When selecting a Lotos plasma cutter, understanding the amp requirements for 120V and 240V models is essential. You’ll find that these machines have varied capabilities based on their voltage settings, impacting their cutting performance and efficiency. The LTP5000D and LTP6000 offer different strengths for specific tasks. Are you making the best choice for your metalwork needs? Let’s explore how these requirements influence your cutting operations.

Understanding Voltage and Amp Requirements

When you’re working with Lotos plasma cutters, understanding their voltage and amp requirements is vital for peak performance. These cutters typically feature dual voltage compatibility, functioning seamlessly at both 120V and 240V. This flexibility allows you to adapt to various power outlets, enhancing your cutting convenience across different settings.

For instance, the Lotos LTP5000D model can operate at 110/120V with a maximum output of 50 amps and at 220/240V, delivering a clean cut thickness of 5/8 inches. To achieve ideal amp efficiency, it’s essential to use a minimum 50 amp breaker when running on 240V. This guarantees the cutter handles higher current demands without compromising performance.

Each model’s amp output varies, like the LTP6000, which offers 60 amps, allowing you to tackle thicker materials with a cutting thickness of 3/4 inch.

Understanding these requirements prevents reduced cutting efficiency and quality, especially on thicker metals.

Comparing Duty Cycles Across Models

When you’re selecting a Lotos plasma cutter, considering the duty cycle variations across models is essential for efficient cutting.

A higher duty cycle allows for longer, continuous cuts, impacting overall performance and productivity.

Duty Cycle Variations

Although selecting a plasma cutter might seem straightforward, understanding duty cycle variations across models is essential for making the right choice. The duty cycle impacts cutting duration, directly influencing how long you can cut before the machine needs a break.

For example, the LOTOS LTP5000D offers a 60% duty cycle at both 25A on 120V and 50A on 240V, allowing for longer use. In contrast, the LOTOS LTP6000 has a 35% duty cycle at 60A on 110V, limiting its cutting duration compared to its 60% at 240V.

Here’s what you should consider:

- LTP7000: 60% duty cycle at 70A on 220V suits thicker materials.

- LT5000D: 60% duty cycle at 60A on 220V for demanding tasks.

- Duty cycle: Critical for sustained performance without overheating.

Efficiency in Continuous Cuts

While choosing a plasma cutter, understanding the efficiency in continuous cuts is essential, especially when comparing duty cycles across different models.

The Lotos LTP5000D excels with a 60% duty cycle at 40A for 220V, providing you with longer cutting sessions without overheating. Its cutting precision is ideal for medium metal thickness, making it versatile for various projects.

For more demanding tasks, the Lotos LT5000D also offers a 60% duty cycle at 60A for 220V, handling thicker metals effortlessly. This is vital if you’re working on intensive metalworking tasks.

The Lotos Supreme CUT60D maintains efficiency across 120V and 240V, thanks to its 60% duty cycle at 60A, accommodating different power needs while ensuring consistent cutting precision and performance.

Impact on Performance

Understanding the impact of duty cycles on performance is essential when comparing plasma cutter models. The duty cycle directly influences cutting precision and the ability to handle various metal thicknesses.

For instance, the Lotos LTP5000D offers a 60% duty cycle at 25A on 120V, allowing for prolonged cutting without overheating. This makes it ideal for tasks that demand precision.

The Lotos LT5000D, with a 100% duty cycle at 40A on 220V, supports continuous operation, perfect for demanding projects requiring consistent accuracy.

Consider these points:

- LTP6000: 60% duty cycle at 60A on 220V enhances cutting thicker materials.

- LTP7000: 70A output offers robust performance for thick metals.

- Model choice: Balances duty cycle with cutting precision and metal thickness needs.

Performance Impacts of Voltage Variations

When using a Lotos plasma cutter, you’ll notice that voltage variations notably impact its cutting efficiency.

Operating at 240V not only allows for thicker cuts but also enhances the duty cycle, meaning you can cut longer without overheating.

