For edge fillet welds, size to the thinner part. If that thinner plate is under 1/4 in., the max fillet weld can equal the plate thickness. For 1/4 in. and thicker, cap the fillet at plate thickness minus 1/16 in. Use AISC/AWS minimums for the other side of the range.

Key takeaways

- Edge max rule: Under 1/4 in. → full thickness; ≥1/4 in. → thickness – 1/16 in.

- Minimums (thinner part): up to 1/4 → 1/8; >1/4–1/2 → 3/16; >1/2–3/4 → 1/4; >3/4 → 5/16.

- Strength tracks throat, which is ~0.707 × leg for equal-leg fillets.

- Oversizing adds heat, distortion, and cost; size to the job, not the ego.

What Determines the Maximum Fillet Weld Size for Your Plate Thickness?

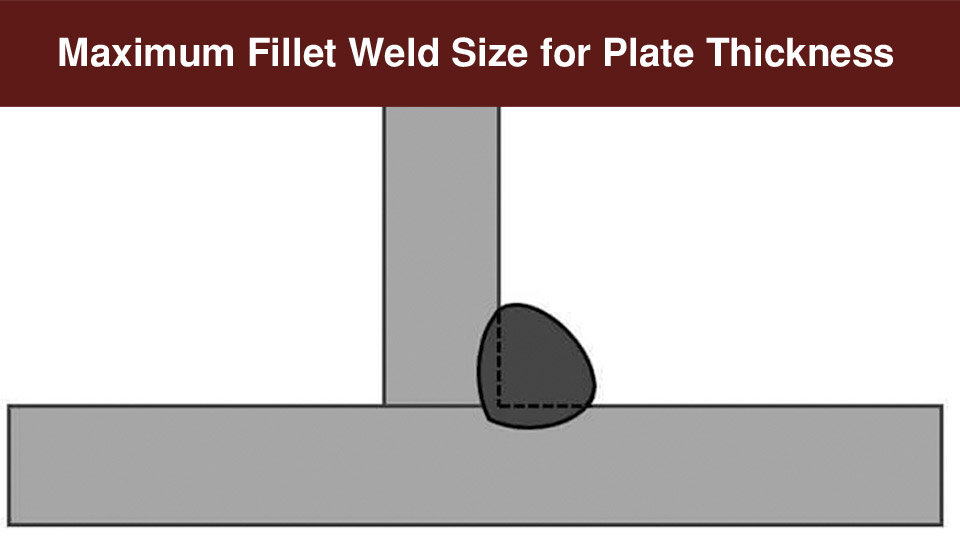

Let’s kick this off with the basics. The maximum fillet weld size isn’t arbitrary—it’s tied directly to the thickness of the thinner plate in your joint. In simple terms, you don’t want your weld leg eating into the base metal more than it should, which could compromise the throat—the real workhorse dimension that carries the load.

For plates under 1/4 inch thick, the max fillet weld size is typically the full plate thickness. Once you hit 1/4 inch or thicker, dial it back to about 1/16 inch less than the plate thickness for edge welds. This protects that corner from melting back and keeps the throat effective.

Why Should You Care About Limiting Fillet Weld Size Based on Plate Thickness?

Oversized welds can lead to distortion, cracking, and failed inspections, while undersized ones risk structural weakness. Limiting size keeps heat input sane, reduces rework, and preserves properties—especially on galvanized, stainless, or aluminum where excess heat is costly.

Breaking Down Fillet Weld Anatomy: Leg Size, Throat, and What It Means for Plate Thickness

The leg is that triangular profile you see—the distance from the root to the toe along each side. The throat is the shortest distance through the weld. For equal-leg fillets, the effective throat is roughly 0.707 × leg, which is what codes use to compute strength.

