You might not know that plasma in Plasma Arc Welding (PAW) isn’t just hot gas—it’s an ionized state of matter. When an inert gas like argon gets superheated and ionized by an electric arc, it transforms into plasma, reaching temperatures as high as 28,000°C. This ionized gas conducts electricity, forming a concentrated arc that revolutionizes the welding process. Curious about how this all enhances welding precision and efficiency?

Understanding Plasma in Welding

Plasma, in the domain of plasma arc welding (PAW), is a unique state of matter you encounter when gas becomes ionized due to an electric current. This ionization transforms the gas into a conductive medium composed of free electrons and ions, essential for achieving the high temperatures required in welding.

In PAW, the arc formed by this plasma can reach staggering temperatures of up to 28,000°C, effectively melting metals like stainless steel and aluminum.

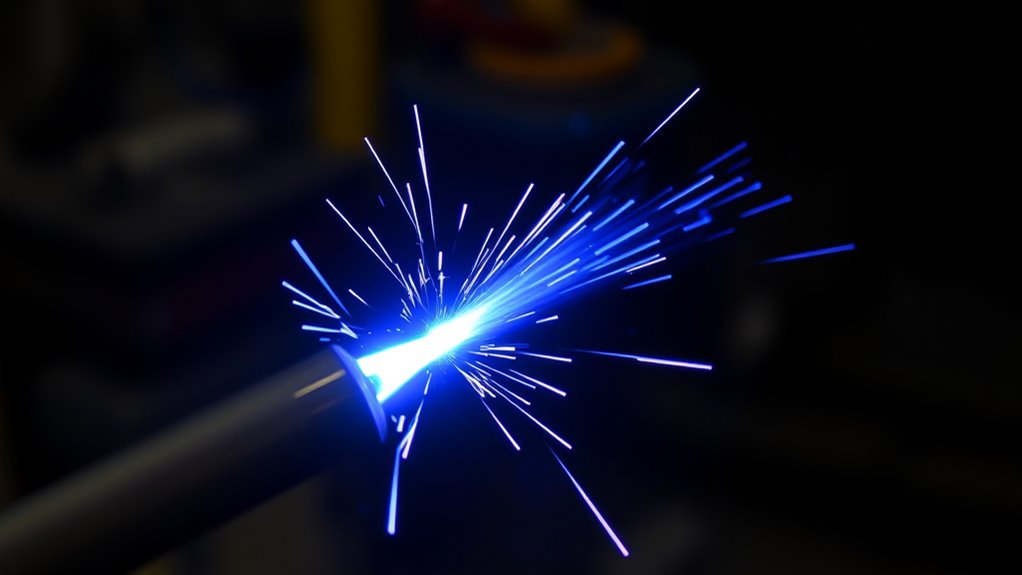

The plasma exits a fine-bore copper nozzle at high velocities, creating a concentrated arc. This configuration enhances penetration and provides precise control over the welding process.

Plasma bursts from a fine-bore copper nozzle, ensuring precise control and enhanced penetration in welding.

The use of inert gases, typically argon or helium, is fundamental. One gas generates the plasma, while another shields the weld from contamination.

The nozzle’s design is critical; a narrower bore increases gas flow rate, directing the plasma for deeper penetration and minimizing heat-affected zones in the material.

The Physics Behind Plasma Arc Welding

When you initiate plasma arc welding, the plasma formation process begins as you heat a gas, such as argon, to high temperatures, causing it to ionize and conduct electricity.

The constriction of the arc through a fine-bore copper nozzle focuses the plasma, enhancing its velocity and energy density. This constricted arc allows for deeper penetration and precision, making it effective for welding challenging materials like stainless steel.

Plasma Formation Process

In the domain of plasma arc welding, understanding the plasma formation process is vital for mastering the technique’s precision and control.

Plasma formation begins when an electric arc ionizes gas, transforming it into a superheated plasma state with free-moving electrons and ions. This process, reaching temperatures up to 28,000°C, is initiated by a tungsten electrode within the torch.

