You’re about to explore the intricacies of Plasma Transferred Arc (PTA) welding, a precision welding process that revolutionizes how metal surfaces are coated and repaired. This method uses a focused plasma arc to create robust, high-quality coatings. You’ll discover its key components, how it differs from other welding techniques, and its applications across various industries. Let’s uncover why PTA welding is the go-to choice for durable coatings and repairs.

Overview of Plasma Transferred Arc Welding

Plasma Transferred Arc (PTA) welding is a sophisticated technique that’s essential for creating robust and long-lasting coatings on metal surfaces. By utilizing a focused electric arc, you can greatly extend the lifespan of your equipment through durable coatings.

The process involves a plasma arc between a non-consumable tungsten electrode and the workpiece, introducing additional metal to form a strong, precise bond upon solidification.

One of the key PTA welding benefits is its ability to achieve high-quality welds with minimal dilution and a small heat-affected zone. This makes it ideal for hardfacing and cladding applications.

You’ll find PTA welding innovations particularly beneficial in industries like aerospace, mining, and manufacturing, where it’s used for coating drill bits, valves, and turbine blades.

The technique allows you to control the thickness and hardness of the welded layer, offering excellent wear and corrosion resistance alongside high precision.

Key Components and Equipment in PTA Welding

When you explore the key components of PTA welding, understanding the precision and control they offer becomes vital. The process relies on a non-consumable tungsten electrode and a plasma nozzle. The plasma nozzle is essential for directing the plasma arc, which is fundamental to maintaining weld quality. Proper equipment maintenance guarantees the stability and longevity of these components, minimizing downtime and guaranteeing consistent welds.

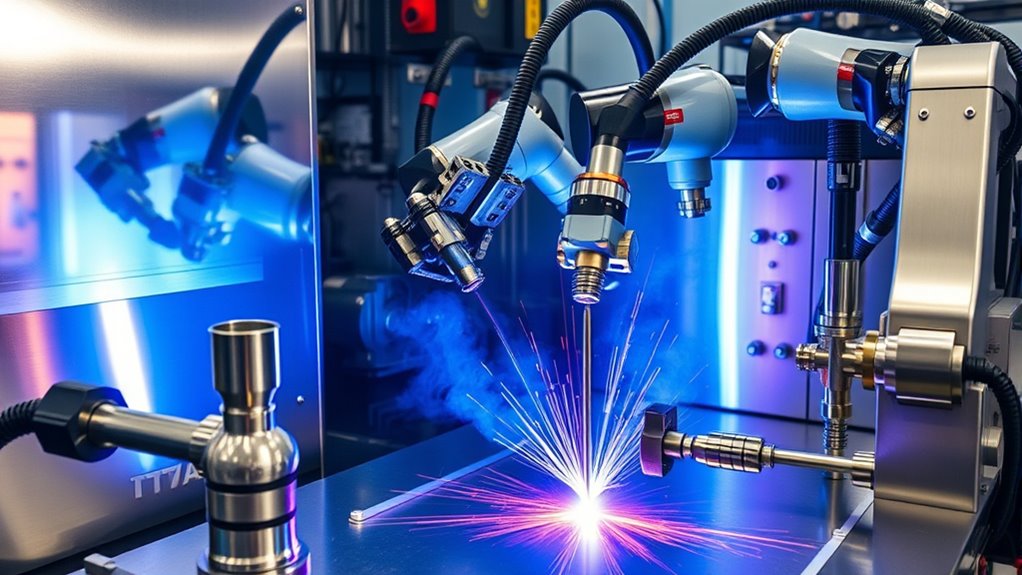

The welding torch in PTA welding generates two arcs: a pilot arc to initiate the process and a main arc that melts the base and filler materials. The feed system introduces filler material in powder form, allowing for precise alloying. Advanced controls manage the arc’s temperature and stability, important for precision.

Gas flow systems, often using argon or helium, stabilize the arc and shield the weld pool. Automated robotic systems can be integrated to increase efficiency, particularly in high-volume settings.

The PTA Welding Process Explained

In the PTA welding process, you initiate the formation of a focused plasma arc by establishing an electric arc between a non-consumable tungsten electrode and the workpiece.

This precision allows the directed gas stream, often argon, to guide the plasma arc, introducing filler material to the welding area for ideal bonding.

As the intense heat facilitates the integration of the filler with the base metal, you achieve a robust metallurgical bond upon solidification.

