When considering Plasma Arc Welding (PAW), you must weigh its high equipment costs and the need for specialized training. The complexity of PAW systems demands skilled operators, which can drive up operational expenses. Additionally, limitations on thin plate welding and specific metal compatibility may restrict your project’s versatility. Safety concerns, such as harmful emissions and strict gas protection requirements, add further challenges. Are you ready to explore these aspects in detail?

High Equipment Costs

Investing in Plasma Arc Welding (PAW) equipment requires a substantial financial commitment, often surpassing tens of thousands of dollars. This high cost is primarily due to the advanced technology needed to generate and control the plasma arc.

Specialized nozzles and power supplies are integral, making PAW equipment considerably more expensive than traditional welding methods. Despite the steep initial investment, you should consider the potential return on investment and long-term savings.

Specialized components elevate costs, but long-term savings and potential ROI make PAW a worthwhile investment.

The precision and efficiency of PAW can reduce material waste and improve production speed, positively impacting your bottom line over time. In addition, the high-quality welds produced by PAW systems often lead to fewer defects and reworks, translating to cost savings.

While the upfront expense is intimidating, evaluating the long-term savings in operational efficiency, reduced material costs, and enhanced product quality can justify the investment. A strategic analysis of these factors will help you make an informed decision.

Complexity and Maintenance Challenges

While the financial commitment to Plasma Arc Welding (PAW) equipment is significant, the complexity of these systems presents its own set of challenges. PAW systems demand a high level of operational efficiency, which is hindered by their intricate setup. The sophisticated machinery requires precise parameter management, making consistent results difficult without substantial experience.

This complexity extends to maintenance strategies, as regular upkeep is essential. Components such as nozzles and electrodes experience considerable wear and tear, leading to increased operational costs if not addressed.

Furthermore, the requirement for high-purity shielding gases complicates maintenance, necessitating careful handling and storage to maintain system integrity. This not only adds to operational burdens but can also contribute to downtime if mismanaged.

The advanced nature of PAW machinery, while offering precision, results in a higher initial investment, demanding careful consideration of maintenance strategies to maximize efficiency and minimize costs.

Need for Specialized Training

You’ll find that operating Plasma Arc Welding (PAW) systems demands specialized skills due to the intricate parameters and equipment control involved.

The complexity of training programs, which often require a thorough grasp of plasma physics and welding techniques, can pose significant challenges in workforce development.

Additionally, obtaining the necessary certifications and expertise not only incurs costs but also creates barriers for industries enthusiastic to adopt PAW technology.

Operator Skill Requirements

Although mastering Plasma Arc Welding (PAW) can be challenging, the need for specialized training is essential due to the process’s complexity and precision requirements. Your operator experience plays a significant role in effectively managing PAW’s high temperatures and concentrated energy.

Skill assessment guarantees you’re adept at controlling welding parameters and understanding the unique plasma arc characteristics, which are markedly different from other welding techniques. Proficiency in this area is critical, as it requires a deep knowledge of shielding gas requirements and the maintenance of a clean, inert environment to maintain weld integrity.

Additionally, your expertise in safety protocols is imperative, given the risks of harmful gases and radiation. Companies often face increased labor costs to secure skilled operators like you.

Training Program Complexity

Given the intricate nature of Plasma Arc Welding (PAW), specialized training becomes essential to mastering this sophisticated process.

You’re dealing with complex equipment that demands precise parameter management to achieve high-quality welds. The training duration can range from several weeks to months, depending on the system’s complexity. During this time, you’ll learn about plasma arc setup, including handling nonconsumable tungsten electrodes and adjusting gas flow rates.

Operator certification often requires a deep understanding of safety protocols due to the emission of harmful gases and radiation. Furthermore, you’ll need expertise in equipment maintenance, such as regular nozzle and electrode replacement.

This multifaceted training guarantees you can troubleshoot effectively, ensuring smooth operation and peak performance.

Certification and Expertise

To excel in Plasma Arc Welding (PAW), attaining certification and expertise becomes imperative due to the intricate nature of the process. You must undergo expert training that explores the complexities of PAW equipment, emphasizing the essential understanding of plasma physics and material-specific parameters.

Certification requirements are stringent, ensuring you can manage high-purity shielding gases to prevent weld defects. This specialized training not only enhances your technical capabilities but also aligns with companies’ priorities for skilled operators, given the high costs associated with PAW technology.

Consequently, organizations often face challenges in sourcing qualified personnel from a limited pool of trained professionals. By meeting these certification requirements, you position yourself as a valuable asset in a demanding and highly specialized field.

