Did you know that a plasma cutter can require up to six times its maximum current from a generator or battery system? When you’re working off-grid, this energy demand calls for strategic power planning. High-capacity batteries, like the Instagrid ONE max offering 2.1 kWh, and robust diesel generators become essential tools. But how do you guarantee compatibility and efficiency while minimizing environmental impact? Let’s explore the technicalities that define off-grid plasma cutting solutions.

Understanding Plasma Cutter Power Requirements

When you’re considering the power requirements for a plasma cutter, it’s important to understand the substantial energy demand these tools impose. Plasma cutter efficiency and power source compatibility are significant factors.

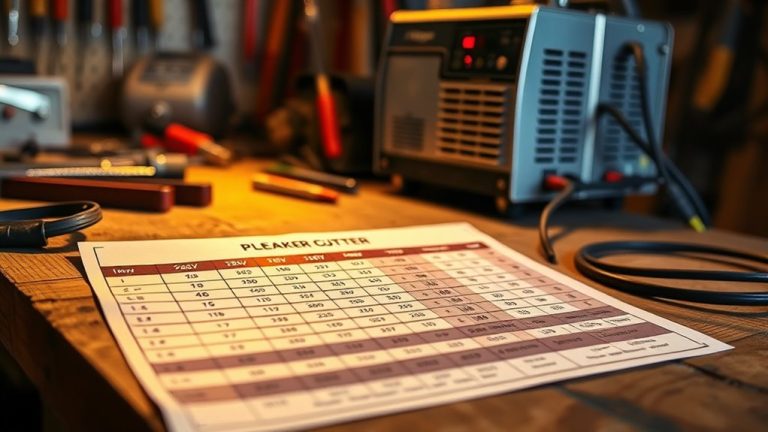

For instance, a 2,600 W plasma cutter can run for about 50 minutes on a fully charged 2.1 kWh battery, emphasizing the need for a robust power supply. To guarantee peak performance, your generator must exceed six times the plasma cutter’s maximum run current, especially for single-phase motors.

Analyzing the PowerPlasma 150H, requiring a 480V three-phase input and consuming 32.5A, highlights the challenge of using standard generators. Consequently, power source compatibility is significant.

Devices like the instagrid ONE max, with its 18,000 W peak power, efficiently support 230 V tools without oversized generators. Additionally, understanding the duty cycle and starting current is crucial for sizing your generator accurately, guaranteeing plasma cutter efficiency during operations.

Battery Systems for Off-Grid Plasma Cutting

When considering battery systems for off-grid plasma cutting, you’ll find that the instagrid ONE max offers a robust solution with its 2.1 kWh energy capacity, supporting continuous operation for an entire workday.

Its lightweight 20 kg design guarantees easy transport to on-site locations, while its fast charging capability gets you back to full power in under 3 hours.

With a runtime of 50 minutes for a 2,600 W plasma cutter, this system maximizes efficiency by eliminating energy waste during idle periods.

Capacity and Runtime Efficiency

While exploring the efficiency of battery systems for off-grid plasma cutting, the instagrid ONE max stands out with its impressive specifications.

With a 2.1 kWh energy capacity, it guarantees an entire workday of metalwork without relying on fuel or oversized generators. For runtime optimization, a 2,600 W plasma cutter powered by this battery can operate for about 50 minutes of actual working time.

This setup emphasizes energy efficiency by maximizing the available power without unnecessary waste. The lightweight 20 kg design enhances mobility, making it ideal for on-site applications.

Its peak power output of 18,000 W supports various 230 V tools, providing robust performance. The absence of emissions and noise pollution further underscores its suitability for diverse work environments.

Portability and Charging Solutions

Designed for both portability and efficiency, the instagrid ONE max’s battery system offers a remarkable solution for off-grid plasma cutting.

Weighing only 20 kg, it’s engineered for transportation convenience—a single person can easily move it across job sites.

With a 2.1 kWh energy capacity, it powers a 2,600 W plasma cutter for approximately 50 minutes, making sure you can tackle various metalwork tasks efficiently.

The schematic diagrams highlight its impressive peak power output of 18,000 W, supporting a range of tools.

Charging efficiency is a cornerstone; it recharges fully in less than 3 hours, assuring minimal downtime.

