You’ve likely heard the claim that a plasma cutter always beats an angle grinder for metal cutting—let’s test that. You’ll weigh thickness, cut quality, speed, and cleanup against cost and PPE. You’ll also factor in kerf width, heat-affected zones, and edge prep for welding. Safety drives each choice: sparks, fumes, grounding, and wheel selection matter. By the end, you’ll know when to cut clean and when to grind smart—if you choose the right sequence.

Tool Capabilities at a Glance

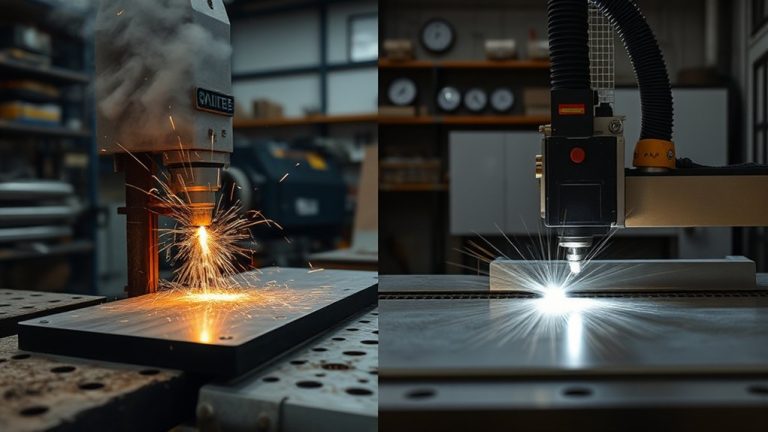

Although both tools cut metal, their strengths diverge: a plasma cutter excels at fast, long, straight cuts and intricate patterns with a narrow kerf in material up to about 5/16 inch, while an angle grinder favors quick, simple cuts and broader utility.

Plasma excels at precise, narrow-kerf cuts; angle grinders deliver quick, simple versatility across tasks.

You’ll choose based on cut geometry, thickness, and finish requirements. For cutting precision, the plasma’s constricted arc delivers minimal kerf and cleaner edges, reducing rework, though light post-cut cleanup is typical. It demands steadier hand control and practice to maintain line quality.

With an angle grinder, you’ll mount a 1 mm cutting disc for rapid access and straightforward cuts. Its tool versatility extends beyond cutting—swap discs to grind, bevel, or prep surfaces without changing machines.

Expect wider kerf and more burr formation, so plan for edge dressing.

Process-wise, confirm dry, clean air and moisture traps on the plasma system. For grinders, inspect discs, flanges, and guards before every cut to maintain performance and control.

Safety and PPE Essentials

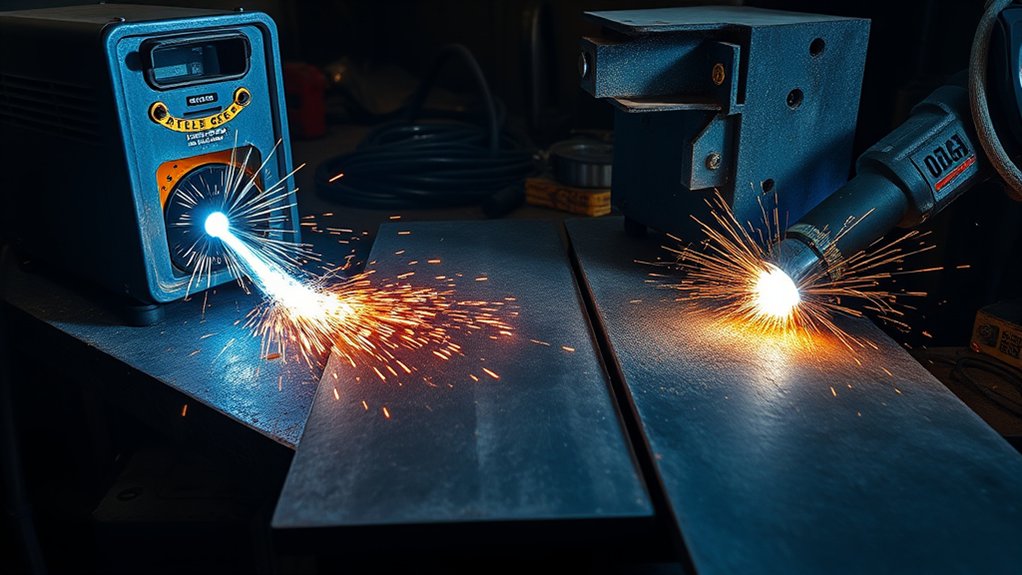

Start with essential protective gear: wear safety glasses, gloves, and a face shield, and position nonflammable clothing and closed-toe footwear to shield against sparks and debris.

