The MIG welding wire speed and voltage chart can be a real game-changer once you know how to use it — but it’s also one of the biggest sources of confusion for many welders. I’ve spent plenty of time chasing the perfect bead, only to realize my wire feed speed or voltage was just a little off.

Too hot, and you burn through thin metal; too cold, and you end up with poor penetration and weak welds. Balancing those settings depends on your metal thickness, joint prep, and even whether you’re running MIG or flux core. Getting that sweet spot means better arc control, smoother beads, and less cleanup.

If you’ve ever wondered how to read and apply a MIG welding wire speed and voltage chart like a pro, stick around — this guide will walk you through the exact settings and tricks I use for clean, consistent welds every time.

What Exactly Are Wire Speed and Voltage in MIG Welding?

In MIG—Metal Inert Gas welding, if you’re new to the lingo—wire speed is how fast the electrode feeds through your gun (inches per minute, IPM). It chiefly controls amperage and penetration. Voltage sets arc length and largely shapes bead profile. In short: wire speed ≈ heat input (amps), voltage ≈ arc length and bead shape.[1]

Why do they matter together? They’re dance partners. Bump up wire speed without touching voltage and the arc can stub; raise voltage too far for the feed rate and the arc gets long and unstable. Good settings balance both.[1]

In my early days as a fab shop apprentice, I once welded a 1/4-inch plate at 18 volts and 150 IPM—looked fine until torque testing showed shallow fusion. Lesson learned: balance is king for everything from short-circuit transfer on thin sheet to spray transfer on thicker stock.

For safety’s sake, start with your machine’s manual and the manufacturer’s parameter chart. OSHA regulates safe work practices, while AWS Z49.1 lays out industry safety guidance—read both alongside the manual.[10][11]

How Does a MIG Welding Wire Speed and Voltage Chart Work?

Ever stare at a chart and think, “This might as well be hieroglyphics”? I’ve been there, squinting at faded printer paper taped to the booth wall. A MIG welding wire speed and voltage chart is your roadmap, plotting starting points based on wire diameter, material thickness, gas, and process.

Columns for thickness (from 18-gauge to 1/4-inch), rows for wire sizes (.023 to .045 inch), and cells with volts and IPM—boom, instant baseline. But it’s a launchpad, not gospel. Gas mix and shop conditions will nudge numbers. Miller’s published tables and calculator are excellent references.[12][2]

Example baseline: For .030-inch ER70S-6 on 1/8-inch mild steel with 75/25 Ar/CO₂, typical starting points are about 19 V and 290 IPM in short-circuit transfer.[2]

Running self-shielded flux-cored? Settings differ by wire classification—don’t assume a flat 10–20% reduction in IPM. Start from the wire’s datasheet or a flux-core calculator and tune from there.[23]

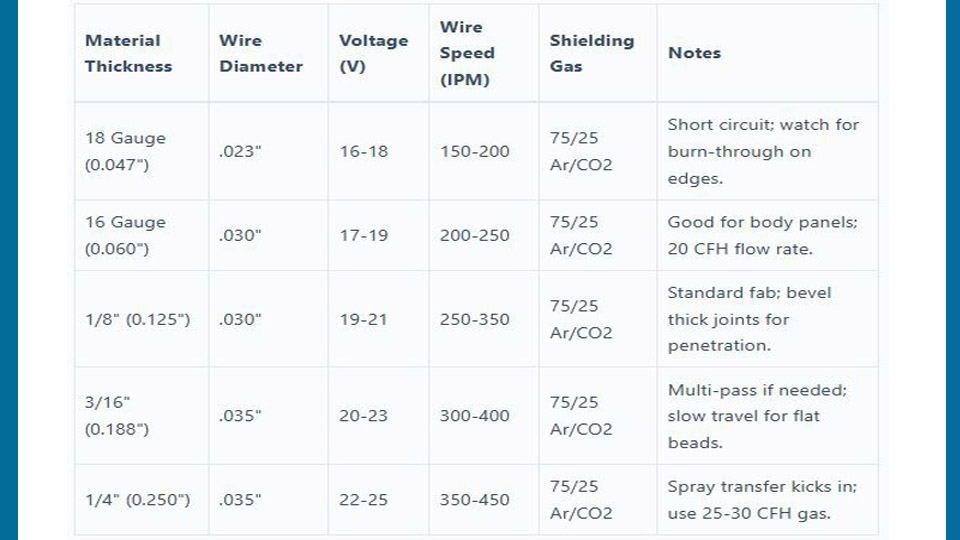

MIG Welding Settings Chart: Tailored for Mild Steel

Mild steel’s the bread-and-butter of most welds. Use these starting values, then fine-tune by bead appearance and sound. Gas flow and stickout matter—see notes.

