One of the biggest lessons I picked up early in the shop was realizing that a weld can look perfect on the surface yet fail the moment real stress is applied. That’s where understanding how to calculate weld strength becomes essential. Whether you’re running MIG for faster fabrication, fine-tuning TIG on stainless, or selecting the right filler rods for different metal thicknesses, the joint’s true performance depends on more than bead appearance.

Factors like joint prep, arc control, and penetration depth directly affect weld quality, safety, and overall structural strength. Many welders — pros and DIY enthusiasts alike — get tripped up by this, wondering why a clean-looking weld won’t hold. In this guide, I’ll walk you through practical, battle-tested ways to calculate weld strength, so your projects are not only cost-efficient and professional-looking but also built to stand the test of time.

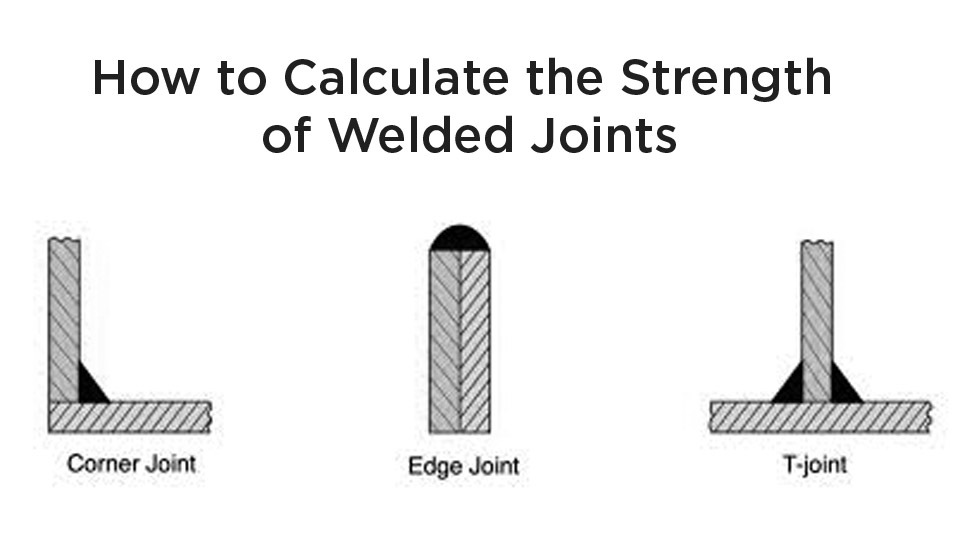

Image by extrudesign

Why Weld Strength Matters

I learned the hard way early in my career when a buddy asked me to weld a bracket for his trailer. I laid down a decent-looking bead, but I didn’t account for the load it would carry. The weld cracked under the weight of his gear, and I had to eat the cost of repairs. That taught me one thing: weld strength isn’t just about looks—it’s about safety, durability, and saving you from costly rework.

Whether you’re a DIYer fixing farm equipment, a hobbyist building a custom gate, or a pro working on a skyscraper, understanding weld strength ensures your joints hold up under tension, shear, or bending forces.

Weld strength calculations help you pick the right filler metal, joint type, and welding process for the job. They also ensure compliance with standards like those from the American Welding Society (AWS), which is critical for professional work in the USA. Plus, knowing the math can save you material costs by avoiding over-welding while still meeting safety margins.

Understanding Weld Joint Types

Before we get to the formulas, let’s talk about the main types of weld joints you’ll encounter. Each has its own strength characteristics, and choosing the right one is half the battle.

Butt Joints

A butt joint is when two pieces of metal are joined end-to-end. Think of welding two plates together to form a flat surface, like in a pipeline or structural beam. These joints are great for tension and compression loads but require precise prep for full penetration. I’ve seen DIYers skip beveling on thicker plates, thinking a single pass will do. Spoiler: it won’t. Incomplete penetration is a common mistake that weakens the joint.

Pro Tip: For plates over 5mm thick, bevel the edges to a V or U shape to ensure the weld fills the gap. Use a grinder to get a clean 30-45° angle for better fusion.

Fillet Welds

Fillet welds are the workhorse of welding, used in T-joints, lap joints, or corner joints where pieces meet at an angle. They’re easier to execute than butt welds because they don’t always need edge prep, but their strength depends heavily on the throat size—the shortest distance from the weld’s root to its face.

I once welded a T-joint for a custom workbench, assuming my bead size was enough. It held for a week before cracking under heavy hammering. Lesson learned: measure your fillet size carefully and calculate the throat to avoid under-sizing.

Lap Joints

Lap joints involve overlapping two plates and welding along the edges. They’re common in sheet metal work or automotive panels. Single transverse lap welds (one side) are weaker than double transverse or parallel welds, so consider your load direction when choosing.

Other Joints

Edge joints and corner joints pop up in specific cases, like thin sheet metal or box frames. They’re less common for load-bearing applications but still need strength calculations, especially if they’re under shear stress.