Plasma Arc Formation

Initiating the Plasma Transferred Arc (PTA) welding process involves the careful creation of a plasma arc, which is established between a non-consumable tungsten electrode and the workpiece.

This process utilizes a stream of argon gas to maintain arc stability and precise heat control. By focusing the heat, the plasma arc becomes considerably hotter and more concentrated than traditional welding methods.

This results in cleaner, more controlled welds with minimal dilution of the base material. The focused heat allows for a reduced heat-affected zone (HAZ), mitigating thermal distortion.

The PTA process excels in applications requiring precise control over the welded layer’s thickness and hardness, making it ideal for hardfacing and protective coatings where precision and quality are paramount.

Filler Material Bonding

With the plasma arc precisely formed, attention turns to the intricate process of filler material bonding in PTA welding.

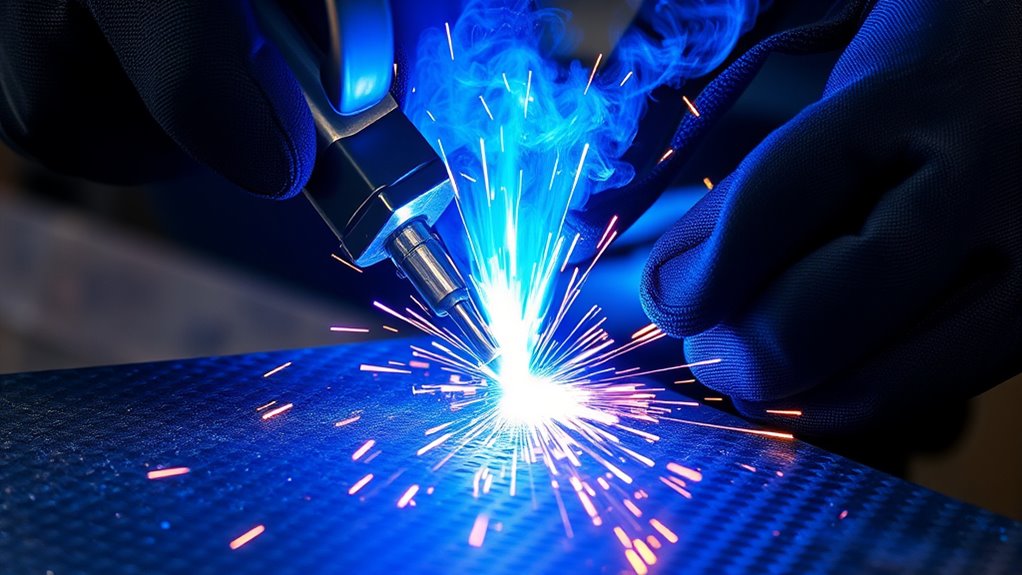

You’ll employ specialized bonding techniques to introduce filler material types, either in powder or wire form, into the molten pool. This pool is created by the intense, focused heat of the plasma arc, which is directed by a gas stream, typically argon or helium.

As the filler material melts and integrates with the base metal, it forms a strong metallurgical bond. Upon solidification, the bond is free of porosity, ensuring high durability and performance.

PTA welding allows precise control over the filler material’s thickness and composition, enabling you to tailor the welded layer’s hardness and wear resistance to meet specific application requirements.

Differences Between PTA Welding and Other Welding Techniques

Although plasma transferred arc (PTA) welding shares some similarities with other welding techniques, its unique characteristics set it apart considerably.

One of the PTA advantages is its ability to generate higher temperatures with a focused plasma arc, offering cleaner and more precise welds. This precision results in a smaller heat-affected zone (HAZ), reducing thermal distortion and preserving the base material’s integrity.

Unlike TIG welding, PTA doesn’t just join metals but enhances them by creating a metallurgical bond with a protective coating, allowing control over the thickness and hardness, reaching up to 68 HRC.

However, PTA disadvantages include higher costs due to specialized equipment and training. Yet, the long-term benefits in durability and maintenance often outweigh these initial expenses.

- Focused Plasma Arc: Achieves higher temperatures for precision.

- Metallurgical Bonding: Enhances protective coatings.

- Smaller HAZ: Reduces risk of distortion.

- Greater Control: Manages thickness and hardness effectively.

- Higher Costs: Requires investment in specialized training.

