When you’re exploring plasma cutter speeds, it’s essential to understand the factors influencing these rates, such as material type and thickness. For example, cutting 1/2-inch mild steel can reach about 15 IPM, while sever cuts push up to 35 IPM. High-definition plasma technology offers even faster speeds for thicker materials. By balancing speed with cut quality, you guarantee efficiency and precision. But how do you consistently achieve ideal results? Let’s investigate further.

Understanding Plasma Cutting Speeds

How exactly do you determine the right plasma cutting speed? You need to evaluate the material’s thickness and type, as these factors directly influence the cutting speed, typically measured in inches per minute (IPM).

Plasma technology advancements have led to cutting speed innovations that allow for speeds ranging from 20 to over 100 IPM. For instance, cutting 1/2-inch mild steel might see a rated speed of 15 IPM, while a sever cut can reach 35 IPM.

High-definition plasma cutting technology further enhances these speeds without sacrificing quality. It’s essential to hit the ideal speed sweet spot: moving too fast risks incomplete cuts and excessive dross, while too slow can cause wider cuts and heat distortion.

Factors Affecting Speed in Plasma Cutting

When evaluating the factors affecting plasma cutting speed, you’ll find that material thickness and type play crucial roles. Thicker materials demand slower speeds to guarantee quality cuts, while aluminum typically cuts faster than stainless steel due to its lower melting point and superior thermal conductivity.

Adjusting amperage settings influences arc power; higher amperage accelerates cutting but risks heat-induced distortion.

A critical aspect of achieving consistent speeds and quality is maintaining the ideal standoff distance between the torch and workpiece. Deviations can disrupt the process, impacting speed and quality.

Similarly, the correct gas type and pressure are essential, as they can either enhance or hinder the cutting process based on material and thickness.

Machine maintenance guarantees peak performance, while operator skill is indispensable for precision and adaptability, allowing you to navigate these variables effectively.

Mastering these factors liberates you to achieve efficient and high-quality plasma cutting.

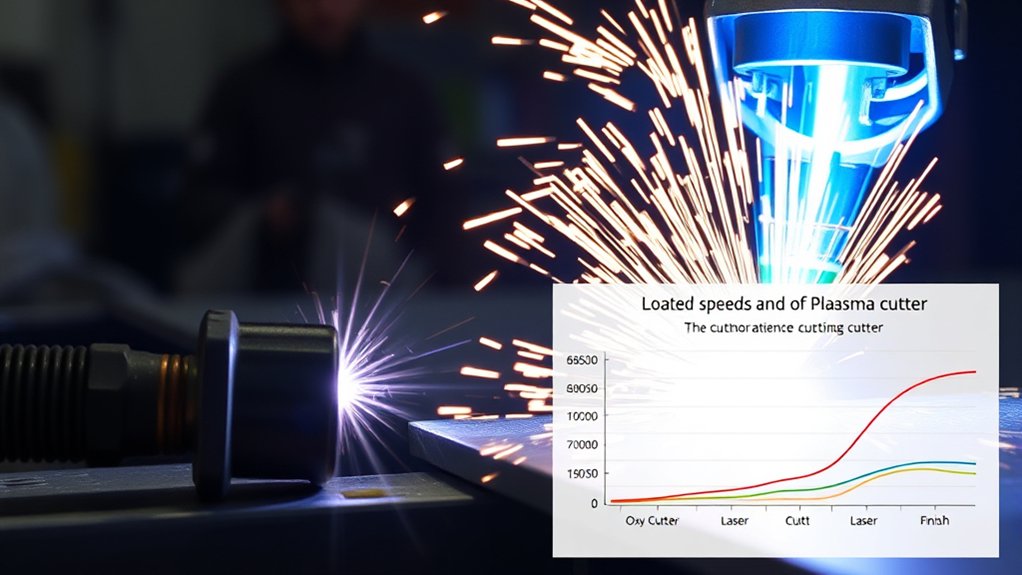

Comparing Plasma Cutting Speeds to Other Methods

Understanding the factors that impact plasma cutting speed equips you to appreciate how it compares to other cutting methods.

In the plasma versus oxy-fuel debate, plasma cutting shines with its speed advantage, achieving 20 to over 100 inches per minute (IPM) compared to oxy-fuel’s modest 5 to 20 IPM, especially for thicker materials. This rapid performance makes it ideal for high-volume settings, where time is a critical factor.

When you look at speed comparisons with laser cutting, plasma holds its ground, especially with high-definition plasma reaching speeds of 60-120 IPM.

While laser cutting averages 20-80 IPM, plasma excels in thicker materials over 1/2 inch, cutting steel at 15-30 IPM, outperforming mechanical methods.

Despite a kerf of 1.7 to 2.2 mm being wider than fiber laser’s 0.1 mm, plasma’s cutting speed for materials like stainless steel and aluminum, at 50-80 IPM, guarantees efficient operation.

