Like choosing the right tool in Apollo’s workshop, you need facts to pick between plasma and laser cutting. You’ll weigh entry costs ($2k–$5k plasma vs ≈$50k+ laser), throughput (plasma 5–20 in/min on thick plate vs laser up to ~120 in/min on thin sheet), and edge quality (laser’s tighter tolerances, smoother edges). Add operating costs, HAZ, material limits, and max thickness—and the ideal choice becomes clear only when you match them to your project’s constraints.

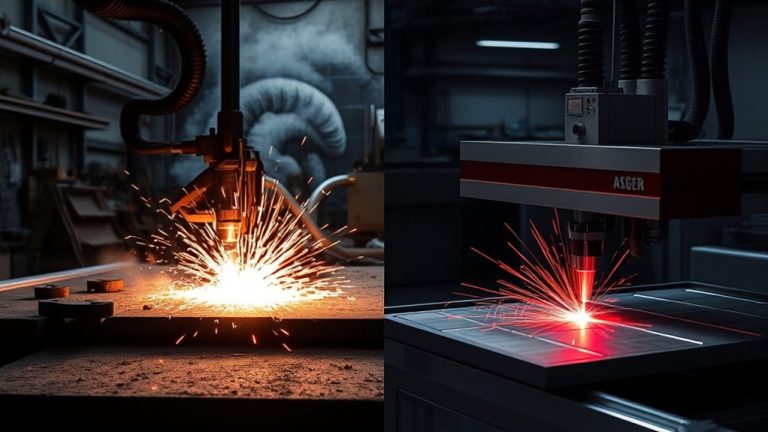

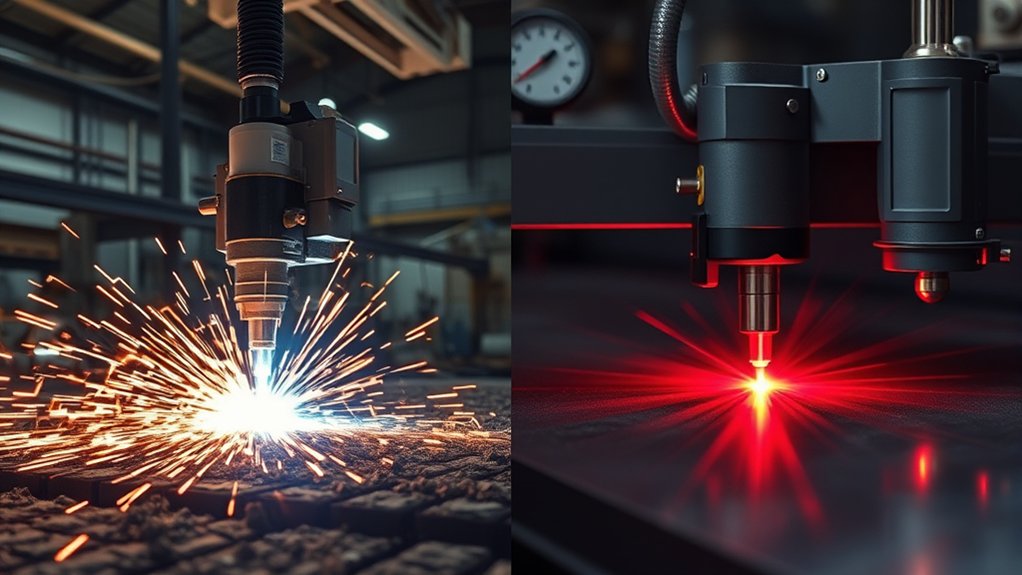

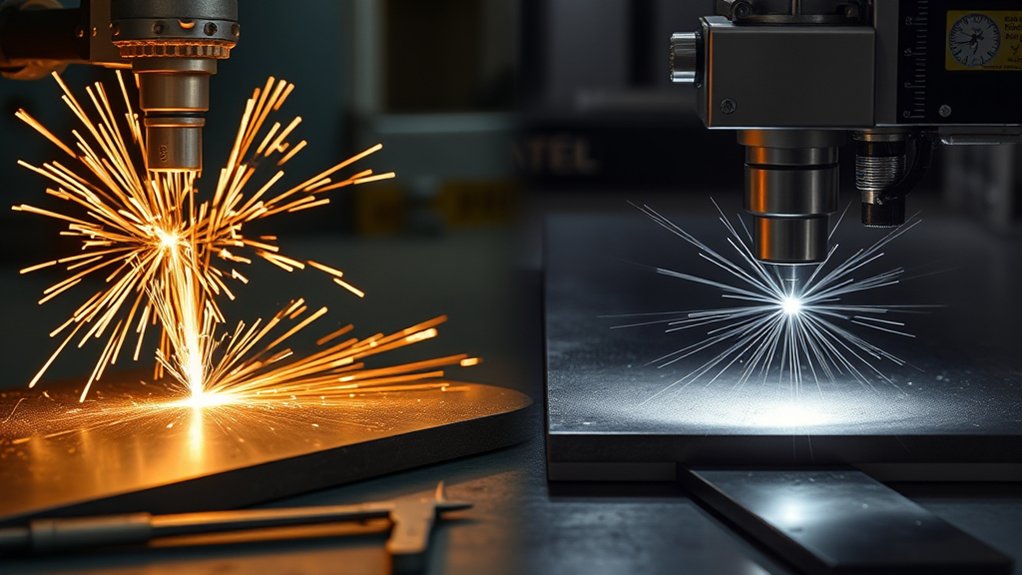

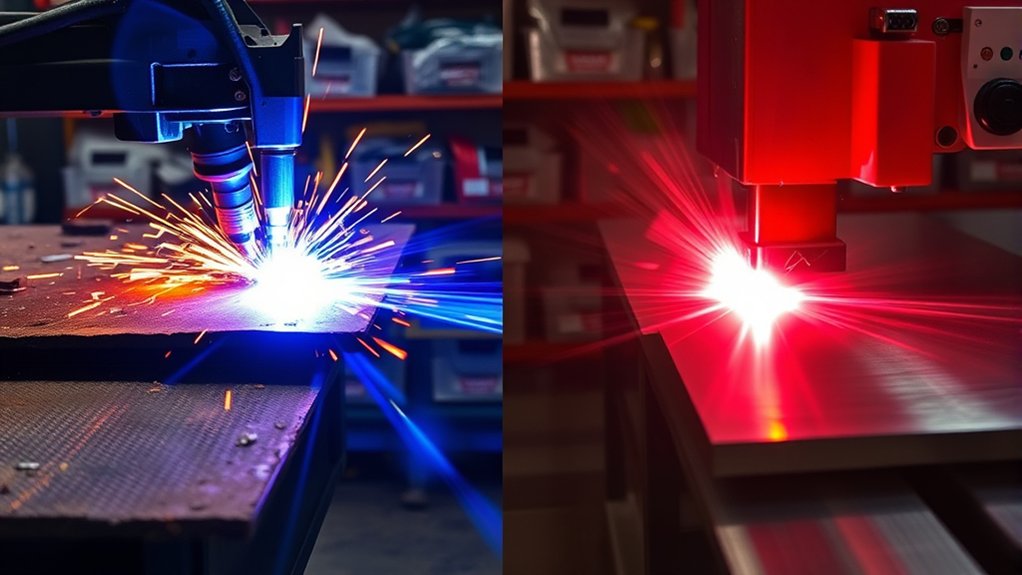

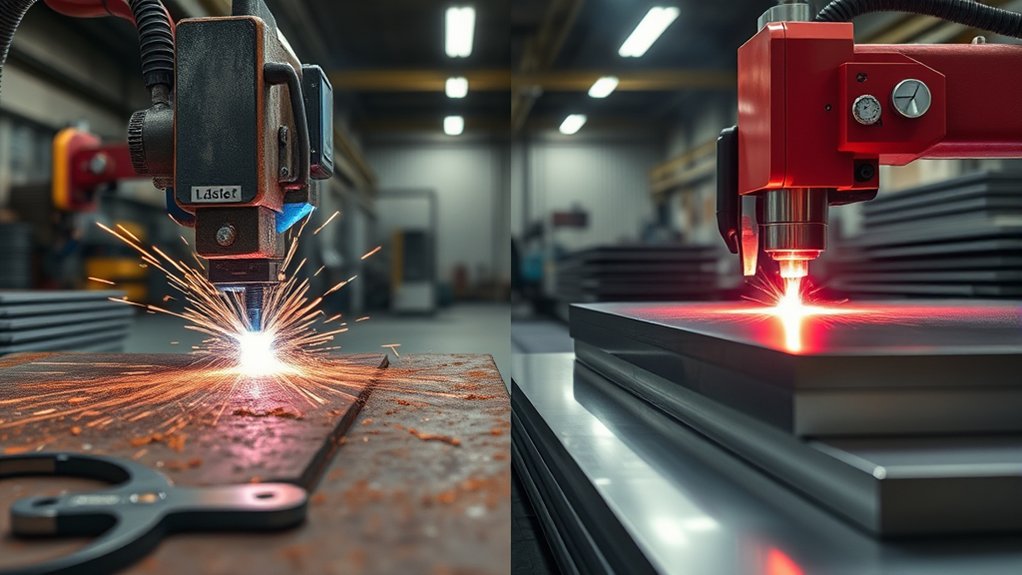

How Laser and Plasma Cutting Work

Two distinct processes power these cutters: photons versus plasma.

With laser beam generation, you drive a high-energy light source through resonators, then focus it via optics to a sub-millimeter spot. CNC motion aligns the nozzle to trace toolpaths while assist gases clear molten material. You’ll process metals, plastics, and wood efficiently on thin sheets, leveraging high energy density and precise thermal input. Expect tight process control, low heat-affected zones, and rapid acceleration on intricate paths.