Before powering up, clamp the workpiece, inspect the grinder and discs for cracks, verify cords and leads, and stand to the side of the cutting path to control kickback and spark spray.

During operation, maintain a safe standoff, manage sparks and hot slag away from combustibles, and follow correct procedures to reduce electrical and fire risks.

Essential Protective Gear

Sparks and metal shards demand disciplined PPE. You’ll align your gear with PPE standards, then verify fit and condition before power-up. Prioritize safety glasses with side shields, a rated face shield, heat-resistant gloves, and flame‑resistant clothing. Add steel‑toed boots for impact protection. For fumes and dust—especially on stainless or aluminum—use a properly fitted respirator. Protect hearing with earmuffs or plugs rated for tool dB levels. Perform PPE maintenance: inspect lenses for scratches, gloves for heat damage, boots for sole integrity, and replace compromised items before use.

| Hazard | Primary PPE | Specification |

|---|---|---|

| Impact/sparks | Safety glasses + face shield | ANSI Z87.1 |

| Heat/splatter | FR clothing, heat gloves | ASTM F1506/arc‑rated |

| Noise/fumes | Hearing protection, respirator | NRR-matched, NIOSH-approved |

Store PPE clean and dry; log inspections to guarantee ongoing effectiveness.

Safe Operating Practices

Before powering up a plasma cutter or angle grinder, establish a safe setup and verify your protections.

Put on PPE: safety glasses, gloves, and a face shield to shield against sparks and debris. Confirm clothing is snug and nonflammable.

Perform tool maintenance: inspect cords, housings, guards, and, for grinders, discs for cracks or wear; replace damaged parts before use. Check consumables and air supply on the plasma cutter.

Secure the workpiece with clamps or a bench vise to eliminate movement. Position your body to the side of the tool’s discharge path for accident prevention.

Route cables and hoses to prevent entanglement. Keep the workspace clean and organized, with fire extinguisher accessible.

Start tools at speed before contacting material; maintain controlled, steady feed.

Choosing the Right Tool by Material and Thickness

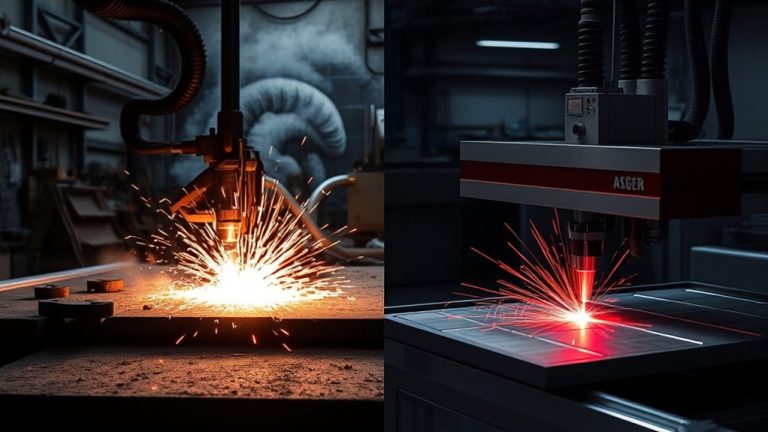

Start by matching thickness to the tool: use an angle grinder with a 1 mm cutting disc for thin sheet to keep cuts fast, clean, and flat, and switch to a plasma cutter once you reach 4–5 mm or need tight curves.

For heavy plate, choose a plasma cutter for precise, clean edges; if you must grind, fit a metal‑cutting blade and control feed rate to avoid overheating.

Always pair consumables to material—aluminum oxide discs for general steel, specialized discs for harder alloys, and adjust technique to prevent warping or kickback.

