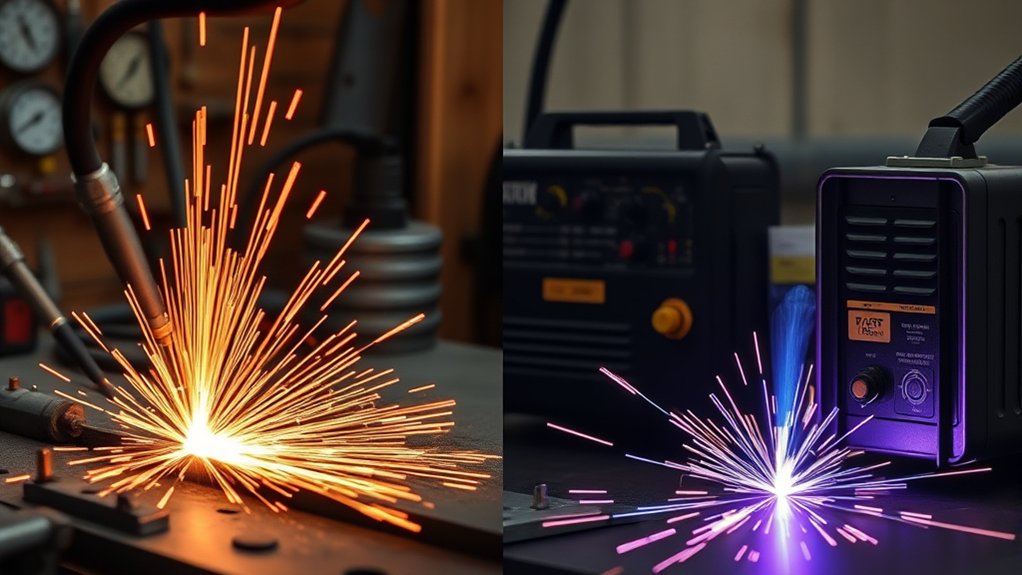

Two sparks, one choice: you need a cutting method that meets spec, budget, and schedule. You weigh plasma’s rapid inches-per-minute, tight kerf, and low rework against oxy-fuel’s lower entry cost and thick-plate capability. Duty cycle, consumable life, and gas usage factor into total cost of ownership. Heat-affected zone, tolerance, and edge finish drive rework time. Power availability and portability set deployment limits. Safety and setup add constraints. Which metrics matter most for your shop?

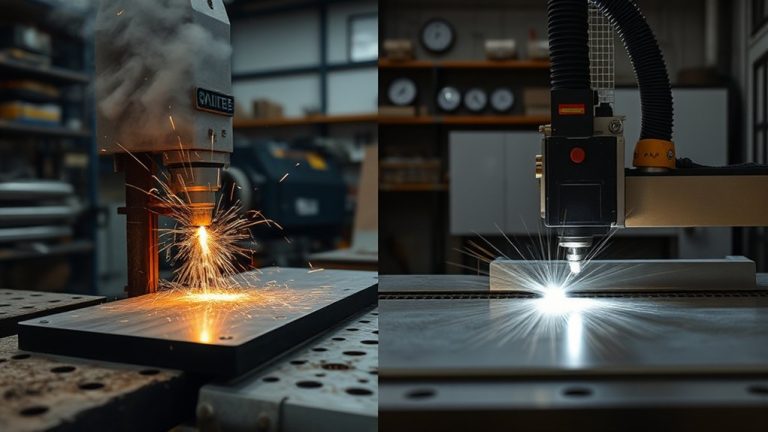

What Is Plasma Cutting?

Plasma cutting is a thermal cutting process that uses an ionized gas stream—plasma—to conduct electricity and form a high-temperature arc that slices electrically conductive metals.

You direct the arc through a constricted nozzle, leveraging plasma properties such as high energy density and electrical conductivity to transfer heat efficiently into the workpiece. The result is rapid material removal with controlled kerf geometry and limited heat-affected zone.

You’ll run a power supply and compressed air or process gases to stabilize the arc and maintain cut quality. Expect narrow kerfs—about 1/16 to 1/8 inch—and smooth edges with minimal slag when parameters are tuned to spec.

On 1/2-inch steel, you can reach cutting speeds up to 80 inches per minute; capacity extends to roughly 2 inches with appropriate amperage.

Because plasma also cuts aluminum and stainless steel reliably, your cutting applications span both ferrous and non-ferrous materials, enabling efficient, standards-compliant fabrication workflows.

