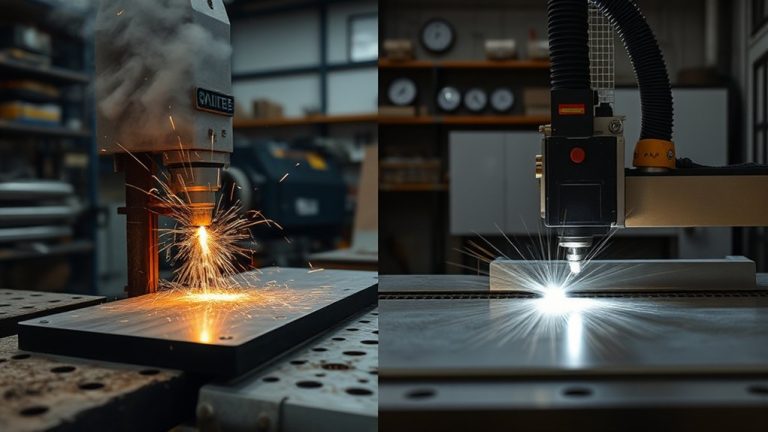

Think of tolerances like shoe sizes—being off by a size hurts: a band saw holds about ±0.5 mm, while plasma often drifts ±1.5–3 mm. You’ll get cleaner, cooler edges on a band saw with minimal burrs and no HAZ; plasma usually needs grinding. Costs widen the gap too: lower capex and consumables favor the saw. But thickness, profiles, and throughput complicate the choice—especially when batch workflows and alloys enter the equation.

Cutting Accuracy: Tolerances and Repeatability

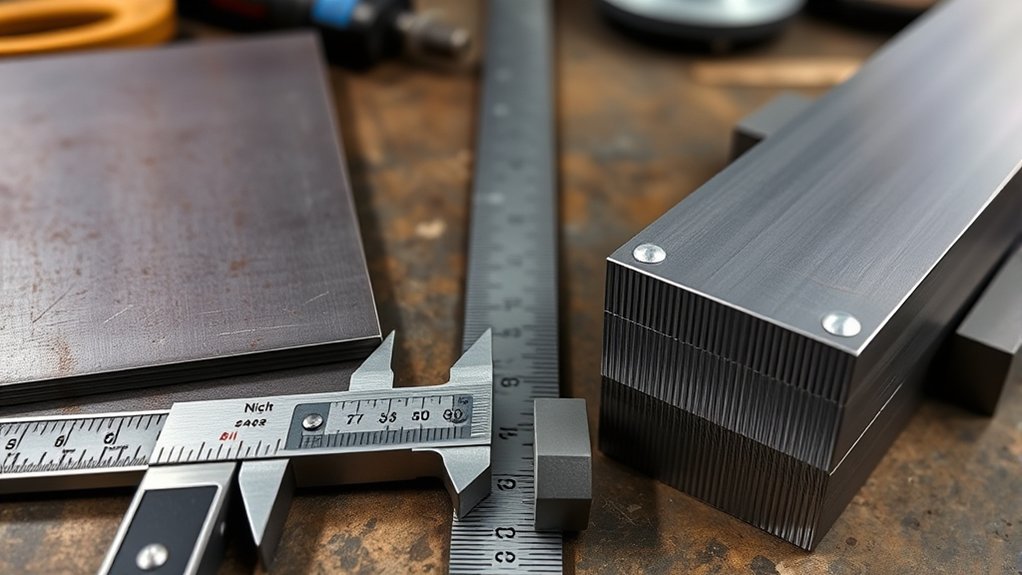

Although both tools can produce clean cuts, band saws deliver tighter, more repeatable accuracy: ±0.5 mm versus plasma’s typical ±1.5–3 mm.

Band saws deliver tighter, repeatable accuracy: ±0.5 mm vs. plasma’s typical ±1.5–3 mm

If you need cutting precision for shafts, brackets, or fixtures, that tighter tolerance translates into reliable part-to-part conformity. Band saws cut cold, so you avoid thermal distortion that can skew dimensions and undermine repeatability. You also benefit from a narrower kerf—typically 3–4 mm—reducing material loss and helping you hold nominal dimensions on tight nests.

In high-volume runs, band saws sustain manufacturing consistency across batches because the process isn’t heat-dependent and blade wear is predictable.

