Updated on December 3, 2025

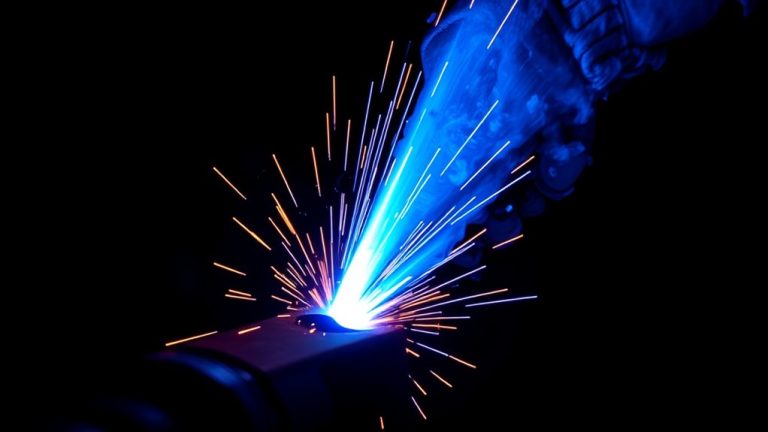

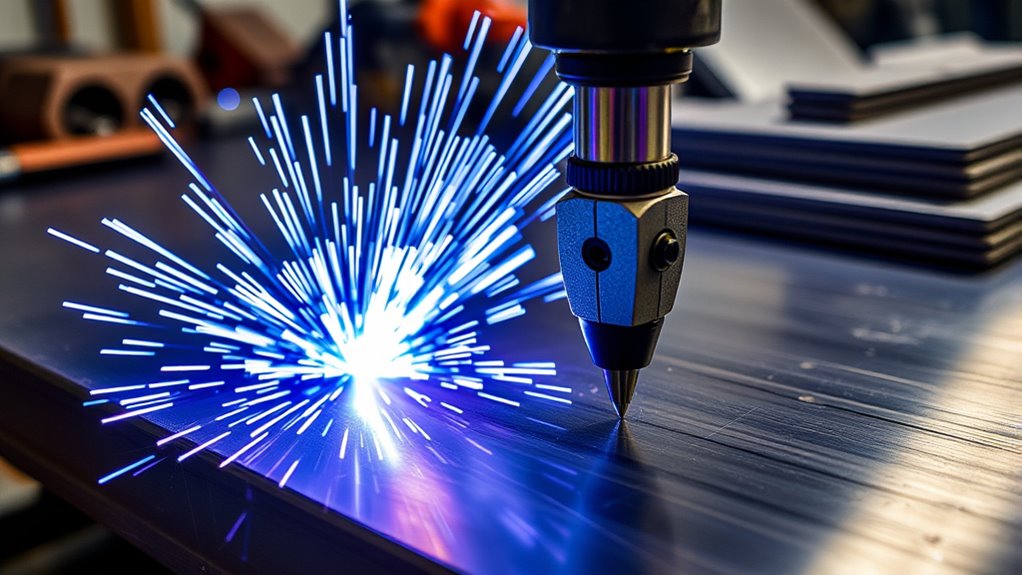

A pilot arc plasma cutter is a powerful tool that generates a high-temperature plasma jet without needing to touch the workpiece. This technology allows for efficient metal cutting on rusty, painted, or expanded metal surfaces, offering superior precision and minimizing dross compared to traditional methods.

What is a pilot arc plasma cutter?

A pilot arc plasma cutter is a metal cutting system that creates a non-transfer pilot arc inside the torch head before contacting the metal. This allows the torch to cut through electrically insulated surfaces—such as paint, rust, or dirt—without requiring direct contact or pre-drilling holes.

Its applications span from automotive restoration to aerospace fabrication, offering rapid, clean cuts. Pilot arc technology also enhances safety by reducing the need for dangerous starting methods. Curious about its specific mechanics and advantages? Keep reading.

Understanding Pilot Arc Plasma Cutting

When you use a pilot arc plasma cutter, understanding its operation is essential for ideal performance. Pilot Arc Starting initiates the cutting process by generating a low-energy electrical arc between the electrode and the nozzle inside the torch.

This method allows you to cut through metal surfaces that are rusty, dirty, or painted without needing to pre-drill holes or grind the surface clean. In these systems, the pilot arc forms in a two-stage process:

- Stage 1: High voltage ionizes the gas inside the torch, creating a pilot arc.

- Stage 2: The arc transfers to the workpiece upon proximity, creating the main cutting arc.

This technique improves cut quality by reducing dross and providing cleaner edges. Modern systems also mitigate the risks of high-frequency interference, protecting sensitive electronics nearby.