| Material Thickness | Wire Diameter | Voltage (V) | Wire Speed (IPM) | Shielding Gas | Notes |

|---|---|---|---|---|---|

| 18 Gauge (0.047″) | .023″ | 16–18 | 150–200 | 75/25 Ar/CO₂ | Short-circuit; minimize heat near edges; ESO ≈ 3/8–1/2″.[20] |

| 16 Gauge (0.060″) | .030″ | 17–19 | 200–250 | 75/25 Ar/CO₂ | Body panels & thin fab; 30–35 CFH typical.[2] |

| 1/8″ (0.125″) | .030″ | ~19 | ~290 | 75/25 Ar/CO₂ | Common baseline from Miller table (short-circuit).[2] |

| 3/16″ (0.188″) | .035″ | 20–23 | 300–400 | 75/25 Ar/CO₂ | Consider multipass; slower travel improves tie-in. |

| 1/4″ (0.250″) — short-circuit / globular | .035″ | 22–24 | 350–450 | 75/25 Ar/CO₂ | With 75/25, high settings move toward globular, not true spray.[4] |

| 1/4″ (0.250″) — spray transfer | .035″ | 24–27 | 400–500+ | Argon-rich (e.g., 90/10 or 98/2) | True spray requires ≥~80–85% Ar gas; increase CFH and ESO ≈ 3/4–1″.[4][20] |

This table is for solid wire. For flux-cored (FCAW), use the wire maker’s datasheet—transfer mode, polarity, and gas (if any) change the numbers significantly.[23]

Position tweaks: Overhead/vertical often benefit from slightly lower voltage and/or reduced wire speed versus flat, with tighter stickout to control the puddle.[1]

Settings for Stainless Steel and Aluminum: Adjusting the Chart for Tougher Metals

Stainless (e.g., 304 with ER308L): For short-circuit on thin stock, a common shielding gas is a tri-mix of 90% He / 7.5% Ar / 2.5% CO₂ — note the order and percentages — which helps wetting and reduces lack of fusion. For thicker sections or spray with stainless, argon-rich mixes (e.g., 98% Ar / 2% O₂) are typical.[5]

| Material | Thickness | Wire Dia. | Voltage | IPM | Gas / Notes |

|---|---|---|---|---|---|

| Stainless 304 (ER308L) | 18 ga | .030″ | 18–20 | 200–300 | Tri-mix 90He/7.5Ar/2.5CO₂, ~25–30 CFH; control heat to limit distortion.[5][6] |

| Stainless 304 (ER308L) | 1/8″ | .035″ | 20–22 | 250–350 | Tri-mix short-circuit; for spray, use argon-rich with O₂/CO₂ adders. |

| Aluminum (e.g., 6061) | 1/16″ | .035″ | 19–21 | 300–400 | 100% Ar, spool or push-pull gun; clean oxide, push technique.[19] |

| Aluminum (e.g., 6061) | 1/8″ | .035″ | 21–23 | 400–500 | Limit preheat; keep ≤~230 °F on thick sections; match filler: 6XXX often ER4043; 5XXX often ER5356.[19][17][18] |

I once botched an aluminum boat transom by sticking to mild-steel settings—too cold and dirty arc. Switched to ~22 V / ~450 IPM with pure argon, cleaned properly, and it flowed smooth. Filler match matters: 6XXX (like 6061) commonly uses ER4043 while 5XXX typically favors ER5356 (or 5356 on some 6XXX when higher strength/anodizing color match is needed).[17][18]

Safety note: Argon is heavier than air—ventilate to avoid displacement. Keep aluminum preheat conservative (generally ≤230 °F) to preserve temper.[19]

