Did you know that plasma cutting aluminum requires careful consideration of amperage based on the thickness of the material? Understanding these nuances guarantees precision and prevents costly mistakes. For instance, cutting up to 1/4 inch needs just 20-30A, while thicker plates demand much more. You must also adjust cutting speed and choose the right gas to avoid warping. Explore the intricate balance of settings and techniques essential for flawless aluminum cuts.

Understanding Aluminum’s Melting Point and Properties

When working with aluminum, understanding its melting point and properties is essential for enhancing plasma cutting processes. The melting point of aluminum is approximately 660°C (1220°F), notably lower than many other metals, which increases the risk of warping during cutting. This low melting point, combined with aluminum’s high thermal conductivity, requires careful management of heat input to maintain cutting efficiency and quality.

The thickness of aluminum plays a vital role in determining the required amperage for plasma cutting. Thinner sheets, often up to 1/4 inch, necessitate lower amperage settings, ensuring precise cuts without excessive dross.

Conversely, thicker aluminum, exceeding 1/2 inch, demands higher amperage to achieve clean, efficient cuts. Different aluminum alloys, which may have varying melting points and structural properties, also dictate specific amperage requirements.

Properly considering these factors will help you achieve ideal cutting performance and minimize material deformation.

Importance of Proper Amperage Settings

Understanding aluminum’s melting point and properties sets the stage for mastering plasma cutting techniques. Proper amperage settings are essential for achieving ideal cut quality when working with varying aluminum thickness. Here’s why:

- Thickness Compatibility: For aluminum up to 1/4 inch, use lower amperage settings (20-30A) to prevent warping and overheating. As thickness increases beyond 1/2 inch, adjust amperage to 60-85A for efficient cutting.

- Enhanced Cut Quality: Adhering to manufacturer’s cut charts guarantees smoother edges and minimizes dross formation, contributing to superior cut quality.

- Balance and Precision: Balancing amperage with cutting speed is critical. Too low amperage risks incomplete cuts, while excessive settings can cause wide cuts and distortion.

Techniques for Cutting Thin Aluminum Sheets

When cutting thin aluminum sheets, you must carefully select the amperage settings to avoid warping while maintaining precision and cut quality.

Choose the appropriate gas and nozzle combination to guarantee a stable arc and ideal kerf width, enabling clean cuts.

Secure the material properly and adjust your cutting speed to balance heat input, which will minimize dross buildup and produce smooth, accurate finishes.

Precision and Cut Quality

Despite the challenges, achieving precision and high cut quality when cutting thin aluminum sheets requires careful attention to various factors.

First, set the amperage to lower levels to prevent warping and excessive heat input, essential for maintaining aluminum’s integrity. FineCut consumables are ideal for achieving a narrow kerf and a stiff arc, ensuring cleaner, more precise cuts.

Moreover, consider these vital techniques:

- Cutting Speed: Adjust it carefully; too fast leads to arc instability, while too slow results in rough edges and dross.

- Torch Height: Maintain a consistent standoff distance to optimize cut quality and minimize warping.

- Parameter Adjustments: Regularly test and adjust cutting parameters to balance speed and amperage, achieving tight tolerances and high-quality finishes.

Proper Amperage Settings

Achieving ideal results in plasma cutting thin aluminum sheets hinges on selecting the proper amperage settings. For cutting thin aluminum (up to 1/4 inch), set your plasma cutter between 20-30 amps to mitigate excessive heat and avoid material warping.

Adhering to these proper amperage settings guarantees precise cuts and minimizes dross formation. Maintaining a cutting speed of 50-100 IPM is vital when cutting thin aluminum using plasma, as it prevents distortion.

Incorporate FineCut consumables to achieve narrower kerf widths, enhancing precision. Always consult the manufacturer’s guidelines for specific aluminum thicknesses and test cuts to fine-tune amperage settings based on the alloy and thickness you’re working with.

This attention to detail will yield superior results in your cutting projects.

Gas and Nozzle Choice

Selecting the right gas and nozzle combination is essential to mastering the art of plasma cutting thin aluminum sheets. For ideal cutting efficiency, follow these guidelines:

- Gas Mixture: Use a nitrogen gas mixture rather than regular air. Nitrogen minimizes oxidation, resulting in cleaner cuts and smoother surfaces.

- Nozzle Type: Opt for copper alloy nozzles. They conduct heat and electricity effectively, improving overall precision and quality of the cut.

- Nozzle Orifice: Choose smaller nozzle orifices. They create a narrower kerf and support higher voltage, which enhances arc stability and precision.

Maintaining a 1/16-inch standoff distance is vital for preventing warping.

Regularly inspect and replace consumables like nozzles and electrodes to sustain cutting efficiency and avoid dross buildup.

Handling Medium-Thickness Aluminum

When cutting medium-thickness aluminum, set your plasma cutter to an amperage range of 40A to 60A for peak performance and minimal dross.

