You might not realize that achieving perfectly straight cuts with a plasma cutter involves more than just a steady hand. It’s essential to prepare your work area meticulously, ensuring safety and precision. By using the right guide and adjusting your equipment settings to suit the metal’s thickness, you can greatly enhance accuracy. But there’s more to it—specific techniques and post-cutting procedures await you, promising to refine your cutting skills.

Preparing Your Work Area for Plasma Cutting

To guarantee a safe and efficient plasma cutting session, begin by preparing your work area meticulously. Choose a stable, flat work surface that’s fireproof to support the metal piece and prevent accidents from sparks or hot debris.

Clear away any flammable materials and organize your workspace to be clutter-free, promoting a secure environment.

Ensure the metal is secured using clamps to prevent movement, which could lead to inaccuracies in your cuts. Proper ventilation is essential to dissipate harmful fumes, particularly when working with materials that might release toxins when heated.

Having all necessary tools and safety equipment within reach is vital. Equip yourself with personal protective equipment (PPE) such as gloves and goggles to shield against potential hazards.

Setting Up the Plasma Cutter Equipment

To set up your plasma cutter correctly, start by placing it on a stable, flat surface to secure all cable and hose connections, preventing any unwanted movement.

Connect the external air compressor to the plasma cutter and activate the high-pressure air flow by adjusting the lever, ensuring a consistent air supply.

Before switching on the plasma cutter, confirm it’s off and plugged into a suitable power source to prevent electrical hazards.

Proper Cable Connections

When setting up your plasma cutter equipment, guaranteeing proper cable connections is essential for safe and efficient operation. Begin by making sure the plasma cutter is powered off to prioritize cable safety. Securely plug the torch and work lead into the power supply, guaranteeing a stable connection. Attach the work lead clamp to a safe part of the metal work surface, away from potential hazards. Connect the gas hose firmly to the back of the system, securing it against air leaks. Double-check all connections for stability before powering on your machine.

Here’s a quick reference table to guide you:

| Task | Action | Importance |

|---|---|---|

| Power Off | Ensure device is off | Prevents electrical risk |

| Secure Connections | Tighten all plugs | Maintains connection stability |

| Verify Setup | Check all connections | Guarantees cable safety |

Liberate your cutting experience by following these steps meticulously.

Securing Air Supply

With your cable connections securely in place, focus next on establishing a reliable air supply to confirm your plasma cutter operates at peak performance.

Connect the cutter to a clean, dry air compressor. This guarantees superior cutting performance by preventing moisture from affecting the plasma stream. Set the air pressure according to the manufacturer’s specifications, typically between 60 to 100 PSI, assuring consistent plasma flow.

Activate the lever on the compressor to engage high-pressure air flow, confirming sufficient air supply before cutting. Check all hose connections for leaks or damage to maintain seamless operation.

Regular air supply maintenance, including inspecting the system for pressure adjustments and flow issues, is essential to avoid interruptions and achieve precise, straight cuts with your plasma cutter.

Adjusting the Plasma Cutter Settings

Before you achieve clean and straight cuts with a plasma cutter, make certain you’re adjusting the settings precisely. Start by making amperage adjustments based on the metal’s thickness. Refer to the manufacturer’s recommended cut charts for peak performance.

Selecting the appropriate cutting modes is vital. Guarantee the plasma cutter is set for the specific type of metal and desired finish. Proper settings liberate you from wasted materials and flawed cuts.

- Adjust amperage: Tailor settings meticulously to match metal thickness.

- Choose cutting mode: Align with material type and finish requirements.

- Set air pressure: Follow manufacturer’s specifications to prevent slag buildup.

Check the torch nozzle for cleanliness, guaranteeing consumables are correctly installed for a consistent plasma stream.

Regular practice on scrap metal sharpens your skills, fostering familiarity and improving accuracy. This disciplined approach empowers you to break free from limitations, enabling precision and efficiency in every cut.

Choosing and Using the Right Guide for Straight Cuts

When selecting a guide for straight cuts with a plasma cutter, consider using materials like MDF or Corian, which resist high temperatures and avoid affecting the tool’s performance.

To guarantee precise alignment, offset your guide from the cutting line, accounting for the torch head’s width.

