When I first picked up a no gas MIG welder, I’ll admit—I was a bit overwhelmed. The idea of welding without shielding gas made me wonder if I could still get clean, strong welds on steel, stainless, or even thin sheet metal. I quickly realized that understanding filler rods, metal thickness, and proper joint prep isn’t optional—it’s essential for consistent bead quality and avoiding common pitfalls like excessive spatter or weak fusion.

I also had to learn the differences between MIG vs TIG, how arc control affects penetration, and why even a small mistake in travel speed or wire feed could compromise a weld. Getting this right matters not just for structural strength and safety, but also for saving time, material, and frustration in real-world projects. Stick with me, and I’ll show you exactly how to master a no gas MIG welder for beginners so your welds come out clean, strong, and reliable every time.

Image by reddit

What Is a No Gas MIG Welder and How Does It Work?

A no gas MIG welder uses flux-cored wire instead of the solid wire and shielding gas combo you’d find in traditional MIG (Metal Inert Gas) welding. The flux inside the wire melts during welding, creating a protective gas shield around the weld pool to prevent contamination from oxygen or moisture. This self-shielding process makes it ideal for beginners who want a straightforward setup without the need for gas cylinders, regulators, or hoses.

The process is semi-automatic, meaning the welder feeds the wire continuously through a welding gun when you pull the trigger. The wire acts as both the electrode and filler material, melting into the joint to form a strong bond. The flux core produces slag—a crusty layer over the weld—that you’ll need to chip off after cooling. It’s similar to stick welding in that sense but faster and easier to control for new welders.

I remember my first time using a flux-cored welder on a rusty gate repair. I was nervous about getting the settings right, but the simplicity of the setup—just the welder, wire, and workpiece—gave me confidence. It’s forgiving on dirty or slightly rusty metal, which is a lifesaver for DIYers working on outdoor projects.

Why Choose a No Gas MIG Welder?

- Simplicity: No gas cylinders mean fewer components to manage, perfect for beginners or hobbyists.

- Portability: Without gas tanks, you can easily move the welder to a job site or your backyard.

- Cost-Effective: Saves money on gas, regulators, and related accessories.

- Outdoor Versatility: The flux shield isn’t affected by wind, unlike gas MIG welding.

Common Mistake to Avoid

One rookie mistake I made was not checking the wire polarity. Flux-cored welding requires DC Electrode Negative (DCEN), unlike gas MIG’s DC Electrode Positive (DCEP). Using the wrong polarity leads to excessive spatter and weak welds. Always double-check your machine’s manual and set the polarity correctly before starting.

Choosing the Best No Gas MIG Welder for Beginners

Picking the right no gas MIG welder is crucial for a smooth start. As a beginner, you want a machine that’s user-friendly, reliable, and versatile enough to grow with your skills. Brands like Miller, Lincoln, and Hobart dominate the U.S. market, offering models tailored for DIYers and students.

Key Features to Look For

- Power Range: Look for a welder with 30–140 amps for small projects or up to 200 amps for thicker materials.

- Wire Feed Control: Adjustable wire feed speed is critical for controlling weld quality.

- Portability: A lightweight machine (under 40 lbs.) is ideal for moving around.

- Thermal Overload Protection: Prevents overheating, especially during long welding sessions.

- Multi-Process Capability: Some welders offer MIG, flux-cored, and stick options, giving you room to experiment.

Top Picks for Beginners

| Welder Model | Amps | Weight | Key Features | Best For |

|---|---|---|---|---|

| Miller Multimatic 215 | 30–230 | 38 lbs | Auto-Set, multi-process, 120/240V | DIYers, growing skills |

| Lincoln Electric SP-140T | 30–140 | 50 lbs | Compact, 120V, user-friendly | Home use, small projects |

| Hobart Handler 140 | 25–140 | 57 lbs | Affordable, reliable, flux-core capable | Budget-conscious beginners |

I started with a Hobart Handler 140 for its affordability and ease of use. It’s a workhorse for small repairs, like fixing a trailer hitch, and it runs on a standard 120V outlet, which was perfect for my garage setup. If you’re eyeing bigger projects, the Miller Multimatic 215 is a step up, offering more power and multi-process options.

Practical Tip

Before buying, check your workspace’s power supply. Most beginner welders run on 120V, but if you plan to weld thicker steel (over ¼ inch), consider a 240V machine. Always read user reviews from welders with similar projects to ensure the machine fits your needs.

Understanding Flux-Cored Wire Types

The heart of no gas MIG welding is the flux-cored wire. It’s not just a consumable—it dictates weld quality, penetration, and ease of use. Choosing the right wire is as important as picking the welder itself.

Common Flux-Cored Wire Types

E71T-GS: A general-purpose wire for mild steel, ideal for beginners. It’s versatile and works well on thin or moderately thick materials.

E71T-11: Similar to E71T-GS but designed for multiple passes, great for thicker steel or structural welds.

E70T-4: Used for high-deposition welds on heavy materials, less common for beginners due to its specialized applications.

