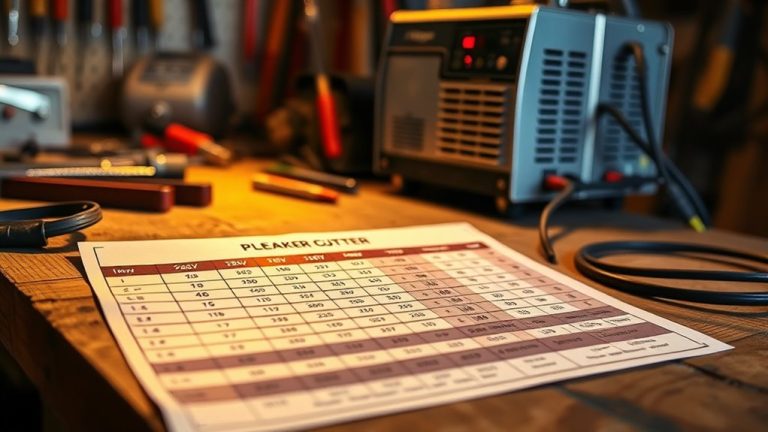

When using a plasma cutter at 220V, you can achieve impressive results, like cutting through materials up to 1 inch thick, depending on the amperage. For instance, a 55A cutter can navigate 1/2 inch steel at about 10 IPM, while a 65A model tackles 5/8 inch at 8 IPM. Understanding these capacities is essential for optimizing your cutting tasks. Explore how these specifications influence your projects and enhance efficiency.

Understanding 220V Plasma Cutters

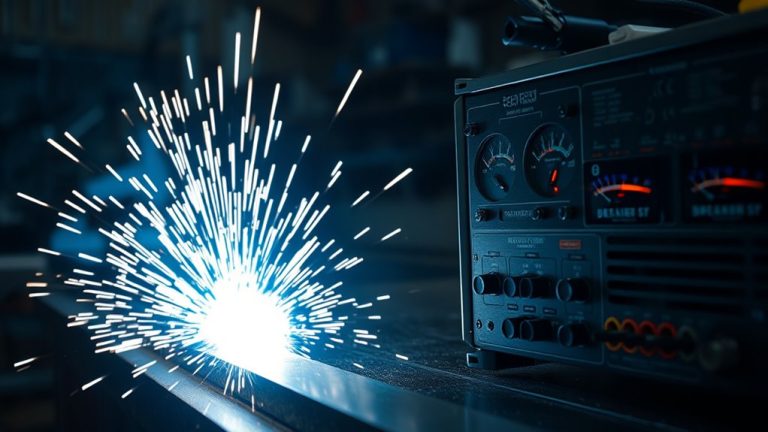

When you explore the domain of 220V plasma cutters, you’ll quickly realize their superiority regarding cutting capacity and efficiency.

These machines offer enhanced plasma cutter features, enabling clean cuts in materials up to 1/2 inch thick and severance cuts up to 3/4 inch. With cutting technology advancements, models like the YesWelder CUT-55DS achieve a cutting speed of about 10 IPM at 1/2 inch thickness.

The 220V power input is pivotal in this efficiency, providing a longer duty cycle and minimizing downtime. For instance, the YesWelder CUT-65DS operates at 100% duty cycle at 45A, allowing extended sessions without overheating.

Additionally, many units incorporate non-touch pilot arc technology, facilitating effective cutting on dirty or rusty metals, especially beneficial for thicker materials.

The increased power from 220V considerably reduces cutting time compared to 110V models, underscoring the technological edge of 220V plasma cutters in demanding applications.

Advantages of Higher Voltage in Plasma Cutting

When you operate a plasma cutter at 220V, you benefit from improved cutting efficiency and enhanced power output.

This setup allows for higher amperage, enabling cleaner cuts in thicker materials at faster speeds.

Additionally, the increased voltage supports a greater duty cycle, ensuring longer continuous operation without overheating.

Improved Cutting Efficiency

While considering the advantages of using higher voltage in plasma cutting, you’ll find that a 220V system offers significant improvements in cutting efficiency.

The increased voltage enhances cut quality by improving arc stability, ensuring cleaner cuts with minimal slag formation. This directly translates to less post-processing, saving you time and effort.

