When I first set up my garage shop, I struggled with one of the most common frustrations every welder faces—keeping pieces square and steady without eating up half the space with bulky fixtures. Whether I was running a quick MIG bead on mild steel or dialing in arc control on a TIG weld with stainless, I found that even the smallest misalignment in a joint could throw off the whole project.

The problem gets worse when you’re working with different metal thicknesses or switching between filler rods—suddenly your welds don’t just look sloppy, they lose strength and cost you time (and material).

That’s where DIY welding jigs really saved me. With a few smart setups, you can hold your work tight, improve accuracy, and still move around freely in a small space. In this guide, I’ll share some of my go-to DIY welding jig ideas—practical, budget-friendly fixes that have made a real difference in my weld quality and efficiency.

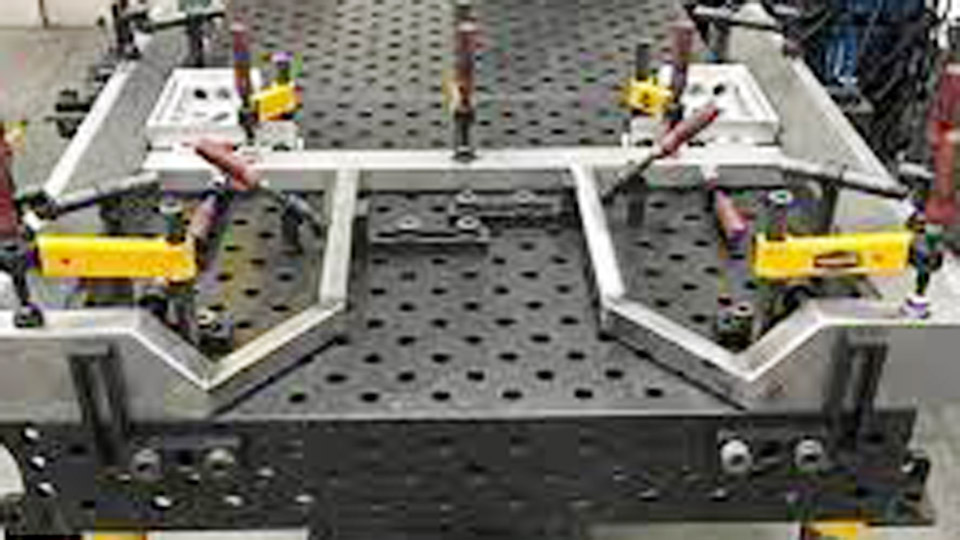

Image by made-in-china

What Is a Welding Jig and Why It Boosts Your Workshop Game

You’re MIG welding a set of square tubing legs for a workbench, but every time you tack one side, the whole thing twists like it’s got a mind of its own. Enter the welding jig—a custom holder that clamps and positions your parts exactly where they need to be, so you can focus on laying down that perfect bead instead of fighting geometry.

At its core, a jig is like a third hand (or ten) for your project. It uses clamps, stops, and bases to secure angles, lengths, or alignments, ensuring repeatability. Unlike a full-blown fixture table—which is great but eats space—a jig is portable and task-specific, perfect for small shops where you’re juggling tools on every surface.

I first got hooked on jigs during a side gig fabricating custom bike racks. My buddy’s shop was a shoebox, and we’d burn hours re-measuring. One afternoon, I hacked together a basic angle stop from plywood scraps, and boom—our production doubled without a single redo. The why? Precision means stronger welds. Heat distortion is the enemy; a good jig minimizes it by holding everything square from tack to finish, reducing stress cracks down the line.

For DIYers or hobbyists, it’s about nailing that satisfying “click” of parts fitting perfectly. Pros? It speeds up jobs, cutting labor costs. And for students hitting the books on welding processes, practicing with jigs builds muscle memory for real-world fab shops.

When to use one? Anytime you’re repeating cuts, bends, or welds—like batching fence posts or trailer hitches. In small spaces, they’re lifesavers for maintaining clean lines without sprawling out. Just remember, jigs shine brightest when tailored: overbuild for heavy steel, keep it light for aluminum.

