You might think any compressor will do, but your plasma cutter demands clean, dry, regulated air to stabilize the arc and protect consumables. You’ll target 80–135 psi, with at least 1.5× the cutter’s CFM requirement, and a 20–60 gallon tank for steady flow and fewer pressure dips. Add proper filtration and a reliable regulator to control dew point and pressure drop. Next, you’ll match duty cycle, hose size, and power to your specific cut profile.

Why Your Plasma Cutter Needs Compressed Air

Although the arc does the cutting, compressed air makes it reliable: your plasma cutter needs a clean, dry, regulated air supply to stabilize the plasma stream, cool the torch, and protect consumables.

You rely on consistent pressure and flow rate so ionization stays steady, kerf remains narrow, and dross is minimized. Most systems specify 80–135 psi; setpoint must match the torch data sheet and be verified at the torch while flowing.

Compressed air also extracts heat from the nozzle and electrode, reducing thermal load and extending service intervals.

To prevent starvation, size your air supply so delivered CFM is at least 1.5× the plasma cutter needs under continuous duty. Shortfalls cause arc fluctuation, widened kerf, and premature wear.

Dryness and filtration directly impact cut quality: moisture or oil disrupts arc constriction and oxidizes components. Maintain dew point below ambient line temperature and use particulate/oil removal to preserve process stability.

Understanding Compressor Basics and Key Specs

Before you pick a compressor for plasma cutting, anchor your choice to specs that govern performance: tank capacity (1–100+ gal) for duty duration, delivered flow rate in CFM at pressure, and regulated outlet pressure.

You’ll compress ambient air into a storage tank; larger tank size supports longer continuous cuts and reduces cycling. Verify the compressor’s rated CFM at a stated PSI, not just displacement CFM.

Target an output flow that’s at least 1.5× your cutter’s consumption to prevent pressure sag during sustained operation. Typical air pressure capability spans 100–135 PSI; many light-duty cutters operate near 80 PSI, while higher-capacity systems need 115 PSI or more.

Aim for 1.5× airflow; expect 100–135 PSI. Light-duty: ~80 PSI; heavy-duty: 115+ PSI.

Ascertain the regulator maintains stable setpoints under load.

Protect the torch with air filters and dryers to remove moisture, oil, and particulates; clean, dry air extends consumable life and prevents arc instability.

Always confirm the compressor’s CFM and PSI ratings align with the manufacturer’s specifications for continuous cutting.

Matching CFM and PSI to Your Plasma Cutter

You should size your compressor with a required flow margin of at least 1.5× the cutter’s stated CFM to prevent pressure sag during continuous cuts.

Target an ideal pressure range matching your unit: small systems operate around 80 PSI, while larger machines often need 115 PSI or more.

Use a quality regulator (and dryer when humidity is high) to hold 6+ CFM at 40–70 PSI minimum at the torch, verifying with inline gauges under load.

Required Flow Margin

When you size air for a plasma cutter, match both flow (CFM) and pressure (PSI) with a deliberate margin so the torch never starves under load.

Build a required flow margin into air compressors for plasma to stabilize pressure and flow during long cuts. Start by selecting an air compressor that exceeds the cutter’s minimum CFM output by at least 1.5× and sustains 40–70 PSI at that flow.

- Target ≥6 CFM at 40–70 PSI as a baseline; larger cutters may require more.

- Set the compressor near 90 PSI, regulate to about 75 PSI at the torch, and verify steady-state delivery.

- Confirm the compressor’s rated SCFM at your operating PSI, not displacement CFM.

This buffer prevents pressure sag, keeps arcs stable, and avoids overheating during extended duty.

Optimal Pressure Range

Although exact specs vary by model, target an air supply that matches your cutter’s required PSI and exceeds its airflow by ~1.5× to maintain arc stability under load.

Define the ideal pressure range by the plasma cutter’s rating: most units operate between 80–135 PSI, with larger systems needing 115 PSI or higher.

Verify your air compressor can sustain the specified PSI at the required flow rate. For a 50‑amp cutter, plan around 6 CFM at 40 PSI, or for continuous duty, about 10 CFM at 100 PSI.

Use a regulator: set the compressor near 90 PSI and the cutter around 75 PSI to stabilize delivery.

Avoid excessive PSI that can damage internal air lines; prevent low airflow that degrades cut quality.

Tank Size, Duty Cycle, and Continuous Cut Performance

You’ll size tank capacity to match duty demands: 20–30 gallons covers light/moderate work, while 60 gallons supports industrial cycles and longer uninterrupted cuts.

Specify a high duty cycle to sustain runtime without thermal limits, and target at least 10 CFM at 100 PSI with 1.5× the cutter’s required flow.

Verify continuous cut airflow by confirming stable pressure and flow throughout the cut, which maintains cut quality and speed.

Tank Capacity Impact

Even with the right plasma cutter, tank size and compressor duty cycle determine whether you can sustain continuous cuts without pressure dips.

