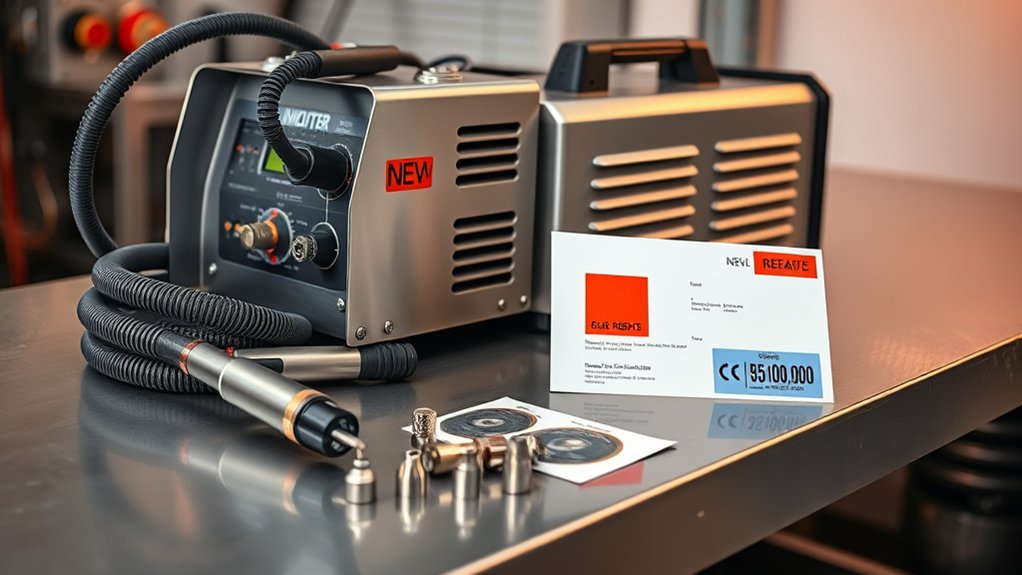

Cut faster, set up quicker, carry less. You’re choosing an all‑in‑one plasma cutter with a built‑in compressor to eliminate external air, standardize portability, and reduce failure points. You’ll want continuous pilot arc stability on painted or rusty steel, an internal moisture separator for drier air, and verified duty cycle at rated output. We’ll compare Powermax30 Air, Tomahawk 30 AIR, and AirForce 12ci, quantify air delivery versus cut quality, and show where the hidden costs surface.

Why Choose a Plasma Cutter With a Built-In Air Compressor

Why pick a plasma cutter with a built-in air compressor? You eliminate the external compressor, reducing footprint, setup time, and leak paths.

A Built-In Air Compressor streamlines portability, so you can move from bench to field without juggling hoses or regulators. With units like the Lincoln Tomahawk 30 Air delivering up to 30 amps and cutting mild steel to 3/8 inch, you meet common fabrication tolerances without upsizing equipment.

You also gain process stability. Continuous pilot arc maintains ionization through rust, paint, or expanded metal, so you don’t retrigger the arc, reducing cycle interruptions and improving edge consistency.

Internal water separators dry the air stream, promoting cleaner kerfs, tighter heat-affected zones, and longer consumable life due to optimized swirling airflow.

Internal water separators deliver drier air, cleaner kerfs, tighter HAZ, and extended consumable life.

Ergonomic torch design cuts hand strain during extended duty cycles, improving control and repeatability. If you value compliance with shop safety and productivity standards, an integrated package minimizes variables and standardizes your cutting workflow.

Top Features to Look For in All-in-One Plasma Cutters

When evaluating all-in-one units, you should verify compressor air output meets the cutter’s rated SCFM and pressure at duty cycle, ensuring stable arc quality under load.

Prioritize continuous pilot arc technology that maintains ignition through rust, paint, or gaps without retriggering, aligning with productivity and safety standards.

Confirm rapid re-strike performance and clean, dry air delivery to minimize dross and extend consumable life.

Compressor Air Output

Compressor air output dictates cut stability, duty cycle, and consumable life in an all‑in‑one plasma cutter, so verify the unit’s delivered flow and pressure under load—not just peak ratings.

For an Air Plasma Cutter w an internal air compressor, confirm the compressor can sustain the torch’s specified SCFM at operating PSI while cutting. Insufficient compressed air causes blowback, dross, widened kerf, and premature nozzle wear.

Target a regulator-stable 90–120 PSI with continuous delivery matching the torch’s SCFM requirement at your typical amperage. Favor systems with efficient air paths, enhanced swirling airflow, and moisture control; an internal water separator, as found on models like the Tomahawk 30 Air, preserves cut quality.

Validate duty cycle at ambient temperature per IEC/EN standards, and check sensor-based low-air protection to prevent torch damage.

Pilot Arc Technology

Although it adds complexity, pilot arc technology is a must‑have in all‑in‑one plasma cutters for consistent, efficient starts on contaminated or discontinuous workpieces. By maintaining a continuous pilot arc, you avoid retriggering when crossing rust, paint, mill scale, gaps, or expanded metal. That stability trims downtime, protects consumables, and delivers cleaner kerfs.