Thin Sheet Scenarios

When you’re working with thin sheet metal up to 1/8 inch, choose the tool by balancing cut quality, heat input, and consumable cost.

Apply cutting techniques that respect material considerations: clamp the work, mark a clear line, and support the kerf to control vibration. An angle grinder with a thin cutting disc delivers clean edges with minimal heat, keeps panels flat, and saves money on discs.

Use a non‑ferrous disc on aluminum to avoid loading. Plasma cuts fast and straight but can leave light slag and heat tint, adding a cleanup step.

- Verify PPE: face shield, cut‑resistant gloves, hearing protection; secure cables and sparks.

- For curves or intricate shapes, favor the grinder; for long straight cuts, plasma is efficient.

- Deburr immediately; confirm edge quality before fit‑up.

Heavy Plate Choices

Thin sheet techniques won’t carry you far once the stock steps past 1/4 inch; tool choice shifts to power, cut quality, and heat control on heavy plate.

For heavy plate considerations, prioritize a plasma cutter. It delivers fast, controlled kerfs and cleaner edges on 4–5 mm and thicker steel, and it’s superior for intricate shapes. Set a solid ground, confirm dry air, choose the correct amperage and standoff, then plan for a brief post-cut grind to remove dross.

Reserve the angle grinder—especially with 1 mm discs—for thinner stock and straightforward trims.

On heavy steel, grinders slow down, wander, and generate excess heat and burrs. Match cutting techniques to the project: confirm thickness, edge tolerance, and shape complexity before you cut, and choose the safer, more precise path.

Speed, Cut Quality, and Cleanup

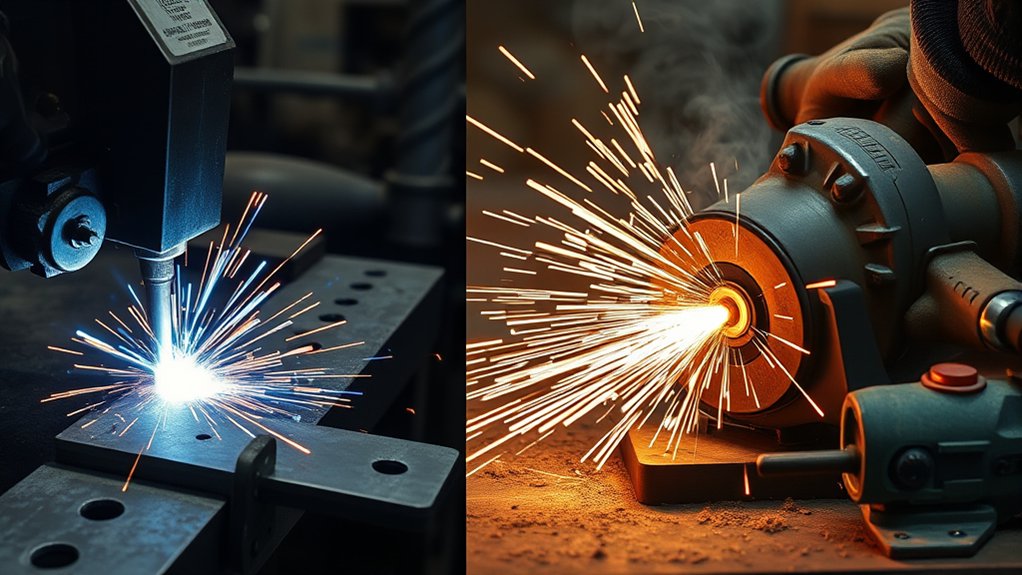

Although both tools can slice steel effectively, you’ll move faster and with tighter radii using a plasma cutter, especially on thicker stock, while an angle grinder takes longer for the same length of cut.

For cutting efficiency, plasma wins on straight lines, curves, and templates; keep travel speed steady and maintain correct torch height to prevent dross. Grinders can track straight edges reliably but slow down on long or thick cuts.

Cut quality depends on technique. Plasma delivers a narrow kerf and minimal HAZ, but you’ll still plan for edge refinement: chip slag, then lightly grind or file.

With grinders, expect a rougher edge and more heat tint; control feed pressure to reduce burrs and wandering.

- Confirm grounding, clear flammables, and direct sparks into a safe zone before cutting.