When I welded a steel frame for a workbench, I used E71T-GS 0.035-inch wire. It gave me smooth welds with minimal spatter on ⅛-inch steel. For thinner materials, like 20-gauge sheet metal, I’d switch to 0.030-inch wire to avoid burn-through.

Wire Selection Tips

Match Wire to Material: Use mild steel wire for carbon steel projects. Stainless or aluminum wires exist but require specific welders.

Check Diameter: Smaller diameters (0.030–0.035 inch) are better for thin metals; larger (0.045 inch) for thicker stock.

Quality Matters: Invest in reputable brands like Lincoln or Hobart. Cheap wire can cause feeding issues and inconsistent welds.

Common Mistake

I once grabbed the wrong wire diameter, thinking it wouldn’t matter. The result? A jammed wire feeder and a frustrating afternoon. Always double-check the wire size against your welder’s specs and project needs.

Setting Up Your No Gas MIG Welder: Step-by-Step Guide

Setting up a no gas MIG welder is straightforward, but small mistakes can lead to poor welds. Here’s how I set up my machine for consistent results, whether I’m in my shop or on a job site.

Step-by-Step Setup

Check Polarity: Set your welder to DCEN (electrode negative). Most machines have a polarity switch or terminal inside the wire compartment.

Load the Wire: Install the flux-cored wire spool, ensuring it feeds smoothly through the drive rollers. Align the roller groove with the wire diameter.

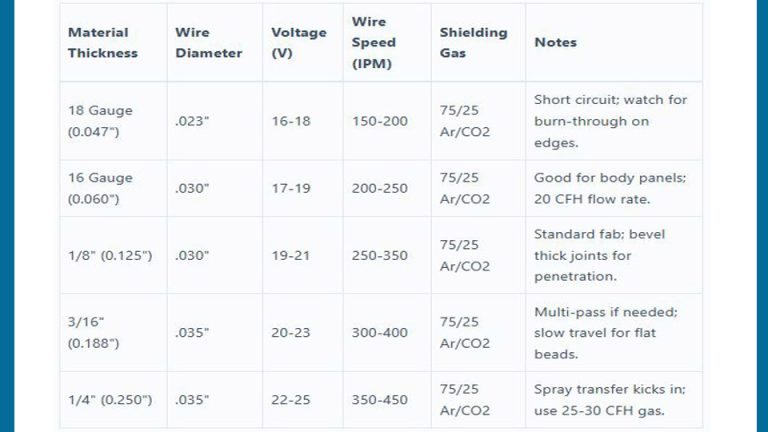

Adjust Wire Feed Speed: Start with the manufacturer’s recommended settings (often printed on the welder). For example, for ⅛-inch steel with 0.035-inch wire, try 150–200 inches per minute (IPM).

Set Voltage: Match the voltage to your material thickness. For 16-gauge steel, 16–18 volts is a good starting point.

Test on Scrap: Run a test weld on scrap metal to fine-tune settings. Listen for a steady “sizzle” sound, like bacon frying, for a good arc.

Prepare the Workpiece: Clean the metal with a wire brush or grinder to remove rust, paint, or grease.

Connect the Ground Clamp: Attach the clamp to the workpiece or a nearby conductive surface to complete the circuit.

When I set up my welder for a farm gate repair, I tested settings on a scrap piece first. It saved me from burning through the thin tubing and gave me confidence in my settings.

Pro Tip

Keep a notebook with your go-to settings for different materials and thicknesses. It’s a lifesaver when you’re switching between projects and helps you dial in the machine faster.

Mastering No Gas MIG Welding Techniques

Technique is where the magic happens in welding. No gas MIG welding is forgiving, but mastering a few basics will elevate your welds from amateur to professional.

Key Techniques

Gun Angle: Hold the welding gun at a 15–20-degree angle from vertical, pushing or pulling the weld pool. I prefer pushing for better visibility on thin materials.

Travel Speed: Move steadily to avoid piling up too much filler (slow speed) or creating weak welds (too fast). Aim for a consistent bead width.

Stick-Out: Keep the wire stick-out (distance from the contact tip to the workpiece) at ¼–⅜ inch for a stable arc.

Weld Patterns: Use a slight zigzag or circular motion for wider joints, like fillets or laps, to ensure good fusion.

I learned the hard way that rushing the weld leads to uneven beads. On a trailer repair, I moved too fast and ended up with a weak weld that cracked under stress. Slow down, practice on scrap, and focus on steady hand movement.

Common Technique Mistakes

- Inconsistent Speed: Varying your travel speed creates uneven beads. Practice maintaining a steady pace.

- Wrong Stick-Out: Too long, and the arc becomes unstable; too short, and you risk burning the contact tip.

- Poor Joint Prep: Skipping cleaning leads to porosity or weak welds. Always prep the surface.

Safety Considerations for No Gas MIG Welding

Welding is rewarding but inherently risky. No gas MIG welding produces more fumes and spatter than gas MIG, so safety is non-negotiable.

