Did you know a 120V plasma cutter can efficiently slice through materials up to 1/4 inch thick? Understanding the amperage settings is essential for ideal performance. For instance, cutting 3/16-inch steel requires 12 amps, while 1/2-inch steel needs 27 amps. As material thickness grows, so does the amperage demand. Discover how enhancing your power supply can greatly boost your cutting capabilities and explore strategies to overcome the limitations of a 120V system.

Understanding 120V Plasma Cutter Limitations

When you’re evaluating a 120V plasma cutter, it’s crucial to understand the inherent limitations imposed by its power supply. Plasma cutter types that operate on a 120V circuit are typically constrained by the lower amperage available, which restricts their ability to cut materials thicker than 1/4-inch.

With a 20 Amp circuit, the voltage factors become critical, as the capacity to maintain effective cutting performance diminishes with increased material thickness.

For instance, cutting 16 gauge steel at 45 amps on a 120V circuit results in a considerable load voltage draw. This often exceeds the circuit’s capabilities, leading to frequent breaker trips during extended use or when attempting to cut thicker materials.

Consequently, if you’re looking for peak performance without these limitations, it’s advisable to think about upgrading to a 240V circuit. This adjustment can greatly expand the cutting capacity and enhance the efficiency of your plasma cutter operations.

Determining Amperage Needs for Various Thicknesses

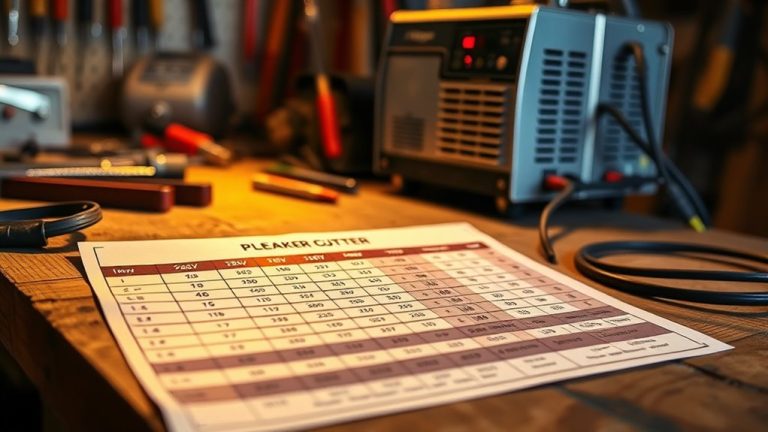

To determine the correct amperage for cutting various material thicknesses, consider the specific guidelines for each thickness level.

Focus on amperage efficiency factors to guarantee both precise cuts and energy enhancement.

Utilize a peak settings chart to match your plasma cutter’s amperage to the thickness of the material, maximizing efficiency and performance.

Material Thickness Guidelines

Understanding the relationship between material thickness and the required amperage is vital for effective plasma cutting.

Accurate cutting techniques depend on matching the amperage to the material thickness. For example, at 120V, 12 amps efficiently cut through 3/16 inch steel, while 27 amps are needed for 1/2 inch steel.

As thickness increases, so does the amperage requirement: 50 amps manage 3/4 inch steel, whereas 55 amps are necessary for cutting up to 1 inch.

For even thicker materials, 100 amps can cut steel up to 1-1/2 inches.

It’s important to consult your plasma cutter’s specific guidelines to guarantee peak performance and quality. This careful consideration guarantees precise cuts and prevents inefficient operation or equipment damage.

Amperage Efficiency Factors

Although determining the correct amperage for plasma cutting can initially seem complex, it’s crucial for achieving ideal efficiency and precision.

Amperage impact on cutting capacity is significant, especially when operating at 120V. For instance, to cut 1/4 inch steel effectively, you should set the machine to 30A. As material thickness increases, so does the amperage requirement; cutting 3/8 inch mild steel typically demands around 45A.

Efficiency optimization means balancing amperage to avoid overloading circuits, particularly when dealing with thicker materials. Using a 30A circuit might limit performance, making a 50A circuit more suitable for effective cutting without tripping breakers.

Manufacturers’ amperage charts are indispensable for determining the precise amperage needs for various material thicknesses.

Optimal Settings Chart

When determining the correct amperage for plasma cutting, it’s vital to refer to an ideal settings chart to confirm precise and efficient cuts. Proper amperage guarantees ideal cutting speed adjustments and prevents unnecessary wear, aiding plasma cutter maintenance.