Moreover, a 220V plasma cutter boosts productivity by enabling faster cutting speeds, vital for industrial applications where time is money. You’ll notice that a 55A cutter at 220V can slice through materials up to 1 inch thick, outperforming its 110V counterpart limited to 3/4 inch.

In addition, longer duty cycles at 220V allow for extended use without overheating, making it ideal for demanding, continuous operations.

Enhanced Power Output

Building on the improved cutting efficiency discussed earlier, operating a plasma cutter at 220V provides substantial advantages in power output.

You benefit from higher amperage, meeting stringent power requirements for cutting thicker materials efficiently. A 60A plasma cutter at this voltage will cut through steel up to 1/2 inch thick with ease, perfect for demanding applications.

Moreover, higher voltage setups maintain voltage stability, minimizing the risk of voltage drops during extended operations. This consistency guarantees steady cutting speeds and quality, even with longer extension cords.

The increased power also enables faster cutting speeds, vital for boosting productivity in industrial settings. Additionally, utilizing 220V improves the duty cycle, allowing longer operation without overheating, necessary for high-volume cutting tasks.

Maximum Thickness Capabilities of 220V Plasma Cutters

Although 220V plasma cutters provide considerable power for cutting, their maximum thickness capabilities vary by model and amperage. The cutting thickness you can achieve depends greatly on the material types you’re working with.

For instance, a 55A plasma cutter can cleanly cut up to 1 inch of mild steel, making it a versatile choice for various applications. If you’re tackling demanding tasks, models like the YesWelder CUT-65DS are capable of severing up to 63/64 inch thick steel and achieving clean cuts of up to 5/8 inch.

For more robust requirements, a 100A plasma cutter at 220V can handle 1-1/2 inch steel, ideal for professional environments where working with thicker materials is common.

Understanding these specifications guarantees you select a plasma cutter that matches your project’s needs, optimizing both performance and efficiency. With the right machine, cutting through considerable materials becomes more manageable and precise.

Speed and Efficiency of Plasma Cutting at 220V

Harnessing a 220V power supply markedly enhances the speed and efficiency of plasma cutting, providing a significant advantage over lower voltage operations.

When operating at 220V, a 55A plasma cutter can achieve clean cuts on mild steel up to 1/2 inch thick with a cutting speed of approximately 10 IPM. This efficiency is notable when compared to the reduced performance at 110V.

- Cutting Speed: At 65A, you can tackle material thickness up to 5/8 inch with a speed around 8 IPM, ensuring precision without sacrificing speed.

- Material Thickness: The increased amperage and voltage facilitate smoother cuts on thicker materials, enhancing the overall quality of the work.

- Enhanced Efficiency: Devices like the YesWelder CUT-55DS with dual voltage capabilities further optimize performance, offering a higher duty cycle that allows for prolonged operation without frequent cooling breaks.

These attributes make a compelling case for utilizing a 220V supply in your cutting tasks.

Selecting the Right Plasma Cutter for Your Needs

Operating a plasma cutter at 220V provides remarkable speed and efficiency, making it vital to choose the right tool for your specific needs. When selecting plasma cutter types, assess the amperage selection critically. Higher amperage enables cutting through thicker materials; for example, a 55A cutter can make clean cuts up to 1 inch of steel.

Consider the Spectrum 875, which manages up to 7/8 inch at 220V, suitable for both hobbyists and industrial applications.

Evaluate the duty cycle of the plasma cutter. A 100% duty cycle at specified amperage guarantees continuous operation without cooling breaks, essential for high-demand tasks.

Analyze cutting speed requirements—typically, a 50A plasma cutter achieves around 10 IPM for clean cuts, depending on material thickness.

Plan for future needs. Opt for a model with a higher cutting capacity than your current demands to accommodate project growth and increase operational efficiency.

Comparing Plasma Cutting to Other Methods

When weighing the benefits of plasma cutting against other methods, you’ll find plasma cutting excels in speed and precision. Plasma technology offers cleaner cuts and faster speeds compared to oxy-fuel cutting. For instance, at 220V, plasma cutters can slice through metals up to 7/8 inch thick, easily outperforming oxy-fuel which is slower due to oxidation processes.

Here’s why plasma cutting is superior:

- Cutting Precision: Plasma cutting provides sharp, precise cuts, especially on materials like stainless steel and aluminum, without the need for preheating.