Mechanisms of Pilot Arc Formation

You initiate the pilot arc by activating the trigger. This sends high-voltage current through the plasma gas, forming a low-energy arc before it even touches the workpiece.

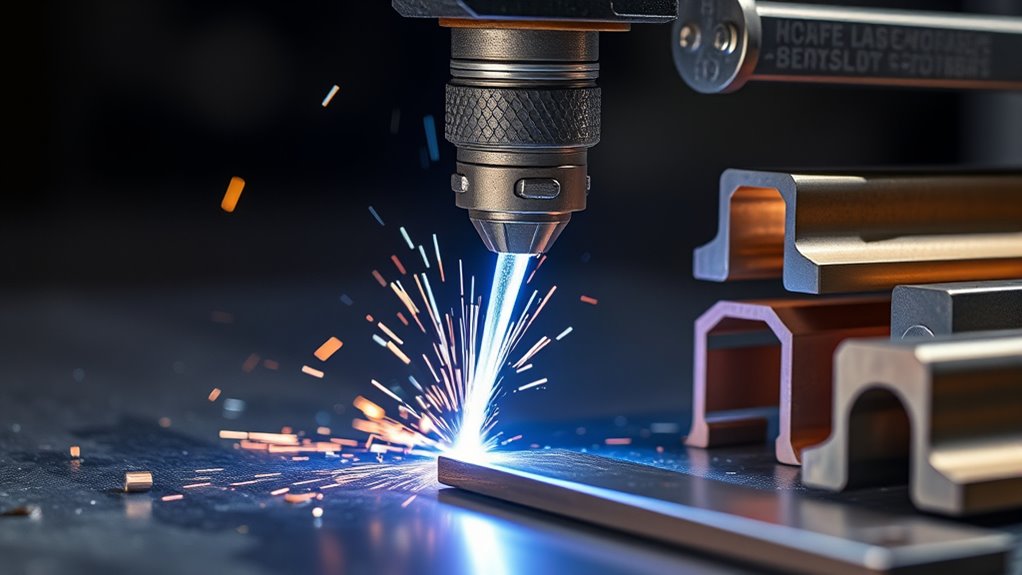

Pilot Arc Initiation Methods

While the goal is efficient arc formation, different cutters use different starting methods:

- High-Frequency (HF) Start: Uses a high-voltage spark to ionize air. It is reliable but can cause interference with CNC machines and laptops.

- Blowback (Spring-Loaded) Start: The electrode physically moves inside the torch (via air pressure) to create a short circuit spark. This is safer for electronics and very common in modern machines.

- Capacitive Discharge: Releases energy bursts to spark arc transfer without direct contact.

Arc Stability Advantages

The pilot arc mechanism guarantees arc stability. Because the arc is already established before it hits the metal, you can cut through expanded metal (grates) or heavily painted surfaces without the arc extinguishing. This continuous plasma flow maintains a stable jet, reaching temperatures up to 40,000°F.

Key Advantages of Using a Pilot Arc Plasma Cutter

Why choose a pilot arc model? The benefits directly impact your workflow:

- Versatility on Dirty Metal: Cuts through rust, paint, and coating without preparation.

- No Contact Required: The torch tip doesn’t need to touch the metal, which extends consumable life.

- Expanded Metal Capability: Easily cuts through mesh or grates where the arc would normally break on a standard cutter.

- Safety: Modern blowback styles minimize high-frequency radiation risks.

Applications in Various Industries

Pilot arc cutters are pivotal across several sectors:

- Automotive: Slicing through rusted body panels and frames without pre-sanding.

- Aerospace: Precision cutting of aluminum and titanium.

- Construction: Rapid resizing of steel beams and structural components on-site.

- Shipbuilding: Managing thick, often oxidized metal plates for hull assembly.

Comparison: Pilot Arc vs. Non-Pilot Arc

Non-pilot arc cutters (often called “touch start” or “scratch start”) require the nozzle to physically touch the metal to complete the circuit. Here is how they compare:

| Feature | Pilot Arc Cutter | Non-Pilot (Touch) Cutter |

|---|---|---|

| Starting Method | Non-contact (hovers above metal) | Contact (must scratch surface) |

| Painted/Rusty Surfaces | Excellent (burns through) | Poor (requires cleaning) |

