When I first tackled MIG welding galvanized steel, I quickly realized it wasn’t as straightforward as running a bead on plain carbon steel. The zinc coating burned off under the arc, throwing up clouds of fumes, spatter, and leaving behind weak spots that made the weld brittle. That’s when it hit me—without the right joint prep, arc control, and filler metal selection, you’re fighting an uphill battle.

A lot of welders wonder if it’s better to grind the zinc, switch to TIG, or adjust settings for different metal thicknesses, and I’ve wrestled with those same questions in my own projects. Getting it wrong can mean wasted time, poor weld quality, or even serious safety risks. In this guide, I’ll share the battle-tested tips and shop-floor tricks that make MIG welding galvanized steel not only doable but reliable, safe, and cost-effective.

Image by mig-welding.co.uk

What Is Galvanized Steel and Why Is It Tricky to Weld?

Galvanized steel is just regular steel coated with a thin layer of zinc to protect it from rust and corrosion. You’ll see it in fencing, guardrails, sheet metal, or even car parts. The zinc acts like a shield, sacrificing itself to keep the steel underneath safe.

Sounds great, right? But when you MIG weld galvanized steel, that zinc layer becomes a headache. It has a low melting point—about 787°F (419.5°C) and a boiling point of ~1,665°F (907°C)—compared to steel’s ~2,500°F, so under the arc it vaporizes quickly, creating fumes and messing with your weld pool (Royal Society of Chemistry, accessed 2025-10-14).

The biggest challenges? First, those zinc fumes can cause metal fume fever, a flu-like illness that’ll knock you out for a day or two. Second, the zinc can cause porosity (tiny holes) in your weld, weakening it. And third, if you don’t prep properly, your weld bead might look like a lumpy mess.

I learned this the hard way early on when I tried welding a galvanized gate without grinding the coating off first—my welds popped and sputtered, and I ended up with a porous bead that wouldn’t pass a visual inspection.

The fix? Proper preparation, the right equipment, and a solid understanding of how to handle the zinc. Let’s break it down.

Safety First: Protecting Yourself When Welding Galvanized Steel

Before we even touch the MIG gun, let’s talk safety. Welding galvanized steel produces zinc oxide fumes, which are no joke. Inhaling them can lead to metal fume fever—think chills, fever, nausea, and a headache that feels like a bad hangover. I’ve seen welders try to tough it out in a poorly ventilated shop, only to spend the next day in bed. Don’t be that guy. For authoritative guidance, see the NIOSH Pocket Guide entry for zinc oxide (accessed 2025-10-14) and OSHA’s hot work requirements (29 CFR 1910.252).

Must-Have Safety Gear

Respirator: Use a NIOSH-approved respirator with a P100 filter for high-efficiency particulate filtration; other N/R/P-series filters at 95 or 99% efficiency are acceptable at lower concentrations per NIOSH guidance. In confined or higher-exposure situations, consider a powered air-purifying respirator (PAPR) (NIOSH NPG—Zinc Oxide, accessed 2025-10-14).

Ventilation: Weld outdoors if possible, or use local exhaust/fume extraction positioned at the arc. A general shop fan isn’t enough—zinc fumes need active removal (OSHA Fact Sheet “Controlling Hazardous Fume and Gases during Welding,” 2013; accessed 2025-10-14).

PPE: Wear a welding helmet with a shade appropriate to your amperage (e.g., MIG 60–160 A: shade 11; 160–250 A: shade 12; 250–500 A: shade 14), a flame-retardant jacket, leather gloves, and steel-toed boots (OSHA Eye Protection Fact Sheet, accessed 2025-10-14).

Hydration: Stay hydrated. Note: the old “drink milk” idea is a myth and does not protect against welding fumes—rely on ventilation and certified respiratory protection instead (Cancer Council Australia, accessed 2025-10-14).

Pro Tip

Set up a portable fume extractor right near your weld zone. It’s a game-changer for keeping fumes out of your lungs and your shop air clean (also aligned with OSHA 1910.252).

Prepping Galvanized Steel for MIG Welding

Prep work is everything when MIG welding galvanized steel. The zinc coating needs to go before you strike an arc, or you’ll end up with a weak, porous weld. Here’s how I do it in my shop.

Step-by-Step Prep Process

Grind Off the Zinc: Use a coarse 36-grit grinding disc or flap wheel to remove the zinc coating at least 1–2 inches around the weld area on both sides of the metal. Be thorough—zinc smeared into the steel can still cause issues. I’ve made the mistake of rushing this step, and my welds ended up looking like Swiss cheese.

Clean the Surface: After grinding, wipe the area with a degreaser or acetone to remove oil, dirt, or residue. A clean surface means a stronger weld.