The ionized gas is ejected through a constricted nozzle, focusing the energy for deep penetration. A pilot arc guarantees the electric arc’s transfer to the workpiece, maintaining arc stability.

Moreover, the gas flow rate, often using argon or helium, is imperative for sustaining plasma characteristics. These elements collectively influence plasma arc welding efficiency and weld quality.

Arc Constriction Effects

Understanding the effects of arc constriction is essential in mastering the physics behind plasma arc welding. When you channel the plasma arc through a fine-bore copper nozzle, it enhances the velocity and temperature of the high-velocity plasma jet, reaching up to 28,000°C.

This increase in heat concentration allows for:

- Deep penetration: The keyhole effect is created, especially effective for thicker materials.

- Weld pool control: Improved penetration and control make it suitable for both thin and thick metals.

- Arc stability and efficiency: Lower current demand enhances stability and overall welding efficiency.

The tungsten electrode plays a significant role as it maintains arc stability while preventing metal blowout.

Proper arc constriction not only optimizes welding efficiency but also provides precise control over the weld pool dynamics.

How Plasma Is Formed in PAW

To grasp how plasma is formed in Plasma Arc Welding (PAW), consider the role of an electric arc in ionizing a gas, typically argon or helium. The process starts with a non-transferred arc struck between a tungsten electrode and the workpiece. The arc’s intense heat pushes temperatures up to 28,000°C, ionizing the gas into plasma—a mix of electrons, ions, and neutral atoms.

As the arc’s current flows, the gas transforms into this electrically conductive state. A fine-bore copper nozzle constricts the arc, accelerating the ionized gas and plasma as they exit. This constriction focuses the heat, enabling deep penetration and precision in welding applications.

The high-speed plasma jet efficiently transfers heat, ensuring effective coalescence during welding. The stability and properties of this plasma are influenced by factors like gas flow rate, arc length, and shielding gas type, which all impact weld quality.

The Role of Plasma in the Welding Process

In plasma arc welding, you generate plasma by ionizing an inert gas, such as argon or helium, as it passes through an electric arc, creating a high-energy, focused jet.

This ionization process is vital since it facilitates efficient heat transfer, achieving temperatures up to 28,000°C, which are essential for effective material penetration and weld pool control.

Plasma Arc Generation

When delving into plasma arc generation in welding, you’ll find it begins with the ionization of gas, typically argon or helium. This ionizing gas creates a high-temperature plasma arc as an electric arc passes through it.

The plasma exits a fine-bore copper nozzle, concentrating energy precisely onto the workpiece. This method guarantees deep penetration and high-speed welding, fundamental for both thin and thick materials, while maintaining stability and weld quality.

Key aspects include:

- Gas Flow: Essential for controlling arc stability and delivering consistent weld quality.

- Electric Arc: Transforms ionized gas into a conductive path for the welding process.

- Welding Process: Achieves minimal heat-affected zones, enhancing material integrity.

In essence, plasma arc generation is critical for precision and efficiency in welding applications.

Ionization and Heat Transfer

Understanding the role of plasma in the welding process involves recognizing its dual function in ionization and heat transfer. When a high-temperature electric arc ionizes the gas, it creates plasma composed of free electrons and ions. This state of matter conducts electricity, facilitating efficient thermal energy transfer to the workpiece.

The plasma arc reaches temperatures up to 28,000°C, enabling precise metal melting and welding. The electric arc’s ionization greatly boosts thermal energy, enhancing heat transfer and expanding welding capabilities.

The plasma arc is focused through a fine-bore copper nozzle, increasing penetration depth and ensuring a stable arc. This stability is essential for high-quality welds with minimal distortion, especially in materials like stainless steel and aluminum.

Key Characteristics of Plasma in PAW

Plasma, the ionized gas in Plasma Arc Welding (PAW), plays a significant role in the process. It forms when a plasma arc is struck between a non-consumable tungsten electrode and the workpiece, creating a focused arc. This arc, constricted by a fine-bore copper nozzle, exits at high velocities, enhancing weld pool penetration and providing stability and control over the welding operation.

