When I first tried setting up a garage workshop on a tight budget, I quickly realized that getting started with welding isn’t just about buying a machine—it’s about making smart choices that affect weld quality, safety, and efficiency. I remember struggling to decide between MIG vs TIG for my first stainless steel project, wondering which filler rods to stock, and how metal thickness and proper joint prep would impact my final welds.

Mastering arc control on thinner materials without blowing through them felt like a puzzle, and I know many beginners face the same headache. That’s why a budget-friendly garage workshop setup matters—not just to save money, but to ensure every weld is strong, clean, and reliable. In this guide, I’ll share the practical, hands-on tips I’ve learned the hard way, so you can start welding like a pro without breaking the bank.

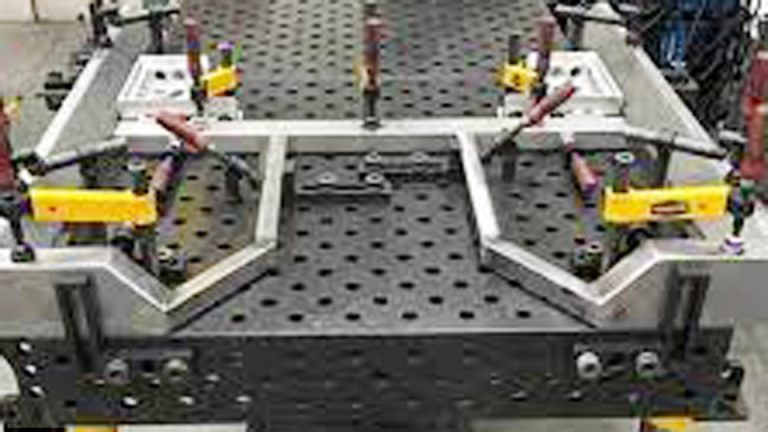

Image by reddit

Why Bother Setting Up a Welding Shop in Your Garage?

It’s a rainy Saturday, and instead of twiddling thumbs, you’re arc-welding a new gate for your driveway. That’s the magic of a garage welding setup—it turns downtime into progress without the commute to a pro shop. For beginners, starting at home means hands-on learning at your pace, but it also highlights why safety and smart planning are non-negotiable. Poor setups lead to fumes building up or sparks igniting clutter, risking health issues like manganese exposure from bad ventilation or fires from overlooked flammables.

In the real world, this matters for weld integrity too. A rushed corner cut on joint prep can mean a brittle weld that snaps on your first heavy lift, costing more in fixes than the setup itself. And cost efficiency? Absolutely—by focusing on versatile, entry-level gear, you avoid the trap of buying “pro” tools you’ll never use. I once helped a buddy skip the $2,000 multi-process beast for a simple MIG unit; he saved enough to stock wire for a year.

For DIY welders and hobbyists, it’s about building skills that pay off in projects like restoring vintage trucks or crafting bar stools. Students and industry workers transitioning to side gigs find it levels the playing field—affordable access to techniques like flux core welding that mimic job-site reliability without the overhead.

The key? Start small, prioritize safety, and scale as you go. Your garage isn’t a factory; it’s your proving ground.

Choosing Your First Welder: Where to Start Without Overspending

Picking a welder feels like choosing your first truck—exciting, but overwhelming if you chase every bell and whistle. For garage beginners, the goal is versatility on a 120-volt household outlet, handling mild steel up to 1/4-inch thick for most home projects. I learned the hard way: My initial buzz box overheated on a 10-minute run, leaving me with half a trailer frame and a lesson in duty cycles.

MIG vs Stick vs TIG: Which Process Fits Your Budget and Skill Level?

MIG (Metal Inert Gas) welding is my top pick for newbies—it’s like a semi-automatic buddy that feeds wire for you, forgiving on minor shakes. It shines on clean steel for frames or repairs, using solid wire with shielding gas or flux core for no-gas simplicity. Pros: Fast, clean beads with minimal cleanup; great for indoor garage work. Cons: Needs gas for best results (adding $100-200 upfront), and it’s noisier than you’d think.

Stick welding, or SMAW, uses coated rods that strike an arc like lighting a match. It’s rugged for rusty or outdoor metal, perfect if your garage doubles as a storage unit for weathered parts. I used one for farm gate fixes—cheap rods at $10 a pack, and it eats dirty joints without complaint. Pros: Portable, wind-resistant, low initial cost ($200-400). Cons: Frequent rod changes interrupt flow, and spatter means more grinding time.

TIG (Tungsten Inert Gas) is the precision artist—think aluminum bike frames or stainless sinks. It uses a foot pedal for heat control, but it’s slower and trickier for beginners. Save it for later; starting here is like learning guitar by shredding solos. Pros: Beautiful, strong welds on thin stuff. Cons: Steep learning curve, higher cost ($500+), and gas dependency.

For budget garage life, go MIG with flux core option—handles 80% of beginner tasks without gas hassles.