What Is Oxy-Fuel Torch Cutting?

Although simple in appearance, oxy-fuel torch cutting is a controlled oxidation process: you preheat ferrous steel with a fuel-gas/oxygen flame (commonly acetylene) to its kindling temperature, then trigger a high‑pressure oxygen jet that rapidly oxidizes and ejects metal to form the kerf.

You’ll use tip sizes, gas pressures, and travel speeds per manufacturer charts to maintain a stable preheat cone and a laminar oxygen stream.

Oxy fuel advantages include exceptional thickness capability—cuts up to roughly 24 inches with the right tip, fuel, and preheat—plus rugged portability and no dependence on electrical power.

You can pierce and sever structural steel in the field with minimal setup.

Oxy fuel limitations center on material scope and precision.

It’s restricted to ferrous metals, generates iron-oxide slag that needs post-cut cleanup, and produces a wider kerf.

On thin stock, you’ll see slower speeds, more heat input, and greater distortion.

Operator skill strongly influences cut quality and repeatability.

Cost Comparison and Operating Expenses

When you budget a cutting process, compare capital outlay, energy draw, and recurring consumables to total productivity. A plasma system’s initial investment ranges from $500 to $30,000+, while a professional torch setup typically runs $800–$1,200. Plasma draws 15–100 amps and consumes electrodes/nozzles ($20–$100 per set).

Torches rely on oxygen and fuel gas refills plus tip replacements. Calculate cost per cut: include power, gas, consumables, operator time, and rework.

Plasma’s higher speed shortens cycle time and labor, often delivering long term savings that offset electricity and consumables. You’ll also reduce downstream expenses because narrower kerfs and lower heat input typically minimize warping-related cleanup.

Torch cutting’s lower entry price can suit intermittent use, but factor tank logistics, gas price volatility, and potential maintenance costs from larger heat-affected zones. For high-throughput shops, the productivity delta of plasma usually improves total cost of ownership. For low volume, stable materials, a torch can remain cost-competitive.

Precision and Cut Quality

Even before you price a job, prioritize how each process meets your tolerance and finish targets. If your spec calls for tight features and minimal rework, plasma delivers clear precision advantages.

Typical plasma kerf ranges 1/16–1/8 in., versus oxy‑fuel’s 1/8–3/16 in., so you remove less material and hold geometry more consistently. Plasma also yields taper under 2°, compared to oxy‑fuel’s 2–5°, improving part fidelity and fit-up.

Control of heat input matters. Plasma minimizes the heat-affected zone, limiting distortion and preserving mechanical properties—especially on thin stock—while oxy‑fuel’s higher thermal load raises warping risk.

That translates directly to better edge quality and less corrective work. Expect tighter tolerances with plasma, commonly ±0.010 in., supporting repeatable, standards-compliant outcomes on precision assemblies.

Oxy‑fuel often leaves slag and rough edges that require grinding or machining, adding non-value-added steps. For applications where dimensional accuracy, clean edges, and minimal post-processing are critical, plasma is the more capable process.

Speed and Productivity

Precision advantages only matter if you can hit throughput targets, and here plasma leads on speed and uptime. You’ll see plasma advantages immediately: up to 80 ipm on 1/2-inch steel versus oxy-fuel’s 8–10 ipm on 2-inch plate.

Faster motion plus sub‑minute setup compresses cycle time, while torch limitations—3–5 minutes for gas tuning and preheat—extend non-cut time. Material-specific settings let you lock in amperage, gas, and travel speed for consistent takt, minimizing operator intervention and idle minutes.

Plasma’s narrow kerf (1/16–1/8 in.) and reduced thermal distortion lower rework, so parts move downstream without secondary ops. On thicker sections, higher‑amperage machines sustain competitive speeds, preserving line balance across mixed workloads.

- Sub‑minute setup: load, program, cut—no prolonged preheat or gas adjustment.

- Optimized parameters: presets standardize cut speed, arc quality, and pierce timing.

- Clean edges: minimal dross decreases grinding, improving true throughput.

Result: higher parts-per-hour, tighter schedules met, less variability run-to-run.

Material Types and Thickness Capabilities

Although both tools cut steel, their material windows and thickness ranges differ substantially.

If you prioritize cutting versatility and material compatibility across shop tasks, plasma leads. It cleanly processes electrically conductive metals—aluminum, brass, copper, stainless, and carbon steel—without preheat. It’s most efficient on thin to mid-gauge stock, delivering narrow kerf (about 1/16–1/8 in.) that preserves geometry and limits thermal distortion. You can pierce and sever up to roughly 2 in., but you’ll get best quality and speed on ≤1/2 in. steel.