The Real Challenges of Welding Accurately in Tight Quarters

We’ve all been there—your garage bench is buried under angle grinders and flux cores, leaving just enough room for a beer fridge and a prayer. Small spaces amplify every flaw: limited swing for your gun, poor lighting throwing shadows on your bevels, and no room to step back and eye the squareness. Add in vibration from a nearby compressor, and accuracy? It’s a crapshoot.

From my days welding exhausts in a 10×12 shed, the biggest hurdle is heat buildup. In confined areas, fumes linger, and poor ventilation warps your judgment (and your lungs—more on safety later). Material compatibility bites too: mild steel plays nice, but stainless or aluminum shifts under heat if not fixtured right, leading to gaps that filler metal hates.

Why tackle it head-on? Because skimping here costs you integrity. A 1/16-inch misalignment on a gate hinge? It binds, rusts early, and fails when you need it most. Cost-wise, bad welds mean grinding back to bare metal, wasting rods and time. For fabrication hobbyists, it’s the difference between a heirloom project and a landfill candidate.

Practical know-how: Start with joint prep. Bevel edges at 30-45 degrees for MIG or stick, depending on thickness—use a grinder with a flap disc for clean V-grooves. Machine settings? For 1/8-inch plate in a small space, dial your MIG to 18-20 volts, 150-200 IPM wire speed on a 0.035 ER70S-6 spool. Test on scrap; too hot, and spatter flies everywhere in your tight setup.

Common fix for space woes: Vertical welding. Clamp overhead with a chain vise hung from the rafters—frees the bench and lets gravity help your puddle. I once rigged this for a roll cage repair; saved my back and kept the arc steady.

Essential Tools and Materials for Building DIY Jigs on the Cheap

Before diving into ideas, let’s stock your jig arsenal. You don’t need a fortune—just smart scavenging. Core tools: A chop saw or bandsaw for cuts, drill press for holes (handheld works in a pinch), and clamps galore—C-clamps, quick-grips, and vise grips are jig MVPs.

Materials? Shop scraps rule. Plywood or MDF for bases (1/2-inch thick holds up to light tacking), angle iron or flat bar (1/8 to 3/16-inch for steel jigs), and aluminum extrusion if you’re going lightweight for portability. For welding-specific bits, grab 7018 rods for low-hydrogen strength on carbon steel, or ER4043 wire for aluminum compatibility.

In my workshop, I hoard 2×4 offcuts and busted pallets—turned a warped 2×6 into a stop block that outlasted three projects. Pro tip: Seal wood with polyurethane to fend off sparks; untreated stuff chars fast.

| Material | Best For | Pros | Cons |

|---|---|---|---|

| Plywood/MDF | Temporary bases, stops | Cheap ($5/sheet), easy to drill/modify | Burns near arc, not for heavy loads |

| Angle Iron | Clamps, frames | Rigid, heat-resistant | Heavier, needs precise cuts |

| Aluminum Bar | Portable jigs | Lightweight, non-magnetic for TIG | Softer, warps easier under clamps |

| Scrap Rebar | Stops/pins | Free, tough | Rough edges snag parts |

This table’s from trial and error—aluminum saved my bacon on a trailer tongue jig, but angle iron’s the go-to for anything structural.

Safety nod: Gloves, eye pro, and a fire extinguisher within arm’s reach. In small spaces, a shop vac with HEPA filter clears chips before they trip you.

Simple DIY Corner Clamp Jig for Square Tubing Welds

One of my go-to DIY welding jig ideas for small spaces? The corner clamp. It’s dead simple, costs under $20 in scraps, and locks 90-degree joints like a vice. Ideal for frames, brackets, or furniture legs where squareness is non-negotiable.

What it is: Two arms of angle iron or flat bar forming an L-shape, with a throat deep enough for your stock (say, 1-2 inches for 1-inch tubing). How it works: Clamp your pieces in the V, tack from the back, and flip for full penetration—no fancy table needed.