- Speed Advantage: A plasma cutter can achieve cutting rates of up to 10 inches per minute (IPM) on thinner metals, vastly outpacing traditional methods.

- Versatility: Unlike mechanical cutting, plasma can handle various conductive metals and isn’t limited by thickness, making it a more versatile choice.

Safety Considerations for High-Voltage Plasma Cutting

Guaranteeing safety during high-voltage plasma cutting is essential, particularly when working at 220V. You must take necessary safety precautions to mitigate risks associated with the high-energy output. Use protective equipment like heat-resistant gloves and safety glasses to shield against burns and flying debris. Plasma cutters at 220V can generate up to 200V, so avoid damp environments and guarantee your equipment is properly grounded to prevent electrical shock.

Follow manufacturer’s safety guidelines and local regulations diligently. A drag shield extension can stabilize the torch, minimizing the risk of accidental contact with the arc.

| Safety Aspect | Recommendation | Purpose |

|---|---|---|

| PPE | Heat-resistant gloves, glasses | Protect against burns and debris |

| Electrical Safety | Proper grounding, dry conditions | Prevent electrical shock |

| Ventilation | Guarantee good airflow | Avoid inhaling harmful fumes |

| Torch Stability | Use drag shield extension | Minimize accidental arc contact |

Prioritize ventilation, especially when cutting materials like stainless steel, to avoid inhaling harmful fumes.

Maintenance and Longevity of 220V Plasma Cutters

To guarantee peak performance and extend the lifespan of your 220V plasma cutter, prioritize regular maintenance. Regularly replacing consumables like electrodes and nozzles is essential for maintaining cutting quality and longevity.

Prioritize regular maintenance to ensure peak plasma cutter performance and longevity through timely consumable replacements.

Here’s a technical guide to confirm your machine’s efficiency:

- Electrode Replacement: Monitor electrode wear and replace them routinely to maintain ideal arc stability and cutting precision. This practice prevents inconsistencies and reduces downtime.

- Moisture Control: Verify your air supply is clean and moisture-free. Moist air can damage internal components, affecting performance and leading to premature failure. Install a moisture trap or dryer if necessary.

- Electrical Connection Inspections: Periodically check and maintain the machine’s electrical connections and power supply. This prevents potential electrical failures, promoting consistent performance.

Follow the manufacturer’s guidelines for cooling and ventilation, especially during extended sessions, to prevent overheating and extend the duty cycle.

Adhering to these practices will maximize the longevity and efficiency of your plasma cutter.

Frequently Asked Questions

What Metals Can Be Cut With a 220V Plasma Cutter?

You can cut various metals like steel, stainless steel, aluminum, brass, and copper using a 220V plasma cutter. Plasma technology efficiently conducts through these conductive materials, offering precise, clean cuts. Analyze each metal’s thickness for best performance.

How Does a Plasma Cutter Work at 220V?

A plasma cutter at 220V generates a plasma arc by ionizing gas, enabling you to cut through metals with high cutting efficiency. It maintains a stable arc, ensuring precise, quick cuts with minimal material distortion.

Is 220V Plasma Cutting Suitable for Beginners?

Yes, a 220V plasma cutter is a delightful introduction for beginners. Embrace beginner techniques, focusing on safety tips like proper grounding and protective gear. Practice precision and control to master cutting with ease and confidence.

What Accessories Are Needed for 220V Plasma Cutting?

For 220V plasma cutting, you’ll need cutting tips to guarantee precise cuts and safety gear like gloves and goggles to protect yourself. Don’t forget a reliable air compressor and a grounding clamp for peak performance and safety.

Can 220V Plasma Cutters Cut Non-Metal Materials?

You can’t use 220V plasma cutters for non-metal applications. They’re specifically designed for metal cutting due to the ionized gas process, which requires conductive materials. Consider alternative tools like water jets for non-metal materials.

Conclusion

So, you’ve explored the world of 220V plasma cutters, appreciating their uncanny ability to slice through steel like butter, yet ironically, it’s not all about power. Even with the allure of thickness and speed, the real choice boils down to understanding your needs and machine maintenance. Who knew that keeping an eye on safety could be more thrilling than watching sparks fly? Embrace the irony—your perfect plasma cutter might just be the one you least expected.