Factors That Affect Weld Strength

Weld strength isn’t just about the joint type. Several factors play into how strong your weld will be, and ignoring them is like welding blindfolded.

Material Properties

The base metal and filler metal set the baseline for strength. For example, mild steel with a yield strength around 36 ksi and a minimum tensile (ultimate) strength of 58 ksi (ASTM A36) should be paired with a compatible filler; a common choice is an E7018 electrode with a 70 ksi weld deposit tensile strength (Ryerson, 2025 retrieved; Exocor, accessed 2025-10-14).

Weld Size and Length

Bigger isn’t always better, but weld size matters. For fillet welds, the leg size (the length of the weld’s sides) determines the throat size, which we’ll use in calculations. Longer welds distribute stress better, increasing strength, but over-welding wastes filler and time.

Welding Process

MIG, TIG, stick, or flux-cored welding each affects joint quality. MIG is great for speed and consistency, but I’ve found TIG gives cleaner, stronger welds for critical jobs like aerospace parts. Stick welding, with rods like E6010 or E7018, is versatile but can introduce slag inclusions if you’re not careful. Always match your process to the material and joint type.

Weld Quality

Porosity, cracks, or incomplete fusion can cut your weld’s strength by 30–50%. I’ve had welds pass a visual inspection but fail under load because of tiny pores I didn’t catch. Non-destructive testing (NDT) like dye penetrant or ultrasonic testing can spot these flaws before they cause trouble.

Load Type

Welds face different forces: tensile (pulling), shear (sliding), or bending. Each requires a tailored calculation. For example, a fillet weld under shear needs a different approach than a butt weld under tension. Misjudging the load type is a common error that leads to failure.

How to Calculate Weld Strength: Step-by-Step

Now, let’s get to the math. Don’t worry—I’ll walk you through it like I’m showing a new welder in my shop. We’ll cover the two most common calculations: fillet welds and butt welds.

Fillet Weld Strength

Fillet welds are often calculated for shear strength, as they’re commonly used in T-joints or lap joints where sliding forces are the main concern. Here’s the process:

Measure the Weld Size: The leg size (s) is the length of the weld’s sides. The throat size (t) is calculated as t = 0.707 × s for a right-angled fillet weld (AISC/AWS). AISC steelwise, 2013

Determine the Weld Length (l): Measure the total length of the weld in inches or millimeters.

Find the Material’s Allowable/Design Stress: For weld metal, the nominal shear strength per AISC 360-22 is 0.60 × FEXX on the effective throat area; design strength = φ × (0.60 × FEXX) × A for LRFD (φ = 0.75 for fillet welds) or allowable strength = (0.60 × FEXX × A)/Ω for ASD (Ω = 2.0). AISC 360-22, 2022; AWS D1.1:2025

Calculate Strength: For a single fillet weld, the commonly used nominal formula is Pn = 0.707 × s × l × (0.60 × FEXX). For a double fillet weld (both sides), double the effective area. AISC steelwise, 2013

Example: T-joint with ¼-in (0.25 in) leg, 6 in length, E7018 (FEXX=70 ksi per AWS classification). Nominal capacity:

Pn = 0.707 × 0.25 × 6 × (0.60 × 70) ≈ 44.5 kips (44,500 lb)Design values: LRFD φPn ≈ 33.4 kips; ASD allowable ≈ 22.3 kips. AISC 360-22, 2022. (E7018 70 ksi: Exocor, accessed 2025-10-14)

Common Mistake: Using ad-hoc “safety factors.” Instead, use code factors: φ = 0.75 (LRFD) or Ω = 2.0 (ASD) for welds, and verify base metal checks where applicable. AISC 360-22, 2022

Butt Weld Strength

Butt welds are typically calculated for tensile or compressive loads. For complete joint penetration (CJP) groove welds made with matching filler, strength is taken as the base metal strength; reinforcement is not counted toward strength in code design. AWS D1.1:2025; AISC 360-22, 2022

- Measure the Cross-Sectional Area: For a full-penetration butt weld, the effective area (A) equals plate thickness (t) × weld length (l).

- Use Base Metal Tensile Strength: For ASTM A36 steel, the specified minimum tensile strength Fu is 58–80 ksi (use ≥58 ksi for calculations). Ryerson, retrieved 2025-10-14

- Calculate: Nominal strength

Pn = A × Fu; LRFD design ≈ φt × A × Fu (φt=0.90 for tension), or check ASD per AISC.

Example: ½-in thick plate, 10 in long (A = 5 in²), ASTM A36 with Fu = 58 ksi ⇒ Pn = 290 kips; LRFD φtPn ≈ 261 kips. AISC 360-22, 2022; Ryerson, retrieved 2025-10-14

Pro Tip: For critical work, size CJP groove welds so the base metal governs; don’t credit cap reinforcement for additional strength unless your governing code explicitly permits it. AWS D1.1:2025

Safety Factors and Industry Standards

In the USA, weld design follows AWS D1.1 and AISC 360. Use LRFD resistance factors (e.g., φ = 0.75 for weld shear; φ = 0.90 for base metal tension) or ASD with Ω = 2.0 as applicable. For cyclic/fatigue loads, use the code’s fatigue provisions rather than generic multipliers. AISC 360-22, 2022; AWS D1.1:2025

Practical Tips for Strong Welds

Here’s where my years in the shop come in handy. These tips will help you apply your calculations in the real world.

