Imagine the power of a small sun harnessed in your workshop with a plasma cutter. To achieve this, understanding its power requirements—watts, amps, and breakers—is essential. A mismatch could lead to inefficient cuts or even damage. With models varying from 30 to 75 amps and voltage needs between 120 to three-phase, choosing the right setup is key. But what does your specific plasma cutter demand to operate at peak efficiency?

Understanding Plasma Cutter Power Requirements

When delving into plasma cutter power requirements, it’s crucial to grasp the electrical demands these machines impose. You’ll find that plasma cutter types vary greatly, influencing power efficiency and electrical setup.

Smaller models operate on 120 or 240 volts, making them suitable for standard residential or small workshop settings. These units typically require less power, aligning with single-phase supply.

However, larger plasma cutter types demand a more robust electrical framework, often necessitating a three-phase power supply and a 40-amp circuit breaker to handle their 1,000-amp full-power operation.

Larger plasma cutters require a three-phase power supply and a 40-amp breaker for 1,000-amp operation.

Calculating the total output power involves multiplying amperage by voltage, which provides the wattage necessary for effective cutting. This metric underscores the significance of matching your plasma cutter type to the available power capacity.

For peak performance, confirm that your workspace can support the power requirements, thereby maximizing the plasma cutter’s power efficiency and cutting capabilities.

Importance of Circuit Breaker Ratings

Understanding circuit breaker ratings is essential to guarantee the safe and efficient operation of plasma cutters. Plasma cutters demand substantial power, frequently necessitating circuit protection beyond standard 15 or 20-amp breakers. Opt for a 30-amp or 50-amp breaker type to accommodate higher power demands without risking overheating or electrical failure.

A 50-amp breaker, capable of managing up to 75 amps, is ideal for larger plasma cutters operating at elevated amperage levels. To promote safety and avoid tripping, consider upgrading circuit breakers or installing dedicated outlets. Proper breaker ratings prevent overheating, critical given plasma cutters can draw up to 1000 amps at full power, albeit not continuously.

This proactive approach not only safeguards your equipment but also curtails potential increases in electricity bills by efficiently managing power consumption. By selecting the right breaker type, you enhance circuit protection, promoting both safety and peak plasma cutter performance.

Evaluating Voltage and Amperage Needs

How do you guarantee that your plasma cutter is operating at its best capacity? Begin by evaluating the voltage and amperage requirements. Smaller plasma cutters typically use 120 or 240 volts. However, larger models might need a three-phase power supply and a 40-amp breaker. Confirming your setup can handle these demands is vital for peak performance.

Evaluate voltage and amperage to ensure your plasma cutter operates at optimal capacity.

To assess whether your power supply meets the amperage requirements:

- Check Circuit Breakers: A 50-amp circuit breaker is recommended to allow a maximum draw of up to 75 amps.

- Consider Material Thickness: Thicker materials, like 5/8″ steel, can increase amperage draw considerably, requiring up to 31 amps.

- Upgrade as Needed: To prevent tripping breakers and guarantee safety, upgrading circuit breakers or installing dedicated outlets for high-powered cutters is advisable.

Choosing the Right Plasma Cutter for Your Workshop

Why is selecting the right plasma cutter essential for your workshop’s efficiency? The right choice guarantees peak power efficiency, meeting your cutting needs without overloading circuits.

Start by analyzing the plasma cutter types suitable for your workspace. Smaller models typically operate on 120 or 240 volts, perfect for light tasks, while heavy-duty cutters might need a 3-phase power supply and a 40-amp breaker.

Evaluate the maximum metal thickness you frequently cut. If regularly cutting 3/4 inch steel, a 50-amp cutter offers the necessary performance.

Verify your electrical system can handle the power demands; high amperage draw demands circuit breakers rated above standard 15 or 20 amps.

Consider duty cycle, as models with higher percentages sustain longer operation without overheating.