Applications of Plasma Transferred Arc Welding Across Industries

In the mining industry, you can greatly enhance equipment durability by employing Plasma Transferred Arc Welding to coat drill bits and crusher parts, reducing wear and abrasion.

Similarly, in the oil and gas sector, this welding technique effectively protects valves and drilling tools, extending their operational life in harsh environments.

Mining Equipment Enhancement

Plasma Transferred Arc (PTA) welding stands as a vital technique in the mining industry, enhancing the durability and efficiency of essential equipment.

By employing advanced hardfacing techniques, you can greatly improve mining equipment durability, ensuring that components like drill bits and crusher parts withstand harsh conditions.

With deposition rates from 2-12 kg/hour and hardness up to 68 HRC, PTA welding offers remarkable wear resistance, essential for abrasive environments. Its low base metal dilution and minimal heat-affected zone maintain structural integrity, reducing thermal distortion.

- Enhances longevity of high-wear components like extruder screws.

- Repairs and strengthens turbine blades, boosting performance.

- Maintains structural integrity with minimal thermal distortion.

- Provides exceptional wear resistance in abrasive settings.

- Extends service life through efficient hardfacing material application.

Oil and Gas Protection

When it comes to safeguarding critical components in the oil and gas industry, Plasma Transferred Arc (PTA) welding is a game-changer. This technique allows you to apply hardfacing materials to surfaces, greatly enhancing coating longevity and corrosion resistance.

By bonding coatings with hardness levels up to 68 HRC, PTA welding provides exceptional wear resistance, which is essential for valves and drilling tools that encounter abrasive materials. The low heat-affected zone (HAZ) ensures minimal thermal distortion, preserving the base materials’ integrity and maintaining sensitive components’ performance.

Additionally, PTA welding supports automation, offering consistent and efficient production of protective layers for high-volume applications. This reduces maintenance costs and extends the operational lifespan of equipment used in oil extraction and processing.

Advantages of Using PTA Welding for Coating and Repair

PTA welding stands out as a superior choice for coating and repair applications due to its ability to form a strong metallurgical bond with the base material. This bond considerably enhances durability and reduces maintenance needs.

The process creates a lower heat-affected zone (HAZ) compared to traditional methods, preserving the integrity of the base material and minimizing thermal distortion. With deposition rates ranging from 2-12 kg/hour, PTA welding efficiently applies wear-resistant coatings, extending the lifespan of parts subjected to harsh conditions.

Achieving deposition hardness up to 68 HRC, it offers exceptional resistance to wear and abrasion.

- Durability Enhancement: Robust metallurgical bonds withstand harsh environments.

- Efficient Coating Application: High deposition rates guarantee quick processing.

- Maintenance Reduction: Porosity-free welds lower failure risks.

- Thermal Integrity: Reduced HAZ minimizes material distortion.

- Wear Resistance: High hardness levels protect against abrasion.

Incorporating these advantages, PTA welding is a strategic choice for industrial applications.

Limitations and Challenges in PTA Welding

Although PTA welding offers numerous advantages, it does present certain limitations and challenges that must be considered. To begin with, the cost analysis of PTA welding is essential due to the high initial investment in complex equipment. This system’s intricate setup demands skilled operator training to maintain quality and performance. Without proper training, achieving ideal results becomes challenging.

| Limitation | Details | Impact |

|---|---|---|

| High Initial Cost | Expensive equipment and components | Increased budget allocation |

| Complex Setup | Requires skilled operators | Necessitates training |

| Material Limitations | Ineffective for certain materials/thicknesses | Limits applications |

| Heat Management | Intense heat generation | Risk of thermal distortion |

| Maintenance Demand | Regular calibration and consumable replacement | Operational efficiency |

Moreover, PTA welding may struggle with certain materials and thicknesses, limiting its applicability. Intense heat, while minimizing the heat-affected zone, risks thermal distortion without effective management. Regular maintenance, including calibration and replacements, is critical, impacting operational efficiency.