High-energy laser optics trace CNC paths, clearing molten material for precise, low-heat cuts on thin sheets.

Plasma arc creation works differently. You initiate an electric arc inside a torch, ionize a gas stream, and accelerate the superheated plasma to melt and eject conductive metal. The process favors thickness; you can cut steels, aluminum, and copper up to about 1.5 inches.

Kerf is wider, but traverse speeds on thick plate are high. Operationally, you’ll tune current, gas type, and standoff to stabilize the arc, manage dross, and maintain ±0.1 mm tolerances on robust, production-level cuts.

Cutting Precision and Edge Quality

Although both tools can slice metal efficiently, their cut quality diverges sharply.

If cutting accuracy drives your tolerance stack, a laser is the clear winner: you can hold ±0.003 mm versus around ±0.1 mm on plasma. That precision pairs with a narrow kerf, so you nest parts tighter, reduce heat-affected material, and conserve stock.

The edge finish also favors laser cutting: expect smooth, burr-free edges with surface roughness commonly Ra 0.8–6 µm, which often eliminates deburring or grinding.

Plasma’s wider kerf and arc dynamics produce rougher surfaces and more dross, so you’ll plan for secondary finishing.

Still, when the part is thick—generally over 30 mm—plasma maintains cut capability where many lasers taper off, even though dimensional fidelity is looser.

Apply this practically: choose laser for thin-gauge to mid-thickness parts demanding tight tolerances, crisp geometry, and minimal post-processing; choose plasma when section thickness dominates and you can accommodate coarser tolerances and additional cleanup.

Speed and Throughput

Throughput hinges on how fast you move metal and how much rework follows.

You’ll see plasma pull ahead on thick stock and laser dominate on thin sheet, but the winner depends on cutting efficiency and the rework that inflates production time.

- Plasma on thick plate: expect roughly 5–20 in/min up to about 1.5 in thickness; ideal when part geometry is simple and cycle time is kerf-limited, not motion-limited.

- Laser on thin sheet (<1/8 in): up to ~120 in/min; excels on dense nests with rapid accelerations and minimal pierce delays.