Regular practice with various guides, such as metal straightedges or ceramic pieces, will improve your cutting accuracy and efficiency.

Selecting Effective Guide Materials

To achieve straight cuts with a plasma cutter, selecting the right guide material is essential. Your guide material selection greatly impacts accuracy, efficiency, and the longevity of your torch tip.

Consider the following:

- Conductive Materials: Metal straightedges like angle bars or square tubing are great for guiding the cutter. They help minimize wear on the torch tip thanks to their conductivity.

- Non-Conductive Materials: Options like wood or MDF eliminate electrical interference and are gentler on the plasma tip.

- Durable Alternatives: Corian or solid surface materials withstand high temperatures without melting, unlike plastics.

Practice consistently with different materials to discover ideal offsets for your torch model. This empowers you to access precision and liberates your cutting potential.

Techniques for Precise Alignment

Achieving precision in your plasma cutting endeavors hinges on mastering alignment techniques with the right guide materials. Start by selecting a metal straightedge like an angle bar or square tubing. These provide a solid guide for dragging your torch, ensuring straight, deviation-free cuts.

For enhanced precision, employ a drag tip to maintain consistent contact with the guide, compensating for the torch head size. Opt for non-conductive guides such as wood or MDF to reduce electrical interference and protect against heat damage.

Experiment with durable, heat-resistant materials like Corian or conduit strut to refine your technique. Regular practice with various guides enhances your familiarity with the plasma cutter, honing your skills and leading to more accurate, liberated cuts over time.

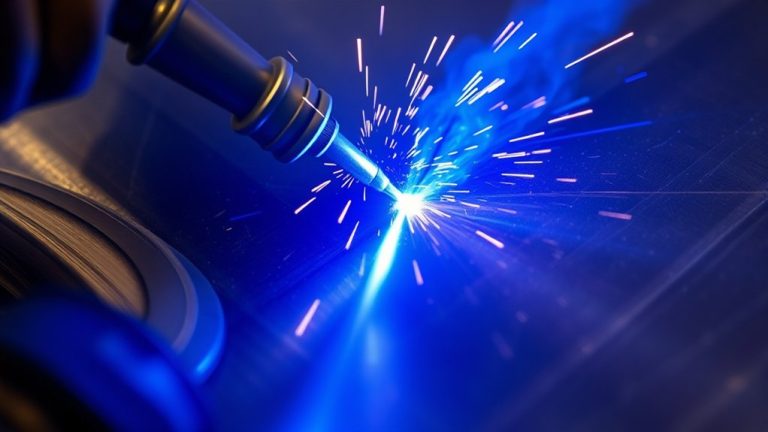

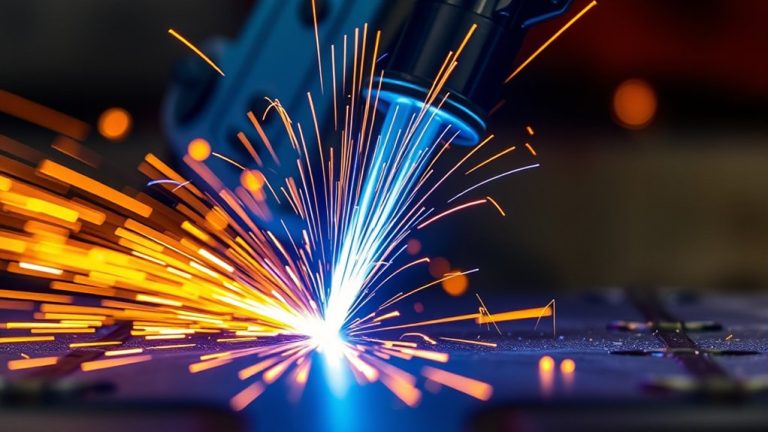

Executing the Plasma Cut With Precision

Although mastering the art of precision cutting with a plasma cutter requires practice, holding the torch at a 90-degree angle to your workpiece is essential for achieving straight cuts with clean edges.

Achieving clean, straight cuts with a plasma cutter hinges on maintaining a perfect 90-degree torch angle.

