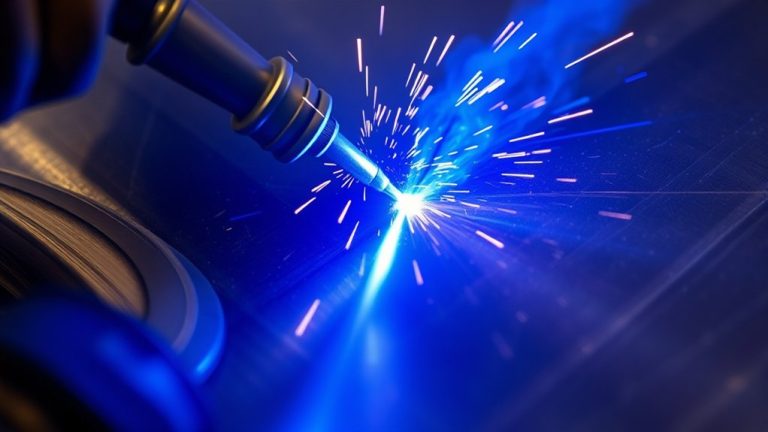

Envision this: you’re about to achieve precision cuts with plasma that rival a surgeon’s scalpel. But what’s the secret? It’s all about mastering key factors such as torch height, cutting speed, and consumable condition. These elements don’t just enhance your cut quality; they define it. Understandably, this is just the beginning. There’s more to uncover about optimizing your plasma cutting accuracy, ensuring your work consistently meets industry standards.

Understanding Plasma Cutting Basics

Plasma cutting is a precise and efficient method used to slice through conductive metals, thanks to its high-temperature plasma jet that reaches up to 40,000° F. Mastering plasma cutting fundamentals is essential to achieving the freedom to cut with precision and efficiency.

By forcing pressurized gases like air or oxygen through a nozzle, you create an electric arc between the electrode and grounded metal. This arc is your gateway to clean cuts.

Understanding cutting technique variations is important. Each technique influences the cut quality, from speed adjustments to nozzle types.

Explore the interplay of machine settings, such as output power and duty cycle, to refine your approach. This knowledge liberates you to adapt to different metals and thicknesses confidently.

Key Components of a Plasma Cutting System

In the domain of precision metal cutting, understanding the key components of a plasma cutting system is essential for ideal performance. Your system’s efficiency begins with a power supply that converts AC to DC, setting the stage for effective operation. The arc starting console initiates the crucial spark, creating the electric arc necessary for cutting. Plasma torch types vary, acting as the primary tool controlling both the arc and flow of plasma for precise results. Consumables—nozzles, swirl rings, and electrodes—are critical for cut quality and accuracy. Arc stability factors depend on the right combination of these elements.

| Component | Function | Impact |

|---|---|---|

| Power Supply | Converts AC to DC | Efficient Operation |

| Arc Starting Console | Generates initial spark | Initiates Cutting Arc |

| Plasma Torch Types | Controls arc and plasma flow | Precision and Versatility |

External gases like air, oxygen, and nitrogen fuel operations, influencing speed and quality.

Selecting the Right Plasma Cutter

To achieve ideal performance with a plasma cutting system, it’s vital to select the right plasma cutter tailored to your specific needs.

Start by considering the output power, as it dictates the maximum thickness you can effectively cut. A higher output power allows you to tackle thicker materials with ease, liberating you to take on more ambitious projects.

Pay attention to the clean cut rating of the machine—this determines the best thickness for achieving precise cuts without excessive dross, ensuring superior quality in your work.

Evaluate the severance cut rating for understanding the maximum thickness achievable at slower speeds, important for planning diverse tasks.

Don’t overlook the duty cycle; it informs you of the machine’s continuous operation capability without overheating, maintaining an efficient workflow.

Finally, consider the cutting speed (IPM), which influences how quickly and accurately you can complete your projects, empowering you to maximize productivity.