- Post-processing impact: plasma’s wider kerf and rougher edge can add grinding time, reducing realized throughput despite fast straight-line speed.

- Laser’s narrower kerf and clean cut often eliminate finishing, boosting effective parts-per-hour on intricate contours and tight tolerances.

- Decision rule: use plasma for heavy sections and low feature density; use laser for complex profiles where reduced rework shortens total production time.

Material Compatibility

You’ll match the tool to the material: plasma confines you to conductive metals (steel, stainless, aluminum, copper), while lasers extend to metals plus plastics, wood, and ceramics.

For thickness, you’ll favor plasma on heavy gauge stock up to ~1.5 in, but choose lasers for thin sections needing ±0.003 mm kerf precision and minimal post-processing.

When cutting reflective metals like brass or copper, you’ll avoid laser back-reflection risks and use plasma for reliable results.

Metals Vs Non-Metals

When material compatibility drives your process choice, know that plasma cutters only work on electrically conductive metals—steel, stainless, aluminum—making them unusable for wood, plastics, or ceramics, while laser cutters span both metals and non-metals.

You’ll match process to metal properties and non-metal applications to avoid downstream issues and rework.

- Plasma: restricted to conductive alloys; ideal when metallurgy, conductivity, and arc stability align.

- Laser: handles metals plus wood, plastics, acrylics, and ceramics; broad fixture and nesting flexibility.

- Mixed-material assemblies: choose laser to process metal brackets and polymer panels in one workflow.

- Precision tasks: leverage laser tolerances (±0.003 mm) for fine features, engraving, and tight jigs.

- Reflective metals: specify appropriate laser sources and assist gases to mitigate back-reflection and dross.

Select plasma for rugged metallic parts; select laser for multi-material, high-detail jobs.

Thickness Limitations

Although both processes can be precise, thickness quickly becomes the gating factor: plasma reliably cuts conductive metals up to ~150 mm for heavy plate work, while lasers typically top out around 25–30 mm in metals and lose efficiency on highly reflective alloys like copper and brass.

You should match process to material thickness and target cutting efficiency. For thick steel or aluminum plate, plasma maintains stable kerf geometry and acceptable taper at high amperage, delivering productive feed rates.

For sheet and medium plate under 25 mm, lasers offer tighter tolerances, smaller kerf, and cleaner edges, improving downstream fit-up.

Remember, plasma is limited to conductive metals; lasers extend to non-metals like wood and acrylic but stall as thickness approaches 30 mm.

Choose by thickness first, then required edge quality.

Reflective Material Handling

Despite similar nominal capabilities on thin sheet, reflective alloys separate the two processes quickly: lasers lose energy to back-reflection on copper, brass, and some aluminums, degrading penetration, widening kerf variability, and risking optic damage, while plasma couples energy via an electrical arc and cuts these conductive, reflective metals reliably.

You’ll choose cutting techniques by how each handles reflective materials under production constraints.

- Expect narrower kerf with lasers in mild steel, but reflection widens kerf and reduces precision on Cu/Br/Al.

- Plasma maintains cut continuity on stainless and aluminum without coatings or absorbers.

- Laser paths may need blackening, fiber sources, or angle tweaks; each adds time and cost.

- Plasma’s arc ignores optical reflectance; consumables, not optics, take the load.

- For uptime and cost, plasma wins on reflective stock; lasers win on non-reflective precision.

Maximum Cutting Thickness

You’ll hit laser thickness limits around 25–30 mm for metals; beyond that, edge quality and speed fall off sharply.

If you need to process heavy plate, plasma offers a practical range up to about 150 mm with fast, robust cuts suited to structural steel.

Use laser for thin sections down to ~0.1 mm where precision and fine features matter, and switch to plasma when throughput on thick stock is the priority.

Laser Thickness Limits

When defining laser thickness limits, anchor your expectations to power, wavelength, and material reflectivity. In laser cutting, you’ll see practical ceilings tied to material thickness and laser type. For common metals, expect reliable performance up to about 25–30 mm; efficiency and edge quality drop past that.