Make certain to select FineCut consumables to achieve a narrower kerf, which is critical for maintaining tight tolerances.

Additionally, adjust the pierce height to 1.5 to 2 times the cutting height to extend the life of your consumables and guarantee clean initial piercings.

Optimal Amperage Settings

For medium-thickness aluminum, setting the plasma cutter to an amperage between 40 and 60 amps is crucial for achieving clean, precise cuts without excessive dross.

To enhance the cut quality, you’ll need to focus on a few critical factors:

- Consistent Cutting Speed: Maintain a speed of 30 to 50 inches per minute (IPM) to avoid overheating and warping.

- Torch Height Adjustment: Maintain a standoff distance of about 1/16 to 1/8 inch for peak performance at these amperage settings.

- High-Quality Consumables: Use consumables specifically designed for aluminum to stabilize the arc and enhance cut quality.

Regularly monitor the arc characteristics to fine-tune the amperage settings for the best balance of speed and quality in medium-thickness aluminum applications.

Choosing Correct Equipment

Choosing the right equipment for medium-thickness aluminum is vital to achieving ideal results. A plasma cutter with an amperage range of 40-70A guarantees clean, precise cuts on aluminum between 1/4 inch and 1/2 inch thick.

Consider the Hypertherm Powermax 85 SYNC, which effectively operates at 200 IPM on 1/4-inch aluminum. It’s important to adjust your cutting speed to match the amperage; a speed that’s too fast can cause incomplete cuts, while too slow can lead to rough edges and excessive heat.

FineCut consumables further enhance cut quality by producing a narrower kerf and focused arc. Regularly monitor and replace consumables like nozzles and electrodes to maintain cutting efficiency and prolong equipment lifespan.

Strategies for Cutting Thick Aluminum Plates

Although cutting thick aluminum plates presents unique challenges, employing the right strategies guarantees excellent results. When diving into plasma cutting aluminum, remember that thicker sections require a higher amperage, typically 100A or more. This guarantees clean cuts without excessive dross or warping.

Here are three strategies to enhance your cutting process:

- Adjust Cutting Speed: Slow down to around 5-10 inches per minute (IPM). This controlled pace allows for proper material penetration and sufficient melting, resulting in smoother edges.

- Improve Gas Mixture: Utilize an argon-hydrogen gas combination to enhance cutting quality and speed, especially in industrial settings where precision is paramount.

- Maintain Torch Height: Consistently keep a standoff distance of 1/8 to 1/4 inch. This precision maintains excellent cut quality and extends the life of your consumables.

Additionally, preheating thick aluminum plates can reduce the energy needed to initiate cuts, leading to enhanced performance and smoother results.

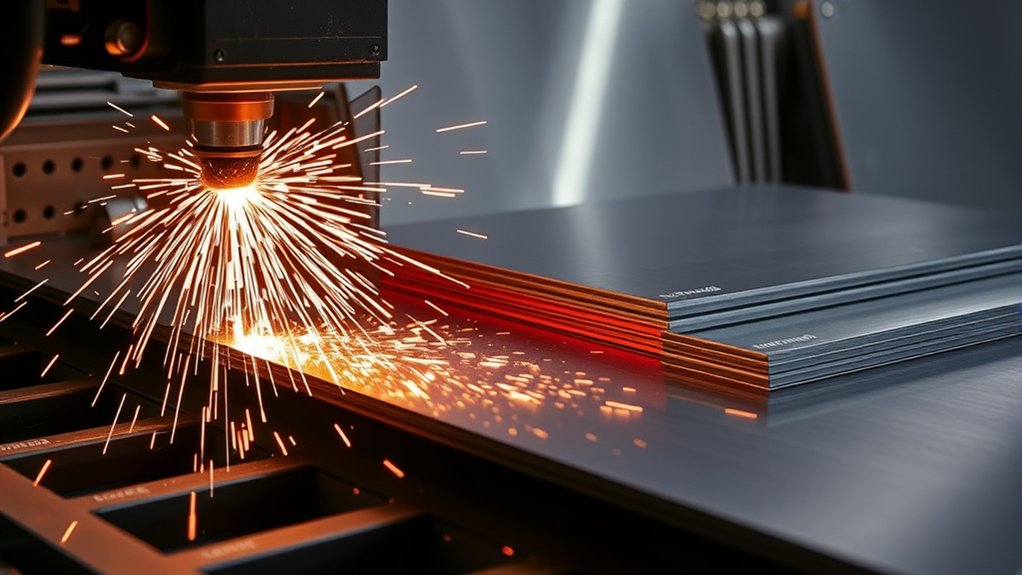

Selecting the Right Plasma Cutter for Aluminum

When you’re selecting the right plasma cutter for aluminum, it’s vital to evaluate the amperage output, especially since cutting thicker aluminum sheets demands higher power to maintain clean cuts.