Verify your power source is compatible, especially since the cutter requires a 50 amp breaker for peak performance on 240V.

Impact on Cutting Efficiency

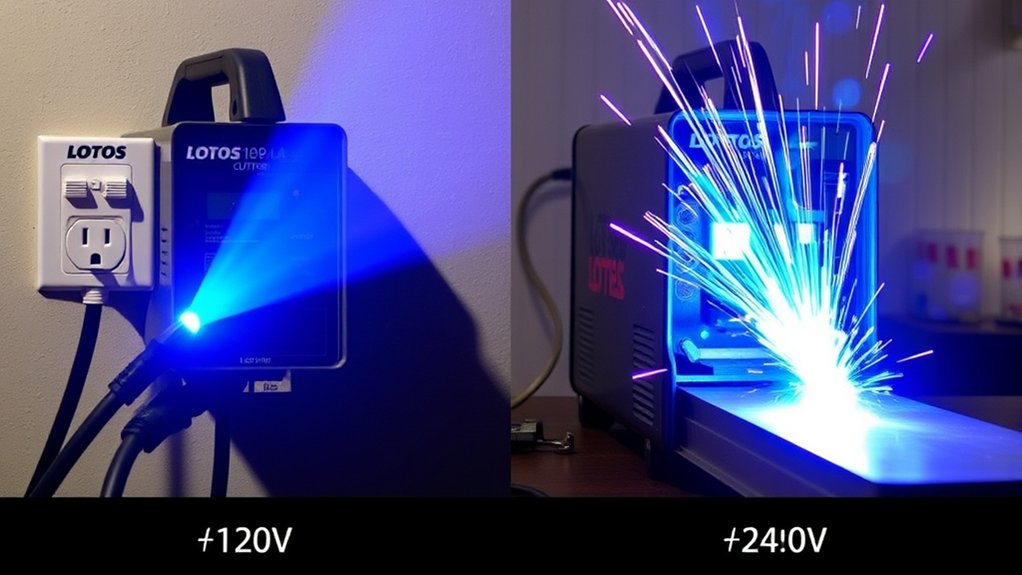

Switching between voltage settings on your Lotos plasma cutter greatly impacts cutting efficiency.

When operating at 240V, you’ll experience enhanced cut quality, allowing you to tackle thicker material with precision. For instance, the Lotos LTP5000D delivers a robust 50 amps at 240V, enabling clean cuts on steel up to 5/8 inch thick.

In contrast, using 120V may limit performance, affecting the smoothness and depth of your cuts. Choosing the right voltage is vital for maximizing cutting efficiency and guaranteeing your machine’s longevity.

- Enhanced Cut Quality: Achieve smoother, cleaner cuts, especially on thicker materials.

- Increased Material Thickness: Cut through denser materials with ease at higher voltage settings.

- Optimized Performance: Confirm your plasma cutter operates efficiently, reducing strain and prolonging lifespan.

Voltage and Duty Cycle

Choosing the right voltage setting on your Lotos plasma cutter not only enhances cutting efficiency but also greatly affects the duty cycle and overall performance.

With dual voltage models like the LTP5000D, plasma technology enables you to switch between 120V and 240V. At 120V, you get a 25A output with a 60% duty cycle, ideal for lighter tasks.

Switching to 240V boosts the cutting current to 50A, maintaining the same duty cycle while delivering cleaner cuts on thicker materials. This adjustment impacts cutting precision, allowing you to handle up to 5/8 inch clean cuts.

Higher voltage optimizes performance, enabling longer continuous cutting and increasing operational efficiency, making your cutting tasks more effective and precise.

Power Source Compatibility

While versatility in power source compatibility is a standout feature of Lotos plasma cutters, it’s essential to understand how voltage variations impact performance.

With dual voltage capability, models like the LTP5000D adapt to different environments by operating on both 120V and 240V power sources. At 120V, it delivers a maximum output of 50 amps, cutting up to 5/8 inch thick steel. However, using a 240V power source greatly enhances performance, offering better cutting speed and efficiency.

