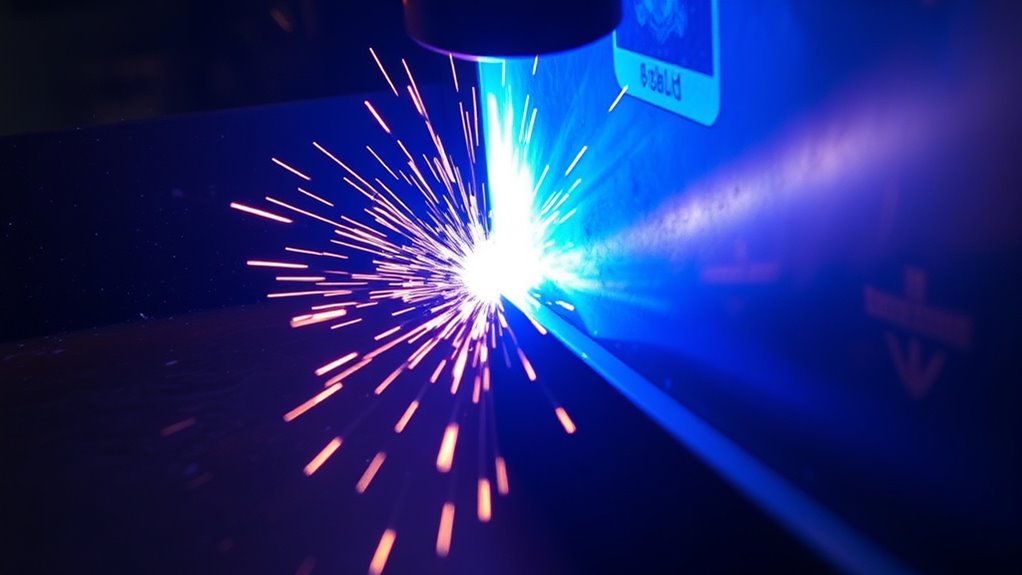

Imagine you’re working on a critical aerospace component needing a precise weld. Keyhole Plasma Arc Welding (KPAW) might just be your solution. This advanced technique uses a concentrated plasma arc to create deep, narrow keyholes, ensuring full penetration in a single pass. It’s particularly effective for thick materials, reducing distortion and the heat-affected zone. How does KPAW achieve such efficiency, and where does it truly shine?

Overview of Keyhole Plasma Arc Welding

Keyhole Plasma Arc Welding, an advanced welding technique, utilizes a concentrated plasma arc to create a deep and narrow keyhole in the workpiece, providing full penetration welds in a single pass.

This method is particularly advantageous for thicker materials, achieving temperatures up to 30,000°C.

You’ll find that it’s a process designed for efficiency, eliminating the need for extensive joint preparation or filler materials.

Benefits of Keyhole Plasma Arc Welding

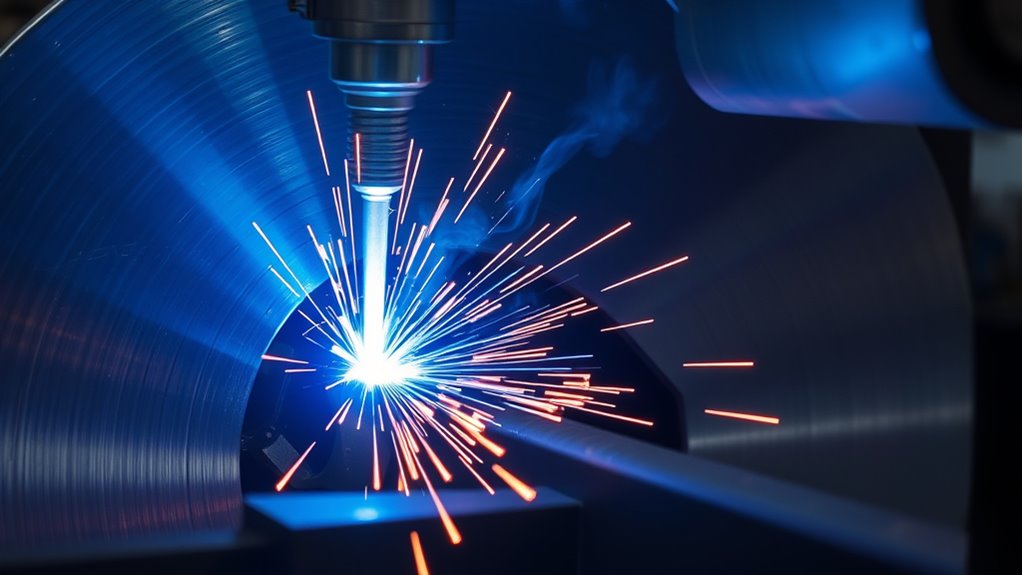

One major advantage of keyhole plasma arc welding is its ability to achieve deep penetration of up to 10mm in a single pass. This reduces the number of passes needed compared to traditional methods, cutting down on time and labor costs, which enhances cost efficiency.

Deep penetration of up to 10mm in one pass reduces time and labor, enhancing cost efficiency.