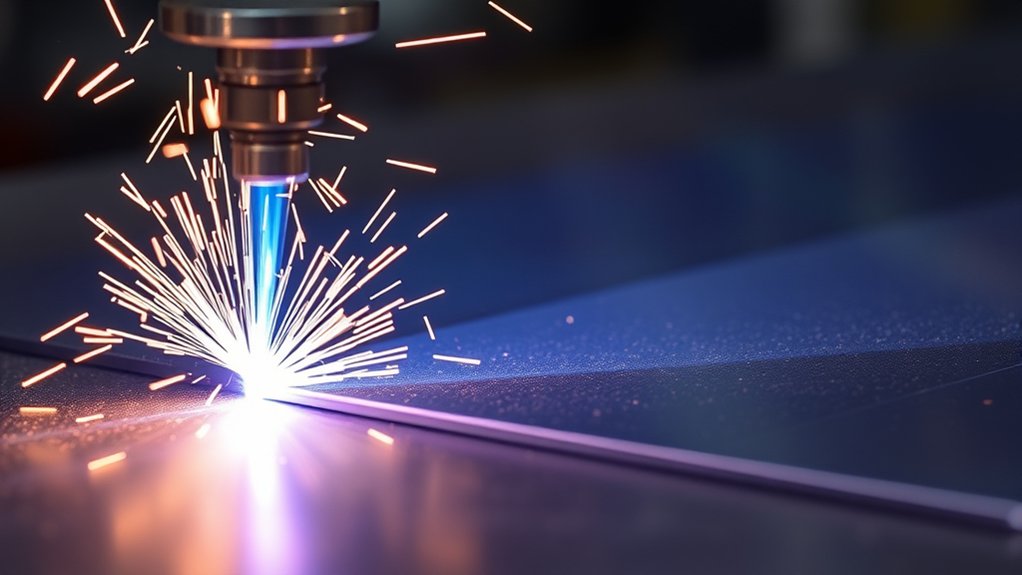

The Importance of Proper Torch Height

Achieving peak cutting performance hinges on maintaining the correct torch height, ideally between 1/16-inch to 1/8-inch, to guarantee arc stability during plasma operations.

You must prioritize torch height calibration to minimize dross formation, ensuring cleaner cuts and superior cut quality. Consistent calibration is your ally in reducing angularity, which can undermine the precision and accuracy of your workpiece.

Regularly checking and adjusting the torch height is essential, allowing you to adapt to varying material thicknesses and maintain consistent results.

As you fine-tune the torch height, you’ll notice its impact on cutting voltage, further enhancing the precision of your cuts. This meticulous attention to detail liberates you from the constraints of imprecise work, empowering you to achieve the exact results you envision.

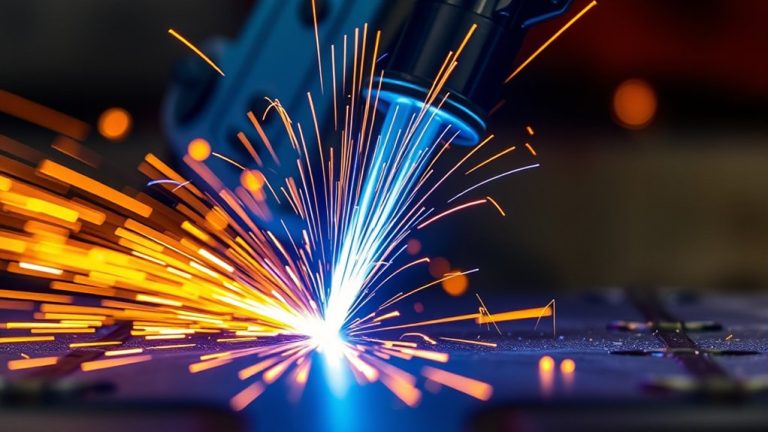

Adjusting Cutting Speed for Precision

When precision is your goal in plasma cutting, adjusting the cutting speed becomes critical. You’ve got to tailor the speed to the thickness and type of metal you’re working with. Run it too fast, and you’ll end up with jagged, poor-quality cuts; too slow, and excessive heat can cause warping.

Aim for a 15–20° arc exit angle against the direction of travel—this guarantees ideal cut quality. The cutting speed should closely align with your plasma cutter’s power settings, guaranteeing the output matches the material’s thickness.

Regularly monitor and tweak the cutting speed during operation to minimize dross formation, which can seriously impact your cut’s precision and quality.

Experimentation is key. By practicing with various materials and thicknesses, you’ll better understand the ideal speeds needed for high accuracy. This process empowers you to achieve cleaner cuts and liberates you from the constraints of imprecision.