Budget Welder Recommendations That Actually Last

Aim for $300-600 to land quality without regret. The Hobart Handler 140 at around $350 is a garage staple—120-volt, welds 24-gauge to 1/4-inch, with a 20% duty cycle at 90 amps for short bursts. Pair it with .030 flux core wire for no-gas runs; I ran mine through a chicken coop rebuild without a hitch.

If you’re eyeing stick, the Forney Easy Weld 261 at $200 is foolproof—21 rod storage slots, 140-amp output. It’s what I loaned to a student buddy; he fixed his truck bed in an afternoon.

For a step up, the Lincoln Electric 140C ($450) adds MIG versatility with a spool gun option for aluminum down the line. Check amperage needs: 1 amp per .001-inch thickness means 125 amps for 1/8-inch steel. Avoid no-name imports under $200—they overheat and fail, turning your setup into scrap.

| Welder Type | Price Range | Best For | Duty Cycle Example | Power Needs |

|---|---|---|---|---|

| MIG (Hobart 140) | $300-400 | Clean repairs, frames | 20% @ 90A | 120V |

| Stick (Forney 261) | $150-250 | Rusty metal, outdoors | 20% @ 90A | 120V |

| TIG (Lincoln Square Wave) | $500-700 | Precision, thin alloys | 20% @ 140A | 120/240V |

These keep you under budget while meeting AWS basics for home use.

Essential Safety Gear: Protecting Yourself Before You Strike an Arc

Safety isn’t a checkbox—it’s what keeps you welding next weekend instead of sidelined. In a garage, where kids or pets might wander, skimping here is a recipe for arc flash burns or fume headaches. My first burn? A cheap glove that melted on a stray spark—lesson learned: Invest $100-150 upfront for gear that lasts.

Start with an auto-darkening helmet ($80-120)—it flips shades instantly to protect your eyes from UV rays that cause “welder’s flash,” like staring at the sun. I swear by the Miller Classic—lightweight, with adjustable sensitivity for garage lighting.

Leather gloves ($20-40) and a flame-resistant jacket ($50) shield hands and torso from spatter. Opt for TIG-style cuffs for wrist coverage; I’ve seen sleeves catch fire from overlooked holes. Add high-ankle leather boots ($60) to stomp out ground fires safely—steel toes if you’re clumsy like I was early on.

Don’t forget a respirator ($30) for flux core fumes—3M half-face with P100 filters traps manganese particles. And chipping hammer/wire brush combo ($15) for slag removal without inhaling dust.

Stage gear on a hook by your table—grab-and-go prevents “just this once” shortcuts.

Ventilation Solutions: Keeping Fumes Out of Your Lungs on a Dime

Nothing kills motivation like a hazy garage reeking of ozone. Welding fumes—zinc oxide from galvanized steel, hexavalent chromium from stainless—build fast in enclosed spaces, risking long-term lung issues. OSHA pushes 10,000 CFM dilution, but for home, we hack it affordably.

Crack the garage door 12-18 inches with a box fan ($25) exhausting outward—pulls fresh air low, pushes fumes high. I rigged mine with a $10 bungee for quick opens; works for MIG sessions under an hour.

For stick or heavy flux core, add a shop vac ($50) with a HEPA filter ducted to a window—sucks smoke at the source. One winter, I skipped this on a gate project; woke up with a metallic taste. Fix: Always weld facing the fan.

Budget upgrade? A $100 inline exhaust fan in a plywood window plug vents 300 CFM quietly. Pair with carbon monoxide detectors ($15)—garages trap exhaust from warm-up vehicles too.

Common mistake: Relying on “it’s just a short weld.” Fumes linger; ventilate every time for clean air and better bead visibility.

Building a Sturdy Welding Table: The Heart of Your Setup

Your table is command central—flimsy ones warp under heat, ruining flatness for square joints. I built mine from 2x4s and 1/4-inch plate for $100; it’s held trailers and tables since.

DIY Table Plans for Under $150

Gather: 4x 2×4 legs (8-footers, $20), 3/4-inch plywood base ($30), 36×36-inch steel plate ($40 from scrap yards). Cut legs to 36 inches, frame with cross-braces for rigidity. Bolt plate atop plywood—clamps hold it fireproof.

Tools needed: Circular saw, drill. Level it on concrete floor; add locking casters ($20) for mobility.

Why this over buying? Commercial ones start at $300; yours custom-fits your garage corner.

Pros: Adjustable height, cheap expansions like fixturing holes. Cons: Initial build time (2 hours).

I drilled 1/2-inch holes every 6 inches for T-slots—perfect for vise mounting without extras.

Quick Fixes for Wobbly or Overheated Tables

If it sags, add diagonal braces. Heat warps? Slag off between passes, or use a water tray underneath for cooling—keeps steel true.