- Fiber lasers typically outperform CO₂ on reflective alloys, enabling slightly greater thickness, but they still stall near 30 mm.

- For steel, plan production around 1–25 mm; beyond this, speed, kerf quality, and gas consumption deteriorate.

- CO₂ lasers struggle on brass and copper due to back-reflection, curbing effective thickness in those applications.

- Specify laser power to match both material and thickness; underpowering yields dross and taper.

- Validate with cut charts: assist gas, focus, and nozzle size materially shift maximums.

Plasma Thickness Range

Although laser systems top out near 30 mm on metals, modern plasma cutters push far beyond, delivering efficient cuts from roughly 6–50 mm and reaching maximum capacities up to about 150 mm.

In practice, you’ll see peak plasma efficiency in the 6–50 mm window, where travel speed, kerf control, and cut face quality align for minimal post-processing. Beyond 50 mm, expect a wider kerf, increased bevel angle, and rougher edges that may require grinding or machining.

For industrial applications—shipbuilding, heavy fabrication, structural repair—the ability to pierce and sever thick plate quickly is decisive.

Specify amperage, gas selection, and torch height control to stabilize the arc on heavy sections. When parts exceed laser limits, plasma offers the throughput advantage, especially on carbon steel and stainless plate.

Surface Finish and Heat-Affected Zone

Surface finish and HAZ set the practical limits on cut quality and downstream work. If you’re chasing high surface quality with minimal thermal distortion, lasers win. Typical laser roughness comes in at Ra 0.8–6 µm, so you often skip grinding. Plasma leaves a rougher edge and wider kerf, so you’ll plan for cleanup to meet cosmetic or sealing specs.

Chasing high finish with minimal distortion? Lasers win—Ra 0.8–6 µm, often skipping grinding. Plasma needs cleanup.

- Laser HAZ: small, yielding tighter geometry control and less warp; expect tolerances around ±0.030 mm.

- Plasma HAZ: larger, increasing risk of warping or microstructural change near the edge; typical tolerances about ±0.1 mm.

- Dimensional accuracy: laser’s smaller HAZ stabilizes features like slots, tabs, and thin webs that would deform under plasma.

- Post-processing: laser parts often go straight to forming or coating; plasma parts may need deburr, grind, or polish to hit finish targets.

- Application fit: choose laser for precision assemblies and gasketed joints; use plasma when finish-critical surfaces aren’t exposed and throughput on thicker stock matters.

Cost Breakdown: Capital and Operating Expenses

If tight HAZ and clean edges matter to your parts, budget will decide how you get there. Start with a cost comparison: entry-level plasma systems run $2,000–$5,000, with production-grade units typically $10,000–$100,000.

Comparable laser systems start near $50,000 and can exceed $500,000; industrial CO₂ lasers frequently top $100,000 before integration. Those capital deltas drive your budget considerations for payback.

On operating expenses, plan roughly $15/hour for plasma versus about $20/hour for laser. Plasma’s cost structure includes consumables—electrodes and nozzles—replaced regularly, especially at higher duty cycles.

Laser maintenance centers on optics—keeping lenses and mirrors clean and aligned—to preserve cut quality and throughput. Factor assist gases, power, and preventive maintenance into both models.

For thick plate production, plasma often delivers faster ROI due to lower acquisition cost and slightly cheaper hourly rates.

If your parts justify premium edge quality, lasers command higher capital and operating budgets, but enable tighter tolerances and reduced post-processing.

Application Scenarios by Industry

When you map cutting technology to real-world parts, match process capability to material, thickness, and tolerance.

In automotive applications and shipbuilding, you’ll lean on plasma for fast, thick-section cuts in steel frames, brackets, and hull panels. Fabrication shops often choose plasma for cost control—about $15/hour versus lasers at roughly $20/hour—when tolerances are moderate and throughput matters.

