for peak performance, as any contamination can disrupt the process.

In HF contact-start systems, the reliance on high-frequency high voltage generates electromagnetic interference, making those specific designs unsuitable for CNC operations and locations with very sensitive electronics.

Despite being user-friendly, the direct handling of high voltage poses safety risks, such as electrical shock.

Plasma Gas Dynamics

As you explore the intricacies of plasma gas dynamics in contact-start plasma cutters, it is crucial to recognize how the system leverages the ionization of gas to achieve effective cutting. The process begins when an arc is initiated through a high voltage spark as the electrode contacts the workpiece. This ionizes the plasma gas, typically air or argon, enhancing its electrical conductivity. The cutting arc reaches up to 40,000°F, vaporizing materials efficiently.

While ideal for clean surfaces, contact-start systems can falter on contaminated materials due to arc initiation challenges. They remain a cost-effective choice for straightforward applications compared to pilot arc systems.

| Plasma Gas | Arc Initiation | Cutting Arc Temperature |

|---|---|---|

| Air/Argon | High Voltage | Up to 40,000°F |

| Conductive | Direct Contact | Vaporizes Materials |

| Efficient | Clean Surfaces | Cost-Effective |

Key Components of a Contact-Start Plasma Cutter

To understand how a contact-start plasma cutter operates, you need to focus on its key components: the torch, electrode, nozzle, and power supply.

The torch design features a consumable electrode that initiates the arc by contacting the workpiece, while the nozzle constrains the plasma flow for precision.

Proper maintenance of these components is essential to guarantee consistent arc initiation and efficient cutting performance.

Torch Design Elements

In the intricate design of a contact-start plasma cutter’s torch, several vital components work together to secure efficient operation. The torch initiates the arc by creating a high voltage spark when its tip makes contact with the workpiece. This allows for immediate current flow.

Key elements include:

- Electrode: Emits the arc, essential for cutting through materials effectively.

- Nozzle: Constrains and directs the plasma stream, guaranteeing precision.

- Spring-loaded Mechanism: Keeps the torch tip in contact with the workpiece until the arc is established.

- Protective Cap: Shields the electrode and nozzle, preventing contamination and potential damage.

These components, paired with a power supply converting AC to high DC voltage, secure the torch’s peak performance in any cutting task.

Arc Initiation Process

When examining the arc initiation process of a contact-start plasma cutter, understanding the physical contact between the electrode and the workpiece becomes essential. This method initiates the electric arc by briefly short-circuiting the electrode against the workpiece, allowing current flow. As the torch presses against the material, it generates a high-temperature plasma jet, reaching up to 40,000°F. Utilizing high frequency (HF) voltage in certain designs aids in arc initiation but can cause electromagnetic interference, affecting nearby sensitive electronics.

| Component | Function | Consideration |

|---|---|---|

| Electrode | Contacts workpiece to start arc | Prone to wear; requires regular checks |

| Workpiece | Conducts current to establish arc | Clean surface for best performance |

| High Frequency | Facilitates arc initiation | Can interfere with electronics |

| Plasma Jet | Cuts through material | High temperature for effective cutting |

| Electromagnetic Interference | Potential risk to nearby devices | Requires careful positioning |

Maintenance Considerations

Understanding the mechanics of arc initiation in contact-start plasma cutters lays the groundwork for effective maintenance. Regular attention to the electrode and work components guarantees peak performance.

Inspect and replace worn electrodes and nozzles frequently, as consistent contact degrades these parts, affecting the spark gap and cutting precision. The spark gap, a critical component, requires vigilant checks since wear can compromise arc initiation reliability, impacting cutting efficiency.

Additionally, high-frequency arc initiation may increase RF emissions, necessitating careful maintenance of nearby sensitive electronics. Effective air filtration is another key element, as contamination can degrade performance and escalate maintenance demands.