Optimizing Speed for Quality Cuts

Achieving an ideal cutting speed is vital in plasma cutting, as it directly impacts the quality of the cut and operational efficiency. You must focus on speed calibration to enhance cutting efficiency, especially when dealing with varying material thicknesses.

High cutting speeds are advantageous, as they reduce the heat-affected zone (HAZ), minimizing surface alterations and chemical reactions, resulting in cleaner finishes. However, if you cut too slowly, you risk wider kerfs and excessive dross, which can compromise the integrity of your cuts. Additionally, slow speeds may cause torch extinguishment, halting your progress.

High cutting speeds yield cleaner finishes, while slow speeds risk wider kerfs and torch extinguishment, compromising cut integrity.

For high-definition plasma cutting, balancing speed and amperage is essential. Higher amperage facilitates faster cutting without sacrificing quality.

Manufacturers offer cutting speed charts for different materials, guiding you to achieve ideal results. By leveraging these resources, you can maximize cutting efficiency, reduce waste, and guarantee precision, freeing you to complete projects with confidence and excellence.

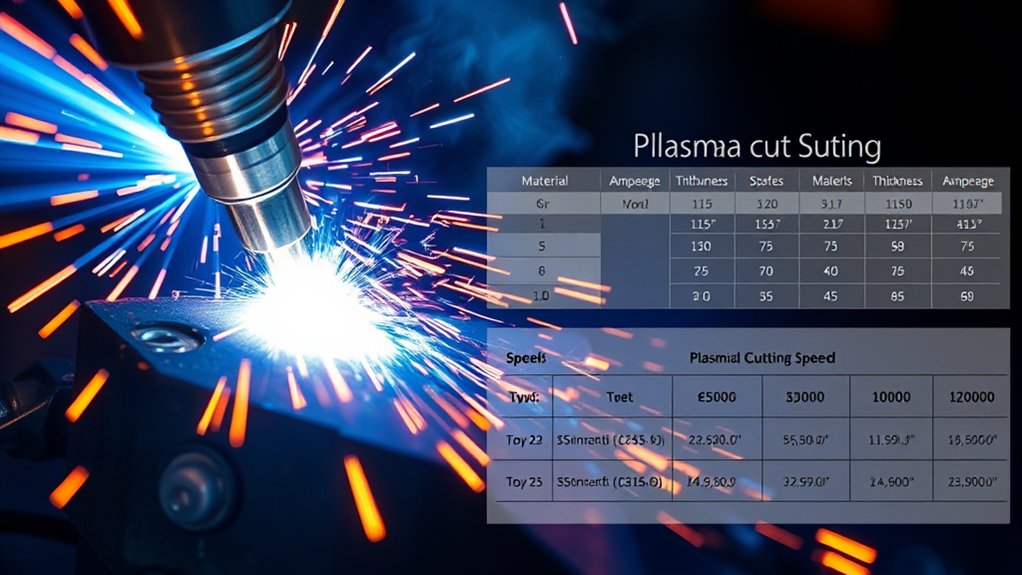

Speed Charts for Different Materials

Although plasma cutting demands precise control, speed charts for different materials offer invaluable guidance in achieving ideal results. Recognizing speed variations is essential when cutting diverse materials like mild steel, stainless steel, aluminum, and copper.

Mild steel, for instance, can be cut between 30-100 inches per minute (IPM), with speed largely determined by material thickness. Stainless steel requires a more cautious approach, typically ranging from 20-80 IPM, especially as thickness increases and cut quality remains paramount.

Aluminum, with its lighter nature, allows for speeds of 40-120 IPM, where thinner sheets benefit from greater agility. Copper, due to its high thermal conductivity, demands a thoughtful balance, cutting at 20-60 IPM. Here, both material thickness and plasma cutter power influence the process.

High-definition plasma systems enhance liberation by achieving over 100 IPM on thinner materials, ensuring precise edge quality and efficient operation. Use these insights to optimize your cutting endeavors.

Common Mistakes With Cutting Speed

When you set the cutting speed too fast, you risk arc instability and increased surface dross, undermining the cut quality.

Conversely, excessive slowness can cause wider kerfs and heat-induced distortions, necessitating a careful balance between speed and quality.

It’s essential to adjust your speed based on the material’s thickness and type, using manufacturer-provided charts to guarantee peak performance and cost-efficiency.

Incorrect Speed Consequences

Plasma cutting demands precise speed control to guarantee high-quality results and cost-efficiency. Achieving cutting efficiency relies on accurate speed calibration.

Too slow, and you risk:

1. Excessive Heat Transfer: This widens cuts, creating rounded edges and increased dross adherence.

2. Torch Extinguishment: Heat build-up can extinguish your torch, disrupting the process.

Conversely, cutting too fast causes:

3. Incomplete Penetration: The plasma arc may not fully penetrate, leaving unfinished cuts.

4. Increased Heat Load: High speeds stress the torch nozzle, risking damage and reducing consumable lifespan.

To optimize performance, carefully calibrate speed. Incorrect speeds compromise cut quality and inflate operational costs.

