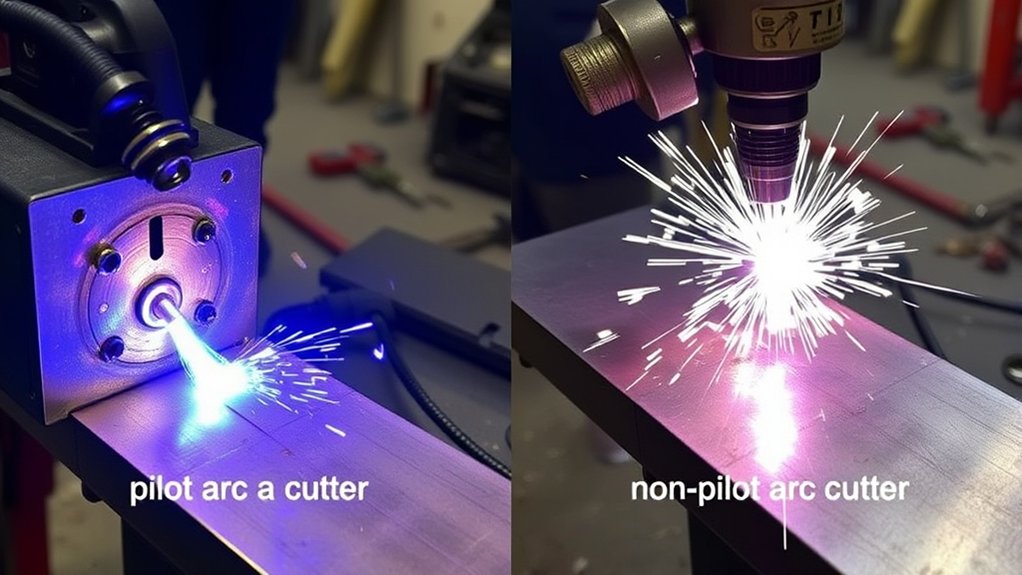

Pilot arc and non-pilot (contact-start) plasma cutters can both cut steel fast. The big difference is how they start the arc. That changes how they handle rust and paint, how easy piercing is, and how much prep you do before you cut.

A pilot arc plasma cutter lights an arc inside the torch first, then transfers it to the metal. So it can start without touching steel, it cuts rusty, painted, or expanded metal more steadily. A non-pilot (contact-start) cutter needs the tip to touch metal to start, so it works best on clean stock.

Key takeaways

- Pilot arc starts without contact, so it’s better for rusty, painted, dirty, or expanded metal and for quick pierces.

- Non-pilot (contact-start) cutters are simpler and often cheaper, but they work best on clean, bare metal.

- Dry air, the right settings, and fresh tips make a bigger difference than most people expect.

Overview of plasma cutting start types

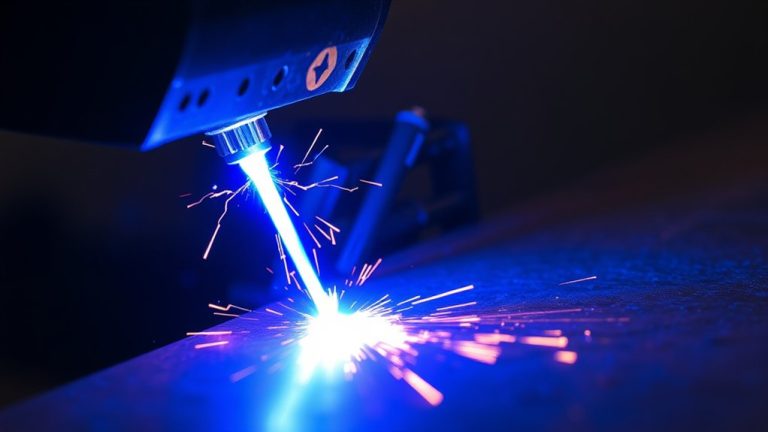

Most handheld plasma cutters use compressed air and electricity to make a hot jet that melts metal and blows it out of the cut. The main difference is how the machine starts the arc:

- Pilot arc (non-touch start): starts a pilot arc inside the torch, then transfers it to the workpiece when the torch is close.

- Non-pilot / contact-start: needs the tip to touch (or nearly touch) clean metal to complete the circuit and start.

If you’re still shopping, see our roundup of the best plasma cutters for home garages and small shops.

What pilot arc plasma cutters do best

Pilot arc machines are built for rougher material. Because the pilot arc does not need instant contact with bare steel, they are more likely to start and keep cutting on:

- rusty or painted plate

- lightly oily metal (wipe first when you can)

- expanded metal and grating (fewer “arc drop-outs”)

They’re also handy for piercing. Many pilot arc torches can pierce directly (within the machine’s rated cut thickness) without drilling a start hole first. That helps on cutouts, brackets, and repair patches.

Related reading: how a pilot arc plasma cutter works.