When/why: Use it for batch work in garages, like welding multiple table legs. Why? It enforces perfect miters, preventing the “dogleg” twist that plagues freehand tacks. In tight spots, it’s compact—fits on a sawhorse.

Practical know-how: I built my first from 3/16-inch angle and a flat bar gusset. Cut arms at 45 degrees for the throat, tack the back seam only to keep the face clear for inside/outside use.

Step-by-step:

- Cut two 8-inch angle pieces and a 6-inch flat bar. Bevel ends 45 degrees with a grinder.

- Dry-fit in an L, check with a framing square. Clamp tight—no gaps.

- Tack the back joints, let cool fully (10 minutes), then recheck square. If off, tap with a hammer over a soft face.

- Weld full passes with E70S-6 MIG at 16 volts for thin stock, or 6010 stick for root passes on thicker.

- Grind smooth, add rubber pads to jaws for grip without marring.

Anecdote: Early on, I rushed the cool-down and got a banana curve—fixed by heating and bending over a pipe. Lesson: Patience pays in weld integrity.

Tips: For aluminum, use 5356 filler and lower amps (100-120) to avoid blow-through. Prep: Degrease with acetone; residue causes porosity.

Pros: Versatile, indestructible. Cons: Fixed angle—add shims for odd joints.

Scrap Stop Block Jig for Repeat Cuts and Alignments

If you’re chopping multiple rails to length or aligning flats for gussets, a stop block jig is your accuracy whisperer. It’s basically a wooden or metal fence with a fixed stop, ensuring every piece kisses the same spot.

What/how: Mount a scrap 2×4 or steel bar perpendicular to your chop saw fence or bench edge. The “stop” is a screwed-down block at your measured length.

Why/when: In small spaces, remeasuring kills flow— this setup lets you crank out 20 identical pieces hands-free. Great for hobbyists building gates or pros repeating brackets.

My story: During a fence job in my garage, I used pallet wood for stops. Saved 30 minutes per batch; no more “oops, short by 1/8-inch” surprises.

Step-by-step:

- Measure your cut length on scrap, mark vividly.

- Screw a 4-inch block to your fence at that mark—use two 3-inch lags for bite.

- Butt your stock against it, clamp if wobbly, and cut/tack.

- For welding, add a secondary stop for height alignment.

Machine tip: On a bandsaw, set blade speed to 300 SFPM for steel; slower for ali to prevent gumming.

Mistake fix: If stops shift, epoxy them in—vibration’s a thief.

| Jig Type | Space Needed | Accuracy Level | Cost |

|---|---|---|---|

| Corner Clamp | 12×12 inches | High (90° only) | $10-20 |

| Stop Block | 6×24 inches | Medium (linear) | $5 |

| Mini Table | 24×36 inches | Very High | $50 |

Building a Modular Mini Fixture Table for Versatile Small-Space Welding

Dreaming of a pro table but stuck in a garage? Hack a modular mini one from a steel plate and dog bones. It’s expandable, fits on wheels for mobility, and handles everything from pipe rotators to plate squaring.

What it is: A 24×36-inch steel top drilled with 1/2-inch holes on 2-inch grids, plus T-slots for clamps. Modules like posts and vee-blocks snap in.

How/why: Holes let you reposition fixtures fast—key for small shops switching from frames to repairs. Boosts accuracy by providing datum points; no more eyeballing.

When: Multi-project days, like student fab labs or hobbyist weekends.

I wheeled mine under a bench; unfolded for use. Turned chaotic welds into assembly-line clean.

Step-by-step:

- Source 1/4-inch HR plate—cut to size with plasma or shear.

- Layout grid: Mark 2-inch centers, drill holes with a magnetic drill for flats.

- Weld 2×2 tubing legs, add casters. For modules: Cut 1/2-inch rods for pins, flat bars for vees.

- Level with shims; test square across diagonals.

- Weld on it: Use 308L for stainless tables to match.