Precision liberates you from inefficiencies, ensuring every cut is sharp, clean, and economically viable.

Balancing Speed and Quality

Achieving ideal cutting performance hinges on the delicate balance between speed and quality. Speed consistency is key to ensuring quality assurance in plasma cutting.

If you cut too slowly, you risk wider cuts and excessive dross, compromising the finish. Conversely, cutting too fast can lead to incomplete cuts and surface dross, undermining the integrity of the workpiece.

Maintaining ideal cutting speed minimizes heat input, reducing the heat-affected zone and preventing distortion. Don’t overlook the importance of matching amperage to material thickness; higher amperage allows faster speeds but requires careful balancing to preserve cut quality.

Regularly consult manufacturer-provided speed charts to optimize settings, avoiding arc instability and consumable damage. Precision in these adjustments liberates your craftsmanship from common pitfalls.

Material-Specific Speed Adjustments

Understanding material-specific speed adjustments is essential for maximizing plasma cutting performance. Speed variations hinge on material thickness, type, and desired cut quality. Here’s a detailed breakdown:

- Mild Steel: Speeds range from 20 to 100 IPM. Adjust based on thickness and amperage.

- Aluminum: Requires faster speeds than steel to prevent heat buildup and guarantee smooth edges.

- Stainless Steel: Needs slower speeds due to higher thermal conductivity, demanding precise calibration to avoid distortion.

- Avoiding Mistakes: Don’t use a one-size-fits-all setting. Tailor speeds for specific material thicknesses using manufacturer charts for best results.

Neglecting these nuances leads to poor cut quality, excessive dross, and potential material waste.

Embrace these adjustments to enhance cutting efficacy, achieving true liberation in your fabrication endeavors.

Tips for Achieving Optimal Cutting Speeds

When seeking ideal cutting speeds with a plasma cutter, it’s vital to focus on matching the machine’s amperage to the material thickness. This alignment guarantees you maximize speed without sacrificing cut quality.

Pay attention to your torch angle and maintain proper nozzle maintenance, as these factors greatly impact performance. A consistent standoff distance of 1/8 inch between the torch and workpiece is essential to avoid distortion and achieve uniform cuts.

Proper nozzle maintenance and consistent torch angle are crucial for distortion-free, uniform cuts.

Regularly refer to manufacturer cutting speed charts to identify the best speed settings for your specific material. Cutting too quickly can result in incomplete cuts and increased dross, while slower speeds may cause excessive heat and wider kerfs.

For enhanced efficiency, consider integrating advanced technologies like Beacon apps, which provide real-time adjustments to maintain ideal voltage and speed. By implementing these strategies, you’ll not only improve the precision of your cuts but also experience greater control and freedom in your projects.

Frequently Asked Questions

Can Plasma Cutters Cut Underwater Without Speed Reduction?

Yes, you can perform underwater cutting without significant speed reduction. Plasma efficiency remains high due to the water’s cooling effect, stabilizing the arc. This liberates you from heat distortion, ensuring precise cuts and maintaining peak performance.

How Does Plasma Cutter Speed Vary With Different Gases?

Plasma cutter speed varies with gas type. Using oxygen boosts speed, enhancing cut quality. Nitrogen and argon-hydrogen mixtures provide slower, precise cuts. Your choice liberates you to optimize efficiency and finish, balancing speed with quality.

Are There Speed Limitations for Handheld Plasma Cutters?

Yes, you’ll encounter speed limitations with handheld plasma cutters. Ideal cutting techniques, material thickness, and power settings all impact efficiency. Mastering these factors liberates you from constraints, allowing precise, swift cuts without compromising accuracy or quality.

How Does Operator Skill Impact Plasma Cutting Speed?

Ah, operator skill—where dreams of lightning-fast cuts meet the reality of practice! With experience, you’ll master cutting techniques, optimizing speed. Precision and control become your allies, liberating you from mundane constraints of mere metal slicing.

Does Ambient Temperature Affect Plasma Cutter Speed?

Ambient temperature affects plasma cutter speed by altering the arc’s stability. You’ll find that extreme conditions can disrupt efficiency. Understanding temperature effects helps you adjust settings, ensuring peak performance despite challenging ambient conditions, freeing you from inconsistent cuts.

Conclusion

You’ve seen how plasma cutting speeds vary greatly based on material and thickness, yet optimization remains key. Manufacturers’ speed charts are invaluable, guiding you to balance speed and quality. Remember, faster isn’t always better; precision demands the right settings. By understanding these dynamics, you can guarantee efficient, high-quality cuts. Always refer to the charts and adjust for factors like material type and thickness. Mastering this will elevate your cutting precision and efficiency to professional levels.