Safety Considerations in Plasma Transferred Arc Welding

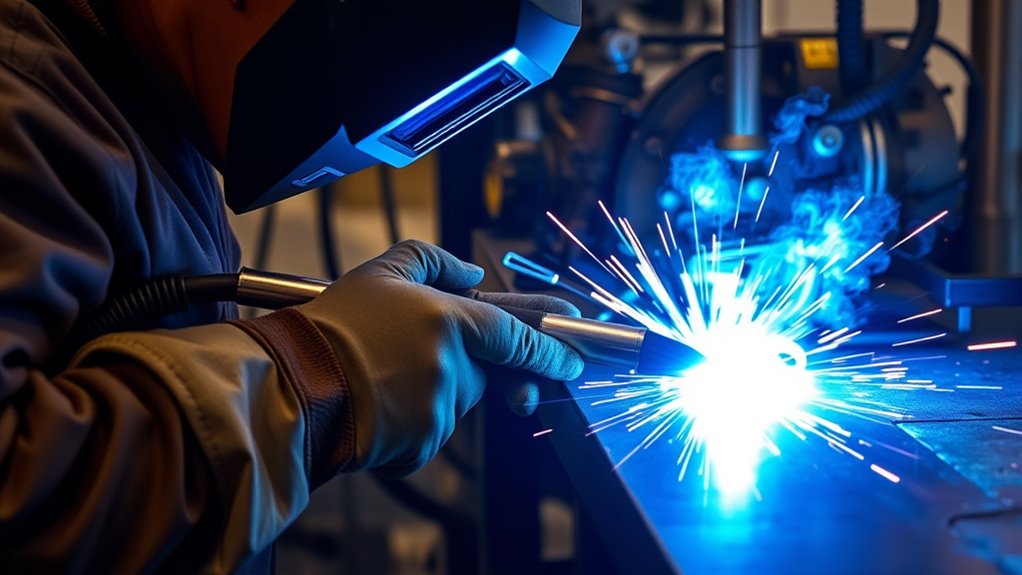

Understanding safety considerations in Plasma Transferred Arc (PTA) welding is essential to operating effectively and minimizing risks. Implementing safety protocols is vital to protect yourself from welding hazards inherent to this process.

Always wear appropriate personal protective equipment (PPE). This includes a welding helmet with the correct shade, flame-resistant clothing, gloves, and closed-toe shoes to shield against sparks and harmful radiation.

Ensure the work area is equipped with proper ventilation to minimize inhalation of harmful fumes. Utilize fume extraction systems or work in a well-ventilated space.

Handle and store welding powders and gases safely. Keep powders in closed containers and inspect hoses regularly for leaks.

Maintain a safe distance from the plasma arc and molten materials to prevent burns. Regularly inspect and maintain PTA welding equipment to reduce the risk of equipment failure.

- Wear appropriate PPE

- Ensure proper ventilation

- Handle and store materials safely

- Maintain a safe distance

- Regularly inspect equipment

Frequently Asked Questions

How Does PTA Welding Affect the Microstructure of Materials?

PTA welding markedly alters the microstructure of materials, enhancing hardness and wear resistance. You’ll notice improved material properties due to refined grain structures and uniform alloy distribution, resulting in superior performance under demanding conditions. Optimize parameters for best results.

What Are Common Troubleshooting Tips for PTA Welding Defects?

Identify PTA welding defects by examining bead appearance and porosity. Troubleshoot by adjusting current and voltage settings, ensuring gas flow consistency, and maintaining clean equipment. Regularly inspect consumables for wear to prevent additional defects. Use structured troubleshooting techniques.

How Does PTA Welding Impact the Environment?

PTA welding impacts the environment by reducing emissions through its efficient energy use. You’ll need to focus on waste management strategies, as the process generates minimal waste compared to traditional methods, enhancing ecological sustainability and operational efficiency.

What Are the Maintenance Requirements for PTA Welding Equipment?

You should conduct regular inspections and guarantee equipment cleaning to maintain PTA welding equipment. Check for wear and tear, replace worn parts promptly, and verify electrical connections. Proper maintenance extends the equipment’s lifespan and guarantees peak performance.

How Does Operator Skill Level Influence PTA Welding Quality?

Your skill level directly impacts PTA welding quality. Operator experience guarantees precise control while skill assessment helps identify areas needing improvement. Develop expertise through structured practice and attention to detail for consistently superior welding outcomes.

Conclusion

In exploring Plasma Transferred Arc (PTA) welding, you see how its precision and control transform industries like aerospace and mining. Coincidentally, as you investigate its technical nuances, you appreciate the strong metallurgical bonds it creates, minimizing heat-affected zones. While its advantages in coating and repair are clear, you also recognize challenges and safety considerations inherent in the process. Ultimately, PTA welding coincides with your pursuit of advanced, reliable solutions for enhancing component durability and extending equipment lifespan.