Zero local emissions guarantee an eco-friendly operation, making the instagrid ONE max a superior choice for clean, mobile metalworking applications.

Diesel Generators: A Reliable Power Source

Diesel generators are essential for off-grid plasma cutting applications, providing reliable power with precision and efficiency. Their ability to handle heavy electrical draws makes them ideal for starting high-demand tools like plasma cutters.

Diesel models operate at lower RPMs than petrol generators, reducing noise pollution—a schematic advantage on remote job sites. Additionally, their design emphasizes fuel efficiency, allowing for prolonged use without frequent refueling, which is economically advantageous when working in secluded areas.

For peak performance and longevity, generator maintenance is vital. Regularly check oil levels, inspect the fuel system, and clean air filters to prevent power interruptions.

A well-maintained generator guarantees consistent power delivery, minimizing downtime and maximizing productivity. Always refer to schematic diagrams for precise guidance on maintenance procedures.

Diesel generators excel in delivering stable, consistent power for your off-grid plasma cutting needs, making sure your operations proceed smoothly and efficiently.

The Role of Automatic Voltage Regulation (AVR)

A reliable diesel generator forms the backbone of any off-grid plasma cutting setup, but maintaining voltage stability is where Automatic Voltage Regulation (AVR) comes into play.

AVR benefits include the ability to keep the generator’s voltage output steady, which is essential for the safe and efficient operation of sensitive equipment like plasma cutters. When you’re dealing with fluctuating power demands, AVR compensates for load changes and prevents damaging voltage spikes.

Imagine a schematic diagram illustrating how AVR smooths voltage variations in both single-phase and three-phase systems. This technology enables your generator to manage heavy electrical draws effectively, ensuring reliable power delivery for demanding tasks.

Comparing Diesel and Petrol Generators

When choosing between diesel and petrol generators for an off-grid plasma cutting setup, understanding their operational differences can be vital.

Diesel generators typically handle heavy electrical loads better, making them ideal for powering plasma cutters requiring substantial wattage. Their fuel efficiency and longevity translate to lower long-term costs, especially with continuous use. Diesel’s higher energy density also means fewer refueling stops, enhancing fuel availability during extended operations.

From a schematic perspective, diesel generators are designed to manage starting current surges effectively, ensuring reliable performance. This reliability is significant in demanding environments where consistent power delivery is non-negotiable.

While diesel engines might require more rigorous generator maintenance, the payoff is in operational efficiency and reduced downtime.

In contrast, petrol generators may seem easier to manage initially but often falter under heavy loads, potentially compromising your cutting tasks.

Noise and Emission Considerations

You’ll find that using the instagrid ONE max for off-grid plasma cutting offers substantial benefits in noise and emission reductions.

Its silent operation enhances working conditions by eliminating the noise pollution typical of combustion generators.

Additionally, schematic diagrams can help visualize emission savings when you shift from traditional oversized generators to this efficient power source.

Silent Operation Benefits

Though often overlooked, the silent operation of the instagrid ONE max system revolutionizes the work environment by virtually eliminating noise pollution during plasma cutting. This quiet efficiency fosters improved focus, allowing you to enhance precision and communication on-site. By eliminating combustion noise, the instagrid ONE max facilitates a seamless workflow and minimizes distractions.

| Feature | Benefit | Impact |

|---|---|---|

| Silent Operation | Improved Focus | Enhanced precision and safety |

| Zero Local Emissions | Cleaner Work Environment | Eco-friendly metalworking |

| Lightweight Design | Easy Transport | Versatile job site application |

Emission Reduction Strategies

By adopting the instagrid ONE max for plasma cutting, you substantially reduce both noise and emissions, transforming your work environment into a model of sustainability.

With its innovative design, the instagrid ONE max offers a cleaner alternative to traditional generators. Consider these key emission reduction strategies:

- Emission Tracking: Monitor emissions effortlessly with the instagrid, ensuring compliance with sustainable practices. Schematic diagrams provide real-time data, enabling precise control.

- Zero Idling: Eliminate energy waste with the instagrid’s no-idle operation, enhancing emission reduction capabilities. Analyze power use through detailed diagrams to optimize efficiency.