Begin by using the pilot feature to initiate the cutting arc. Guide the torch steadily, maintaining a consistent cutting speed to prevent incomplete cuts or overheating.

For ideal results, consider these tips:

- Torch Angle: Keep a consistent 90-degree angle to guarantee the plasma cuts through the material cleanly.

- Cutting Speed: Adjust and maintain the speed to avoid burning or jagged edges.

- Practice: Use scrap metal to refine your technique, improving your ability to cut straight lines and intricate shapes.

Adjust your guide or offset the cutting line if necessary to accommodate the torch head size. This guarantees your cuts are precise and accurate.

Post-Cutting Procedures and Equipment Maintenance

After you finish your cuts, it’s vital to follow proper post-cutting procedures to guarantee both safety and equipment longevity. First, turn off the plasma cutter immediately to prevent accidental activation. Disconnect the ground clamp to eliminate any electrical hazards while handling your newly cut material.

Next, verify the air supply is off by rotating the lever to the perpendicular position; this prevents air leaks and protects the system.

To maintain equipment longevity, wind up the plasma gun line, air line, and ground line neatly. This prevents tangling and extends the life of your equipment.

Regular inspections are significant, so examine the torch nozzle and consumables for wear and debris. Cleaning these components routinely guarantees maximum cutting performance and prolongs the lifespan of your plasma cutter.

Tips for Improving Cutting Accuracy and Efficiency

Once you’ve guaranteed your plasma cutter is properly maintained and safely powered down, focus on enhancing your cutting accuracy and efficiency.

Start by using a straight edge or guide, like an angle bar or square tubing, clamped to your workpiece. This stabilizes your cutting path, ensuring straight lines.

Clamp a straight edge or guide to your workpiece to stabilize your cutting path for straight lines.

Consider employing a drag tip on your plasma cutter; it allows the torch to glide effortlessly along the guide, minimizing electrical interference and ensuring clean, precise cuts.

Practice refining your cutting techniques by adjusting the torch angle and distance. Keeping the torch at a 90-degree angle to the material minimizes uneven edges.

Experiment with different material types for guides, such as non-conductive wood or Corian, which withstand high temperatures.

- Ensure straight lines: Use a straight edge or guide.

- Reduce interference: Utilize a drag tip for clean cuts.

- Enhance precision: Maintain a 90-degree torch angle.

Frequently Asked Questions

Can a Plasma Cutter Be Used on Non-Metallic Materials?

You can’t use a plasma cutter on non-metallic materials. Explore plasma cutter alternatives for non-metallic applications, like laser cutters or water jet systems, which offer precise, versatile solutions, empowering you to achieve detailed cuts on diverse materials.

How Can I Prevent Warping While Cutting Thin Metal Sheets?

Like a gentle breeze calming turbulent waters, guarantee warp prevention by adjusting your plasma cutter’s speed and amperage settings according to the metal thickness. Maintain consistent movement and support the sheet to preserve its integrity, empowering precision and freedom.

What Personal Protective Equipment Is Necessary for Plasma Cutting?

You must wear safety gear, including protective gloves, a welding helmet with a proper shade, fire-resistant clothing, and steel-toed boots. Ensuring your safety allows you to focus on your craft and release your creative potential.

How Do I Know if My Air Compressor Is Compatible With the Plasma Cutter?

Imagine a seamless dance between machine and air. Check your plasma cutter specifications for required compressor pressure. Confirm your compressor meets or exceeds this. Listen for smooth operation; a symphony of precision awaits when compatibility is achieved.

What Are the Common Troubleshooting Steps for a Plasma Cutter Not Igniting?

Check your power supply and make certain connections are secure. Verify the air pressure is correct and inspect the consumables for wear. Clean the torch tip. These plasma cutter troubleshooting steps help resolve ignition failure liberating your creativity.

Conclusion

You’ve mastered the art of slicing through metal with the precision of a craftsman, your plasma cutter dancing like a skilled artist’s brush. The fiery arc carves effortlessly through steel, leaving behind a smooth, clean edge. As the sparks settle, a sense of accomplishment washes over you, knowing you’ve transformed raw material into a masterpiece. Maintain your equipment diligently, and your cuts will always be true. With practice, each slice sings with the harmony of precision and skill.