- Inspect and replace worn electrodes and nozzles frequently

- Regularly check spark gaps for wear

- Monitor RF emissions affecting nearby electronics

- Guarantee effective air filtration to prevent contamination

Advantages of Using Contact-Start Plasma Cutters

Although traditional cutting methods have their place, contact-start plasma cutters offer distinct advantages that make them increasingly popular among hobbyists and small workshops. These machines are designed to initiate the arc by creating a high-voltage spark when the torch tip touches the workpiece. This efficient arc initiation facilitates faster cutting speeds, enhancing productivity over some conventional techniques.

Additionally, non-HF contact-start plasma cutters generate less electromagnetic interference than traditional high-frequency start systems, helping them coexist with environments containing sensitive electronics when installed and grounded correctly.

Moreover, these cutters can handle a broad range of materials, especially clean or lightly prepared metals. They can cut through light surface rust or thin paint once the arc is established, but heavily rusty or thickly painted surfaces are still where pilot arc systems typically excel and may require less surface preparation.

Their affordability, particularly in low-budget models, further accentuates their appeal, providing accessibility for smaller operations aiming for high performance without a hefty investment.

Potential Drawbacks of Contact-Start Plasma Cutting

Despite their advantages, contact-start plasma cutters come with some drawbacks that you should consider. The reliance on a high voltage spark to initiate cutting can lead to potential damage to the workpiece. When the torch touches the surface, it risks marring or distorting the material, particularly on delicate or thin metals.

High voltage sparks in contact-start plasma cutters can mar or distort delicate metals, posing a risk to the workpiece.

Additionally, especially in HF contact-start systems, electromagnetic interference (EMI) can be significant. This interference may disrupt nearby sensitive electronic equipment, making these cutters unsuitable for environments containing such devices unless you use EMI-mitigating designs and follow good installation practices.

Regular maintenance is also required due to wear and tear on the torch and electrode from constant contact with the workpiece. This necessity can increase downtime and costs over time.

Furthermore, the high voltage needed for operation poses inherent safety risks, including the threat of electrocution if safety protocols aren’t strictly followed.

- High voltage spark can damage the workpiece.

- HF contact-start systems can generate significant EMI affecting electronics.

- Requires frequent maintenance due to wear.

- Safety risks from high voltage spark.

Comparing Contact-Start and Pilot Arc Systems

When weighing the pros and cons of plasma cutting systems, it’s important to contemplate the distinct operational mechanisms of contact-start and pilot arc systems.

Contact-start plasma cutters initiate their arc by touching the electrode to the material, creating a high-voltage spark. This process can result in a slight delay as the arc stabilizes, and it tends to wear down consumables faster. Additionally, older high-frequency contact-start systems can generate more electromagnetic interference (EMI), which might disrupt nearby sensitive electronics.

In contrast, pilot arc systems create a small arc within the torch before engaging the workpiece. This feature allows for cleaner starts and enhanced performance on surfaces with contaminants like paint or rust.

They’re especially valued in CNC applications for their reliability and precision, as they don’t require direct contact to begin cutting. Ultimately, pilot arc systems offer a more refined approach with reduced maintenance needs and better adaptability to varied conditions.

Best Practices for Contact-Start Plasma Cutting

To master contact-start plasma cutting, focus on several key practices that enhance efficiency and safety.

Begin by maintaining proper air pressure as specified in your plasma cutter’s manual—many entry-level air plasma units run best with flowing pressure in the 60–70 psi range. This helps stabilize the arc and supports consistent cutting performance.

Ensure air pressure remains stable within your manufacturer’s recommended range (often around 60–70 psi for many hobby-class air plasma cutters) for optimal cutting performance and arc stabilization.

Regular checks for obstructions are essential, as they can hinder the electrode’s movement and disrupt arc initiation.

Safe handling techniques are non-negotiable; be constantly aware of your surroundings to avoid accidental contact with the plasma torch, which can cause burns or injuries.

Consider these best practices:

- Maintain Proper Air Pressure: Verify air pressure matches the specifications in your manual, typically around 60–70 psi during operation for many machines.

- Check for Obstructions: Regularly inspect the electrode path for any blockages.

- Handle with Care: Practice safe handling techniques to prevent accidents and injuries.