- Noise Control: Embrace complete operational silence, minimizing noise pollution and improving on-site working conditions. Detailed schematics facilitate understanding of sound dynamics.

Transitioning to instagrid ONE max, you can achieve calculable emission savings, reinforcing your commitment to eco-friendly metalworking.

Ensuring Power Reliability in Remote Locations

When you’re working in remote locations, guaranteeing power reliability is vital, and that’s where the instagrid ONE max excels. Offering a peak power of 18,000 W, it’s designed to handle demanding metalwork tools without oversized generators. In remote settings, this guarantees uninterrupted workflow efficiency.

The unit’s 2.1 kWh energy capacity can sustain a full day’s metalworking, underscoring its efficiency in off-grid applications.

Consider a scenario: you’re using a magnetic base drill in an isolated area. The instagrid ONE max supports drilling approximately 223 holes in stainless steel, highlighting its capability for diverse tasks. Weighing just 20 kg, its lightweight design enhances mobility, essential for on-site assignments.

Schematic diagrams illustrate its zero idling feature, eliminating energy waste and emissions. This combination of sustainable practice and robust performance guarantees power reliability, making the instagrid ONE max an indispensable asset in remote locales.

Optimizing Energy Solutions for Heavy-Duty Tools

Harnessing ideal energy solutions for heavy-duty tools is crucial in maximizing efficiency and minimizing downtime, particularly in remote locations.

To achieve the best energy efficiency and tool compatibility, consider the following strategies:

Consider strategies for optimal energy efficiency and tool compatibility, ensuring peak performance and reduced downtime.

- Utilize High-Capacity Batteries: The instagrid ONE max offers peak power of 18,000 W, ideal for powering a 2,600 W plasma cutter for about 50 minutes. This means you can handle demanding tasks without frequent recharging.

- Select Portable Solutions: With its lightweight 20 kg design, the instagrid ONE max guarantees you can easily transport power to different job sites, providing flexibility and reducing setup time.

- Incorporate Renewable Energy: Charging the instagrid ONE max through renewable sources greatly cuts emissions, promoting sustainable practices in metalworking.

When sizing generators for heavy-duty tools, make sure they’re at least six times the maximum run current for single-phase motors.

This assures reliable performance and tool compatibility across various applications. Invest in these solutions to enhance your off-grid operations.

Frequently Asked Questions

How Does Weather Affect Off-Grid Plasma Cutter Performance?

Weather impacts off-grid plasma cutter performance through temperature fluctuations and humidity levels. You’ll find that extreme temperatures can cause overheating, while high humidity affects electrical conductivity. Analyzing schematic diagrams helps identify modifications to maintain ideal cutting efficiency.

What Maintenance Is Required for a Generator Powering a Plasma Cutter?

You must immerse yourself in generator maintenance, focusing on fuel management, oil changes, and air filter checks. Imagine this: without proper care, your generator sputters to a halt. Regular inspections and schematic diagrams guarantee seamless plasma cutter operation.

Can Solar Power Be Used for Plasma Cutting Off-Grid?

Yes, you can use solar power for off-grid plasma cutting. Verify solar panel efficiency meets energy needs and choose an inverter that handles surges. Review schematic diagrams for ideal setup, ensuring all components work seamlessly together.

What Are Common Troubleshooting Steps for Off-Grid Plasma Cutters?

Guarantee your power supply is sufficient and connections are secure. Check for consistent arc stability by inspecting consumables and connections. Refer to schematic diagrams for troubleshooting electrical issues, guaranteeing components are aligned with technical specifications.

How Long Do Batteries Typically Last When Used With Plasma Cutters?

Like a marathon runner pacing themselves, your battery life depends on energy consumption. Typically, it lasts 30-60 minutes. Analyzing your schematic diagrams helps optimize usage, ensuring efficient power management and extending operational time for your plasma cutter.

Conclusion

When powering an off-grid plasma cutter, you must guarantee your setup is both efficient and eco-friendly. High-capacity batteries like the Instagrid ONE max deliver portable power, while diesel generators offer reliability for heavy loads. Remember, your generator’s capacity should exceed the cutter’s maximum current by at least six times. This guarantees seamless operation and reduces emissions. By analyzing your specific needs and employing schematic diagrams, you can optimize your energy solutions for remote, heavy-duty tasks efficiently.