Plasma systems can hit spec on many geometries, but variation increases with heat input, consumable wear, and setup, making repeatability harder to guarantee within ±1.5–3 mm.

When your drawing calls for tight tolerances and stable process capability, a band saw’s controllable feed, cold cut, and narrow kerf provide higher Cp/Cpk potential and lower risk of dimensional drift.

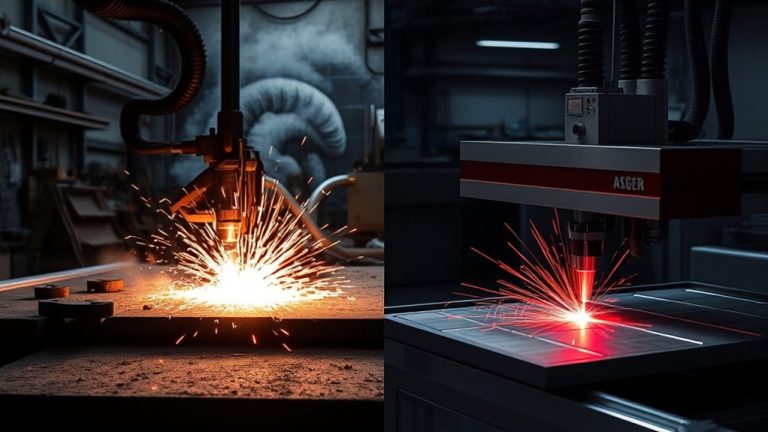

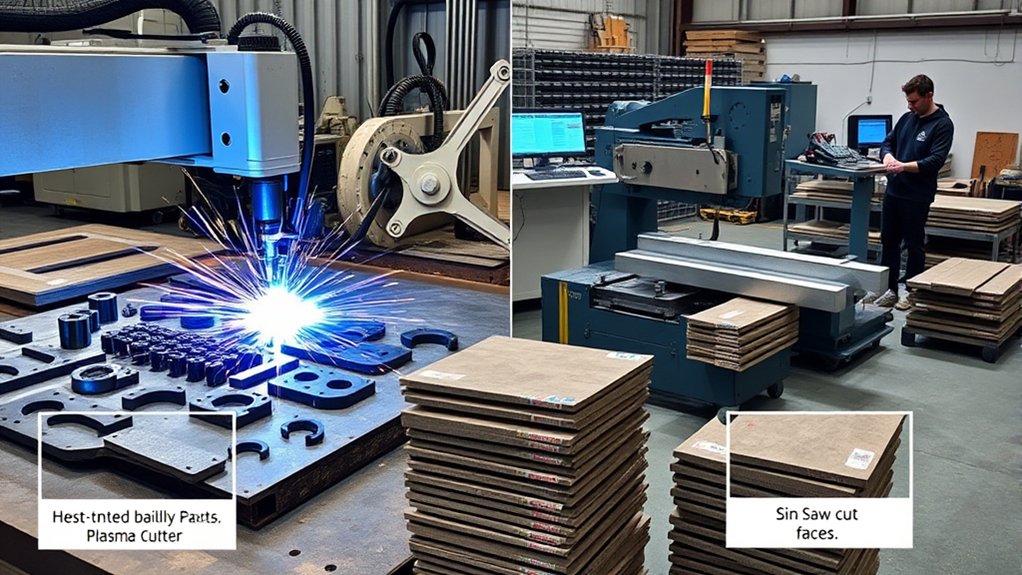

Edge Finish: Burrs, HAZ, and Post-Processing Needs

When you compare edge finish, you’ll see band saws generate fewer burrs due to cold cutting and a narrow 3–4 mm kerf, while plasma often leaves rougher edges that need grinding.

You also avoid a heat-affected zone with a band saw, preserving material properties and preventing warping; plasma introduces HAZ that can alter microstructure and hardness.

The result: less post-processing time and cost with band saws, especially when tight surface quality is required.

Burr Formation Differences

Because cutting method directly dictates edge condition, expect plasma to leave more burrs and a measurable heat‑affected zone, while a band saw delivers cleaner, colder edges.

You’ll see higher burr formation with plasma because the arc melts and ejects material; the wider 3–6 mm kerf increases material waste and leaves solidified slag along the cut.

By contrast, a band saw’s narrower 3–4 mm kerf and cold cutting action produce fewer burrs and more uniform edges.

Practically, plasma often requires extensive deburring and grinding to reach acceptable surface finish.