Choose oxy-fuel when your scope includes very thick carbon steel. A properly sized torch can sever up to about 24 in., though you must account for preheat and a wider kerf (about 1/8–3/16 in.), which increases heat-affected zone and material loss.

Oxy-fuel’s material compatibility is primarily ferrous; it struggles on non-ferrous alloys. In practice, deploy plasma for mixed-metal work and precision profiles, and reserve oxy-fuel for heavy-section carbon steel.

Portability, Power Needs, and Setup Time

With material limits in mind, evaluate how each tool moves and powers up on the job. You’ll mobilize a plasma cutter fast—sub‑minute setup is typical—but you must supply electricity and clean, dry compressed air. Many units need 220/240V at 50–100A; without proper service, productivity stalls. Compact inverter models around 20 lb improve portability for shop-to-field moves.

Mobilize plasma fast: sub-minute setup, but ensure 220/240V power and clean, dry air.

By contrast, oxy-fuel torches are self-contained and excel where power’s unavailable, though cylinders, regulators, and hoses add bulk and transport constraints.

For repeatable cutting techniques, plasma reduces downtime with quick arc starts; torches require 3–5 minutes for gas mix, leak checks, and ignition. Plan equipment maintenance accordingly: air filtration for plasma consumable life; regulator inspection and hose integrity for oxy-fuel reliability.

- Verify site power capacity, air quality, and duty cycle before deploying plasma.

- Assess cylinder logistics, regulator settings, and tip sizing for oxy-fuel.

- Standardize setup checklists to cut nonproductive time and rework.

Safety Considerations and Consumables

You’ll spec PPE to match the process: insulated gloves and a face shield for high-voltage plasma, and flame-resistant gear for oxy-fuel.

Ascertain compliant ventilation—capture plasma fumes and manage oxy-fuel gases with leak checks, purge protocols, and proper storage.

Track consumables efficiently: monitor electrode/nozzle wear to replace $20–$100 sets before cut quality degrades, and schedule fuel checks to control costs and reduce hazard exposure.

Personal Protective Equipment

Even when the workpiece seems routine, treat plasma cutters and oxy‑fuel torches as high‑hazard tools and equip accordingly.

Define your PPE essentials with safety measures that match each process hazard. For plasma, use ANSI Z87.1 safety glasses with side shields under a properly rated shade to block intense UV and arc flash. Add flame‑resistant clothing (NFPA 2112/2113), gauntlet gloves, leather boots, and hearing protection.

For oxy‑fuel, select heat‑rated goggles or a face shield to stop flame glare and hot slag. Maintain respiratory protection consistent with your hazard assessment.

- Eye/face: Z87.1 glasses, process‑appropriate shade, face shield for grinding/slag

- Hands/body: FR jacket, gauntlet gloves, leather boots; no synthetics

- Program: inspect/replace plasma consumables (electrodes/nozzles), verify PPE condition, document safety checks

Ventilation and Fumes

Although plasma cutting typically emits fewer fumes than oxy‑fuel, treat both processes as fume‑generating operations that require engineered controls and disciplined maintenance.

Define ventilation requirements per material, amperage, and duty cycle; verify airflow with capture velocity measurements at the arc. Use local exhaust hoods, downdraft tables, or on‑torch extraction to meet fume management targets. Supplement with general dilution only after source capture is maximized.

Account for oxy‑fuel’s higher emissions, including iron oxide particulates and combustion byproducts; position intakes to prevent recirculation and manage slag cleanup to avoid re‑entrainment.

For plasma systems, maintain electrodes and nozzles to minimize arcing instability that elevates fume output. Validate controls with air monitoring and adjust setpoints when cutting coated, painted, or oily stock.

Where controls can’t meet limits, deploy properly fitted respirators.

Consumable Lifespan Tips

When you manage consumables with the same rigor as other critical components, you extend service life and reduce safety risks. Implement consumable maintenance as a scheduled task, not a reaction.

Inspect plasma electrodes and nozzles every shift; expect 1–3 hours of cutting time depending on material and thickness. Hard alloys like stainless or aluminum shorten life and raise costs ($20–$100 per set), so track run-time and amperage.

For oxy-fuel, clean tips, check regulators, and replace worn tips to prevent flashbacks and erratic cuts. Use OEM or certified high-quality parts and follow manufacturer parameters to preserve cutting efficiency and stability.