For thin aluminum sheets up to 1/4 inch, lower amperage settings are ideal to prevent warping, ensuring precision without sacrificing material integrity. Medium thicknesses, ranging from 1/4 to 1/2 inch, require a balanced approach between cutting speed and power to achieve best results.

Industrial-grade plasma cutters, such as the Hypertherm MAX200, offer up to 200A, important for handling plates over 1/2 inch thick, delivering slower, precise cuts.

Meanwhile, models like the Hypertherm Powermax 85 SYNC excel with a cutting speed of 200 IPM for 1/4-inch aluminum, underscoring the significance of matching amperage output to material thickness.

Inverter-based plasma cutters are preferred for their efficiency and stable arcs, ensuring high-quality cuts across varying aluminum thicknesses.

Best Practices for Clean Cut Edges

Evaluating the appropriate plasma cutter for aluminum sets the stage for achieving clean cut edges, a key element in guaranteeing high-quality finishes. Achieving ideal cut quality requires precise control over several parameters.

First, align the amperage with the aluminum’s thickness; thicker materials demand higher amperage for smooth, clean cuts.

Ensure the amperage matches the aluminum thickness for achieving smooth, clean cuts on thicker materials.

Second, maintain a consistent cutting speed as specified in your equipment manual. This approach prevents excessive thermal input, which can cause rough edges and dross buildup.

Third, confirm the torch’s height and angle remain steady throughout the cut. Proper torch alignment stabilizes the arc, minimizing edge melting and distortion.

Regularly inspect and change consumables like nozzles and electrodes. Worn parts compromise cut quality and increase dross formation, hindering your goal of clean cuts.

Gas Selection for Aluminum Plasma Cutting

Selecting the right gas for aluminum plasma cutting is essential to achieving high-quality results. For aluminum sheets less than 5 mm thick, nitrogen is your go-to for both plasma and shielding gases. This choice optimizes cut quality by reducing oxidation.

When handling aluminum thicker than 6 mm, pair nitrogen as the plasma gas with water as the shielding gas. This combination enhances cut quality and minimizes dross production.

While air can be used in the plasma cutting process, it often results in rough finishes due to oxidation, making it less desirable for achieving superior cut quality. For thicker aluminum, consider H-35 or H-2 gas mixtures, with nitrogen as the shield gas, to prevent overheating and improve cutting performance.

Safety Precautions and Considerations

While plasma cutting aluminum offers precision and efficiency, it’s essential to prioritize safety to prevent accidents and equipment damage.

Plasma cutting aluminum requires prioritizing safety to avoid accidents and equipment damage.

Begin by adhering to vital safety precautions and using appropriate personal protective equipment (PPE). Wear heat-resistant gloves, safety glasses, and reinforced boots to shield yourself from hot metal splatter and sharp edges.

Proper equipment setup is also important:

- Grounding: Verify correct grounding to prevent electrical shocks, as cutting aluminum involves high voltage arcs.

- Ventilation: Be mindful of hydrogen gas accumulation, especially when cutting underwater. Adequate ventilation and explosion-proof safety gear are necessary.

- Cutting Consumables: Regularly inspect nozzles and electrodes for wear. Worn components can lead to poor cut quality and increased dross, posing safety risks.

Lastly, follow manufacturer guidelines for cutting parameters, such as amperage and speed settings. This prevents excessive heat, which can lead to warping and safety compromises during the cutting process.

Prioritize these measures to maintain a safe and efficient cutting environment.

Frequently Asked Questions

How Thick Can a Plasma Cutter Cut Aluminum?

You can cut aluminum alloys up to 2 inches thick with a plasma cutter, depending on your machine’s design. Make certain you balance cutting speed and arc stability for clean cuts, particularly on thicker materials, to avoid defects.

What Are the Settings for Plasma Cutting Aluminum?

Adjust plasma settings like tuning a fine instrument for aluminum quality. Set amperage according to thickness, maintain consistent cutting speed, and use nitrogen for thin sheets to achieve precision, minimizing oxidation and maintaining ideal performance.

How Thick Can a 100 Amp Plasma Cutter Cut?

You can cut aluminum up to 1 inch thick with a 100 amp plasma cutter. Adjust cutting speed based on material types and thickness. Make certain safety measures are in place to prevent accidents and maintain peak performance.

Can You Cut Aluminum With a Plasma Cutter?

Absolutely, you can cut aluminum with a plasma cutter. With various cutter types and aluminum cutting techniques, make certain you follow safety precautions. Choose the right amperage, like a modern-day blacksmith, for precise, clean cuts.

Conclusion

Mastering plasma cutting aluminum is akin to a conductor orchestrating a symphony; every element must harmonize. By calibrating amperage to thickness—like tuning an instrument—you’ll guarantee precision and prevent distortion. Opt for the right plasma cutter and gas, akin to selecting the finest tools for an artisan’s craft. Prioritize safety and leverage industry best practices to achieve seamless cuts. With these strategies, your aluminum projects will shine, reflecting your technical prowess and attention to detail.