Plan time for scraping, flap wheels, or belt sanding.

Band saw cuts typically meet ±0.5 mm tolerances with minimal touch‑up, reducing secondary operations.

Fewer burrs also mean less risk of dimensional drift and faster downstream assembly.

Heat-Affected Zone Impact

Even with optimized parameters, heat input dictates edge cleanup and cost.

Plasma cutting creates a pronounced heat-affected zone that drives thermal effects: microstructural change, heat distortion, and oxide scale.

You’ll see burrs typically ranging from 0.5–1.5 mm, raising grinding or polishing time and risking edge taper.

The wider HAZ can also harden edges, accelerating abrasive wear and extending cycle time.

Expect more rework to restore tolerances and surface integrity.

Cost Breakdown: Equipment, Consumables, and Operating Expense

You’ll see a stark gap in upfront equipment costs: a capable plasma cutter often starts near $3,600 CAD, while a used portable band saw can be under $200.

Factor in consumables and upkeep—plasma tips/electrodes wear faster and add recurring spend, whereas band saw blades typically last longer and cost less per cut.

Include operating overheads too: plasma needs compressed air and more power plus cleanup, while band saws use less energy and usually incur lower maintenance.

Upfront Equipment Costs

Two price tiers define the choice: expect around $3,600 CAD for a plasma cutter capable of exceeding 5/8″ capacity versus roughly $350 for a portable bandsaw with a Swag table. Your initial investment hinges on throughput needs and budget considerations.

Plasma’s capital cost buys high cut speed and profile flexibility; the bandsaw’s low entry price favors simple straight or curved cuts with minimal setup.

- Capability: Plasma at ~$3,600 CAD supports thick plate and complex geometry; the ~$350 bandsaw suits tube, angle, and flat stock with slower feed.

- Infrastructure: Plasma may need a 240V circuit and compressed air; the bandsaw typically runs on standard power.

- Footprint: Plasma requires clearance and fume management; bandsaw plus table is compact.

- Payback: Choose plasma if cycle-time reduction offsets the higher purchase price.

Consumables and Upkeep

While the upfront price sets the stage, consumables and upkeep determine your true cost per cut. With plasma, you’ll replace electrodes and nozzles regularly; consumable lifespan varies by amperage, duty cycle, and air quality. Expect $100–$300/year for consumables, plus gas or dry air, filters, and periodic torch service.

Maintenance frequency is higher due to airflow, moisture control, and arc-start components.

Band saws primarily consume blades. At $20–$50 each, a quality blade often outlasts multiple plasma consumable sets, especially in mild steel. Lower maintenance frequency—simple lubrication, wheel cleaning, and guide alignment—keeps operating expense predictable.

Net result: plasma’s higher operating load (consumables, filtration, gas/air, maintenance) elevates recurring costs. Band saws typically deliver lower total ownership cost and stable cost per cut for precision work.