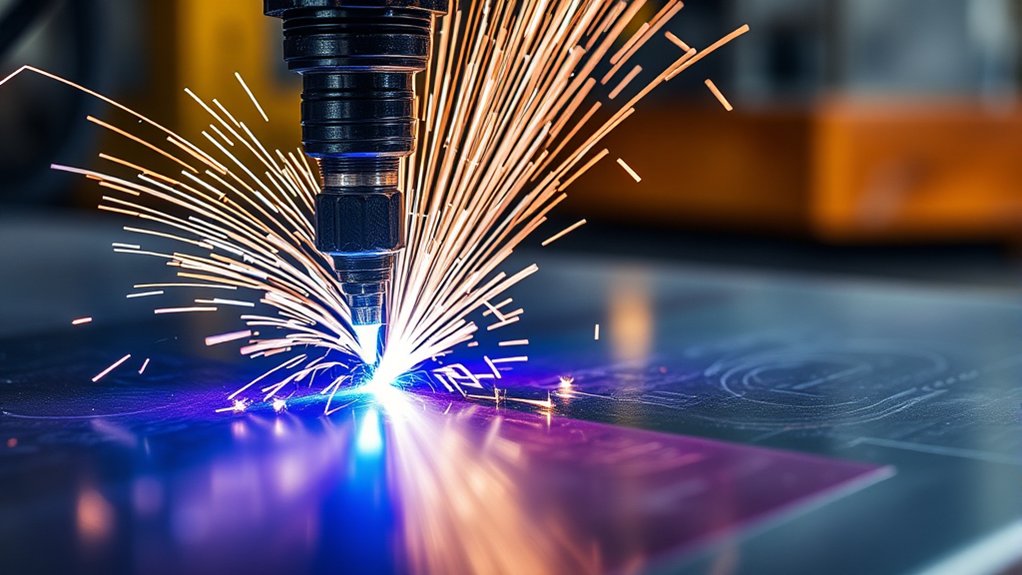

The Role of Consumables in Accuracy

To maintain precision in plasma cutting, you must prioritize the condition of your consumables, as worn nozzles, electrodes, and swirl rings can destabilize the plasma arc and degrade cut quality.

Regular inspection is critical, since even minor wear can alter kerf width, misaligning it with your design specifications.

Consumable Wear Impact

In plasma cutting, the condition of consumables like the nozzle and electrode directly impacts accuracy and cut quality. As consumables wear, you’ll notice indicators such as a larger or irregularly shaped nozzle tip, which can increase kerf width and reduce precision.

Monitoring these wear indicators is essential for optimizing consumable lifespan and maintaining high-quality cuts. Worn consumables lead to inconsistent arc stability, causing poor cut quality. Contamination or damage introduces irregularities, affecting cutting speed and depth, which compromises accuracy.

To harness precision and achieve tighter tolerances, consider using lower-amp consumables. They help minimize kerf width, ensuring cleaner cuts.

Regular Inspection Necessity

Although it might seem routine, regular inspection of consumables like nozzles and electrodes is critical for maintaining plasma cutting accuracy.

You’ll want to keep a close eye on wear indicators; these are telltale signs of degradation that can lead to inconsistent arc stability and compromised cut quality.

Establish a consistent inspection frequency to catch issues early—before they escalate. Check for wear, damage, or contamination, as even slight irregularities can cause poor cuts and increased dross formation.

Remember, the integrity of the tip hole is essential for precision. Over-tightening the retaining cup can restrict necessary movement, introducing inaccuracies.

Periodic replacement of consumables, especially when dealing with thicker materials, guarantees peak performance.

Stay vigilant—accurate cuts mean liberated productivity.

Choosing the Appropriate Gas for Cutting

Choosing the right gas for plasma cutting is essential for achieving precise cut quality and efficiency.

You’ll want to take into account factors like material type and desired edge finish, as oxygen delivers excellent edge quality on carbon steel, while nitrogen offers cleaner cuts on stainless steel and aluminum.

For enhanced performance, particularly with aluminum, using argon or mixed gases like H35 can boost cutting speed and reduce dross.

Gas Selection Tips

To optimize plasma cutting performance, you must carefully consider gas selection, as the choice of gas directly impacts cut quality and efficiency. Prioritize gas efficiency and moisture control to enhance consumable life and cut performance. Oxygen is excellent for thicker materials, offering superior edge quality, though it may cause oxidation. Shop air is typically sufficient for mild steel, aluminum, and stainless steel, but argon or nitrogen is preferable for sensitive materials. The H35 mixture, combining hydrogen and argon, excels in aluminum cutting by reducing dross.

| Gas Type | Material | Benefits |

|---|---|---|

| Oxygen | Thick materials | Exceptional edge quality |

| Shop Air | Mild steel, etc. | Cost-effective, accessible |

| H35 | Aluminum | Reduces dross, smooth cuts |

Select gases based on material needs to maximize cutting speed and precision.