Finally, assess portability—compact models are easier to move, but larger machines deliver more power. Balancing these factors assures efficiency and effectiveness in your workshop.

Impact of Power Consumption on Electricity Bills

When operating a plasma cutter, you’ll notice its substantial amperage draw, which can greatly impact your electricity bills.

To manage these costs effectively, consider implementing efficient energy management strategies, such as monitoring the duty cycle and optimizing usage patterns.

Additionally, evaluating your electrical infrastructure for potential upgrades can help mitigate the financial impact of high power usage.

High Power Usage Costs

Despite the impressive capabilities of plasma cutters, their substantial power consumption can greatly impact electricity bills. To achieve power efficiency and cost savings, it’s essential to understand the energy dynamics involved.

Plasma cutters can utilize approximately 1,000 amps at full power, markedly affecting your energy costs. When operating on a 50-amp circuit, these devices might draw up to 39 amps under low voltage conditions, leading to higher electricity expenses. Furthermore, the high power requirements coupled with the need for a robust air supply can further elevate operational costs.

To manage these expenses, consider:

- Monitoring usage: Regularly track the energy consumption of your plasma cutter.

- Optimizing settings: Adjust settings for efficiency.

- Shorter operation periods: Limit extended high-amperage use.

Efficient Energy Management

Managing the power consumption of plasma cutters is key to controlling electricity bills. You need to focus on energy efficiency to achieve cost savings.

Plasma cutters, drawing roughly 1,000 amps at full capacity, can spike your electricity usage. If you’re operating on a 50-amp circuit, the draw may reach 75 amps, escalating energy costs and necessitating upgraded circuit breakers. This can lead to additional expenses.

To enhance energy efficiency, guarantee your plasma cutter connects to dedicated outlets with appropriate circuit ratings. This strategic approach helps mitigate the financial impact on your electricity expenses.

Upgrading Electrical Systems for Plasma Cutter Use

To guarantee your plasma cutter operates efficiently, you must assess your circuit breaker capacity since these machines often require a 30-amp or 50-amp breaker.

Installing dedicated outlets is essential to accommodate the high power demands, thereby preventing tripping and guaranteeing safe operation.

For peak performance, consult with an electrician to evaluate your current electrical infrastructure and make necessary upgrades.

Circuit Breaker Capacity

When upgrading electrical systems for plasma cutter use, understanding circuit breaker capacity is vital to guarantee safe and efficient operation. Plasma cutters often demand more than standard 15 or 20-amp breakers, typically requiring a 30-amp or 50-amp breaker.

Selecting the right circuit breaker types is important, as a 50-amp breaker can support up to 75 amps, accommodating high-amperage models. Proper breaker installation guarantees the system handles the substantial power draw without tripping.

- Evaluate workshop capacity: Determine if existing wiring supports new demands.

- Select suitable breakers: Match breaker capacity with the plasma cutter’s requirements.

- Consult a professional electrician: Ensure compliance with electrical codes and ideal setup.

Upgrading may also involve wiring enhancements to meet the cutter’s high amperage needs.

Dedicated Outlet Installation

Installing a dedicated outlet for your plasma cutter is essential to guarantee it operates efficiently and safely.

Begin the installation process by consulting an electrician to assess your workshop’s current electrical capacity. Plasma cutters often require a circuit breaker rated at 30 or 50 amps, surpassing standard 15 or 20-amp outlets.

Upgrading may involve installing heavier gauge wiring, especially for 240V systems, to handle the high amperage draw. A dedicated outlet prevents voltage drops, ensuring consistent power supply, fundamental for maintaining cutting efficiency and avoiding equipment damage.

Consider future power needs during installation; larger plasma cutters might demand more power, requiring additional electrical modifications. Proper planning guarantees seamless operation and safeguards your plasma cutter’s longevity.