Consider these compatibility factors:

- Higher Voltage Benefits: 240V provides longer duty cycles and handles thicker materials more effectively.

- Breaker Requirements: Use a minimum 50 amp breaker at 240V to prevent overloading.

- Workshop Flexibility: Dual voltage guarantees the cutter adapts to various power setups.

Efficiency in Heavy-Duty Tasks

When tackling heavy-duty tasks, Lotos plasma cutters, like the LTP5000D and LTP6000, offer remarkable efficiency and flexibility.

These models excel in heavy duty applications due to their performance enhancement. Operating efficiently at dual voltages (120V and 240V), they adapt seamlessly to various power sources.

The LTP5000D delivers up to 50 amps at 240V, enabling clean cuts through materials as thick as 5/8 inch and severance cuts up to 3/4 inch, making it perfect for robust metalwork.

The LTP6000, with its 60 amps output, handles even more demanding tasks, cutting through materials up to 3/4 inch thick with ease.

Moreover, both models feature a 60% duty cycle at maximum output. This means you can operate them for extended periods without worrying about overheating.

The automatic dual voltage and high amperage capabilities guarantee these plasma cutters maintain ideal efficiency and performance across diverse industrial and DIY projects.

Operational Periods and Cutting Capabilities

With their dual voltage capability, Lotos plasma cutters like the LTP5000D and LTP6000 offer remarkable operational flexibility and cutting prowess. You can tackle various cutting materials with ease.

When using the LTP5000D on a 120V power source, you benefit from a duty cycle of 60% at 25A, allowing longer operational periods without overheating. This is ideal for moderate cutting tasks.

Switch to 240V, and the LTP5000D reaches a maximum output of 50A, making clean cuts up to 5/8 inch and severing materials up to 3/4 inch.

The LTP6000 enhances your capabilities even further, supporting up to 60A on 240V, and handling clean cuts through materials as thick as 3/4 inch.

To maximize performance, verify your setup includes a minimum 50 amp breaker for higher amperage settings.

- 120V operation: 60% duty cycle at 25A

- 240V operation: 50A, clean cuts up to 5/8 inch

- LTP6000: Cuts 3/4 inch thick materials

Importance of Duty Cycle in Metal Cutting

Understanding the duty cycle in metal cutting is essential for efficient operation and productivity. The duty cycle significance lies in how long your plasma cutter can run before needing a break.

For instance, a model like the Yeswelder CUT-55DS PRO boasts a 60% duty cycle at 25A for 120V, meaning it can cut for 6 minutes out of every 10 without overheating. This high duty cycle is vital for professionals engaged in extensive cutting tasks, ensuring you don’t waste time waiting for the machine to cool.

When selecting a plasma cutter, consider the duty cycle alongside amperage. Together, they determine the machine’s performance and suitability for your projects.

A 35% duty cycle at 110V, for example, allows just 3.5 minutes of operation before a 6.5-minute cooldown, affecting workflow. Optimizing your cutting tasks involves choosing a plasma cutter with a duty cycle that matches your work demands, enhancing productivity and efficiency.

Advantages of Dual Voltage Plasma Cutters

Although the world of metal cutting offers various tools, dual voltage plasma cutters stand out for their versatility and convenience. Devices like the Lotos LTP5000D operate on both 120V and 240V power sources, making them adaptable to diverse environments.

Dual voltage plasma cutters, like the Lotos LTP5000D, offer unmatched versatility by operating on both 120V and 240V power sources.

This flexibility allows you to work efficiently without worrying about different electrical setups, enhancing portability benefits considerably. The automatic voltage detection feature guarantees a seamless switch between power sources, so you don’t have to fiddle with manual adjustments.

Operating at 240V boosts the available amperage, which means more efficient cuts and longer duty cycles for heavy-duty tasks. This dual voltage capability not only makes it easy to transport and use in different locations but also brings cost savings by optimizing power consumption according to your project’s needs.

- Flexibility: Seamlessly switch between 120V and 240V.