Joint Preparation

Cleanliness is everything. I’ve had welds fail because I didn’t grind off rust or mill scale. Use a wire brush or grinder to clean the joint, and chamfer edges for butt welds on thicker plates. For fillet welds, ensure a tight fit-up to avoid gaps that weaken the joint.

Machine Settings

Your welding machine settings depend on the process and material. For MIG on mild steel, I set my voltage around 18–22V and wire speed at 200–300 IPM for a ¼-inch fillet. For stick welding with E7018, I run 90–120 amps for a 1/8-inch rod. Test on scrap metal first to dial in your settings.

Filler Metal Selection

Match your filler to the base metal’s strength. For mild steel, E7018 or ER70S-6 (MIG) are solid choices. For stainless, 308L or 316L fillers work well. I once used an E6010 rod on a structural job because it was all I had—big mistake. The weld held but didn’t meet code due to poor penetration.

Testing Your Welds

For critical jobs, test your welds. Visual inspection catches surface flaws, but NDT like dye penetrant or ultrasonic testing finds hidden defects. If you’re a DIYer, do a simple stress test by loading the joint (e.g., hanging weight on a bracket) to see if it holds.

Comparison Table: Weld Joint Types

| Joint Type | Best For | Pros | Cons | Typical Filler |

|---|---|---|---|---|

| Butt Joint | Structural beams, pipelines | High strength, clean look | Needs precise prep | E7018, ER70S-6 |

| Fillet Weld | T-joints, lap joints | Easy to execute, versatile | Weaker under tension | E6010, E7018 |

| Lap Joint | Sheet metal, automotive | Simple setup | Limited strength | ER70S-6, 308L |

| Edge Joint | Thin sheets | Minimal material use | Weak for heavy loads | 4043 (aluminum) |

Common Mistakes and How to Fix Them

Undersized Welds: Calculate the throat size and double-check your measurements. If the weld fails, grind it out and re-weld with a larger bead.

Poor Penetration: Increase amperage or use a slower travel speed. For butt welds, ensure proper beveling.

Weld Imperfections: Slow down your technique to avoid porosity or inclusions. Clean the joint thoroughly before welding.

Ignoring Load Type: Always consider whether the joint faces tension, shear, or bending. Adjust your calculation and joint design accordingly.

Real-World Applications

In construction, weld strength calculations ensure beams and columns can handle skyscraper loads. In automotive, lap welds on frames must withstand vibrations and crashes. For DIYers, calculating strength for a trailer hitch or gate ensures it won’t fail when you need it most. I once helped a student weld a custom motorcycle frame—crunching the numbers ensured it could handle high-speed stresses without cracking.

Conclusion

Calculating the strength of welded joints is like having a roadmap for safe, reliable welds. By understanding joint types, mastering the math, and applying practical tips, you’re ready to tackle any project—whether it’s a backyard repair or a professional fabrication job.

You now know how to measure weld size, pick the right filler, and account for real-world stresses. Always design and check against the governing code (AWS D1.1/AISC 360) and include appropriate LRFD or ASD factors for safety. AWS D1.1:2025; AISC 360-22

FAQ

What is the formula for fillet weld strength?

For a single fillet weld in shear, a common nominal check is Pn = 0.707 × s × l × (0.60 × FEXX), where s is leg size, l is weld length, and FEXX is electrode classification strength. Design (LRFD) uses φ = 0.75; ASD uses Ω = 2.0. AISC steelwise, 2013; AISC 360-22

How do I choose the right filler metal for my weld?

Match the filler’s tensile strength to the base metal and your WPS. For mild steel, E7018 or ER70S-6 are common; for stainless, 308L or 316L are typical. Verify electrode classifications and properties per manufacturer/AWS. E7018 data (AWS class), accessed 2025-10-14

Why do my welds keep cracking?

Cracks often come from poor joint prep, mismatched materials, or excessive heat input. Clean the joint, use the right filler, and dial in your machine settings. For susceptible materials or thick sections, preheating can reduce cracking risk per WPS/code.

Can I calculate weld strength without testing?

Yes—calculations give a good estimate, but testing (visual, NDT, or proof loading) improves real-world reliability. For code work, qualify procedures/personnel and inspect per AWS D1.1. AWS D1.1:2025

What’s the difference between tensile and shear strength in welds?

Tensile strength measures resistance to pulling forces (common in butt/CJP groove weld checks). Shear strength measures resistance to sliding forces (common in fillet welds). Use the correct code equations and factors for the load type. AISC 360-22