| Consumable Life | Longer (less splashback) | Shorter (clogs nozzle) |

| Cost | Higher initial investment | More affordable |

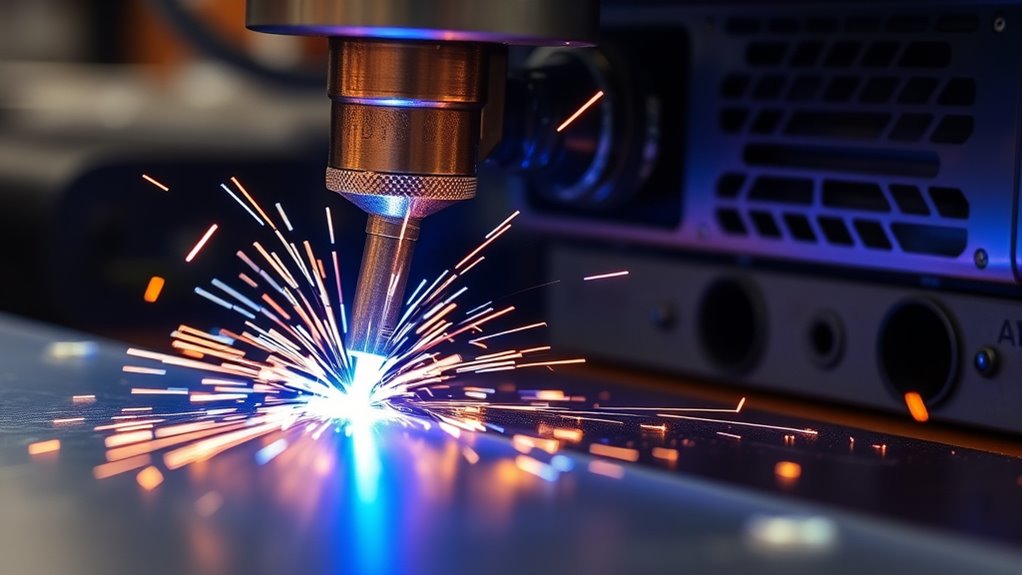

Essential Components

Three main systems work together:

- Power Supply: Converts AC line voltage into constant DC current.

- Arc Starting Console: Generates the high-frequency or blowback voltage to ionize the gas.

- Torch & Consumables: Includes the electrode, swirl ring, and nozzle. The swirl ring spins the gas to focus the plasma jet, ensuring straight, clean cuts.

Safety Considerations and Best Practices

Plasma cutting involves high voltage and extreme heat. According to standard safety practices (refer to American Welding Society guidelines), you must prioritize protection:

- Eye Protection: Use a welding helmet or cutting goggles with the correct shade (usually shade 5–9 depending on amperage).

- Ventilation: Cutting painted or coated metals releases toxic fumes. Use a respirator or fume extractor.

- Clothing: Wear flame-resistant jackets and gloves to protect against sparks and UV radiation.

Maintaining Your Pilot Arc Plasma Cutter

Routine maintenance ensures longevity:

Tip: Regularly inspect the electrode and nozzle. A pitted electrode or a widened nozzle orifice will cause a wandering arc and poor cuts.

Ensure your air supply is clean and dry. Moisture in the air line is the #1 killer of plasma consumables. Use a water separator or air dryer system.

Choosing the Right Plasma Cutter

When selecting a unit, consider:

- Duty Cycle: How long can it run continuously? (e.g., 60% at 40A).

- Input Power: Do you need dual voltage (110V/220V) for portability?

- Environment: If you use CNC tables or computers nearby, avoid HF start models and choose a “Blowback” start pilot arc cutter to prevent interference.

Future Trends

The industry is moving toward smarter, more efficient machines. Expect to see higher energy efficiency, better integration with IoT for predictive maintenance, and continued evolution of HF-free starting methods to make plasma cutters safer and more compatible with modern digital workshops.

Frequently Asked Questions

How does the pilot arc work?

A pilot arc uses a two-stage initiation process where high-voltage electricity ionizes gas inside the torch head. This creates a stable plasma jet that cuts through conductive materials like rusty or painted metal without requiring direct contact.

What is the difference between pilot arc and non-pilot arc plasma cutters?

Pilot arc cutters generate the arc inside the torch, allowing them to cut dirty or painted metal without touching it. Non-pilot (touch start) cutters must physically touch the metal to start the arc, making them difficult to use on uneven or coated surfaces.

What is the difference between a touch arc and a pilot arc plasma cutter?

A touch arc cutter relies on a “scratch start” method where the nozzle must drag on the metal. A pilot arc cutter maintains a non-contact arc, which preserves consumable life and allows for better precision on detailed work.

What are the disadvantages of plasma arc cutting?

The main disadvantages are the high initial equipment cost, the noise level, and the creation of hazardous fumes which require proper ventilation. Additionally, the edge quality on very thick plates may not be as square as laser cutting.

Conclusion

In summary, a pilot arc plasma cutter is the superior choice for versatility and efficiency. Whether you are dealing with salvaged rusty steel or need precision cuts on aluminum, the ability to maintain an arc without contact changes the game. By choosing the right machine and following safety protocols, you can achieve professional-grade results in any fabrication project.