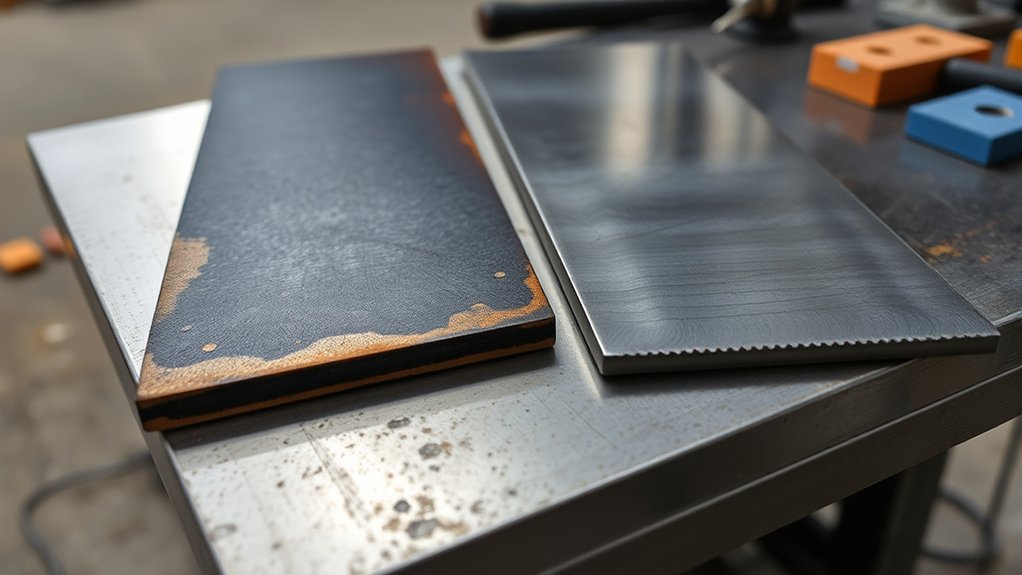

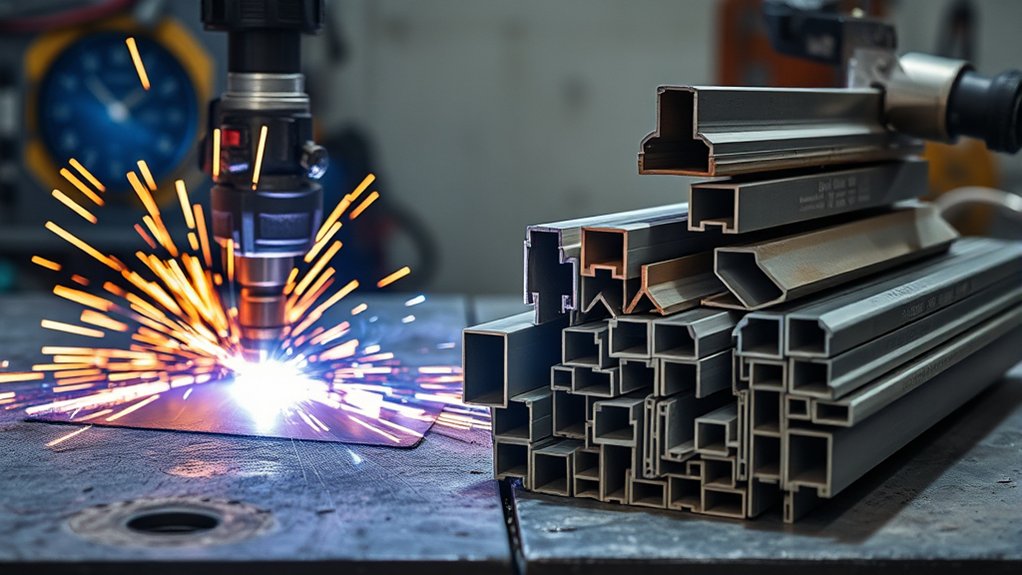

Material Capabilities: Thickness, Profiles, and Alloys

Even though both machines tackle a wide range of metals, their material envelopes differ sharply in thickness, profiles, and alloy behavior. You’ll see clear material limitations and profile versatility trade-offs.

1) Thickness: A band saw reliably slices stainless plate up to ~300 mm, dwarfing plasma’s typical ~50 mm ceiling. For ultra-thick sections, the band saw owns the envelope.

2) Profiles: Plasma excels on flat sheets with intricate geometries and tight internal radii. Band saws dominate structural profiles—pipes, tubes, angles—delivering straight, square cuts on long stock without fixturing complexity.

3) Alloys and integrity: Band saws are cold-cutting, preserving microstructure and preventing HAZ-induced warping across stainless, carbon steels, and structural alloys. Plasma’s thermal cycle can distort thin sections, especially on heat-sensitive alloys.

4) Edge quality by material: Band saws produce cleaner edges with minimal burrs, trimming deburr time across mixed alloys.

For aluminum, choose band saws for precise bars and tubing; choose plasma for thicker sheet plate where contour complexity outweighs edge refinement.

Throughput and Workflow: Setup, Nesting, and Batch Production

Because production speed hinges on setup and repeatability, throughput favors the band saw in most batch scenarios.

You gain setup efficiency with CNC-controlled auto-feed and fixture presets, so once you dial in parameters, the saw runs unattended, producing consistent cuts across hundreds or thousands of pieces. Stacking sheets or feeding long bars lets you multiply output per stroke, making 1,000+ part runs practical with short cycle times and minimal changeovers.

Band saw workflows also benefit from nesting optimization. By planning stock lengths and cut sequences with optimized nesting software, you minimize trim waste and reduce tool idle time. Cold cutting preserves material integrity, so you avoid heat-related distortion and secondary operations, shortening the end-to-end takt.

Plasma can match speed on thin plate, but precise jobs often need longer setup, detailed kerf compensation, and complex nesting, which slows ramp-up.