Strict Gas Protection Requirements

You’ll find that Plasma Arc Welding demands high-purity shielding gas to prevent weld contamination, which greatly increases operational costs due to the necessity for specialized gas supplies.

Maintaining gas supply reliability is critical, as any fluctuations in gas purity or flow can severely impact weld quality, leading to defects such as porosity.

To guarantee consistent weld quality, it’s vital to adhere strictly to gas protection protocols and invest in additional equipment for gas filtration and monitoring.

High-Purity Gas Necessity

While Plasma Arc Welding (PAW) offers precision and efficiency, it demands strict adherence to high-purity gas requirements to function effectively. The gas purity of shielding gases like argon or helium is vital for maintaining the plasma arc’s stability and integrity. Impurities can cause defects such as porosity, compromising weld quality. Specialized gas handling systems guarantee the consistent delivery of these high-purity gases, though they add complexity and cost. Operators must be trained to manage and monitor gas quality, as contamination drastically impacts results. The stringent gas purity requirements can limit PAW’s accessibility in less specialized industries due to the necessary investment.

| Aspect | Requirement | Impact |

|---|---|---|

| Gas Type | Argon, Helium | Stability of Plasma Arc |

| Purity Level | High-Purity | Defect Prevention |

| Handling System | Specialized | Increased Complexity & Cost |

| Operator Training | Essential | Consistent Quality Control |

Gas Supply Reliability

Guaranteeing gas supply reliability is vital in Plasma Arc Welding (PAW), as even minor fluctuations in gas quality or delivery can lead to significant defects.

You must carefully evaluate gas supply alternatives to guarantee high-purity shielding gas, which is important for preventing contamination. The strict gas protection requirements increase operational costs since premium gases are pricier than standard options.

Additionally, supply chain reliability is critical; any interruption can cause costly downtime and defects like porosity. Operators need extensive training to manage gas flow and pressure accurately, as incorrect settings can destabilize arcs.

- Increased operational costs: High-quality gases are expensive.

- Training demands: Proper management of gas flow and pressure is essential.

- Complex equipment needs: Specialized handling equipment adds complexity.

Impact on Weld Quality

Achieving ideal weld quality in Plasma Arc Welding (PAW) hinges on maintaining strict gas protection, which is vital for preventing contamination and guaranteeing the weld’s integrity.

You need high-purity shielding gases like argon or helium to avoid weld defects such as porosity and lack of fusion. This requirement drives up operational costs and demands sophisticated gas handling systems.

To optimize the process, you must ascertain precise flow rates and continuous monitoring. Failing to do so complicates operations and requires skilled operators to maintain consistent quality.

The stringent gas protection limits PAW’s effectiveness in environments prone to contamination, restricting its industrial applicability.

Consequently, mastering gas management is essential in achieving defect-free, high-quality welds in PAW.

Limitations on Thin Plate Welding

Despite its advantages for thick materials, Plasma Arc Welding (PAW) presents significant challenges when applied to thin plate welding. The concentrated heat and focused arc characteristics of PAW can easily cause the material to burn through, as the welding techniques struggle to accommodate reduced material thickness. This results in a high potential for exceeding the melting point, leading to rapid failure.

The narrow heat-affected zone (HAZ) generates excessive thermal stress, causing distortion in thin materials. You must carefully manage welding parameters, as even slight deviations can cause significant damage. High energy density, while beneficial for thicker materials, becomes a liability with thin plates where precision and control are critical.

Frequent adjustments and specialized techniques increase the complexity, creating hurdles compared to more adaptable methods like TIG or MIG welding.

Consider the emotional toll of these challenges:

- Risk of material failure

- Increased complexity and stress

- Demanding precision and control

Limited Performance on Certain Materials

Plasma Arc Welding, known for its precision on thicker materials, faces notable limitations when applied to specific materials, especially non-ferrous metals like copper and magnesium alloys.

These metals present challenges due to their high thermal conductivity and reactivity, requiring careful thermal management to avoid issues like overheating and burn-through. You might find that PAW struggles with material compatibility when working on alloys demanding precise heat control, as the rapid cooling inherent in this process can lead to cracking or inadequate fusion.

Moreover, welding reactive metals necessitates specialized techniques and precautions to prevent contamination and maintain weld integrity.

You also need to take into account the specific gas compositions and flow rates essential for different materials, complicating the welding process and limiting versatility.

Such complexities in material compatibility demand an expert approach, as the necessity for precise thermal management can hinder PAW’s effectiveness on certain non-ferrous materials.