In PAW, two inert gases are essential: one generates the plasma, and the other acts as a shielding gas to prevent oxidation, guaranteeing high-quality welds.

This setup offers several advantages:

- Heat Concentration: The focused arc guarantees precise heat application, minimizing defects.

- Control and Stability: The fine nozzle and high velocities improve control, reducing tungsten inclusions.

- Clean Environment: Dual inert gases maintain a clean welding zone, enhancing weld quality.

Understanding these characteristics allows you to appreciate the technical precision and effectiveness of PAW.

Applications of Plasma Arc Welding

Building on the key characteristics of plasma in PAW, let’s explore its practical applications across various industries.

In the aerospace industry, plasma welding is essential for precision welding of turbine blades, demanding high-quality welds with minimal distortion. The arc welding process excels in providing high welding speeds while accommodating both thin and thick materials, including stainless steel, a common aerospace material.

In the automotive industry, PAW’s efficiency is unmatched, facilitating the rapid joining of metal components, streamlining production rates, and reducing costs. This high-speed capability is imperative for meeting the demanding pace of automotive manufacturing.

Meanwhile, in medical device manufacturing, PAW delivers precision welding for small, intricate parts, ensuring the integrity of surgical instruments.

In the food and beverage industry, PAW is essential for fabricating hygienic and durable steel tubes and vessels, maintaining product safety. Its versatility in welding stainless steel and aluminum makes it a preferred choice across these sectors.

Safety and Equipment Considerations in PAW

When engaging in plasma arc welding (PAW), guaranteeing safety and proper equipment handling is paramount. A plasma torch, equipped with a fine-bore copper nozzle, is essential for achieving the focused, high-temperature welding required in PAW.

To prevent overheating and maintain peak performance, water-cooled torches are fundamental. This cooling system secures the longevity and efficiency of the nozzle.

Safety doesn’t stop at equipment; protective gear is crucial. You’ll need:

- Helmets and gloves: Guard against ultraviolet radiation and potential burns.

- Noise protection: Essential, as welding noise can reach 100 dB.

- Ventilation systems: Critical to dissipate fumes and gases.

Regular maintenance, including thorough inspections, is necessary to keep your PAW equipment in top condition. This proactive approach prevents costly downtimes and guarantees reliable operation.

Frequently Asked Questions

What Is Plasma in Plasma Welding?

In plasma welding, you deal with ionized gas exhibiting plasma characteristics. It enhances thermal and electrical conductivity, stabilizes the arc, and allows precise temperature control. Inert gases support plasma formation, optimizing welding technology and the process.

What Is Plasma Arcing?

Imagine you’re controlling a sun’s surface. Plasma arcing involves using plasma physics to create arc formation with ionized gas, optimizing heat generation for various welding techniques. Prioritize thermal conductivity, energy efficiency, safety measures, and diligent equipment maintenance.

What Is a Plasma Arc Used For?

You’re using a plasma arc for precision welding and cutting, capitalizing on plasma technology’s thermal dynamics for industrial uses. Its energy efficiency and distinct plasma characteristics guarantee safety measures and equipment maintenance are essential in welding processes.

What Are the Disadvantages of Plasma Arc Welding?

You’re facing high cost considerations and extensive training requirements due to equipment complexity. Safety concerns arise from radiation exposure and noise levels. Maintenance demands include managing heat input for arc stability. Process limitations affect material compatibility and energy efficiency.

Conclusion

In Plasma Arc Welding, think of plasma as the sculptor’s chisel—it’s the tool that shapes and joins metals with precision. By harnessing an electric arc to ionize gas, you’re creating a focused, intensely hot plasma jet. This jet is your guiding light, allowing deep penetration and control. Remember, your mastery over this powerful force not only welds metal but also crafts innovation across industries. Safety gear is your armor, shielding you as you forge connections in both materials and ideas.