AISC and AWS Rules: Your Go-To Guidelines for Maximum Fillet Weld Sizing

In the U.S., AISC’s Specification Section J2.2b limits edge fillets to t (if t < 1/4 in.) or t – 1/16 in. (if t ≥ 1/4 in.). AWS D1.1/D1.1M (2020 and 2025 editions) provides compatible minimums (Table 7.7). If in doubt, size to the thinner part and follow the WPS.

| Plate Thickness (in.) — thinner part | Minimum Fillet Size (in.) | Maximum Fillet Size (in.) — Edge Welds |

|---|---|---|

| Up to 1/4 | 1/8 | Equal to thickness |

| Over 1/4 to 1/2 | 3/16 | Thickness − 1/16 |

| Over 1/2 to 3/4 | 1/4 | Thickness − 1/16 |

| Over 3/4 | 5/16 | Thickness − 1/16 |

When Does Plate Thickness Dictate a Smaller Fillet Weld? Real-World Scenarios

Lap joints at edges are the classic case for the max rule to avoid edge melt-back. T-joints on plate faces don’t have that edge limitation, but watch distortion and heat input—especially on high-carbon steels.

Step-by-Step: How to Calculate and Apply the Maximum Fillet Weld Size

- Measure both parts. The thinner thickness governs sizing.

- Identify joint type. Edge/lap/corner → apply the t–1/16 edge rule for t ≥ 1/4 in.; otherwise full-thickness.

- Estimate throat. Effective throat ≈ 0.707 × leg (equal-leg).

- Prep and fit-up. Clean to bright metal; keep gaps tight unless qualified otherwise.

- Set parameters. Use your WPS or a trusted calculator to dial in amperage/voltage/wire feed; validate on scrap.

- Weld, measure, verify. Use a fillet gauge mid-weld, not only at the ends.

Common Mistakes and Quick Fixes

Oversizing: Adds heat and cost; sequence and clamp to reduce warping. Undersizing: Risks lack of fusion; ensure minimums and proper travel speed. Process mismatch: Match filler and process to the base metal strength and position.

Best Practices for Prep Across Thicknesses

Thin (<1/4 in.): usually no bevel, tight fit, low heat. Thicker: clean land or slight bevel for consistent fusion. Ventilate especially on galvanized.

Machine Settings for Cleaner Fillet Welds

Use your WPS first. Otherwise, treat the numbers here as starting points and confirm with a reputable calculator or manufacturer’s charts. Every joint, position, and wire type changes the window.

Fillet Welds in Everyday Applications: Trailers, Frames, and Structural Builds

On trailers and frames, right-sizing welds keeps parts straight and saves filler. In structural work, follow code/written procedures—multi-pass fillets, sequencing, and preheat as required.

Pros and Cons of Pushing Fillet Weld Limits on Thicker Plates

Going bigger boosts capacity but raises distortion and cost. Often it’s smarter to add length or passes instead of size.

Advanced Tips: Multi-Pass Fillets and Filler Selection

Build throats with multiple passes rather than a single hot, wide bead. For low-hydrogen needs on thick plate, store and bake rods per manufacturer recommendations.

Conclusion

Always size to the thinner member, respect edge limits to avoid melt-back, and lean on AISC/AWS basics. Keep a notebook of settings and outcomes—you’ll dial in faster than any class.

FAQs

- What is the minimum fillet weld size for a 1/2-inch plate?

- 3/16 in. (because 1/2 in. falls in the “over 1/4 to 1/2” range). Use a larger size if required by load/WPS.

- Can I weld a fillet larger than the plate thickness?

- On edge/lap/corner joints, no—follow the edge max rule. On T-joints on plate faces, the edge rule doesn’t apply, but distortion and cost usually limit size.

- Why do fillet welds warp on thicker plates?

- Heat input and uneven shrinkage. Clamp well, balance your sequence, and control interpass per WPS.

- How do I measure fillet weld size accurately?

- Use a fillet gauge to check leg length; remember ,strength tracks the effective throat (≈0.707 × leg for equal-leg fillets).

- What process is best for thin plates?

- MIG short-circuit or TIG for control. SMAW can work, but requires tight control of your parameters.

Related resources