Consider these settings:

- Thin Materials: Use 12A for cutting up to 3/16-inch steel, minimizing warping and overheating risks.

- Medium Thickness: For 1/2-inch steel, adjust to 27A, balancing speed and precision.

- Thick Materials: Employ 50A for 3/4-inch steel, guaranteeing clean cuts without compromising equipment.

For maximum efficiency, remember that 100A can cut up to 1-1/2-inch steel at 120V.

Always consult your plasma cutter’s manual for specific guidelines, enhancing performance and prolonging tool life.

Selecting the Right Breaker for Your Plasma Cutter

Selecting the right breaker for your plasma cutter is essential for peak performance and safety. Confirming breaker compatibility with your machine’s requirements will prevent tripping and power interruptions.

For example, a Powermax 45xp operating on a 50A breaker offers superior performance, particularly when cutting materials thicker than 1/2 inch. This setup aligns breaker capacity with the cutter’s amperage demands, allowing for smooth operation.

If you’re using a 30A breaker, it’s feasible for cutting steel under 1/2 inch, but consulting an electrician guarantees safety and efficiency. A 120V 20A circuit limits your capability to effectively cut materials thicker than 1/4 inch, highlighting the importance of proper circuit capacity for your plasma cutter.

Additionally, using a 30A breaker on a 220V outlet may suffice under certain conditions, but upgrading to a 50A breaker is advisable for uninterrupted operation, especially in industrial settings.

Enhancing Cutting Performance With Higher Amperage

Elevating your plasma cutter’s amperage settings can greatly enhance cutting performance, especially when dealing with thicker materials. By implementing precise amperage adjustments, you can achieve faster cutting speeds and improved efficiency.

When cutting 1/2-inch steel, using 40-45 amps is typical, but increasing to 60 amps results in cleaner cuts and minimizes dross formation. Here’s how to optimize your cutting techniques:

- Match Amperage to Material: Confirm the plasma cutter’s amperage output aligns with the material thickness. This prevents incomplete cuts and excessive slag, providing a cleaner finish.

- Maintain Stable Arc: Higher amperage helps sustain a stable arc, essential for manual cutting. This minimizes the risk of arc interruptions and maintains consistent performance.

- Optimize for Efficiency: Increasing amperage boosts cutting speed and efficiency, but remember to stay within recommended ranges to avoid overheating equipment or tripping breakers.

These strategies will elevate your cutting capabilities markedly.

Managing Duty Cycle Constraints on 120V Systems

Although plasma cutters operating on a 120V system provide convenience and portability, they come with inherent duty cycle constraints that users must manage effectively.

Successful duty cycle management is vital for maintaining cutting efficiency. A 20A plasma cutter on a 120V circuit typically operates at a 20-25% duty cycle when using maximum output. This means you can cut for about two minutes before the cutter requires a 6-8 minute cooling period. If ignored, overheating may occur, leading to subpar performance and potential equipment damage.

To optimize cutting efficiency, always monitor the duty cycle closely. Cutting thicker materials on a 120V system demands caution, as it can cause circuit breakers to trip and result in ineffective cuts due to diminished power.

For enhanced performance and to alleviate duty cycle restrictions, consider upgrading to a 30A or 50A supply. This upgrade can greatly improve the cutter’s operational capacity and reduce downtime.

Safety Precautions for Plasma Cutting on 120V

When plasma cutting on a 120V circuit, prioritize wearing essential protective gear like heavy-duty gloves, safety glasses, and reinforced boots to shield against sharp edges and heat.

Monitor your amperage settings to prevent electrical hazards and disruptions, ensuring you don’t exceed the circuit’s capacity.

Additionally, maintain a clear workspace, handle cut parts cautiously due to residual heat, and confirm that your plasma cutter’s power requirements align with the circuit to optimize safety and performance.

Essential Protective Gear

To guarantee safety during plasma cutting on 120V, wearing the right protective gear is essential. Implementing safety practices minimizes the risk of injury from sharp edges, hot metal debris, and flying sparks.

First, always wear heavy-duty gloves to shield your hands. Plasma cutting generates sharp edges and hot metal debris, making hand protection vital.

Second, use safety glasses with side shields to prevent eye injuries from sparks and molten metal. For enhanced protection, consider adding a face shield to safeguard against intense light and heat.

Third, confirm you’re wearing heat-resistant boots to protect your feet from burns or falling equipment.