Factors That Influence Your MIG Wire Speed and Voltage Choices

No chart lives in a vacuum. Thickness drives amperage and transfer mode; wire type (solid vs. flux-cored) alters parameters and polarity; joint design (butt vs. fillet) changes puddle volume; environment affects gas flow/porosity. Maintain proper electrode stickout: ~3/8–1/2″ for short-circuit; ~3/4–1″ for spray/pulsed.[20]

Travel speed is sneaky: too fast narrows and cools the bead; too slow overheats and widens it. Tune voltage/WFS until the arc sounds like steady bacon, not fireworks.[1]

Modern synergic MIG features (e.g., Auto-Set™) can auto-suggest parameters from wire size and thickness—handy for new operators or quick setups.[13][14]

Step-by-Step Guide to Setting Up MIG Wire Speed and Voltage

Let’s walk through dialing in settings like you’re my greenhorn helper on a Monday morning pour-over.

- Assess the Job: Measure thickness. Pick wire (ER70S-6 for mild steel?); confirm .030″ or .035″ spool; 75/25 gas connected?

- Consult the Chart: For 1/8″ mild, start near 19 V / 290 IPM with 75/25. Set polarity DCEP (gun positive).[2]

- Prep the Piece: Degrease, grind to bright metal, fit-up square, tack generously.

- Fire a Test: ESO ~1/2″, 10–15° push for a flatter bead and visibility (drag/backhand tends to increase penetration).[16][21][22]

- Inspect & Tweak: Flat bead with good wash? Great. Convex/narrow → raise WFS; long/hissy arc → trim voltage. Use bead appearance to guide adjustments.[1]

- Weld & Monitor: Keep travel steady; cool between passes as needed.

Common MIG Welding Mistakes with Wire Speed and Voltage—and Quick Fixes

Welding a go-kart frame at 25 V / 200 IPM? That long arc will punish you with turbulence and undercut. Fix: drop to ~19–20 V, increase WFS to stabilise, and shorten stickout to ~1/2″.

- Voltage Too High: Flat, overly wide bead; undercut on thin metal. Fix: reduce 1–2 V; check ESO.

- Wire Speed Too High: Excess spatter; burnback. Fix: reduce 25–50 IPM; verify drive roll tension.

- Wire Speed Too Low: Cold, convex bead. Fix: increase IPM; confirm solid ground.

- Inadequate Gas Coverage: Pinholes/porosity. Fix: 30–35 CFH (75/25), adjust for drafts; inspect nozzle/diffuser for spatter buildup.[2][24]

Pros and Cons of Different MIG Transfer Modes Tied to Settings

Short-circuit (~16–21 V, lower IPM): versatile on thin material with lower heat input. Spray (higher volts/IPM + argon-rich gas): smooth, high deposition for ≥1/4″ plate. Pulsed MIG modulates current between peak and background to achieve controlled droplet transfer at lower average heat—great for out-of-position and thinner sections compared to conventional spray. Note: machines like the Millermatic 255 include Pulsed MIG; the Millermatic 252 does not.[9][7][8]

Shop Tips for Optimizing MIG Settings on US Machines

Manufacturer parameter charts are your friend (many are printed behind a door on the machine). Keep consumables tidy: clean/replace nozzles, contact tips, gas diffusers, and liners regularly; clogged nozzles wreck shielding.[24][25]

Technique cues for solid wire:

- Electrode stickout: ~3/8–1/2″ (short-circuit); ~3/4–1″ (spray/pulsed).[20]

- Travel angle: 10–15° push for wider, flatter beads and visibility; drag (pull/backhand) typically increases penetration.[16][21]

- Gas coverage: Use appropriate nozzle size; keep the diffuser/nozzle free of spatter for stable shielding.[24]

Students: Practice across positions and thicknesses; industry folks: align practice with AWS Z49.1, and log your parameters. DIYers: a simple settings notebook or phone pics save time later.