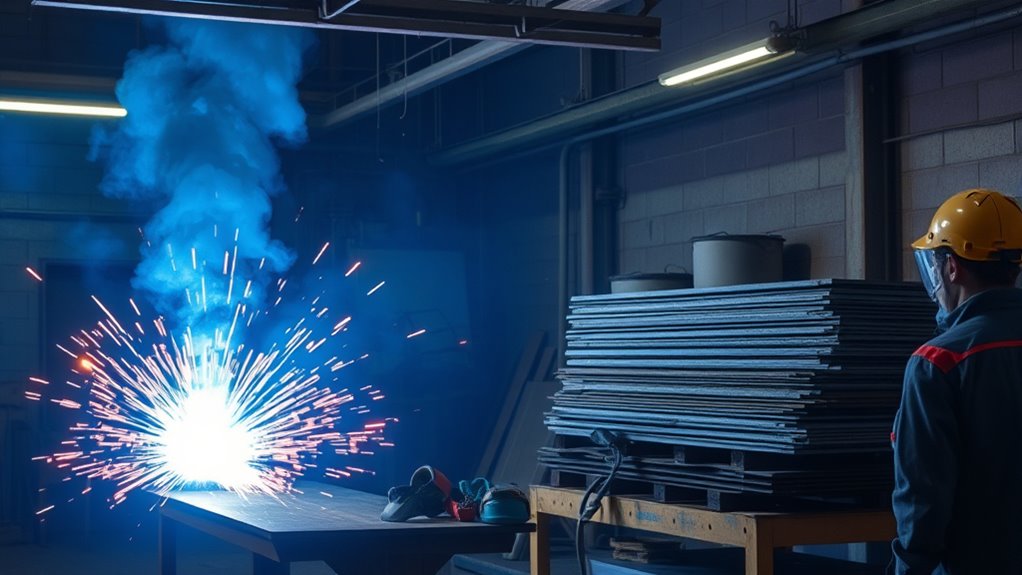

Safety Concerns and Harmful Emissions

When engaging in Plasma Arc Welding (PAW), you must be acutely aware of the safety concerns and harmful emissions associated with this process. Hazardous emissions like ozone and nitrogen oxides are byproducts, necessitating efficient ventilation systems to maintain ideal air quality.

Without proper ventilation, these emissions can pose significant health risks. Protective gear is essential to shield you from the ultraviolet radiation emitted during welding—failure to do so can result in severe skin burns and eye damage.

Safety protocols are non-negotiable, as the intense heat can generate sparks and molten metal, increasing the risk of fires and burns. Specialized equipment often requires additional safety measures, such as enclosures, to effectively contain emissions.

- Inadequate ventilation can lead to respiratory issues.

- Lack of protective gear might result in serious injuries.

- Neglecting safety protocols could cause catastrophic accidents.

Diligently monitor air quality to mitigate risks and guarantee a safe welding environment.

Frequent Replacement of Components

In plasma arc welding, you must pay close attention to the wear and tear of nozzles and the longevity of electrodes, as these components require frequent replacements.

This constant need for new parts not only escalates maintenance costs but also leads to increased downtime, affecting productivity.

To mitigate these issues, verify that operators are well-trained in monitoring component wear and performing timely maintenance to sustain peak welding performance.

Nozzle Wear and Tear

Exposed to temperatures that can exceed 28,000°C, the nozzle in plasma arc welding faces significant wear, demanding frequent replacements.

You’ll find that regular nozzle replacement isn’t just a minor inconvenience—it can account for up to 20% of your total welding costs.

Nozzle design improvements and the use of improved materials are essential to mitigate these expenses.

However, even with advancements, a worn nozzle risks arc instability and defects, affecting weld quality.

Monitoring nozzle condition is vital, but it requires skilled technicians, increasing labor costs and training needs.

Plus, frequent replacements disrupt production schedules, causing costly downtime.

- Increased operational costs

- Potential defects in weld quality

- Disruptions and increased downtime

Electrode Longevity Concerns

Although plasma arc welding is renowned for its precision and capability to handle high temperatures, it also brings challenges related to electrode longevity. The wear mechanisms inherent in high-temperature conditions necessitate frequent replacement of electrode materials, typically every 10 to 20 hours of operation. This frequency is influenced by welding parameters and the materials being welded. As a result, the need for constant attention to electrode conditions can lead to increased downtime and operational costs.

| Factor | Impact | Solution |

|---|---|---|

| Electrode Materials | Quick wear | Select high-durability materials |

| Wear Mechanisms | Frequent replacements | Improve welding techniques |

| Downtime | Reduced productivity | Schedule regular maintenance |

| Operator Skills | Specialized training | Provide thorough training |

| Operational Costs | Increased expenses | Optimize component usage |

Your attention to these factors is essential for maintaining efficiency.