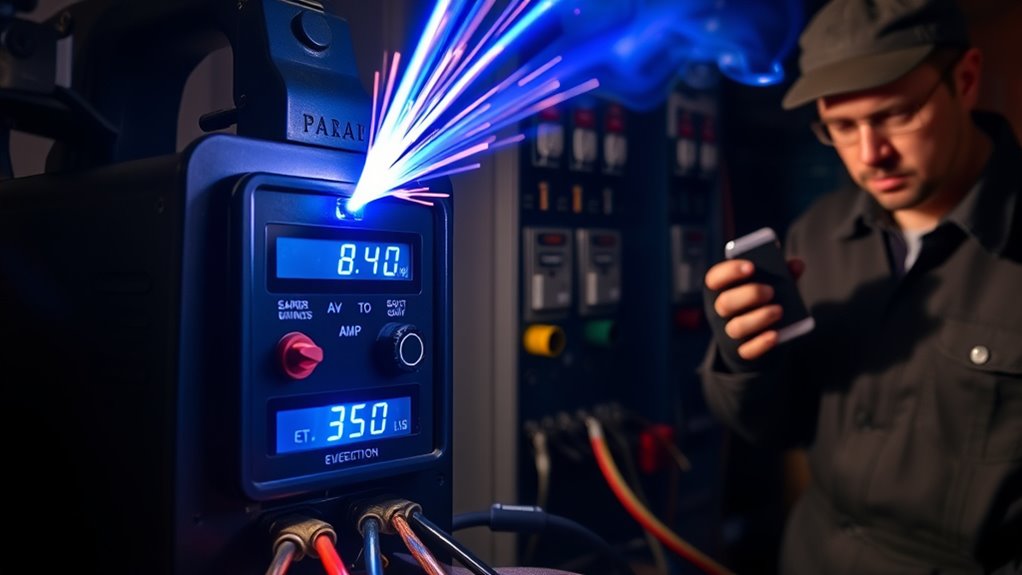

Safety Considerations for High-Power Equipment

Given the immense power requirements of plasma cutters, guaranteeing safety in their operation is vital. You need to take into account several important factors, especially when dealing with equipment that demands approximately 1,000 amps at full power.

Ensuring safe operation of plasma cutters is crucial due to their high power demands, often reaching 1,000 amps.

First, make certain your circuit breakers are rated adequately—ideally, a 50-amp breaker should be in place to handle the load safely and efficiently.

Implementing proper safety gear is also essential. Plasma cutters generate over 100 decibels of noise, so effective noise control measures, such as ear protection, are significant. Additionally, proper ventilation and respiratory protection are mandatory to mitigate the inhalation of hazardous fumes produced during cutting.

Here are key safety measures:

- Use ear protection to manage noise levels and prevent hearing damage.

- Guarantee adequate ventilation to disperse harmful fumes in confined spaces.

- Install circuit breakers rated higher than standard 15 or 20 amps for safe operation.

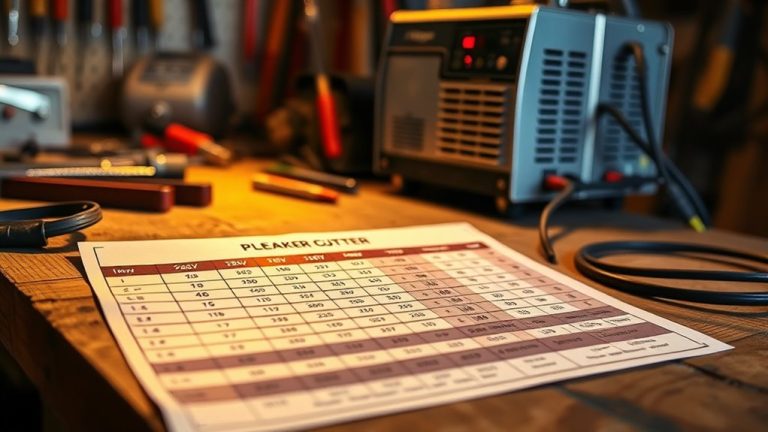

Comparing Plasma Cutter Models and Their Power Needs

Selecting the right plasma cutter model involves analyzing each unit’s power needs and capabilities. When conducting plasma cutter comparisons, consider models like the Hypertherm Powermax 30xp and 45xp. The 30xp operates efficiently on both 110V and 220V with a 30A circuit, making it power-efficient for lighter tasks.