Advanced Tricks: Layering Settings for Multi-Pass Welds

On thick joints, a cooler root (e.g., short-circuit) followed by hotter fill/cap (spray or pulsed) balances fusion and width. For verticals, a controlled weave with toe pauses can help. Adjust your chart per layer—often a slight reduction in WFS for hot starts improves consistency.[1]

Safety First: How Proper Settings Keep You Out of Trouble

Settings aren’t just cosmetic—they’re safety. Unstable arcs increase spatter and fire risk; excessive heat can over-stress guns and cables. Ground properly; wear FR gear and appropriate PPE. See AWS Z49.1 and OSHA 1910 Subpart Q for requirements and best practices; NFPA 70E informs electrical safety and arc-flash PPE planning.[10][11]

Wrapping It Up: You’re Ready to Arc with Confidence

We’ve gone from decoding the MIG chart to troubleshooting beads that’d make a porcupine jealous. Start with thickness and wire size, use the chart for baselines, then trust your eyes and ears. Balance voltage for arc length and wire speed for heat. Prep like your paycheck depends on it—because it does.

Before every big job, weld a “witness coupon” that matches your base metal. Log the settings that nail it, and you’ll cut setup time in half next round.

FAQs

What’s the Ideal Wire Speed for 1/8-Inch Mild Steel MIG Welding?

For 1/8-inch mild steel with .030-inch ER70S-6 and 75/25 gas, start about 19 V / ~290 IPM (short-circuit) and adjust based on bead behavior.[2]

How Do I Know If My MIG Voltage Is Too High?

Signs: a “hissy,” long arc; flat, wide beads; excess spatter. Try reducing 1–2 V and confirm stickout isn’t excessive. Aim for a steady, crisp sizzle.[1]

Can I Use the Same Settings for Flux-Cored Wire as Solid Wire?

Not exactly. FCAW (self-shielded or gas-shielded) has different transfer and recommended parameters. Start from the wire’s datasheet or a flux-core calculator, then tune.[23]

Do Settings Change for Aluminum MIG Welding?

Yes—aluminum needs higher WFS and typically 100% argon. Use spool or push-pull for consistent feed. Clean oxide, push the puddle, and keep preheat modest (generally ≤230 °F). For filler, 6XXX often ER4043; 5XXX often ER5356.[19][17][18]

References

- Miller — MIG Welding: Setting the Correct Parameters. (Published May 30, 2025).

- Miller (Canada) — MIG Welding Parameter Choices table. (Accessed 2025-10-14).

- Miller — Gas selection & flow for MIG. (Accessed 2025-10-14).

- WeldingAnswers — Shielding Gas for GMAW (argon % for spray). (Accessed 2025-10-14).

- Lincoln Electric — MIG Welding Stainless Steel. (Accessed 2025-10-14).

- Airgas — 90% He / 7.5% Ar / 2.5% CO₂ tri-mix. (Accessed 2025-10-14).

- Miller — Millermatic 255 (Pulsed MIG). (Accessed 2025-10-14).

- Miller — Millermatic 252 (no Pulsed MIG). (Accessed 2025-10-14).

- Lincoln — Pulsed GMAW overview (C3240). (Accessed 2025-10-14).

- AWS Z49.1 — Safety in Welding, Cutting, and Allied Processes. (Accessed 2025-10-14).

- OSHA 29 CFR 1910 Subpart Q — Welding, Cutting, and Brazing. (Accessed 2025-10-14).

- Miller — Weld Setting Calculators. (Accessed 2025-10-14).

- Miller — Auto-Set™ Technology. (Accessed 2025-10-14).

- Miller — Auto-Set™ tips. (Published May 30, 2025).

- Miller — MIG Basics for Mild Steel. (Accessed 2025-10-14).

- Miller — Quick Tip: Push vs. Pull. (Accessed 2025-10-14).

- Lincoln — SuperGlaze 4043 (typical for 6XXX). (Accessed 2025-10-14).

- Lincoln — SuperGlaze 5356 (typical for 5XXX). (Accessed 2025-10-14).

- Lincoln — Guide to Aluminum Welding (preheat ≤230 °F). (Accessed 2025-10-14).

- Lincoln — GMAW Fundamentals (stickout ranges). (Accessed 2025-10-14).

- Red-D-Arc — Forehand vs. Backhand (push vs. pull). (Accessed 2025-10-14).

- Topwell — Forehand vs. Backhand. (Accessed 2025-10-14).

- Miller — Flux-Cored Calculator. (Accessed 2025-10-14).

- Bernard/Tregaskiss — MIG gun consumables best practices. (Accessed 2025-10-14).

- ABICOR BINZEL — MIG gun maintenance guide. (Accessed 2025-10-14).