You need sufficient tank capacity to buffer demand and maintain airflow at or above the cutter’s required CFM. For heavy-duty work, a 60-gallon tank or larger stabilizes line pressure during continuous cuts; smaller 20–30 gallon tanks suit short, light passes but recover often.

- Size for demand: target compressor output ≥1.5× the cutter’s CFM to keep regulator pressure stable across long cuts.

- Match storage to load profile: larger tanks reduce cycling frequency and pressure sag between compressor recovery events.

- Quantify risk: insufficient tank capacity or a low duty cycle increases downtime, causes pressure decay at the torch, and degrades cut quality and throughput.

Compressor Duty Cycle

Duty cycle sets the ceiling for how long your compressor can run to sustain a plasma cutter’s airflow without overheating or shutting down. You should size the compressor duty cycle to match your cut duration and restart intervals.

For light to moderate work, pair a 50–100% duty cycle with a tank size of 20–30 gallons; for industrial profiles, target 60 gallons and near-continuous duty.

Verify CFM: specify at least 1.5× the plasma cutter’s consumption to protect air supply under load. Example: a 10 CFM @ 100 PSI unit supports a plasma cutter needing 6 CFM, providing margin during repetitive cuts.

Higher CFM extends run time between motor rest periods, stabilizes pressure, and reduces cycling. Align duty cycle, CFM, and tank size to prevent thermal trips and pressure sag.

Continuous Cut Airflow

Continuous cut airflow hinges on matching tank size, duty cycle, and delivered CFM to the plasma cutter’s demand so pressure never sags mid‑cut. For continuous cuts, size your air compressor to deliver a flow rate about 1.5× the torch’s requirement—target ~10 CFM at 100 PSI.

Set the compressor to ~90 PSI and the plasma cutter’s pressure regulator to ~75 PSI to stabilize arc quality and consumable life.

- Choose a compressor tank size: 20–30 gallons for moderate work; 60 gallons for industrial cycles where long cuts demand stored volume.

- Specify a high duty cycle so the pump sustains CFM without thermal shutdown during extended passes.

- Evaluate cut length and material to quantify required air volume and prevent pressure droop that degrades kerf and speed.

Air Quality: Filtration, Drying, and Regulation

While plasma cutting tolerances are forgiving in some areas, air quality isn’t one of them: you need clean, dry, and stable air to protect consumables and maintain cut consistency.

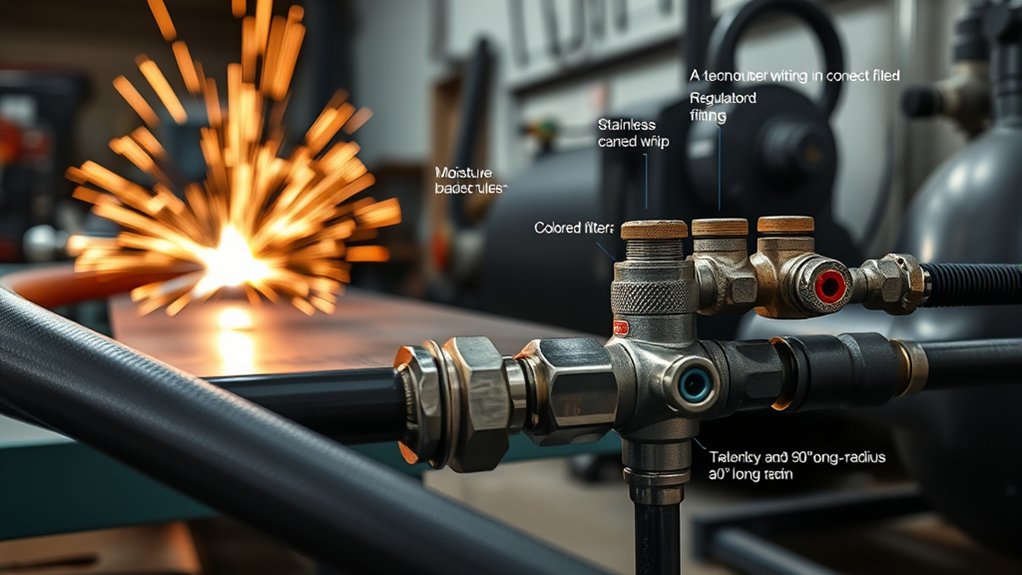

Prioritize air quality with point-of-use filtration, drying, and regulation to maximize consumable life and cut accuracy. Install a high-efficiency coalescing filter at the plasma inlet to capture water, oil aerosol, and particulates; place a particulate prefilter upstream to extend service intervals.

Prioritize clean, dry air at the torch: point-of-use filtration, drying, regulation, coalescing filter, upstream particulate prefilter.

Target ISO 8573-1 Class 1.2.2: particulate Class 1, moisture Class 2, oil Class 2. In humid shops, add a refrigerated dryer sized for your compressor’s SCFM and pressure; verify dew point at line pressure to prevent condensation during high-duty cycles.

Set the regulator to the torch manufacturer’s required dynamic pressure and confirm under flow with a calibrated gauge.