Additionally, flame-resistant clothing, like long-sleeved shirts and pants, should be worn to reduce burn risks from sparks and molten metal.

Electrical Safety Measures

Guaranteeing electrical safety during plasma cutting on a 120V system is vital for preventing accidents and maintaining efficiency.

You’ll need to connect the plasma cutter to a properly rated electrical circuit, ideally with a 20-amp breaker, for maximum circuit protection. This setup helps prevent tripping and guarantees smooth operation.

Implement effective grounding techniques to minimize the risk of electrical shock. Regularly inspect the cutter’s components, such as hoses and connections, to avoid electrical failures.

Closely monitor the amperage settings, staying within the manufacturer’s recommended parameters to prevent overheating.

Additionally, maintaining a clear, ventilated workspace free of flammable materials is essential for safety.

Prioritize these measures to guarantee a secure and efficient plasma cutting environment.

Proper Handling Techniques

As you commence on plasma cutting with a 120V system, adopting proper handling techniques is important to guarantee safety and efficiency.

First, always wear appropriate personal protective equipment (PPE) like heavy-duty gloves, safety glasses, and reinforced boots. This minimizes risk from sharp edges and hot metal debris.

Second, maintain a workspace free of flammable materials with adequate ventilation to mitigate inhalation of harmful fumes.

Proper lifting is critical: use correct techniques when handling heavy or large cut pieces to prevent strain or injury.

Finally, part cooling is essential—handle newly cut parts cautiously, allowing them to cool to avoid burns or cuts.

Regular inspection and maintenance of the plasma cutter also guarantee safe operation and reduce electrical hazards.

Upgrading Power Supply for Improved Cutting Capacity

When considering the power supply upgrade for your plasma cutter, it’s essential to recognize the impact of amperage on cutting capacity. A power supply with higher amperage, like a 50 amp circuit, greatly enhances cutting performance, particularly for materials over 1/2-inch thick.

Circuit upgrades are important if your current setup is a 120V 20 amp circuit, which restricts you to cutting thicknesses around 1/4 inch. This limitation can lead to tripped breakers and inefficient cuts.

To maximize your plasma cutter’s efficiency, install a dedicated circuit supporting the machine’s peak amperage. This prevents overloads during prolonged operations and avoids overheating issues.

Install a dedicated circuit for your plasma cutter to prevent overloads and ensure efficient, uninterrupted operation.

Users consistently report improved performance and safety with upgraded systems, as the enhanced power supply reduces circuit failure risks. Investing in an electrical system upgrade not only boosts your cutting capabilities but also guarantees safer, more reliable operation during demanding tasks with your plasma cutter.

Frequently Asked Questions

Can Plasma Cutters Work With Generators on 120V?

Yes, you can use plasma cutters with generators on 120V, but verify plasma generator compatibility. Check the generator’s 120V power requirements and its ability to maintain consistent voltage to avoid fluctuations that could affect cutting performance.

How Does Ambient Temperature Affect Cutting Performance?

Think of Icarus soaring too close to the sun. Higher ambient temperatures can reduce cutting efficiency due to thermal expansion and cooling demands. You must consider ambient factors for peak performance and minimize temperature effects on your plasma cutter.

What Is the Lifespan of a 120V Plasma Cutter?

A 120V plasma cutter’s lifespan varies based on factors like usage frequency, quality, and environmental conditions. Regularly clean the torch, check consumables, and guarantee proper ventilation to extend its life. Consistent maintenance enhances performance and longevity.

Are There Any Portable 120V Plasma Cutters?

Yes, you’ll find portable 120V plasma cutters designed for user portability. These lightweight models are engineered for easy transport, enabling efficient cutting tasks remotely without sacrificing power, making them ideal for fieldwork and off-site repairs.

How Do Consumables Impact Cutting Quality on 120V?

Consumables greatly impact cutting quality; maintaining them guarantees consistent cutting efficiency. You might think it’s minor, but worn parts cause irregular arcs and reduced precision. Regular consumable maintenance is essential for peak performance in 120V plasma cutters.

Conclusion

When operating a plasma cutter on a 120V supply, remember that you’re effectively limited to cutting materials no thicker than 1/4 inch. Curiously, just a modest increase from 27 amps to 50 amps on a 240V circuit can triple your cutting capacity from 1/2-inch to 3/4-inch steel. Consider the amperage and duty cycle constraints carefully to optimize performance. Upgrading your power supply not only enhances cutting efficiency but also reduces the risk of frequent breaker trips.