Pairing pilot arc with a built‑in Compressor, as seen in units like the Lincoln Tomahawk 30 Air, yields a compact, portable system with adjustable output to match material thickness and alloy.

1) Continuous arc bridging: keeps the cut active across perforations and mesh without arc dropouts.

2) Reduced cycle interruptions: fewer restarts improve takt time and cut consistency.

3) Adjustable amperage: tune output for thickness while preserving edge quality.

4) Integrated Compressor synergy: stable air supply supports reliable pilot arc initiation.

Best Models: Powermax30 Air, Tomahawk 30 AIR, and Hobart AirForce 12ci

You’ll compare cutting performance—Powermax30 Air’s 3/8 in mild steel capacity versus Tomahawk 30 AIR’s continuous pilot arc on contaminated surfaces and the lighter-duty AirForce 12ci.

You’ll assess portability and ergonomics across their integrated compressors and torch designs, then quantify value using pricing, rebates (e.g., Tomahawk’s $700), and included accessories.

You’ll align each model to task profiles and duty-cycle expectations to guarantee standards-compliant selection.

Cutting Performance Comparison

While all three units integrate onboard air, the Powermax30 Air clearly leads cutting performance, severing mild steel up to 5/8 inch with consistent arc stability and robust compressor output.

You’ll see cleaner kerfs, faster travel speeds, and fewer dross islands on Mild Steel compared with the others, especially on thicker stock.

- Powermax30 Air: Maintains smooth, continuous cuts at higher duty loads; compressor flow sustains arc density, enabling precise severance and quality edge finish on 1/2 inch plate and beyond.

- Tomahawk 30 AIR: At 30 A, it reliably cuts up to 3/8 inch; continuous pilot arc and rapid re-strike excel on rusted/painted material, minimizing stops.

- Hobart AirForce 12ci: Portability-focused; mixed air output limits cut speed and edge quality on thicker sections.

- User trend: Hypertherm’s air delivery and reliability drive superior consistency and cut repeatability.

Portability and Ergonomics

Three integrated-air models—Powermax30 Air, Tomahawk 30 AIR, and Hobart AirForce 12ci—prioritize portable, low-setup operation with ergonomics suited to sustained use.

You’ll carry the Powermax30 Air’s 27-pound frame easily, meeting site-mobility requirements without sacrificing control. The Tomahawk 30 AIR’s Built-In Compressor eliminates external air lines, reducing ancillary equipment and failure points.

Hobart’s AirForce 12ci combines a lightweight chassis with an integrated compressor, aligning with field-service expectations for rapid deployment.

All three Plasma Cutters implement ergonomic torch geometry, balanced leads, and compliant grips to limit wrist deviation and hand fatigue under extended duty cycles.

Continuous pilot arc capability sustains clean starts on rusty or painted material, minimizing stops and repositioning. This directly improves cut continuity, task cadence, and operator endurance in variable environments where fast setup and repeatable handling are mandated.

Pricing, Rebates, Value

Value clarity starts with street pricing and incentives: integrated-compressor plasma cutters begin near $1,149.72, and select discounts reach $255.76, with free shipping over $300 in the continental US reducing total cost of ownership.

You’ll benchmark value by combining street price, rebates, and logistics to compute delivered cost per amp and per duty-cycle percentage.

- Powermax30 Air: Premium pricing aligns with superior reliability and cut quality; value maximizes when Free Shipping and occasional discounts apply.

- Tomahawk 30 AIR: Lincoln’s $700 rebate, plus up to $200 on accessories within 30 days, can materially undercut peers on net price.

- Hobart AirForce 12ci: Attractive entry pricing, but mixed air output feedback may impact throughput value.

- Total value stack: Base price − discount − rebate + tax − Free Shipping credit = net acquisition cost.

Real-World Performance: Air Output and Cutting Quality

Even with ample amperage, a plasma cutter’s real-world performance hinges on air delivery—both volume and quality—because low output produces erratic arcs, dross, and taper.

You should verify rated SCFM at cutting pressure, not just idle PSI, and confirm duty-cycle airflow stability. Consistent delivery under load correlates directly with kerf straightness, minimal bevel, and lower post-cut cleanup.

Evaluate vendor support and logistics—reliable parts availability and shipping on all orders—because maintaining air integrity depends on timely filters and consumables.

Models like the Hypertherm 30 Air demonstrate why superior output matters: stable arc column, cleaner edges, and reduced heat-affected zone.

Conversely, users often report that underperforming units, including some Hobart models, starve the torch, causing frequent arc dropouts and slag adhesion.

Continuous pilot arc technology further improves continuity through paint, mill scale, and rust without retriggering, reducing arc restarts that distort cut geometry.

The Lincoln Tomahawk 30 Air’s internal water separator mitigates moisture-induced arc flutter, preserving cut quality and consumable life.

Pricing, Discounts, and Rebate Opportunities

Air delivery dictates cut quality, but your budget and incentives determine which integrated-compressor unit you can justify. Entry pricing starts at $1,149.72, but you should model total ownership cost against available discounts, Shipping, and rebates. Free shipping on orders over $300 within the continental US compresses landed cost, while select models offer up to $255.76 off list, helping you meet a target cost-per-amp metric.