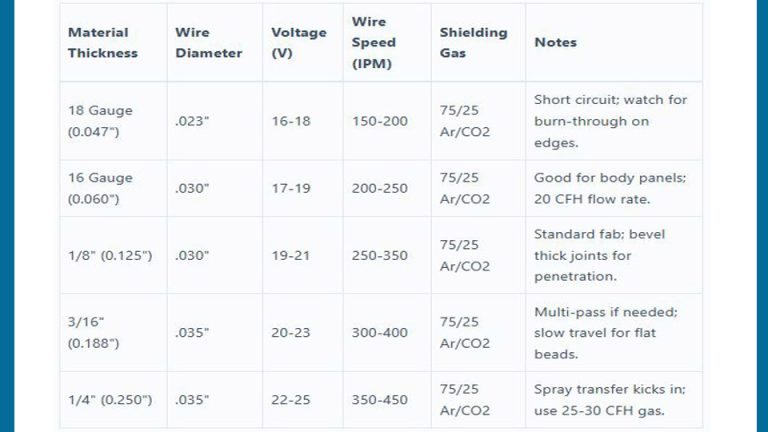

Check for Thickness: Galvanized steel comes in various gauges, from thin sheet metal to thick structural plates. Match your wire size and machine settings to the material thickness (more on that later).

Apply Anti-Spatter Spray: This helps prevent spatter from sticking to the weld area, which is especially useful since galvanized steel tends to produce more spatter than bare steel.

Common Mistake

Don’t just burn off the zinc with your torch. It might seem faster, but it creates more fumes and can contaminate your weld pool. Grind it off properly to save yourself headaches.

Choosing the Right MIG Welder and Settings

Not all MIG welders are created equal for galvanized steel. You’ll need a machine with enough power to handle your material thickness and the right settings to control the arc. Here’s what to consider.

Welder Requirements

Amperage: For thin galvanized sheet (1/8 inch or less), a 110–140A welder like the YesWelder MP200 works fine. For thicker plates (1/4 inch or more), go for a 200–300A machine like the Miller Millermatic 255.

Duty Cycle: Look for at least a 30% duty cycle at your target amperage to avoid overheating during long welds.

Gas vs Gasless: Shielding gas is preferred for cleaner welds, but flux-cored wire (gasless) is better for outdoor jobs where wind might blow gas away.

Recommended Settings

Shielding Gas: A 75% argon/25% CO2 mix (C25) is ideal for mild steel and galvanized steel. It reduces spatter and gives a smooth arc. For thicker materials, you might try 100% CO2 for deeper penetration, but expect more spatter.

Wire Feed Speed and Voltage: Start with a wire feed speed of 150–200 inches per minute (IPM) and voltage around 18–22V for 1/8-inch steel. Adjust based on your welder’s chart. I always fine-tune by listening to the arc—it should sound like steady bacon frying, not popping popcorn.

Wire Type: Use ER70S-3 or ER70S-6 filler wire (0.030–0.035 inch diameter for most jobs). ER70S-3 is great for cleaner welds with less spatter, while ER70S-6 handles dirtier surfaces better.

My Go-To Setup

For a 1/8-inch galvanized steel fence post, I use my Hobart Handler 210 MVP with a C25 mix, 0.035-inch ER70S-3 wire, 19V, and 180 IPM. I push the torch at a 10-degree angle to keep the arc stable and minimize spatter.

MIG Welding Techniques for Galvanized Steel

Now that your steel is prepped and your machine is dialed in, let’s talk technique. MIG welding galvanized steel requires a steady hand and some specific moves to get a clean, strong weld.

Push vs. Pull Technique

Push Technique: Push the torch forward at a 10–15-degree angle. This gives better visibility and a smoother bead, especially on thin material. It’s my go-to for sheet metal jobs like HVAC ducts.

Pull Technique: Pulling (or dragging) the torch increases penetration but can produce more spatter. Use this for thicker plates or when you need deeper weld fusion.

Stick-Out and Travel Speed

Keep your contact-tip-to-work distance (CTWD) at about 3/8 inch. Too long, and you’ll get a weak arc; too short, and you’ll burn your tip. Move at a steady pace—about 10–15 inches per minute for thin steel, slower for thicker stuff. If your bead looks uneven, you’re probably moving too fast.

Common Mistake

Don’t rush your travel speed to “get it over with.” I did this once on a galvanized trailer frame, and the weld was so shallow it cracked under load. Take your time for proper penetration.

Filler Wire and Shielding Gas Options

Choosing the right filler wire and shielding gas is critical for MIG welding galvanized steel. Here’s a quick comparison to help you decide.

| Option | Pros | Cons |

|---|---|---|

| ER70S-3 Wire | Less spatter, cleaner welds | Less forgiving on dirty surfaces |

| ER70S-6 Wire | Better for rusty or coated surfaces | More spatter, slightly messier bead |

| C25 Gas (75% Argon/25% CO2) | Smooth arc, minimal spatter | More expensive, wind-sensitive |

| 100% CO2 Gas | Deeper penetration, cheaper | More spatter, rougher bead |

| Flux-Cored Wire | No gas needed, great for outdoors | More cleanup, less precise |

When to Use What

- ER70S-3: Best for clean, prepped galvanized steel in a controlled shop environment.