- Verify gas flow, standoff, and amperage before each cut

- Replace parts at wear limits; don’t run to failure

- Log consumable changes, materials, and settings for trend analysis

Which Tool Fits Your Projects?

You should match the tool to material and thickness: plasma excels on thin to mid-gauge and non‑ferrous metals with narrow kerf, while oxy‑fuel is efficient on very thick ferrous plate.

If you need speed on 1/2-inch steel and clean edges, pick plasma; if you routinely cut 2-inch steel, choose oxy‑fuel.

For portability and power, oxy‑fuel works off-grid with cylinders, while plasma requires electrical supply and compressed air.

Material and Thickness

For material and thickness, match the tool to the metal and the cut spec.

Start by mapping cutting materials and thickness limitations to your tolerance and kerf requirements. Plasma excels on electrically conductive metals—steel, stainless, aluminum—delivering ±0.010 accuracy and a 1/16–1/8 in kerf with minimal heat distortion.

It’s efficient on thin to medium stock and capable up to about 2 in. Oxy-fuel is optimized for thick ferrous plate, reaching 24 in, but it struggles on non-ferrous alloys and produces a wider 1/8–3/16 in kerf and more slag.

- Thin to medium: use plasma for speed (e.g., 1/2 in steel at ~80 ipm) and clean edges.

- Thick ferrous: choose oxy-fuel for economical, deep sections.

- Tolerance-driven parts: prioritize plasma to reduce rework.

Portability and Power

Although both tools travel well, portability hinges on power and support gear. If you’ve got electricity and an air source, a compact inverter plasma cutter delivers excellent power efficiency and sub-minute setup. Many models weigh around 20 pounds, but plan for the compressor—your true weight comparison must include hoses and air capacity.

Oxy-fuel torches remain the most mobile: no power required, cylinders are widely available, and field setup takes 3–5 minutes for gas tuning.

Match power to material. Plasma reliably handles precise work on thin to 2-inch stock, ideal when accuracy and turnaround matter. For industrial sections up to about 24 inches, oxy-fuel provides higher thermal capacity and simpler logistics in remote sites.

Choose based on access to power, transport constraints, and required cut thickness.

Frequently Asked Questions

Can Plasma Cutters or Torches Be Used Outdoors in Windy Conditions?

Yes, you can, but you must mitigate wind effects. For plasma, use windshields, raise amperage, and shield the arc. For torches, use larger tips, adjust oxygen/fuel, and block drafts. Always follow manufacturer outdoor conditions specifications.

How Do Weather and Humidity Affect Cut Consistency and Equipment Lifespan?

Weather and humidity degrade cut quality and shorten equipment lifespan. You’ll see arc instability, moisture-contaminated consumables, and corrosion. Mitigate with dry air/gas, enclosures, preheat, and strict equipment maintenance—desiccant dryers, scheduled inspections, IP-rated storage, and post-use drying preserve consistency and service life.

What Training or Certifications Are Recommended for Each Method?

You pursue welding certifications and safety training for both. For plasma, complete manufacturer courses, NFPA 51B practices, PPE competency. For oxy-fuel, obtain AWS Oxy-Fuel certification, cylinder-handling training, hot-work permits, and fire-watch protocols. Document everything; audit annually; maintain proficiency.

How Noisy Are Plasma Cutters Versus Oxy-Fuel Torches During Operation?

Plasma cutters are louder than oxy-fuel torches, often exceeding 90–100 dB. You’ll require hearing protection. Torches typically run 70–85 dB. For operational comfort, manage noise levels with earmuffs, acoustic barriers, and compliant shop noise controls.

Are There Environmental or Emissions Differences Between the Two Methods?

Yes. You’ll see lower emission levels with plasma cutting—no combustion byproducts. Oxy‑fuel generates CO2, CO, NOx, and fumes from fluxes. For environmental impact, use fume extraction, compliant gas handling, and consumable recycling per OSHA/ISO guidelines.

Conclusion

You cut faster, you spend smarter, you deliver cleaner. With plasma, you hit tighter tolerances, reduce slag, and minimize rework; with torches, you trade speed for simplicity and thicker cuts. You balance duty cycle, consumables, and power; you weigh portability, setup, and safety. If you need precision, productivity, and repeatability, you choose plasma. If you need low-tech robustness and very thick steel, you choose oxy-fuel. Define standards, match specs, optimize workflow—and your cut quality follows.