Model total ownership: entry $1,149.72, free shipping, discounts, and rebates drive landed cost.

- Baseline: Compare units at $1,149.72 against your required duty cycle and cut capacity; validate value via routine price comparisons to confirm market competitiveness.

- Instant discounts: Deduct up to $255.76 where applicable; document invoice pricing and discount codes for audit trails and warranty compliance.

- Rebates: The Lincoln Electric Tomahawk 30 AIR carries a $700 rebate, plus a potential $200 accessory rebate; submit within 30 days and verify “while supplies last.”

- Landed cost: Include Shipping (often free >$300), taxes, and consumables; calculate effective net by subtracting discounts and confirmed rebates from delivered price.

Essential Safety Gear and Accessories

Though plasma cutters with onboard compressors streamline setup, you still need standards-compliant PPE to control heat, UV/IR, impact, and noise hazards at the cut zone.

Start with hand protection: Tillman Cowhide Leather Drivers Gloves ($13.24) shield against radiant heat and sharp edges; make sure they fit snugly for dexterity.

Protect your eyes with StarLite Safety Glasses ($1.65) meeting ANSI Z87.1, providing impact resistance and UV filtration; keep a clean spare on hand.

For noise, use VIBE Earmuffs ($20.65) with adequate NRR to maintain exposure below OSHA/NIOSH limits.

Add Fire Resistant FR7A Cotton Sleeves ($8.97), compliant with NFPA 2112/ASTM F1506 characteristics, to guard forearms from sparks and minor slag.

Improve visibility with an ANSI/ISEA 107 Class 2 Break-Away Hi-Vis Safety Vest (from $10.80) to reduce struck-by risks around moving equipment.

Inspect PPE before each shift, replace damaged items, and store gear dry and uncontaminated.

Tips for Maximizing Portability and Consumable Life

While portability is built into plasma cutters with onboard compressors, you can extend uptime and consumable life by managing airflow, duty cycle, and contamination control with the same rigor you apply to cut parameters.

Extend uptime by rigorously managing airflow, duty cycle, and contamination alongside your cutting parameters.

Apply disciplined Cutting Techniques, align settings to material, and protect the machine between moves to keep performance consistent.

- Use ergonomic grips and balanced torch leads to reduce hand fatigue, stabilize standoff, and maintain straight travel speed; this limits arc wander and nozzle wear during extended cutting sessions.

- Purge with the front panel control before and after cuts to stabilize airflow, evacuate condensate, and prevent spatter ingestion; verify pressure with a gauge to keep the plasma stream laminar.

- Adjust continuous output control to the minimum amperage that achieves full penetration for the given thickness; oversetting raises thermal load and shortens electrode and nozzle life.

- Service the internal water separator per schedule and store the unit in a protective cover like the Lincoln CanVAS Cover; contamination control improves cut quality and extends consumables.

Frequently Asked Questions

How Loud Are Built-In Compressor Plasma Cutters During Operation?

They typically register 75–90 dB(A) at 1 meter. You’ll perceive intermittent spikes during compressor cycling. Verify manufacturer Noise Levels, measure with IEC 61672 Class 2 meters, and mitigate using isolation pads, enclosure damping, compliant PPE, and workplace exposure calculations (OSHA/ISO).

Can I Connect an External Compressor if Needed?

Yes, if the unit supports External Compatibility via 1/4″ NPT and 90–120 psi. Notably, 70% of field setups use dryers. Verify duty cycle, SCFM, regulator bypass, and ISO 8573-1 Class 2–3 dryness.

What Maintenance Schedule Do Integrated Compressors Require?

They require monthly filter checks, quarterly drain/condensate inspections, semiannual leak tests, and annual service per ISO/ASME guidelines. You log pressures, duty cycle, and temperature. Maintenance Tips: replace filters, test safety valves, verify oil-free specs, calibrate regulators, and torque fittings.

How Do Ambient Temperature and Humidity Affect Performance?

Ambient temperature and humidity directly impact Performance Factors: you’ll see reduced air density, higher inlet temperatures, moisture loading, and derating. You compensate by adhering to ISO conditions, using aftercoolers, dryers, proper filtration, and monitoring duty cycles and dew points.

Are Built-In Units Compatible With Generators and Inverter Power?

Yes—many support generators and inverters, but only with clean, stable sine wave output and adequate surge capacity. Imagine towing a trailer: mismatched hitch fails. Verify Power Source Compatibility: THD <5%, inverter-grade, 2–3× surge, compliant grounding, voltage regulation.

Conclusion

You’re the pilot guiding a compact starship—plasma cutter and compressor fused as one hull—meeting spec, minimizing setup time, and hitting repeatable tolerances. With continuous pilot arc as your navigation beacon and dry air as your life-support, you cut through oxidized debris like vacuum. Choose models with verified duty cycles, clean air management, and ergonomic controls. Track consumables, maintain filters, and follow PPE standards. Do that, and your field and bench missions stay precise, portable, and economically efficient.