Costly Component Maintenance

Addressing the challenges of electrode longevity naturally leads us to the issue of costly component maintenance in plasma arc welding. Frequent replacement of components like nozzles and electrodes is unavoidable due to wear, greatly impacting component longevity. This necessity drives up operational costs and requires meticulous maintenance scheduling.

High-current applications, in particular, accelerate nozzle erosion, necessitating regular checks and replacements. Downtime for maintenance disrupts productivity, adding further strain. Additionally, keeping an inventory of replacement parts increases costs and complicates logistics, especially in high-volume production environments.

The intricate nature of PAW systems means that a single component failure can lead to expensive repairs and prolonged maintenance periods.

- Increased Operational Costs

- Disrupted Productivity

- Complex Logistics Management

Limited Versatility in Applications

When considering the limitations of Plasma Arc Welding (PAW) regarding versatility, it’s crucial to examine its specific application constraints.

In applications comparison, PAW struggles with thin materials due to its high heat concentration, leading to potential burn-through and distortion. Material compatibility also becomes an issue, specifically with copper and magnesium alloys, whose unique properties can hinder effective welding.

In addition, PAW demands high-purity shielding gas, limiting its use in environments where consistent gas quality isn’t feasible. This constraint can greatly affect your decision-making if you’re operating in settings with less controlled conditions.

Furthermore, the complexity and sophistication of PAW equipment mean it’s not ideal for smaller-scale workshops or industries that lack specialized skills for maintenance and training.

Finally, the necessity for strict gas protection and the risk of producing harmful gases during welding further restrict its versatility, making it less suitable for environments that can’t provide stringent safety measures.

Barriers to Adoption in Certain Industries

Even as Plasma Arc Welding (PAW) offers precision and efficiency, significant barriers hinder its adoption across various industries. The high initial investment cost of PAW equipment can be prohibitive, especially for businesses with smaller budgets.

High initial costs of Plasma Arc Welding equipment deter adoption, especially for smaller businesses.

Industry specific applications often demand technology advancements that PAW struggles to meet due to these financial constraints. Furthermore, operators need specialized training to handle PAW’s complexities, which adds to operational costs and deters industries from adopting this advanced welding process.

The requirement for high-purity shielding gases and stringent gas protection measures further complicates logistics, particularly for smaller manufacturers.

- Financial Strain: The hefty initial investment and associated training costs can be intimidating.

- Operational Complexity: Maintenance demands, like frequent nozzle and electrode replacements, can disrupt production.

- Material Limitations: Limited performance on metals such as copper and magnesium alloys restricts its use, impacting broader industry adoption.

These barriers must be overcome for PAW to achieve wider industry acceptance.

Frequently Asked Questions

How Does PAW Compare to Other Advanced Welding Techniques?

You’re comparing PAW to other advanced techniques by noting its efficiency and versatility. PAW efficiently handles thicker materials with precision, while its versatility allows application in diverse industries. Analyze how these factors balance against other methods’ attributes.

What Are the Environmental Impacts of PAW?

PAW’s environmental impacts include emission concerns due to high-energy consumption and potential hazardous gas production. You must prioritize efficient waste management to minimize environmental degradation and adhere to regulations, ensuring sustainable operations and reduced ecological footprint.

Is PAW Suitable for Underwater Welding Applications?

PAW isn’t the best choice for underwater welding due to underwater challenges like equipment sealing and safety concerns from electric shock risks. You’d need specialized equipment and rigorous safety protocols to address these inherent issues effectively.

Can PAW Be Automated for Industrial Use?

Imagine programming a symphony: automation in PAW for industrial use is like orchestrating precise notes. You can automate it, but challenges arise in scalability due to complex setups and ensuring consistent quality across diverse applications.

How Does PAW Affect Weld Quality Over Time?

You’ll notice that Plasma Arc Welding provides excellent weld consistency and long-term durability. Its precision reduces defects, ensuring reliable joints over time. However, factors like maintenance and operator skill can influence overall quality. Regular inspections are essential.

Conclusion

In exploring Plasma Arc Welding, you’ll find it coincidental that its advanced technology, while impressive, ironically drives up costs and demands skilled labor. You’re faced with a system that requires stringent gas protection, posing safety challenges and restricting versatility. Despite its potential, PAW struggles with thin materials and metal compatibility, limiting adoption in certain industries. As you weigh its benefits against these drawbacks, consider if PAW’s technical demands align with your operational capabilities and strategic goals.