When repeatability, low scrap, and batch cadence matter, the band saw delivers higher throughput and steadier workflow.

Safety, Noise, and Shop Environment Considerations

Although both tools can be shop staples, their risk profiles differ sharply: plasma cutting throws sparks and molten spatter that elevate fire risk and demand flame‑resistant PPE, face/eye protection, and strict hot‑work controls, plus localized fume extraction for metal oxides and gases.

Plasma cutting launches sparks and spatter, heightening fire hazards and requiring robust PPE and fume extraction.

A band saw’s guarded blade and e‑stop reduce fire hazards and contact injuries, and its cutting produces minimal debris.

You’ll also manage noise pollution differently. Plasma arcs are loud due to high‑velocity ionized gas; bandsaws run quieter, lowering hearing‑conservation burdens.

Ventilation needs diverge: plasma cutting emits fumes and gases that require downdraft tables or hoods; bandsaws primarily create chips and dust.

- Plasma: hot-work permits, clear spark zones, Class ABC extinguishers; Band saw: chip control and blade guarding.

- Plasma: LEV near torch, maintain capture velocity; Band saw: dust collection optional.

- Plasma: higher heat/noise elevate operator fatigue; Band saw: longer comfortable duty cycles.

- Plasma: arc flash and UV risk; Band saw: mainly pinch and laceration risks.

Choosing the Right Tool for Your Application and Budget

Where should you spend your money and why? Start with your tolerances, edge requirements, and material types. If you need precision, a band saw delivers ±0.5 mm vs plasma’s ±1.5–3 mm. That accuracy plus cleaner edges, fewer burrs, and minimal heat-affected zones reduces post-processing time and abrasive costs.

Assess tool versatility against thickness. For heavy-duty work, band saws cut stainless plate up to 300 mm; plasma typically tops out around 50 mm. Kerf matters for material yield: band saws at 3–4 mm conserve stock better than plasma’s 3–6 mm, compounding savings on bulk orders.

Model total cost of ownership. Band saws generally cost less upfront and run cheaper due to longer blade life and fewer consumables; plasma incurs torch parts, tips, and gas.

Choose plasma only if you prioritize faster freeform profiles on varied material types and can tolerate wider tolerances and extra finishing. Otherwise, the band saw maximizes precision and budget.

Frequently Asked Questions

How Portable Are Entry-Level Plasma Cutters Versus Benchtop Band Saws?

Portable plasma units typically weigh 20–35 lb, include shoulder straps, and run on 120V/240V, so you’ll carry them easily. Benchtop band saws weigh 40–80 lb, require stable surfaces, and awkward dimensions reduce mobility compared with portable plasma.

What Power Requirements Differ Between Plasma Cutters and Band Saws?

You’ll find plasma cutters demand higher power consumption—often 30–60A at 240V—while band saws typically draw 5–15A at 120V. Don’t worry about energy efficiency; duty cycles and inverter tech keep plasma’s overall energy use competitive.

How Do Maintenance Schedules Compare Over a Year of Weekend Use?

You’ll service the band saw quarterly; you’ll replace blades biannually. You’ll service the plasma cutter bimonthly; you’ll replace consumables monthly. Maintenance frequency favors the saw. Cost analysis: saw ~$120/year; plasma ~$300–$600/year, depending on consumable usage and air filtration.

Can Either Tool Integrate With CNC or Digital Templates Easily?

Yes—plasma cutters pair smoothly with CNC compatibility and digital templates; you’ll ride lightning. You’ll import DXF, set kerf, and automate nests. Bandsaws lag: limited CNC retrofits, manual setups, basic jigs. Expect tighter tolerances, faster throughput, quantified repeatability.

What Training or Skill Level Is Needed for Consistent Results?

You need basic safety training and intermediate technical skills. Expect 10–20 hours practice to calibrate settings, master feeds, and fixture work. You’ll verify tolerances with gauges, follow SOPs, and document parameters to achieve repeatable, production-grade consistency.

Conclusion

Think of the band saw as a micrometer and the plasma cutter as a marker. If you need ±0.5 mm accuracy, clean edges without HAZ, and minimal rework, the band saw keeps your tolerances tight and your costs low. Plasma moves faster on thick plate and complex profiles but brings ±1.5–3 mm variation, rough edges, and higher operating expense. Match the tool to your print: precision and economy favor the saw; speed on heavy sections favors plasma.