Effects on Cut Quality

When selecting the appropriate gas for plasma cutting, the choice profoundly affects cut quality and efficiency. Oxygen delivers excellent edge quality but watch out for edge oxidation.

For mild steel, aluminum, and stainless steel, air suffices, yet nitrogen boosts cut speed and quality, especially on non-ferrous metals. The H35 gas mixture of hydrogen and argon enhances results on aluminum, promoting cleaner cuts and minimizing dross formation.

Don’t overlook the importance of moisture removal from your gas setup; moisture leads to contamination and shortens consumable lifespan, degrading cut quality.

Tailoring your gas selection to the material type and thickness isn’t just essential—it’s liberating. Optimize your cutting process with the right gas and achieve precise, high-quality results consistently.

Optimal Gas Combinations

Understanding the impact of gas choice on cut quality is key to mastering plasma cutting. With oxygen, you achieve exceptional edge quality, though it may oxidize cut edges—ideal for specific tasks.

For stainless steel and aluminum, nitrogen excels by minimizing oxidation, producing cleaner edges.

Shop air suffices for home cutting of mild steel, aluminum, and stainless steel, but remember to remove moisture to extend consumable life.

For superior gas performance on aluminum, consider the H35 mix—hydrogen and argon—which boosts cutting efficiency by enhancing speed and quality.

The secret to optimizing cutting is selecting the right gas for your material’s type and thickness, reducing dross formation, and greatly improving overall cutting efficiency.

Choose wisely to liberate your cutting potential.

Maintaining a Clean and Safe Workspace

Although often overlooked, maintaining a clean and safe workspace is critical to guaranteeing high-quality plasma cutting results. Proper workspace organization and contamination prevention are essential for achieving precision and efficiency.

Start by regularly removing rust, dirt, and debris from the cutting area to prevent any interference with your process. This not only keeps your workpiece in prime condition but also guarantees your cuts remain sharp and accurate.

Moisture is a stealthy adversary in plasma cutting, leading to poor-quality cuts and excessive wear on consumables. Always check that your materials are dry before starting.

Moisture sneaks in, degrading cuts and wearing down consumables; ensure materials are dry before cutting.

An organized workspace enhances safety and streamlines your workflow by making tools and materials easily accessible, minimizing downtime and boosting productivity. Conduct regular maintenance to keep your work environment tidy and free from clutter, thereby reducing accident risks.

Frequently Asked Questions

How Does Humidity Affect Plasma Cutting Accuracy?

You’ll notice humidity impacts plasma cutting accuracy by affecting arc stability and material quality. Control humidity and other environmental factors to maintain precision. Achieving this frees you from costly errors, enhancing your operational efficiency and technical prowess.

Can Plasma Cutting Be Automated for Improved Precision?

Imagine a maestro orchestrating a symphony, each note precise. Automated systems in plasma cutting act similarly, enhancing precision. You’ll achieve improved results, liberating from manual errors and boosting efficiency, creating a perfect harmony in metal fabrication.

What Is the Impact of Electrical Supply Fluctuations on Cutting Accuracy?

Electrical supply fluctuations can severely impact cutting accuracy. You must guarantee voltage stability and precise current regulation to maintain precision. Unstable power leads to inconsistent arcs, affecting cut quality, wasting materials, and limiting your creative freedom.

How Do Different Metals Affect Kerf Width?

“Different strokes for different folks” applies here. Aluminium thickness and steel composition greatly impact kerf width. Thicker aluminium increases kerf due to heat dispersion, while varying steel compositions alter kerf through element reactivity and melting points.

Can Software Aid in Enhancing Plasma Cutting Accuracy?

Yes, software integration optimizes design by adjusting parameters for cleaner cuts. You’ll experience improved precision through real-time monitoring and adjustments, liberating you from manual errors and enhancing overall plasma cutting accuracy in your industrial processes.

Conclusion

To ace plasma cutting accuracy, think of it like tuning a vintage radio—every knob matters. Keep your torch height in the 1/16-inch to 1/8-inch range for that golden arc stability. Don’t forget to swap out consumables like nozzles and electrodes before they become relics. Pick the right gas for your material, and you’ll be cutting with a laser focus. By minding these details, you’ll guarantee your cuts are sharper than a vinyl record’s groove.