- Avoid Over-Tightening: Don’t tighten the torch cap excessively, and avoid clamping the torch in the lower 3 inches to protect the nozzle.

Troubleshooting Common Issues in Contact-Start Plasma Cutting

In contact-start plasma cutting, guaranteeing ideal performance often hinges on addressing common issues that may arise during operation. Arc starting can be problematic if the workpiece surface is dirty or coated. It is crucial to pre-clean the workpiece to avoid contamination that might impede arc initiation. Confirm air pressure is correctly set within the range recommended by your cutter’s manual—often around 60–70 psi while cutting for many air plasma systems—which is essential for optimal arc starting.

Torch maintenance is important for cutting efficiency. Regularly inspect the torch cap, as over-tightening can restrict electrode movement and affect cutting quality. Worn tips and electrodes should be replaced to maintain arc stability.

| Issue | Solution |

|---|---|

| Dirty Workpiece | Pre-clean surface |

| Arc Fails to Initiate | Check air pressure and electrode |

| Inconsistent Arc Starting | Avoid over-tightening torch cap |

Safety Tips for Contact-Start Plasma Cutter Users

Although plasma cutting is a highly efficient method for metal fabrication, guaranteeing safety is paramount for users of contact-start plasma cutters. Adhering to safety tips can greatly reduce the risk of accidents.

Always wear protective gear, including fire-resistant gloves, long sleeves, and appropriate eye and face protection (safety glasses plus a face shield or welding helmet with a filter shade selected according to standards such as ANSI Z49.1 and OSHA’s eye and face protection rules), to shield yourself from burns and eye damage caused by the intense light and flying debris. Keep your work area clean and free from flammable materials to prevent fire hazards from sparks and molten metal, and provide adequate ventilation or fume extraction, especially when cutting coated or galvanized metals.

Be mindful of the risk of electrical shock, particularly in damp conditions; verify your equipment is properly grounded. Regular inspection and maintenance of your plasma cutter, especially the torch and consumables, are essential to avoid malfunctions that could lead to accidents. For more detailed guidance, review the ANSI Z49.1 safety standard for welding, cutting, and allied processes and OSHA’s welding, cutting, and brazing safety resources.

- Protective gear: Always wear gloves, flame-resistant clothing, and appropriate ANSI-approved eye and face protection.

- Fire prevention: Clear flammable materials from the area.

- Electrical safety: Ground equipment properly to avoid shocks.

- Maintenance: Inspect and maintain the cutter regularly.

Frequently Asked Questions

What Is the Difference Between Contact and Non Contact Plasma Cutters?

You should differentiate plasma cutting techniques by initiation: contact-start requires touching the workpiece, while non-contact methods (such as many pilot arc systems) don’t. Pay attention to safety precautions and equipment maintenance, as contact-start demands more upkeep due to electrode wear from physical contact.

Will a 20 Gallon Air Compressor Run a Plasma Cutter?

Can a 20-gallon air compressor run a plasma cutter? Absolutely, if the plasma cutter requirements align with the air compressor specifications. Verify your compressor meets the cutter’s CFM and PSI needs for desired cutting thickness capabilities.

How Does a Plasma Cutter Work Step by Step?

You’ll start by positioning the torch. Initiate the plasma arc by pressing it against the material. The gas flow ignites, ionizing into plasma. This enhances cutting speed but affects electrode life, needing regular maintenance.

What Are Some Common Mistakes Made With Plasma Cutting?

You often overlook plasma cutting techniques, like setting the right air pressure and maintaining cut height. Ignoring safety precautions and material compatibility can lead to poor cuts. Regular maintenance, including checking air filters, guarantees peak performance.

Conclusion

You’ve navigated the electrifying world of contact-start plasma cutters, a tool that boldly demands respect with its high-voltage flair. While it can slice through many common shop steels and light surface coatings, don’t let its bravado fool you—it’s a diva requiring constant pampering and wary of sensitive electronics, especially in older HF-start designs. Ironically, this cutting-edge marvel is both a craftsman’s dream and a technician’s challenge. So, embrace its quirks, but remember, even the sharpest blade has its edge.