- Inspect consumables: fresh plasma tips and high-quality discs stabilize cut quality.

- Stage cleanup tools: chipping hammer, flap disc, file, and a vac for debris control.

Cost, Consumables, and Long-Term Value

Before you choose a cutter, map the real costs: purchase price, consumables, duty cycle, and the time you’ll spend per foot of cut.

Start with the initial investment. A basic plasma unit often exceeds an angle grinder’s price, even though budget cutters start near $200. Factor operating expenses: plasma tips and electrodes wear with amperage, pierces, and airflow quality; grinders primarily consume discs, which are cheaper and multi-purpose.

Match costs to your project profile. If you’re processing thicker steel or complex contours, plasma’s speed and precision reduce labor minutes and consumable burn, improving cost per part.

For occasional, simple cuts, a grinder’s lower entry price and broad utility keep total spend down.

Account for duty cycle and power needs to prevent overheating, wasted time, and unsafe workarounds. Include air supply and PPE in your totals.

Consider depreciation: quality plasma cutters hold resale value; angle grinders depreciate faster. Choose the tool that minimizes lifetime cost for your workload.

Techniques, Tips, and When to Switch Tools

You’ve weighed costs; now set up for clean, safe cuts by matching technique to the job. Choose your tool by thickness and tolerance. For stock over 1/8-inch or complex profiles, prioritize a plasma cutter for speed, accuracy, and less distortion.

Hold the torch at 90 degrees, set amperage to the material, and use a straightedge or circle guide to stabilize motion. For thin sheet or quick trims, an angle grinder with the correct cutoff wheel delivers fast, simple lines and easy surface cleanup.

Use disciplined cutting techniques: steady travel speed, consistent standoff, and planned exits to minimize dross. Deburr and verify edge quality before fit-up. Practice deliberate tool switching: rough with plasma, then blend edges and remove slag with a grinder for final fit.

- Match tool to thickness, tolerance, and geometry; avoid forcing either tool beyond its envelope.

- Prioritize PPE, stable workholding, and controlled sparks.

- Inspect edges; switch tools to reduce rework and waste.

Frequently Asked Questions

Can Either Tool Run off a Standard Household Circuit Without Tripping Breakers?

Yes, but it depends. You verify power requirements, compare them to your circuit capacity, then select appropriate amperage. An angle grinder usually fits 15A circuits. Small inverter plasma cutters may need 20A; larger units demand dedicated 240V circuits.

How Does Cold Weather Affect Plasma Cutter Performance and Arc Stability?

Cold weather effects reduce gas ionization, thicken lubricants, and stiffen leads, causing arc stability challenges. You preheat workpieces, dry and warm air supply, keep consumables warm, shorten lead lengths, increase amperage slightly, verify duty cycle, and wear insulated, dry PPE.

What Power Generators Are Suitable for Mobile Cutting or Grinding Setups?

You’ll choose portable generators with clean inverter output, appropriate power ratings, and robust surge capacity. Size 5–8 kW for plasma, 3–5 kW for grinders. Ascertain 120/240V availability, low THD (<5%), GFCI protection, bonding compliance, and proper grounding.

Are There Environmental or Ventilation Requirements for Indoor Plasma Cutting?

Yes. You must provide robust fume extraction, maintain adequate air changes per hour, and verify airflow direction. Implement spark/slag containment, combustible clearance, grounded tables, and fire watch. Monitor gases and particulates, enforce PPE, and document indoor safety procedures and inspections.

How Do Plasma Cutters and Grinders Impact Nearby Electronics or Wi‑Fi?

They can cause electromagnetic interference and signal disruption. You’ll isolate power circuits, ground equipment, and route leads away from antennas. Use shielded cables, ferrites, surge protection, and distance sensitive devices. Test with spectrum analysis, then adjust placement, duty cycle, and shielding.

Conclusion

In the shop’s dim light, you hold two keys: the plasma’s lightning and the grinder’s whetstone. You choose by thickness, tolerance, and time. For steel over 4–5 mm and tight profiles, you trace with arc and air; for thin sheet to 1/8 inch and straight chops, you guide the abrasive wheel. You verify ground, clamp work, check PPE, set parameters, manage sparks, and deburr. When kerf, heat, or edges drift, you switch tools—precision first, safety always.