The process creates a smaller heat-affected zone (HAZ), preserving the mechanical properties of surrounding materials and minimizing distortion. This is essential for maintaining the integrity of your workpiece, especially in applications requiring high precision.

Furthermore, keyhole plasma arc welding doesn’t require edge preparation or filler materials, simplifying joint preparation and lowering operational costs.

With welding speeds reaching up to 250 mm/min, productivity is noticeably boosted, making it ideal for high-volume manufacturing. Its process versatility allows you to work with various metals like carbon and stainless steels, making it suitable for critical applications in aerospace and nuclear industries, where reliability and efficiency are paramount.

Key Settings for Optimal KPAW Performance

When optimizing keyhole plasma arc welding (KPAW) performance, precise control of key settings is essential to achieve the desired weld quality and efficiency.

Start by configuring the welding parameters with a plasma arc current over 100A for full penetration in thicker materials. Make certain the plasma gas flow rate is set at approximately 0.01 m³/min. This, coupled with a shielding gas flow of Argon plus Hydrogen at 0.02 m³/min, effectively protects the weld pool, preventing contamination.

Maintain a welding speed of 250 mm/min, achieving roughly 1 meter of welding in 4 minutes for peak efficiency.

Adjust the electrode tip angle between 30 to 60 degrees, enhancing arc stability and penetration. Make certain a proper balance between the plasma nozzle bore diameter and the current level. Opt for the largest bore diameter compatible with the current to stabilize the arc and avoid premature nozzle wear or melting.

Applications of Keyhole Plasma Arc Welding

Incorporating keyhole plasma arc welding (KPAW) into your manufacturing processes can greatly enhance production efficiency and weld quality. KPAW is particularly beneficial in aerospace applications, where constructing fuel tanks and submarine hulls demands high integrity and strength.

Its capability to achieve single-pass welds on materials up to 10mm thick considerably boosts efficiency compared to traditional methods, minimizing the need for multiple passes and reducing potential defects.

In pipeline construction, KPAW’s deep penetration capabilities make it ideal for building thick-walled pipelines and tanks, especially in the chemical and oil industries.

This welding method accommodates a variety of metals, including carbon steels, stainless steels, and various alloys, offering versatility across different sectors.

Additionally, KPAW helps in reducing operational costs and can increase tube mill speeds by over 100% for thick-walled tubes, thereby optimizing production rates.

Adopting KPAW can transform your manufacturing processes by enhancing both performance and cost-effectiveness.

Comparing KPAW to Other Welding Techniques

While incorporating keyhole plasma arc welding (KPAW) into your manufacturing processes offers considerable advantages, understanding how it compares to other welding techniques is essential for informed decision-making.

KPAW excels with its deeper penetration and narrower heat-affected zones than traditional TIG welding, enabling single-pass welds on materials up to 10mm thick without edge preparation. This capability considerably enhances productivity with welding speeds around 250 mm/min.

Unlike MIG/MAG welding, KPAW often forms autogenous welds, reducing material costs and simplifying procedures by eliminating the need for filler materials.

Compared to friction stir welding, KPAW is more efficient for thicker materials, as it utilizes a concentrated plasma arc for complete fusion.

Despite these advantages, the versatility of KPAW allows its application across diverse industries like aerospace and energy, offering strong, reliable joints.

However, KPAW’s limitations may include higher equipment costs and a steeper learning curve, potentially requiring specialized training.

Frequently Asked Questions

What Materials Are Best Suited for Keyhole Plasma Arc Welding?

When considering keyhole plasma arc welding, you’d find aluminum alloys and stainless steel are best suited. These materials offer excellent thermal conductivity, allowing precise control over penetration and weld quality, essential for achieving ideal structural integrity in your applications.

How Does KPAW Affect the Environment?

Do you realize how KPWA affects the environment? It reduces energy consumption due to its efficiency, but careful management of emissions and resource usage is essential to minimize its environmental impact. Always analyze operational factors for sustainability.

Can KPAW Be Automated for Large-Scale Production?

Yes, you can automate KPAW for large-scale production. Automation benefits include increased production efficiency, consistent weld quality, and reduced labor costs. Implementing robotic systems and advanced controls guarantees precision and repeatability, enhancing overall operational throughput in industrial settings.

What Safety Precautions Are Necessary for KPAW Operators?

Imagine you’re gearing up for a dance with fire. You must wear protective gear, like a suit of armor, to shield against welding hazards. Guarantee ventilation, use proper eye protection, and follow protocols for ideal operator protection.

Is Specialized Training Required to Operate KPAW Equipment?

Yes, specialized training is crucial. You need KPAW certification to guarantee you’re equipped with the necessary operator skills. This training involves mastering equipment control, understanding welding parameters, and executing precise techniques for peak performance and safety.

Conclusion

You’ve just journeyed through the universe of Keyhole Plasma Arc Welding, a technique so powerful it could weld the stars together. By mastering its ideal settings, like a plasma arc current over 100A, you gain access to unparalleled precision and efficiency. KPAW’s ability to minimize distortion and the heat-affected zone makes it indispensable in industries like aerospace and oil. When compared to other techniques, its superiority is as clear as the brightest constellation in the welding sky.