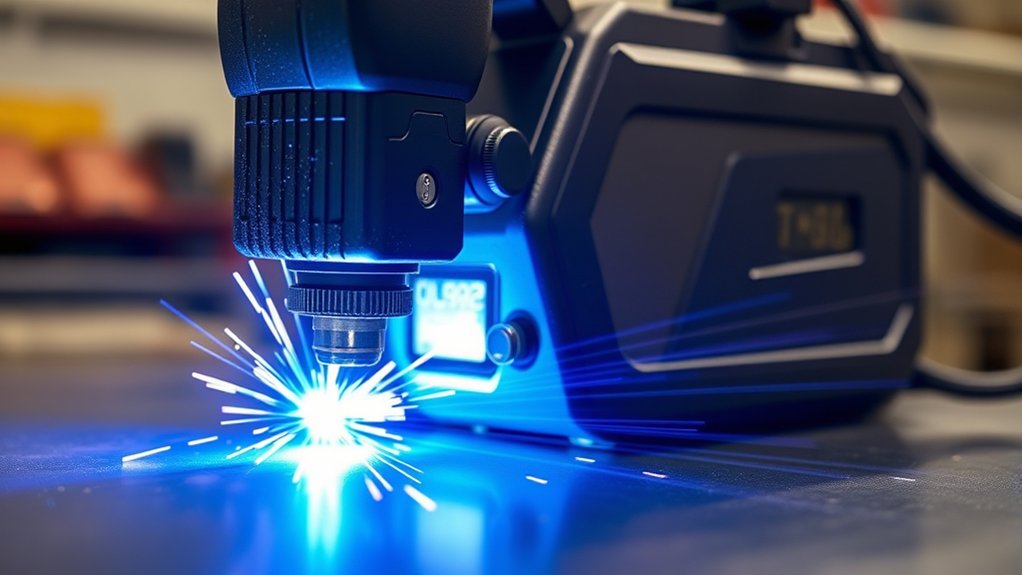

What non-pilot (contact-start) plasma cutters do best

Non-pilot cutters can be a great fit when your workpieces are clean and you want a lower-cost machine. Many entry-level models are compact and easy to carry.

The trade-off is surface sensitivity. Paint, mill scale, rust, and grime can block a reliable start. When that happens, you may need to grind a small spot, move your clamp, or retry the start.

Related reading: how contact-start plasma cutters work.

Pilot arc vs non-pilot: quick comparison

| Feature | Pilot arc | Non-pilot (contact-start) |

|---|---|---|

| Starting on rust/paint | Often starts and cuts with little prep | Often needs clean bare metal to start |

| Expanded metal / grating | More stable, fewer arc drop-outs | More likely to lose the arc |

| Piercing | Commonly pierces without a drilled hole | May need a start hole or very clean contact |

| Price | Often higher upfront | Often lower upfront |

| Consumables | Pilot arc time can add wear, but it avoids tip sticking and failed starts | Less pilot-arc burn time, but contact starts can damage tips if dragged or stuck |

Cost and portability considerations

Contact-start machines often cost less because the start system is simpler. Pilot arc models cost more, but they can save time when you cut rusty or coated steel, pierce often, or work with expanded metal.

Portability depends more on size and build than on start type. Still, many small contact-start units are very light, which is useful for quick repairs and mobile jobs.

Setup tips that improve cuts on any machine

- Keep air dry: Wet air can cause an unstable arc, more dross, and faster tip wear. Use a water separator and, in humid shops, an air dryer unit.

- Use the right amps: Match amperage and travel speed to the metal thickness for a cleaner edge.

- Watch torch tips: A worn nozzle or electrode is a common cause of hard starts and rough cuts.

- Hold a steady gap: If your torch supports a drag tip, use it. If not, keep the right gap.

Which one should you choose?

- Choose a pilot arc cutter if you cut rusty/painted stock, expanded metal, or you want easy piercing and fewer failed starts.

- Choose a non-pilot (contact-start) cutter if you mostly cut clean steel, want a simpler setup, and don’t mind cleaning a small start spot.

Either way, good air, fresh tips, and safe habits matter.

FAQs

Do pilot arc plasma cutters need to touch the metal to start?

No. A pilot arc starts inside the torch and then transfers to the workpiece when the torch is close, so it can begin cutting without direct contact.

Can a non-pilot plasma cutter cut rusty or painted steel?

Sometimes, but it’s less reliable. Contact-start cutters usually need a clean spot to start the arc, so you may have to grind or scrape a small area first.

Do you need to drill a start hole for piercing?

Many pilot arc machines can pierce directly within their rated thickness. With contact-start cutters, a drilled hole or a very clean start spot often makes piercing easier and reduces misfires.

Does “pilot arc” always mean high-frequency start?

No. Pilot arc describes having a pilot arc, not the start method. Many modern machines use blowback (lift-arc) starts that create a pilot arc without high-frequency noise.

How does humidity affect plasma cutter performance?

Moist air can lead to an unstable arc, extra dross, and faster tip wear. A moisture trap and dry compressed air supply help keep starts steady and cuts cleaner.

Can you cut underwater with a standard pilot arc plasma cutter?

Usually no. Underwater plasma cutting uses specialized gear and methods; a normal air plasma cutter is not designed for submerged cutting and can be dangerous if used that way.

Conclusion

If you cut a lot of rusty, painted, or expanded metal, a pilot arc plasma cutter can save time and frustration. If you mostly cut clean steel and want a simple, lower-cost tool, a non-pilot (contact-start) cutter can work well. Match the start type to your typical jobs, and keep your air dry and torch tips fresh.