- Portability: Work efficiently in varied locations.

- Cost Savings: Optimize power use for different tasks.

Choosing the Right Model for Your Needs

When selecting the right plasma cutter model for your needs, consider the specific cutting thickness you require and the power sources available in your workspace. The Lotos LTP5000D is a versatile choice with dual voltage capabilities, operating on 110/120V or 220/240V. It delivers up to 50 amps at 120V, handling cuts up to 5/8 inch. For more demanding tasks, the LTP6000 offers 60 amps on 220V, cutting materials up to 3/4 inch thick. Need even more power? The LTP7000 provides 70 amps, ideal for thicker materials while maintaining dual voltage compatibility.

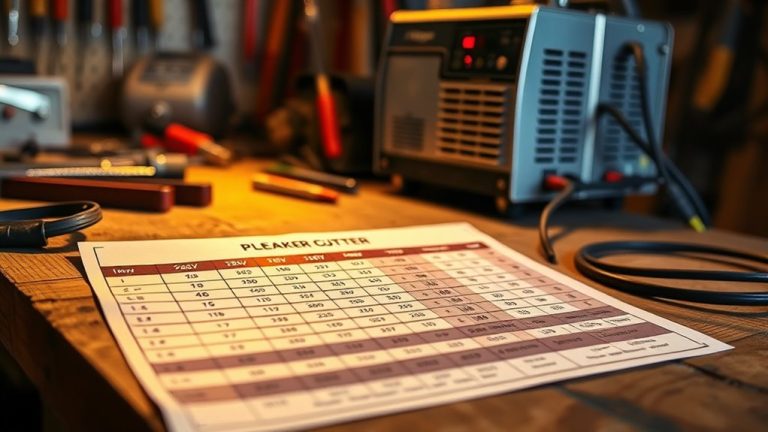

| Model | Maximum Output | Cutting Thickness |

|---|---|---|

| LTP5000D | 50 amps | Up to 5/8 inch |

| LTP6000 | 60 amps | Up to 3/4 inch |

| LTP7000 | 70 amps | Thicker materials |

Model selection should align with your cutting requirements and available power sources, ensuring efficient and effective performance.

Frequently Asked Questions

What Maintenance Is Required for Lotos Plasma Cutters?

You should regularly inspect and clean the nozzle and electrode, check the air filter, and guarantee proper ventilation. These maintenance tips will enhance plasma cutter performance and longevity, ensuring your equipment stays in top shape.

Are There Compatible Accessories for Lotos Plasma Cutters?

You’re in luck! There’s a treasure trove of plasma cutter accessories and compatible consumables for Lotos models. Find replacement tips, electrodes, and nozzles that fit like a glove, ensuring your cutter performs at its sharpest.

Can Lotos Plasma Cutters Be Used for Non-Metal Materials?

You can’t use Lotos plasma cutters effectively for non-metal applications. They’re designed specifically for cutting conductive metals, so attempting to cut non-metal materials won’t work due to the technology’s reliance on electrical conductivity.

How Do I Troubleshoot Common Issues With Lotos Plasma Cutters?

Think of your cutter as a ship steering through rough waters. When it falters, check connections, replace consumables, inspect air pressure, and clean components. These troubleshooting tips will help you sail smoothly through common problems.

What Safety Precautions Should Be Taken When Using Lotos Plasma Cutters?

Wear appropriate safety gear like gloves and eye protection. Make certain your workspace is clear of flammable materials to prevent fire hazards. Always check for proper grounding and ventilation. Don’t forget to follow the manufacturer’s instructions diligently.

Conclusion

When choosing between Lotos plasma cutters, understanding the dance of volts and amps is vital. The LTP5000D and LTP6000 models each offer unique strengths tailored to your cutting needs. The LTP5000D is a versatile performer, while the LTP6000 slices through thicker materials with ease. Consider your specific requirements and the significance of duty cycles. Ultimately, selecting the right model guarantees you’ll cut through projects like a hot knife through butter, maximizing efficiency and performance.