Essential Safety Gear

- Welding Helmet: Use an auto-darkening helmet with a shade range of 9–13 for clear visibility and eye protection.

- Gloves: Heavy-duty leather gloves protect against burns and spatter.

- Jacket or Apron: Fire-resistant clothing prevents burns from hot slag.

- Respiratory Protection: Flux-cored welding creates heavy fumes. Use a respirator or weld in a well-ventilated area.

- Boots: Steel-toe boots with non-slip soles are ideal for shop or job site safety.

I once skipped ventilation while welding in a tight shed. The fumes gave me a headache for hours. Now, I always use a fan or portable exhaust system, especially for long sessions.

Safety Tips

- Clear the Area: Remove flammable materials like rags, paint, or fuel cans from your workspace.

- Check Equipment: Inspect cables and the gun for wear before starting.

- Ground Properly: Ensure the ground clamp is secure to avoid electric shock.

Pros and Cons of No Gas MIG Welding

No gas MIG welding is a game-changer for beginners, but it’s not perfect. Here’s a breakdown to help you decide if it’s right for your projects.

Pros

- Beginner-Friendly: Simple setup and forgiving on imperfect technique.

- Portable: No gas tanks make it easy to move to job sites or outdoor projects.

- Cost-Effective: Saves on gas and regulator costs.

- Wind-Resistant: Ideal for outdoor welding where gas shields fail.

Cons

- More Spatter: Flux-cored welding produces more spatter than gas MIG, requiring cleanup.

- Slag Removal: You’ll need to chip off slag after each weld, adding time.

- Lower Weld Aesthetics: Welds may not be as clean as gas MIG, especially on thin materials.

- Fume Production: More fumes mean you need better ventilation.

Real-World Applications for No Gas MIG Welding

No gas MIG welding shines in practical, everyday scenarios. Here are some applications where it’s a go-to choice:

- Automotive Repairs: Fix exhaust systems, chassis, or body panels. I’ve used it to patch a rusted truck bed with great results.

- Farm and Ranch Work: Repair gates, fences, or equipment in windy fields where gas MIG fails.

- DIY Projects: Build furniture, trailers, or sculptures. I welded a steel fire pit for my backyard using flux-cored wire.

- Construction and Fabrication: Tackle structural welds on thicker steel, like beams or frames.

For students or hobbyists, no gas MIG welding is a great way to practice without investing in a full gas setup. Pros often use it for quick repairs on job sites where portability is key.

Troubleshooting Common No Gas MIG Welding Issues

Even with a beginner-friendly process, things can go wrong. Here are common issues and fixes based on my experience.

Issue: Excessive Spatter

- Cause: Incorrect voltage, wire feed speed, or polarity.

- Fix: Check for DCEN polarity and adjust voltage or wire speed. Test on scrap metal to find the sweet spot.

Issue: Poor Penetration

- Cause: Low voltage or slow travel speed.

- Fix: Increase voltage slightly and maintain a steady travel speed. Ensure the metal is clean.

Issue: Wire Feed Problems

- Cause: Misaligned rollers, wrong tension, or low-quality wire.

- Fix: Check roller alignment, adjust tension, and use high-quality wire from trusted brands.

I once dealt with constant wire jams because I overtightened the drive rollers. Loosening the tension and realigning the spool fixed it instantly.

Conclusion: Why You’re Ready to Weld with a No Gas MIG Welder

No gas MIG welding is a fantastic starting point for beginners, hobbyists, and even pros who need a portable, cost-effective solution. You’ve learned how to choose a welder, select the right flux-cored wire, set up your machine, and master techniques for strong, reliable welds.

By understanding polarity, practicing steady hand movements, and prioritizing safety, you’re equipped to tackle projects from auto repairs to backyard builds. The beauty of flux-cored welding is its forgiveness—it lets you focus on learning without the complexity of gas systems.

FAQ

What is the best no gas MIG welder for a beginner?

The Hobart Handler 140 and Lincoln SP-140T are excellent choices for their affordability, ease of use, and compatibility with 120V outlets. Look for models with adjustable wire feed and thermal overload protection for safety and versatility.

Can I use a no gas MIG welder on thin metal?

Yes, but you’ll need to use thinner wire (0.030-inch) and lower voltage settings to avoid burn-through. Practice on scrap metal to dial in the settings for materials like 20-gauge steel.

How do I reduce spatter when using a no gas MIG welder?

Ensure you’re using DCEN polarity, clean the workpiece thoroughly, and adjust wire feed speed and voltage to match the material thickness. A steady travel speed also helps minimize spatter.

Is no gas MIG welding safe for indoor use?

It’s safe with proper ventilation. Flux-cored welding produces heavy fumes, so use a fan, exhaust system, or respirator. Always wear a welding helmet, gloves, and fire-resistant clothing.

Can I weld aluminum with a no gas MIG welder?

Most no gas MIG welders are designed for mild steel. Welding aluminum typically requires a gas MIG setup with a spool gun and argon shielding gas. Check your welder’s manual for compatibility.