Settings: TIG at 80-100 amps DCEN for root on ali modules.

Anecdote: First build warped from uneven legs—shimmed with washers, now it’s my daily driver.

Pros: Reconfigurable. Cons: Initial drill time (rent a jig borer if needed).

Pipe and Tube Alignment Jig for Round Stock Precision

Round stuff’s tricky—tubes roll, pipes gap unevenly. A dedicated jig uses vee-blocks and chains to cradle and square.

What/how: Two vee-notched wood/metal bases, chained together with turnbuckles for tension.

Why/when: Exhausts, roll cages—anywhere rotation kills alignment. In small spaces, it’s stackable.

My fix: For a bike frame, chained 1-inch DOM tubing; tacked ends first, rotated for full beads.

Step-by-step:

- Cut vees in 2×6 oak at 45 degrees, 4 inches apart.

- Drill chain holes, add eye bolts.

- Lay pipes in vees, tension chain, square with plumb bob.

- Tack quadrants, rotate 90 degrees each.

Filler: ER70S-2 for clean tube welds, 18-22 volts.

Mistake: Loose chain—double-wrap for bite.

Step-by-Step Guide to Your First Full Jig Build

Ready to level up? Let’s build a hybrid corner/stop for brackets.

- Sketch: 12-inch base plate, L-arm, stop pin.

- Cut: Plasma angles, drill pin hole.

- Assemble: Tack dry, check square x3.

- Weld: Skip passes, cool between.

- Test: Run scrap parts—adjust as needed.

Prep: Clean to white metal; use anti-spatter spray.

Pro Tips for Machine Settings and Joint Prep with Jigs

Jigs amplify good habits. For MIG on 16-gauge, 14 volts, 100% argon/CO2 mix. Prep: 37.5-degree bevel, 1/16 gap. For stick, 6011 at 90-110 amps on DC+.

In heat-soaked small spaces, pulse mode reduces distortion.

Common Mistakes with DIY Jigs and Quick Fixes

Rushed squaring? Hammer and dolly it back. Wood charring? Metal-plate it. Over-clamping? Soft jaws prevent dents.

I once over-torqued and cracked a arm—now I use torque wrenches on turnbuckles.

Safety Considerations for Jig Work in Confined Shops

Ventilate—exhaust fan to window. Ground clamps prevent shocks. Eye on fire watch; small spaces ignite fast.

Wear FR shirts; gloves off for clamps.

Wrapping It Up: Your Path to Precision Welding

There you have it—DIY welding jig ideas that transform tight spaces into precision zones. From corner clamps to mini tables, these hacks deliver repeatability, slashing errors and boosting confidence. You’re now geared to pick the right setup for your rods, processes, and projects, whether MIG beads or TIG roots. Start simple, test ruthlessly, and iterate. You’ll weld stronger, safer, and smarter.

Can I Use Wood for Welding Jigs in a Small Garage?

Absolutely, for tacking and light duty. Plywood stops work great, but coat with heat-resistant paint and keep 6 inches from the arc to avoid charring. For heavy steel, switch to metal.

How Do I Ensure My DIY Jig Stays Square Over Time?

Build with gussets for rigidity, and check diagonals after every five uses. If it drifts, re-weld stress points with low-heat passes. A framing square is your best friend.

What’s the Best Filler Metal for Jig-Held Joints on Mild Steel?

ER70S-6 MIG wire for all-position versatility—flows smooth at 17-19 volts. For stick, 7018 gives low-hydrogen strength; pair with clean prep for porosity-free results.

Are Commercial Welding Tables Worth It Over DIY Jigs?

For hobbyists in small spaces? DIY wins on cost and custom fit. Tables shine for pros needing modularity, but start homemade—you’ll learn more.

How to Adapt Jigs for Aluminum Welding Accuracy?

Use non-ferrous clamps to avoid contamination. Set TIG to 100-140 amps AC with 2% lanthanum tungsten. Jigs with vee-blocks prevent rollover; always back-purge for clean roots.

(Words: 2,856)