Must-Have Hand Tools and Accessories for Everyday Welding

Beyond the welder, these $100-200 in basics make prep and finish smooth. Skip them, and you’re grinding welds with pliers—trust me, it sucks.

C-clamps (6- and 12-inch, $20 set) secure joints; magnetic squares ($15) hold 90-degree angles hands-free. My go-to for T-joints.

Right-angle grinder ($40) with flap discs chamfers edges—prevents blow-through on thin stock. Add a 4.5-inch cutoff wheel for metal slicing.

Vise ($30, bench-mount) grips for bending; chipping hammer ($10) knocks slag fast.

| Tool | Cost | Use Case | Tip |

|---|---|---|---|

| C-Clamps | $20/set | Joint holding | Quick-release for speed |

| Angle Grinder | $40 | Prep & cleanup | 4,000 RPM min for steel |

| Magnetic Squares | $15 | Alignment | 6-inch for small parts |

| Bench Vise | $30 | Clamping/bending | Swivel base for angles |

Stock .030 flux core wire ($20/2lb)—ER71T-11 for mild steel compatibility.

Organizing Your Garage Workshop: Efficiency Without the Chaos

A cluttered shop breeds mistakes—like tripping over leads mid-arc. Zone it: Welding corner (table, welder on cart), storage wall (pegboard for tools, $20), and “dirty” area for grinding.

I use milk crates ($5 each) for rod/wire sorting—labeled for quick grabs. Weld cart ($50 DIY from pipe) rolls gear close, shortening leads to cut resistance.

Semantic tip: Group by process—MIG shelf separate from stick rods avoids mix-ups in filler compatibility.

Common fix: Overhead hooks for helmets/gloves—keeps ’em dust-free.

Step-by-Step Guide to Setting Up and Running Your First Project

Ready to weld? Let’s tack a simple bracket—tests your setup end-to-end.

- Prep the Joint: Grind rust off 1/8-inch steel angles. Bevel edges 30 degrees for penetration.

- Set the Machine: MIG at 18 volts, 60 wire speed for .030 flux core. Ground clamp tight—loose ones arc wildly.

- Secure and Ventilate: Clamp pieces, fan on, door cracked.

- Strike and Run: 1/2-inch stick-out, drag technique at 45 degrees. Pause every 3 inches to avoid overheating.

- Cool and Inspect: Chip slag, grind smooth. Check for porosity—bubbles mean dirty metal.

My first? A wonky shelf—taught me slow travel speed fixes undercut.

Troubleshooting Common Beginner Errors in Your Garage Setup

Beginners burn hottest on prep skips. Mistake #1: Dirty metal—rust causes porosity. Fix: Wire brush every time; acetone wipe for oils.

Overheating welder? Exceed duty cycle—10 minutes on, 40 off at max amps. I fried a cheap one pushing 30 minutes; now I time bursts.

Spatter everywhere? Too much voltage—dial back 2 volts, clean nozzle. Flux core’s messier, but no gas saves $50/month.

Vent forgotten? Fumes linger—headache city. Always fan first.

Joint gaps? Clamp tighter; use filler rod if needed for compatibility.

Machine Settings and Prep Tips for Stronger, Cleaner Welds

Settings are your recipe—wrong ones mean weak beads. For mild steel MIG: 16-20 volts, 40-80 IPM wire speed based on thickness. Test on scrap: Puddle should wet out without burn-through.

Prep hacks: Bevel thick joints >1/4-inch for root pass. Match filler to base—ER70S-6 for clean steel.

Anecdote: I once mismatched rod on galvanized—zinc popped like fireworks. Now, I degas with heat first.

Pro know-how: Preheat cold steel to 150°F for crack resistance; garage winters demand it.

Wrapping Up

There you have it—your blueprint for a garage that hums with productive arcs. You’ve got the tools, tips, and traps to sidestep, so you’re primed to weld with purpose, not panic. Key takeaways? Prioritize safety and prep for welds that hold; budget gear builds skills faster than splurges. Now grab that scrap and build something—your first strong joint will hook you for life. Pro tip: Keep a weld log—note settings and fixes; it’ll shave hours off future jobs.

What’s the Cheapest Reliable Welder for a Garage Beginner?

A 120-volt flux core MIG like the Hobart 140 around $350—handles home repairs without gas costs or 240V wiring.

Do I Need Shielding Gas for My First Setup?

Not if you use flux core wire; it self-shields for $20 spools. Gas adds versatility later but ups expense by $100+ initially.

How Can I Ventilate My Garage Weld Area Cheaply?

Crack the door with a $25 box fan exhausting out—effective for short sessions. Add a $50 shop vac for targeted pull.

What’s the Biggest Mistake New Welders Make in Setup?

Skipping metal prep—rusty joints lead to porous, weak welds. Always grind and wipe clean for integrity.

Can I Build a Welding Table from Scrap?

Absolutely—use 2×4 frame and surplus plate for under $50. Just ensure it’s level and heat-resistant to avoid warps.