Maintain filters, drains, and separators on a fixed interval. Neglect increases arc instability, dross, and electrode/nozzle wear, driving up cost per cut.

Hose, Fittings, and Piping for Optimal Flow

Air quality only pays off if your delivery hardware can move the volume your torch demands. Size the air supply line to the run length: use 3/8” ID for lines up to 75 ft, and 1/2” ID beyond that to hold pressure and sustain high flow efficiency.

Keep the path short and straight; every extra foot, bend, or quick-connect adds pressure drop. Match hose and fittings to the line’s diameter—don’t neck down at couplers or regulators.

- Use copper piping for mains. It’s durable, smooth-bore, and maintains flow with minimal pressure loss.

- Specify high-flow filters and water/oil separators downstream of the tank and before the plasma cutter to protect internal components and stabilize arc quality.

- Verify all connectors are full-flow designs and rated above compressor output pressure.

Document your system: line sizes, lengths, and component Cv.

Pressure-test, leak-check, and log static vs. dynamic pressure at the torch while cutting to confirm compliance with the cutter’s airflow spec.

Power, Noise, and Portability Considerations

Before you pick a compressor for your plasma cutter, quantify three constraints: power output, acoustic profile, and mobility.

Specify power first: target at least 6 CFM delivered at 40–70 PSI at the tool, not just at the pump. Verify duty cycle and thermal limits to sustain continuous cuts without pressure sag. Dual-voltage capability (110V/220V) increases deployment flexibility across job sites and panels.

Address noise next. Compare dB(A) ratings at 1 meter: many low-end units exceed 60 dB, while quiet designs approach 40 dB, which better suits residential or shared workshop environments. Lower noise improves communication, reduces PPE fatigue, and aligns with local ordinances.

Finally, assess portability. For field work, prioritize compact mass, integrated handles, and wheel kits. Smaller air compressor packages move faster and set up easier for light tasks.

For heavy-duty stations, a 60-gallon tank minimizes cycling, stabilizes line pressure, and buffers transient demand without oversizing the motor.

Selecting the Right Compressor: Light, Moderate, and Heavy-Duty Use

How do you match compressor capacity to the cut profile without overspecifying? Start with the plasma cutters’ datasheet. Specify an air compressor whose airflow and pressure meet or exceed the stated requirement at duty cycle. Undersupply causes arc instability and dross; oversupply wastes cost and power.

Match compressor capacity to your cuts: meet datasheet airflow/pressure. Avoid undersupply instability and oversupply waste.

- Light-duty: target a 20–30 gallon tank and 4–6 CFM at 90 PSI. This supports short, intermittent cuts on thin material with stable airflow and minimal recovery lag.

- Moderate use: step to a 60-gallon tank and ≥10 CFM at 100 PSI. You’ll maintain consistent kerf quality during longer runs and reduce compressor cycling.

- Heavy-duty: require 10–15+ CFM at 100 PSI with large storage and dual-phase capability for continuous cutting and thermal headroom.

Verify plug/phase compatibility, pressure switch range, and regulator accuracy. Size filtration and dryers to the airflow. Align hose ID and quick-connects to minimize pressure drop.

Always baseline against the cutter’s required airflow and pressure, then add 15–25% margin for line losses and future tooling.

Frequently Asked Questions

What Size Compressor Do You Need to Run a Plasma Cutter?

You’ll need a compressor delivering ~10 CFM at 100 PSI. Match plasma cutter specifications, size compressor tank size to 20–60 gallons, account for power requirements, guarantee 1.5× airflow efficiency margin, and verify duty cycle supports continuous cuts.

How Much Air Pressure Do I Need to Run a Plasma Cutter?

You need 80–135 psi plasma cutter pressure; aim 40–50 psi for aluminum. Like tuning a carb, ideal air flow drives plasma cutter efficiency. Verify air quality requirements, compensate leaks, consider altitude derate, and follow compressor maintenance tips for standards-compliant performance.

How Many CFM Do I Need for a Plasma Cutter?

You’ll need 1.5× the cutter’s consumption: small units 4–6 CFM, 50 A about 6 CFM at 40–50 PSI, larger 12+ CFM. Match Compressor types, manage Noise levels, guarantee Air flow stability for Plasma efficiency and Cutting speed.

What Size Air Compressor Do I Need for the Titanium Plasma 65?

You need a 20–30 gallon compressor delivering 6 CFM at 70 PSI; for continuous duty, target 10 CFM at 100 PSI. Align plasma cutter specifications for air compressor compatibility, ideal air pressure, titanium plasma performance, and plasma cutter efficiency.

Conclusion

You don’t guess; you spec. Match your cutter’s CFM ×1.5 at 80–135 psi, or you trade crisp kerfs for slag. Choose 20–60 gal tanks for steadier pressure; pick duty cycles that align with continuous cuts. Dry, filter, and regulate air to standards, or burn through consumables. Size hoses and fittings to minimize pressure drop, not budget. Balance amperage demands with noise and portability. Precision isn’t optional—your compressor either stabilizes the arc, or sabotages it.