- ER70S-6: Use if you can’t fully remove the zinc or are welding slightly dirty steel.

- C25 Gas: My default for most indoor jobs—clean welds and less post-weld grinding.

- Flux-Cored: Handy for field work, like fixing a galvanized gate outdoors.

Anecdote

I once tried using 100% CO2 on a thin galvanized sheet because I was out of C25. Big mistake—the spatter was so bad I spent more time cleaning than welding. Stick with C25 unless you’re welding thick plates.

Post-Weld Treatment: Restoring Corrosion Resistance

After welding, the zinc coating is gone from your weld area, leaving the steel vulnerable to rust. To keep that corrosion resistance, you need to reapply a protective layer.

Steps for Post-Weld Treatment

Clean the Weld: Use a wire brush to remove spatter and slag. A clean weld ensures better coating adhesion.

Apply Zinc-Rich Paint: Use a cold galvanizing compound to spray or brush over the weld; zinc-rich paint is an accepted touch-up method under ASTM A780 (American Galvanizers Association summary of ASTM A780, accessed 2025-10-14).

Inspect the Weld: Check for cracks or porosity using a magnifying glass or dye penetrant for critical jobs. A porous weld on a galvanized pipe can lead to leaks or failure.

Maintenance: Store welded parts in a dry environment and inspect annually for rust, especially in harsh conditions like coastal areas.

Pro Tip

Apply two thin coats of zinc-rich paint instead of one thick one. It dries faster and adheres better, giving you longer-lasting protection.

Common Challenges and How to Fix Them

Even with the best prep, MIG welding galvanized steel can throw curveballs. Here are the most common issues I’ve run into and how to handle them.

Porosity in the Weld

- Cause: Zinc vapor trapped in the weld pool.

- Fix: Grind off more zinc before welding, slow your travel speed, and increase gas flow to 20–25 CFH.

Excessive Spatter

- Cause: Too much zinc left on the surface or incorrect settings.

- Fix: Use anti-spatter spray, lower your voltage slightly, and switch to a C25 gas mix if you’re using 100% CO2.

Weak Weld Penetration

- Cause: Insufficient amperage or moving too fast.

- Fix: Bump up your amperage and slow your travel speed. For butt welds, widen the gap slightly to improve penetration.

Anecdote

On a job welding galvanized ductwork, I kept getting porosity despite grinding. Turned out, my gas flow was too low—bumping it to 22 CFH cleared it up. Always double-check your regulator!

Applications of MIG Welding Galvanized Steel

This process pops up in all sorts of projects, from DIY to industrial. Here are a few real-world examples:

- DIY: Repairing a galvanized trailer or building a custom gate.

- Hobbyist: Crafting outdoor sculptures or furniture from galvanized sheet.

- Professional: Welding HVAC ducts, guardrails, or structural components in construction.

- Students: Practicing on galvanized steel to learn about material challenges and safety.

Each application demands attention to prep and safety, but MIG welding’s speed and versatility make it a top choice.

Conclusion

MIG welding galvanized steel isn’t just another weld—it’s a skill that demands respect for the material and the process. By grinding off the zinc, using the right settings, and prioritizing safety, you can create strong, clean welds that hold up in the real world.

Whether you’re a DIYer fixing a fence, a hobbyist building a masterpiece, or a pro tackling a big job, you’re now equipped to handle galvanized steel like a seasoned welder. Always keep a spare respirator filter in your shop—you never know when you’ll need it, and it’s a small price to pay for staying healthy.

FAQ

Can you MIG weld galvanized steel without removing the zinc coating?

You can, but it’s not recommended. Welding over zinc creates toxic fumes and weak, porous welds. Always grind off the zinc at least 1–2 inches around the weld area for safety and quality.

What’s the best shielding gas for MIG welding galvanized steel?

A 75% argon/25% CO2 mix (C25) is best for most jobs. It gives a smooth arc and minimal spatter. For thicker steel, 100% CO2 can work but expect more cleanup.

What wire should I use for MIG welding galvanized steel?

ER70S-3 or ER70S-6 (0.030–0.035 inch) are your best bets. ER70S-3 is cleaner for prepped surfaces, while ER70S-6 handles slight zinc residue better.

How do I avoid metal fume fever when welding galvanized steel?

Wear a NIOSH-approved respirator, use local exhaust/fume extraction, and weld in a well-ventilated area. Grinding off the zinc before welding also reduces fume production (NIOSH, accessed 2025-10-14; OSHA Fact Sheet, accessed 2025-10-14).

Can I use flux-cored wire for galvanized steel?

Yes, flux-cored wire is great for outdoor welding since it doesn’t need shielding gas. Just be ready for more cleanup, as it produces more slag and spatter than gas-shielded wire.