For aerospace applications, electronics, and medical devices, laser excels on thin metals with intricate geometries, holding ±0.003 mm and delivering clean, burr‑free edges that minimize downstream finishing.

- Automotive: Plasma for chassis tabs, crossmembers, and suspension plates in 6–25 mm steel.

- Shipbuilding: Plasma for bulkheads and stiffeners; productivity prioritized over edge polish.

- Aerospace: Laser for titanium and aluminum skins, brackets, and honeycomb details; tight tolerances.

- Electronics: Laser for EMI shields and micro-features in thin stainless or copper.

- Medical devices: Laser for surgical components needing pristine edges and micron-level accuracy.

You can also pair waterjet for heat‑sensitive polymers and composites.

Choosing the Right Method for Your Project

Curious which cutter fits your build? Start by mapping project requirements to material, thickness, tolerance, and finish.

Map your project’s needs to material, thickness, tolerance, and finish before choosing a cutter.

If you’re cutting thick conductive metals fast—up to ~150 mm—choose plasma; it tolerates mill scale and dirty surfaces and runs about $15/hour. For thin stock up to ~30 mm, tight tolerances, and minimal post-processing, pick laser; it yields smooth, burr-free edges but operates around $20/hour.

Factor budget constraints. Plasma systems typically cost $10k–$100k, making them attractive for shops prioritizing throughput on steel or aluminum. Lasers start near $50k and can exceed $500k, justified when precision, small features, and mixed materials (including non-metals) matter.

Estimate total cost per part, not just machine price: include cut speed, edge quality (secondary finishing for plasma), nesting efficiency, downtime, energy, and maintenance.

Evaluate cleanliness and fixturing capability: lasers need clean surfaces and stable setups. When material is thin and geometry complex, laser wins; when thickness and speed dominate, plasma leads.

Frequently Asked Questions

What Safety Equipment Is Required for Plasma and Laser Operators?

You need safety gear: ANSI Z87+ shaded eye protection, face shield, flame-resistant clothing, cut-resistant gloves, hearing protection, steel-toe boots, and respirator with proper cartridges; add fume extraction, interlocks, and grounding. Maintain operator training, lockout/tagout, and clear hot-work procedures.

How Loud Are Plasma Versus Laser Cutters During Operation?

Plasma cutters are louder: you’ll hear plasma noise around 90–100 dBA, peaking near 105 dBA; laser sound typically stays 70–85 dBA. You’ll choose enclosures and hearing protection accordingly, especially above 85 dBA or with high-duty-cycle jobs.

Can Either Method Be Used in a Home Garage?

Yes, but you must engineer controls. In a Home workshop, guarantee Equipment compatibility: dedicated 240V circuits, ventilation (≥400 CFM), fire-rated enclosure, grounded tables, dry air, fume filtration, eye/ear PPE, gas storage compliance, and municipal permits.

What Maintenance Schedules Do Plasma and Laser Systems Require?

You’ll service plasma systems daily-weekly: inspect consumables, check gas, clean filters, align torch—boosting equipment longevity. For lasers, perform weekly optics cleaning, monthly alignment, quarterly chiller/filter checks; schedule annual professional calibration. Maintenance frequency follows duty cycle, environment, and OEM intervals.

How Do Environmental Regulations Affect Fume Extraction and Disposal?

A stitch in time saves nine: you size extraction systems to meet fume regulations, calculate airflow (CFM) from process emission rates, select HEPA/activated carbon, monitor VOC/particulate, log capture efficiency, segregate waste, manifest hazardous residues, and validate disposal via certified recyclers.

Conclusion

You’ve seen the numbers: plasma cutters cost $2k–$5k and move 5–20 in/min on thick stock, while lasers start near $50k and sprint up to 120 in/min on thin sheet with tighter tolerances and cleaner edges. So what matters more—budget or microns? If you need precision, minimal HAZ, and fine features (aerospace, medical), choose laser. If you prioritize thickness, speed, and efficiency (automotive, shipbuilding), pick plasma. Match your tolerances, material, and throughput targets to the process, then execute.