In contrast, the 45xp, requiring a 50A breaker, draws up to 39A in low voltage scenarios, suitable for more demanding applications. Both can run on a 30A circuit; however, the 45xp’s performance may diminish when cutting thicker materials, necessitating electrical upgrades.

Understanding power efficiency involves calculating total output power, a product of amperage and voltage. Higher amperage settings enhance cutting speeds and performance on thicker metals.

Consequently, select a model that aligns with your specific cutting needs by evaluating power requirements and ensuring your electrical setup supports the chosen plasma cutter’s operational demands. This precision will optimize your cutting performance.

Tips for Efficient Plasma Cutter Operation

After evaluating the power requirements of different plasma cutter models, let’s focus on maximizing their operational efficiency.

To begin, understanding cutting techniques and material selection is key. Adjust the amperage based on material thickness; higher amps facilitate faster cuts, while lower settings are ideal for intricate shapes or thinner materials. Always verify your electrical infrastructure supports the high demand, typically around 1,000 amps at full power. Installing a 50-amp circuit breaker can help manage these loads effectively, providing a buffer against tripping.

Adjust amperage to material thickness; ensure your infrastructure supports high demand for efficient plasma cutting.

Regularly monitor the duty cycle, which indicates how long the cutter can operate before needing a cooldown. A 60% duty cycle, for example, limits operation to 6 minutes every 10 minutes to prevent overheating.

Here are some additional tips:

- Check circuit capacity: Upgrade or add dedicated outlets if necessary.

- Optimize settings: Match amperage to material type and thickness.

- Monitor duty cycle: Prevent overheating by adhering to operational limits.

Frequently Asked Questions

Can Plasma Cutters Operate on Solar Power Systems?

Yes, you can operate plasma cutters on solar power systems if you optimize for plasma efficiency. Confirm your solar setup meets the required wattage and amperage. Analyze power demands and match them with your solar inverter’s capacity for seamless operation.

What Is the Noise Level of a Plasma Cutter?

A plasma cutter’s noise level can reach 85 to 120 dB, depending on the material and settings. You should guarantee compliance with sound regulations by using hearing protection and regularly monitoring noise levels to mitigate risks.

How Do Environmental Factors Affect Plasma Cutter Performance?

Temperature fluctuations and humidity levels directly impact plasma cutter performance. You should guarantee stable environmental conditions because high humidity can cause arc instability, while extreme temperatures may affect component efficiency, leading to inconsistent cuts and increased maintenance needs.

Are There Portable Plasma Cutter Options for Remote Locations?

You’re in luck; there are portable plasma cutter options for remote locations. Picture sleek, lightweight models humming with precision. Battery-powered options guarantee you slice through metal effortlessly, analyzing every cut with technical accuracy, guaranteeing seamless, uninterrupted operations.

What Maintenance Is Required for Optimal Plasma Cutter Efficiency?

For maximum plasma cutter efficiency, regularly replace filters and clean the torch. Verify electrodes and nozzles are free of debris. Check for leaks and proper air pressure. These steps prevent malfunctions and enhance performance.

Conclusion

When choosing a plasma cutter, you must consider power requirements carefully. Did you know that a larger plasma cutter can consume up to 8,250 watts? This statistic highlights the significance of ensuring your electrical system can handle such demands. Evaluating your workshop’s voltage and amperage needs is essential for peak performance and safety. By understanding these technical details, you can make informed decisions, ensuring efficient operation and avoiding potential hazards or increased electricity costs.